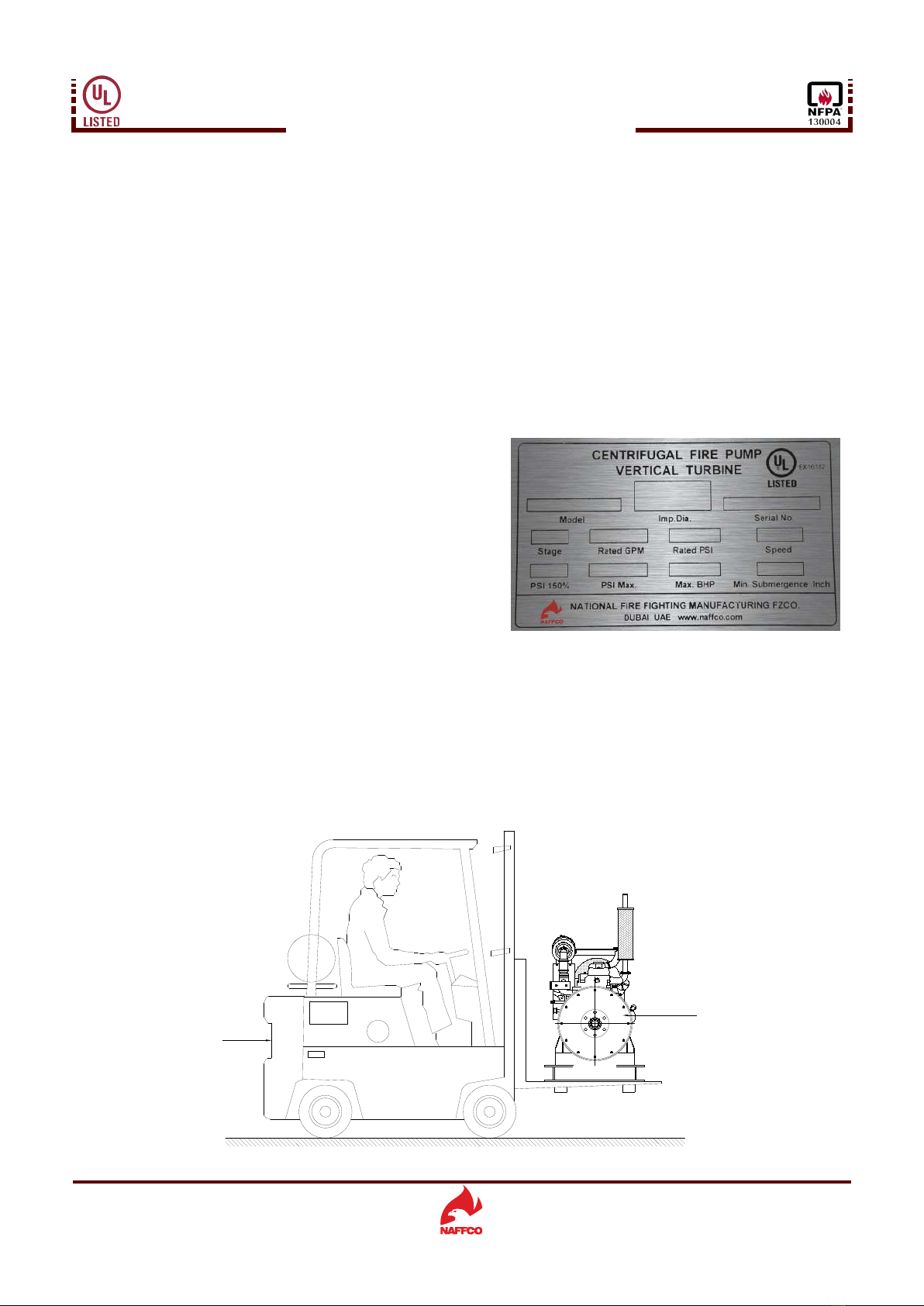

DO NOT OPERATE THIS PUMP AT ANY PRESSURE, FLOW

RATE, OR LIQUID TEMPERATURE OTHER THAN THOSE

WHICH SHOWN ON THE NAME PLATE. DO NOT PUMP

ANY LIQUID OTHER THAN WATER. IGNORING THIS

WARNING CAN RESULT IN PUMP FAILURE AND SERIOUS

PERSONAL INJURY OR DEATH.

1of 46

Subject to change without prior notice

INSTALLATION OPERATION AND MAINTENANCE INSTRUCTIONS

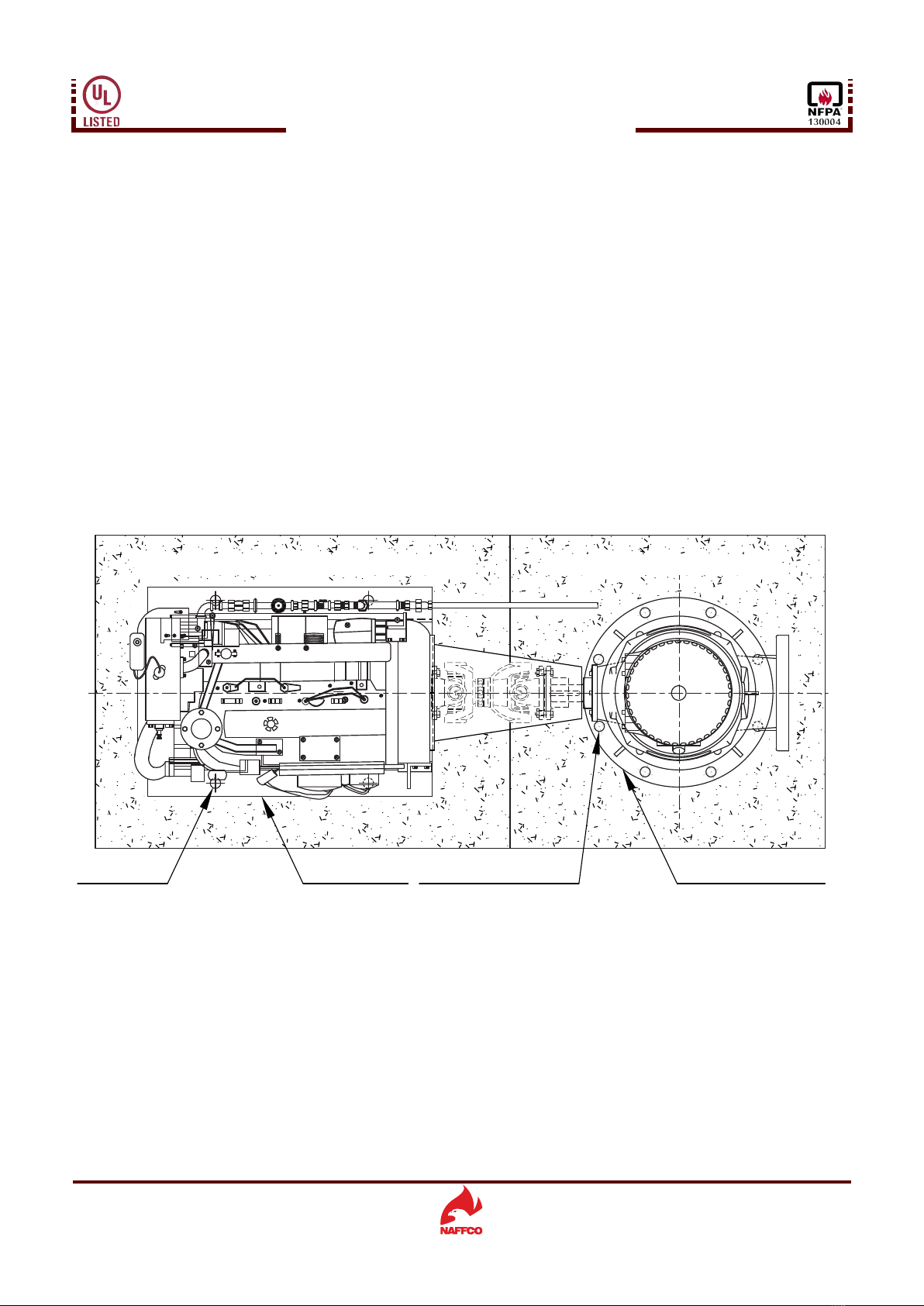

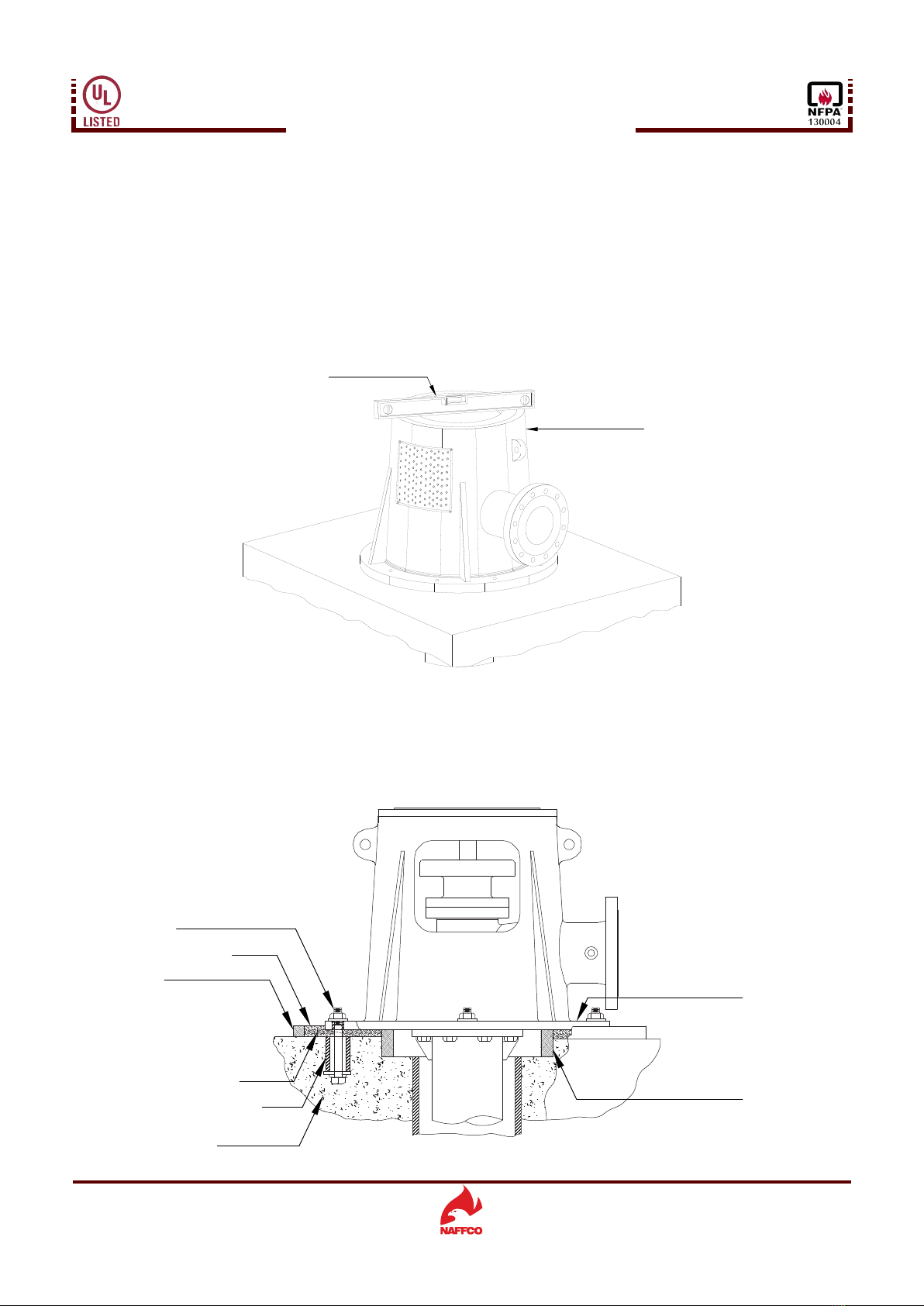

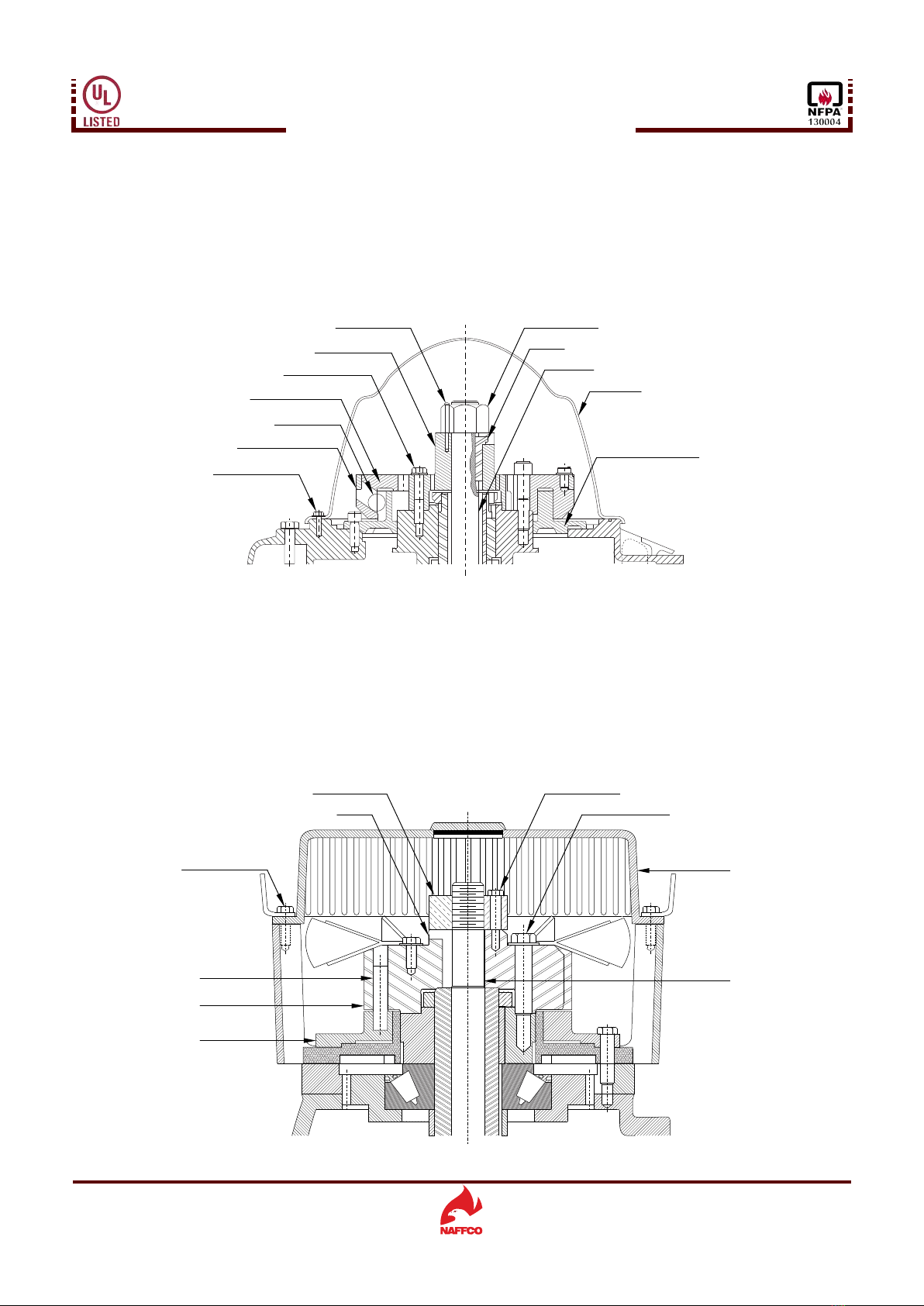

FIRE PUMPS - NF-VTP SERIES

Ref. No. NFVTP-IOM/2016/V.02

1.1. General Safety Instructions

1.2. Electric Hazards

Check proper earth connection of the electric, diesel, jockey controllers and electric motors.

Make sure safety labels and operation labels are stuck in the controllers if damaged please get from NAFFCO and

replace.

Use only qualified personnel for installation and maintenance.

Electric motor cables terminals should be properly terminate and covered with terminal cover.

Inspect cable and connector if any damage replace immediately.

Do not keep tools on top of battery, this could result short circuit.

1.3. Mechanical Hazards

Wear eye protection during welding, grinding, drilling etc. Wear ear protection while operating diesel engine. Always

wear safety shoes and safety gloves.

Monitor water leakage of pump gland packing. If excessive leak adjust the packing, do not place hands or finger into

this area.

During maintenance disconnect battery negative terminal connector.

Do not refuel the engine when its running, fuel fumes are highly flammable.

Diesel engine exhaust pipe line should be insulated from temperature and it should be kept separate from discharge

line.

2. INTRODUCTION

This manual provides general instruction for the installation, operation, maintenance, dismantling and assembling of

vertical turbine fire pump manufactured by NAFFCO, U.A.E. Each centrifugal fire pump is tested in our factory as per

1. SAFETY

If the safety labels are missed or damaged, contact NAFFCO and get label and replace.

While starting pump set make sure pump set drive shaft guard fixed in the pump set.

Only proper tools of correct size shall be used for maintenance and service.

Do not wear loose clothing that could catch on moving parts.

Pump room should be kept clean from oil, waste cloth, water and easily explosive materials.

Pump room should not be treated a like store room.

Fire pump should be monitored during running to ensure that it was started due to an actual demand and water tank

should be monitored to avoid dry run condition.