NAG/IM/HHP 400/01/22 5

1. INTRODUCTION

Nagman’s calibration hand pump is designed to manually

generate pressure between 100 / 200 / 350 / 400 bar

(depends on model).

This pump is manufactured with high quality components for

calibrating Analog / Digital gauges by comparison method. It

can be used for lab and field applications.

HHP is an ideal pressure source for calibrating pressure

transmitters, pressure transducers and pressure gauges.

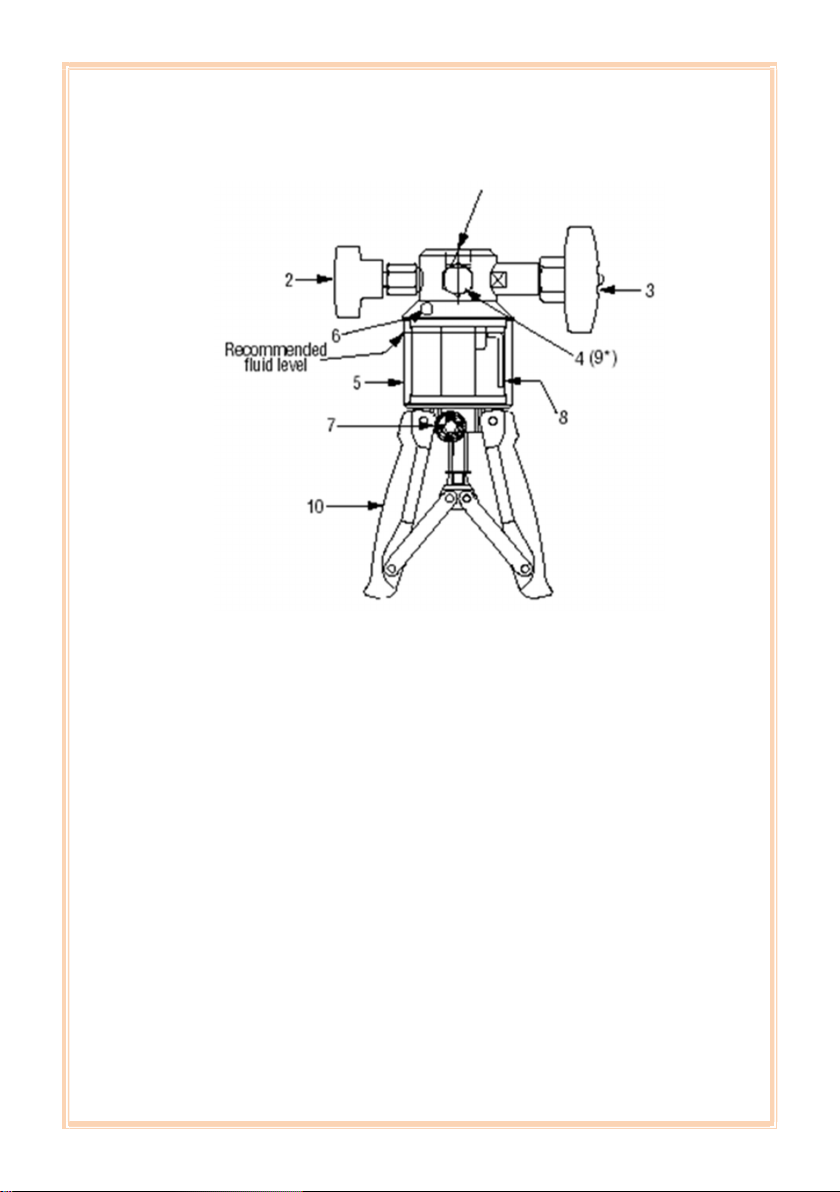

There is a Low / High pressure selector switch in the pump,

which is used for selecting low/high pressure output. It is

fitted with a fine Adjustment valve and a Release valve.

The output pressure / vacuum of the hand pump can be

adjusted precisely by the fine Adjustment valve while

calibration. Release valve is used for releasing the pressure /

vacuum after calibration.

The output pressure model ranges are :