7

W415-1371 / 09.15.14

EN

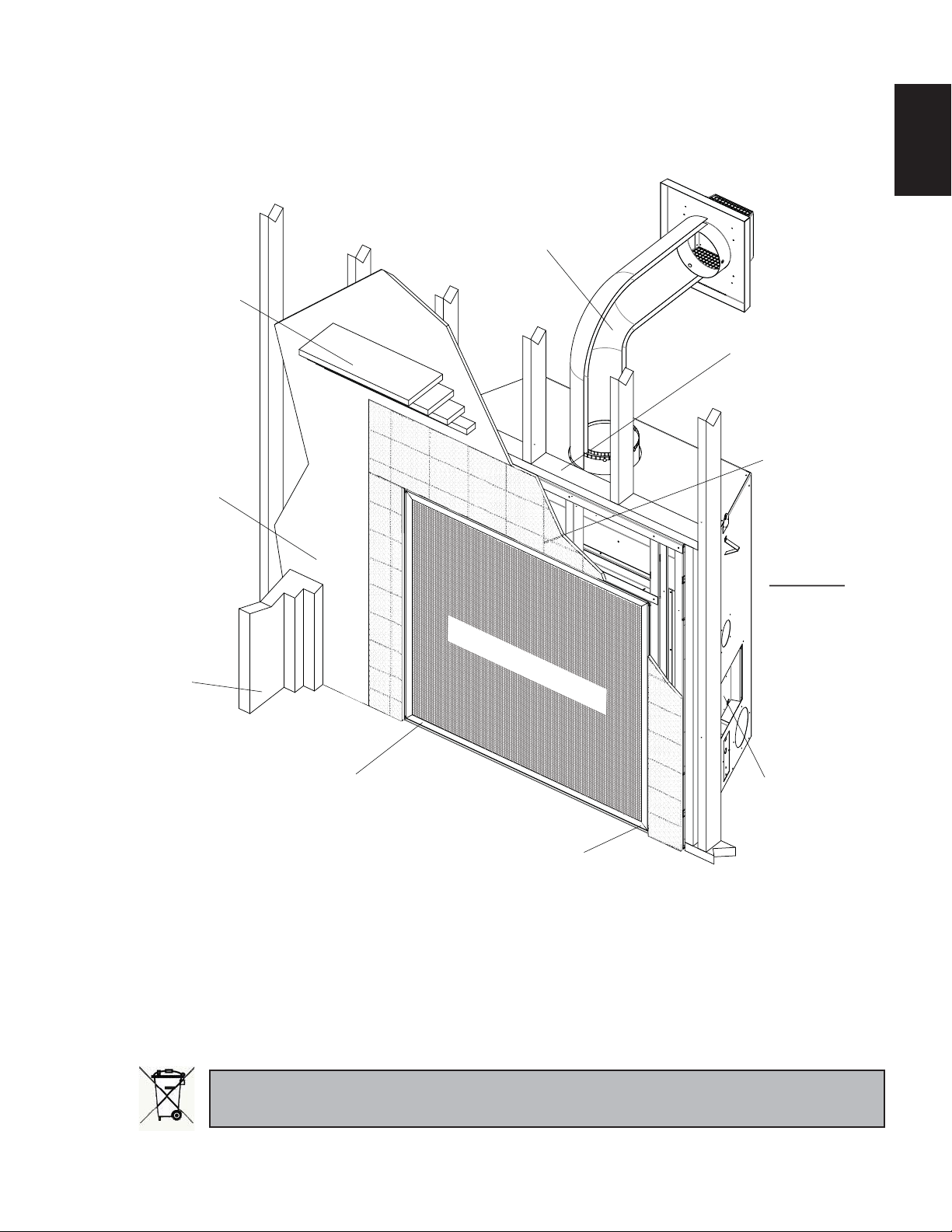

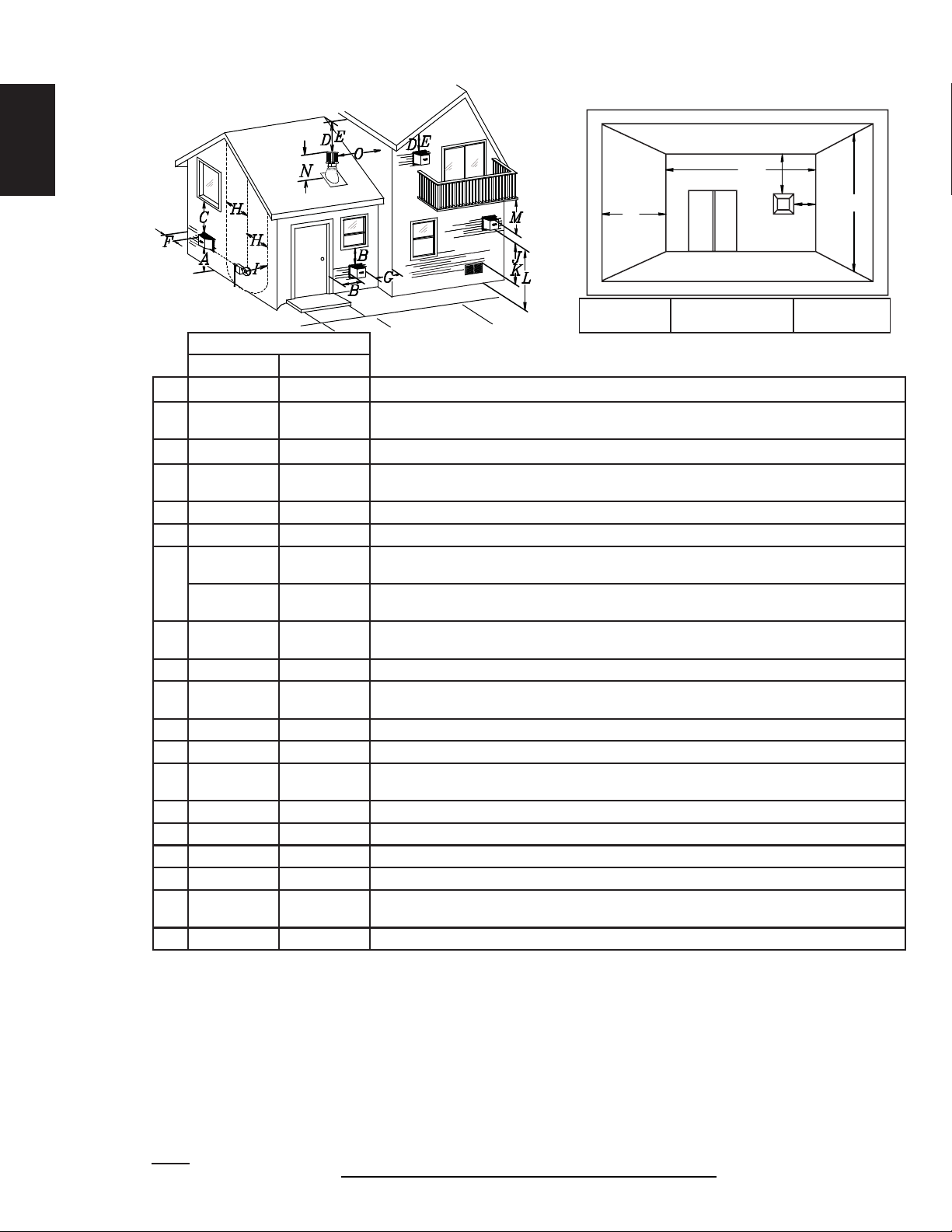

2.4 RATING PLATE INFORMATION

NOTE: The protective wrap on plated parts is best removed when

the assembly is at room temperature but this can be improved if

the assembly is warmed, using a hair dryer or similar heat source.

This appliance is equipped with a remote control system, which

requires batteries (supplied) to be installed. The transmitter takes 1

9V battery and in the case of a power failure the receiver takes 4 “AA”

batteries.

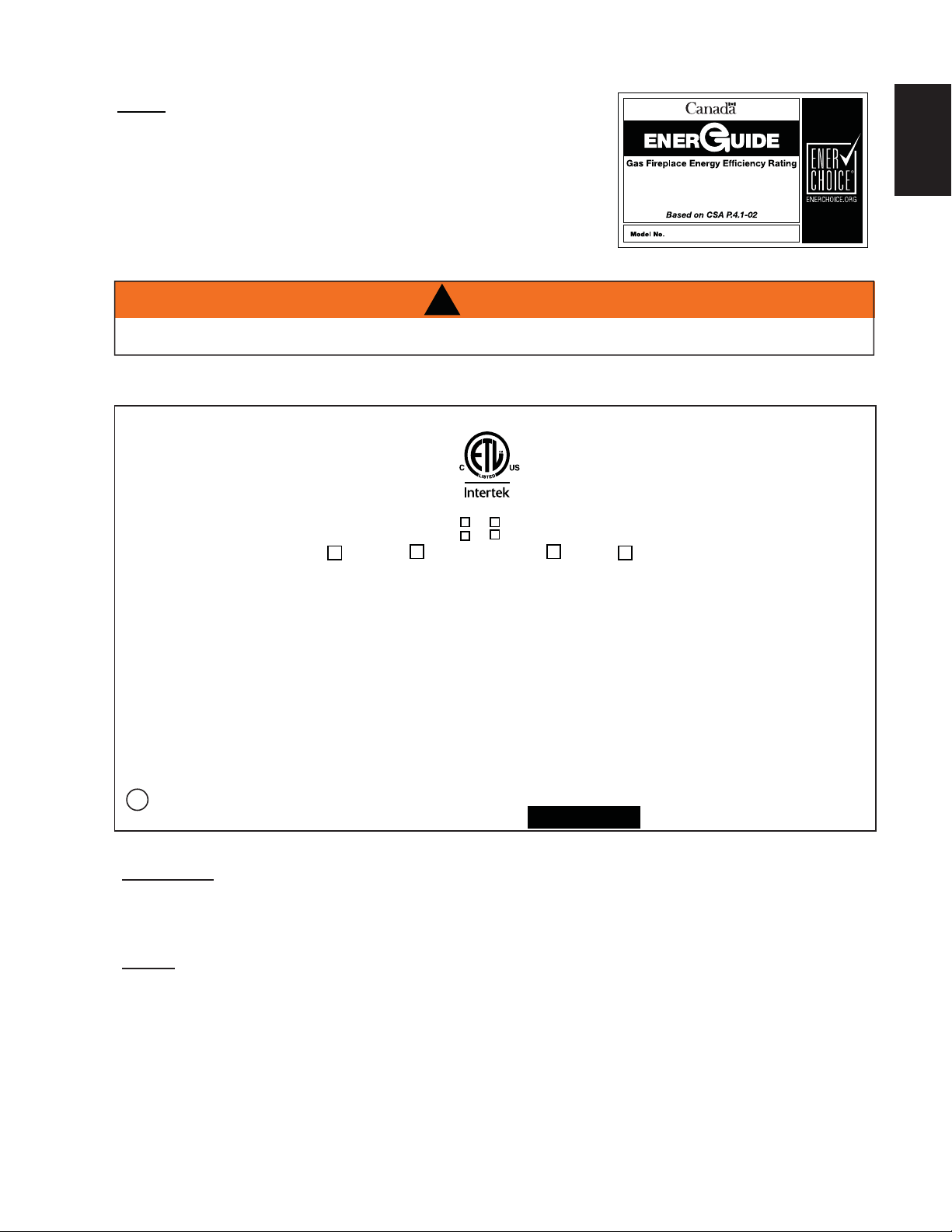

INSTALLER: It is your responsibility to check off the appropriate box on the rating plate according to

the model, venting and gas type of the appliance.

The illustration is for reference only. Refer to the rating plate on the appliance for accurate information.

NOTE: The rating plate must remain with the appliance at all times. It must not be removed.

65%

HDX52

Both the rating plate and lighting instructions are attached to a cable and inserted along the left side of the ap-

pliance.

!

WARNING

ALLOW APPLIANCE TO COOL BEFORE PERFORMING ANY MAINTANCE OR CLEANING.

W385-1928 / C

CHDX52N CHDX52P

CONFORMS TO / CONFORMEAUX: ANSI Z21.50-2014, CERTIFIED TO / CERTIFIE CSA2.22-2014 VENTED GAS FIREPLACE / FOYER À GAZ VENTILÉ.

DIRECT VENT GAS FIREPLACE.

NOT FOR USE WITH SOLID FUEL.

FOR USE WITH GLASS DOORS

CERTIFIED WITH THIS UNIT ONLY.

WARNING: DO NOT ADD ANY MATERIAL

TO THE APPLIANCE, WHICH WILLCOME IN

CONTACT WITH THE FLAMES, OTHER THAN

THAT SUPPLIED BY THE MANUFACTURER

WITH THE APPLIANCE

DECORATIVE PRODUCT: NOT FOR USE AS A

HEATING APPLIANCE.

MINIMUM CLEARANCE TO

COMBUSTIBLE MATERIALS:

TOP 0"

FLOOR 0"

RECESSED DEPTH 29"

SIDES 0"

BACK 0"

VENT TOP 3"

VENT SIDES & BOTTOM 2"

VERTICAL VENT 1"

MANTEL 6"*

TOP SIDES & BACK: PER STAND OFF SPACERS FOR FRAMING

MATERIALS. FOR FINISHING MATERIALS SEE OWNER’S MANUAL

*MAXIMUM HORIZONTAL EXTENSION 2". SEE INSTRUCTION MANUAL FOR GREATER

EXTENSIONS. SEE OWNER’S INSTRUCTION MANUAL FOR MINIMUMAND

MAXIMUM LENGTHS.

ELECTRICAL RATING: 115V.60HZ. LESS THAN 12 AMPERES

WOLF STEEL LTD.

24 NAPOLEON ROAD, BARRIE, ON, L4M 0G8 CANADA

SPÉCIFICATIONS ÉLECTRIQUES : 115 V,

60HZ. MOINS DE 12 AMPÈRES.

HDX52N HDX52P

MODEL PROPANE /

PROPANE MODÈLE FOYER À D'ÉVENT DIRECT. UN

COMBUSTIBLE SOLIDE NE PAS

ÊTRÉ UTILISÉ AVEC CET

APPAREIL. UTILISER AVEC LES

PORTE VITRÉES HOMOLOGUÉES

SEULEMENT AVEC CETTE UNITÉ.

ADVERTISSEMENT : N’AJOUTEZ PAS

A CETAPPAREIL AUCUN MATÉRIAU DEVANT

ENTRER EN CONTACT AVEC LES FLAMMES

AUTRE QUE CELUI QUI EST FOURNI AVECT

CET APPAREIL PAR LE FABRICANT.

PRODUIT DÉCORATIF: NE PAS UTILISER

COMME APPAREIL DE CHAUFFAGE

DÉGAGEMENTS MINIMAUX DES MATÉRIAUX

COMBUSTIBLES :

DESSUS 0"

PLANCHER 0"

PROFONDEUR DE L’ENCLAVE FACE 29"

CÔTÉS 0"

ARRIÈRE 0"

DESSUS DU CONDUIT D’EVENT 3"

CÔTÉS ET DESSOUS DU CONDUIT

D’EVENT 2"

CONDUIT D’EVENT VERTICAL 1"

TABLETTE 6"*

DESSUS, CÔTÉS & ARRIÈRE : SELON LES ESPACEURS DE

DÉGAGEMENT POUR LES MATERIAUX D’OSSATURE SELON

LA MANUELDE PROPRIÉTAIRE POUR LES MATÉRIAUX DE

FINITION. *L’EXTENSION HORIZONTALE MAXIMALE : 2".

RÉFÉRER AU MANUALD’INSTRUCTION POUR DES

EXTENSIONS PLUS GRANDES. RÉFÉRER AU MANUEL

D’INSTALLATION DE PROPRIÉTAIRE.

MODEL NATURAL GAS /

GAZ NATURAL

0-4500FT (0-1370M) ALTITUDE / ÉLÉVATION 0-4500FT (0-1370M)

55,000 BTU/H

INPUT / ALIMENTATION 55,000 BTU/H

37,000 BTU/H REDUCED INPUT / ALIMENTATION RÉDUITE 36,500 BTU/H

3.5"WATER COLUMN/D’UNE COLONNE D’EAU MANIFOLD PRESSURE / 10"WATER COLUMN/D’UNE COLONNE D’EAU

PRESSION AU COLLECTEUR

4.5"WATER COLUMN/D’UNE COLONNE D’EAU MINIMUM SUPPLY PRESSURE / 11"WATER COLUMN/D’UNE COLONNE D’EAU

PRESSION D’ALIMENTATION MINIMALE

7.0"WATER COLUMN/D’UNE COLONNE D’EAU MAXIMUM SUPPLY PRESSURE 13"WATER COLUMN/D’UNE COLONNE D’EAU

PRESSION D’ALIMENTATION MAXIMALE

65.2% P.4 FE 65.2%

SERIAL NUMBER/ NO. DE SÉRIE: HDX52

L’APPAREIL DOIT ÉVACUER SES GAZ EN UTILISANT

L’ENSEMBLE D’ÉVACUATION PROPRE ANAPOLEON. RÉFÉRER

AU MANUEL D’INSTALLATION DE PROPRIÉTAIRE POUR

L’EVACUATION PRECISE. IL EST IMPORTANT DE BIEN

RÉINSTALLER ET RESCELLER L’EVENT APRÉSAVOIR ASSURÉ

LE MAINTIEN DU SYSTÉME DE PRISE D’AIR.

THE APPLIANCE MUST BE VENTED USING THEAPPROPRIATE

NAPOLEON VENT KITS. SEE OWNERS INSTALLATION MANUAL

FOR VENTING SPECIFICS. PROPER REINSTALLATIONAND

RESEALING IS NECESSARYAFTER SERVICING THE VENT-AIR

INTAKE SYSTEM.

THIS APPLIANCE MUSTBE INSTALLED IN ACCORDANCE WITH LOCALCODES, IFANY; IF NONE, FOLLOW THE

CURRENTANSI Z223.1 OR CSAB149, INSTALLATION CODES. VENTED GAS FIREPLACE.APPROVED FOR

BEDROOM, BATHROOM AND BED-SITTING ROOM INSTALLATION. SUITABLE FOR MOBILE HOME

INSTALLATION IF INSTALLED IN ACCORDANCE WITH THE CURRENT STANDARD CAN/CSA Z240MH SERIES

GAS EQUIPPED MOBILE HOMES, IN CANADA OR INTHE UNITED STATES THE MANUFACTURED HOME

CONSTRUCTION AND SAFETYSTANDARD, TITLE 24 CFR, PART 3280. WHEN THIS US STANDARD IS NOT

APPLICABLE USE THE STANDARD FOR FIRE SAFETY CRITERIA FOR MANUFACTURED HOME INSTALLA-

TIONS, SITES AND COMMUNITIES,ANSI/NFPA 501A. FOR USE WITH BARRIER W565-0148. FOLLOW THE

INSTALLATION INSTRUCTIONS LOCATED IN THE INSTALLATION MANUAL

INSTALLER L’APPAREIL SELON LES CODES D’INSTALLATION ANSI Z223.1 OU CSA-B149 EN VIGUER.

FOYER À GAZ VENTILÉ. HOMOLOGUÉ POUR INSTALLATION DANS UNE CHAMBRE À COUCHER, UNE SALLE DE

BAIN ET UN STUDIO.APPROPRIÉ POUR INSTALLATION DANS UNE MAISON MOBILE SI SON INSTALLATION

CONFORME AUX EXIGENCES DE LANORME CAN/CSA Z240MH SÉRIE DE MAISONS MOBILES ÉQUIPÉESAU

GAZ EN VIGEUR AU CANADAOU AUX ÉTATS-UNIS DE LA NORME DE SECURITE ET DE CONSTRUCTION DE

MAISONS MANUFACTUREE,TITRE 24 CFR, SECTION 3280. DANS LE CAS OU CETTE NORME D’ÉTATS-UNIS NE

PEUT ETREAPPLIQUÉE, SE REFERER ALA NORME RELATIVE AU CRITÈRE DE MESURES DE SÉCURITÉ

CONTRE L’INCENDIE POUR LES INSTALLATIONS DANS LES MAISONS MANUFACTURÉS, LES SITES ET LES

COMMUNAUTÉS, ANSI/NFPA 501A. POUR UNE UTILISERAVEC BARRIÈRE W565-0148. SUIVEZ LES

INSTRUCTIONS D'INSTALLATION SE TROUVENT DANS LE MANUEL D'INSTALLATION.

9700539 (WSL)

4001658 (NAC) 4001657 (NGZ)

4001659 (WUSA)

OPTIONAL FAN KIT: NZ64 ENSEMBLE DE VENTILATEUR FACULTATIF: NZ64