WARNING

CONTENTS

(Page) (Page)

- 2 -

PRECAUTIONS TO BE OBSERVED BEFORE AND

DURING SERVICING TO AVOID POSSIBLE EXPOSURE

TO EXCESSIVE MICROWAVE ENERGY

(A) Do not operate or allow the oven to be operated with the

door open.

(B) Make the following safety checks on all ovens to be serviced

before activating the magnetron or other microwave source,

and make repairs as necessary:

(1) Interlock operation

(2) Proper door closing

(3) Seal and sealing surfaces (arcing, wear, and other

damage)

(4) Damage to or loosening of hinges and latches.

(5) Evidence of dropping or abuse

(C) Before turning on microwave power for any service test or

inspection within the microwave generating compartments,

check the magnetron, waveguide or transmission line, and

cavity for proper alignment, integrity and connections.

(D) Any defective or misadjusted components in the interlock,

monitor, door seal, and microwave generation and trans-

mission systems shall be repaired, replaced, or adjusted

by procedures described in this manual before the oven is

released to the owner.

(E) A microwave leakage check to verify compliance with the

Federal Performance Standard should be performed on

each oven prior to release to the owner.

WARNING

This service information is designed for experienced repair technicians only and is not designed for use by the general public. It does not

contain warnings or cautions to advise non-technical individuals of potential dangers in attempting to service a product.

Products powered by electricity should be serviced or repaired only by experienced professional technicians. Any attempt to service or repair

the product or products dealt with in this service information by anyone else could result in serious injury or death.

1.This product should be serviced only by trained, qualified personnel.

2.Check for radiation leakage before and after every servicing according to the “procedure for measuring radiation leakage.”

3.If the unit cannot be repaired on site, advise the customer not to use until unit is repaired.

4.There are special components used in the microwave oven which are important for safety. These parts are marked with

a on the replacement parts list. It is essential that these critical parts should be replaced only with the manufacture’s

specified parts to prevent microwave leakage, shock, fire, or other hazards. Do not modify the orginal design.

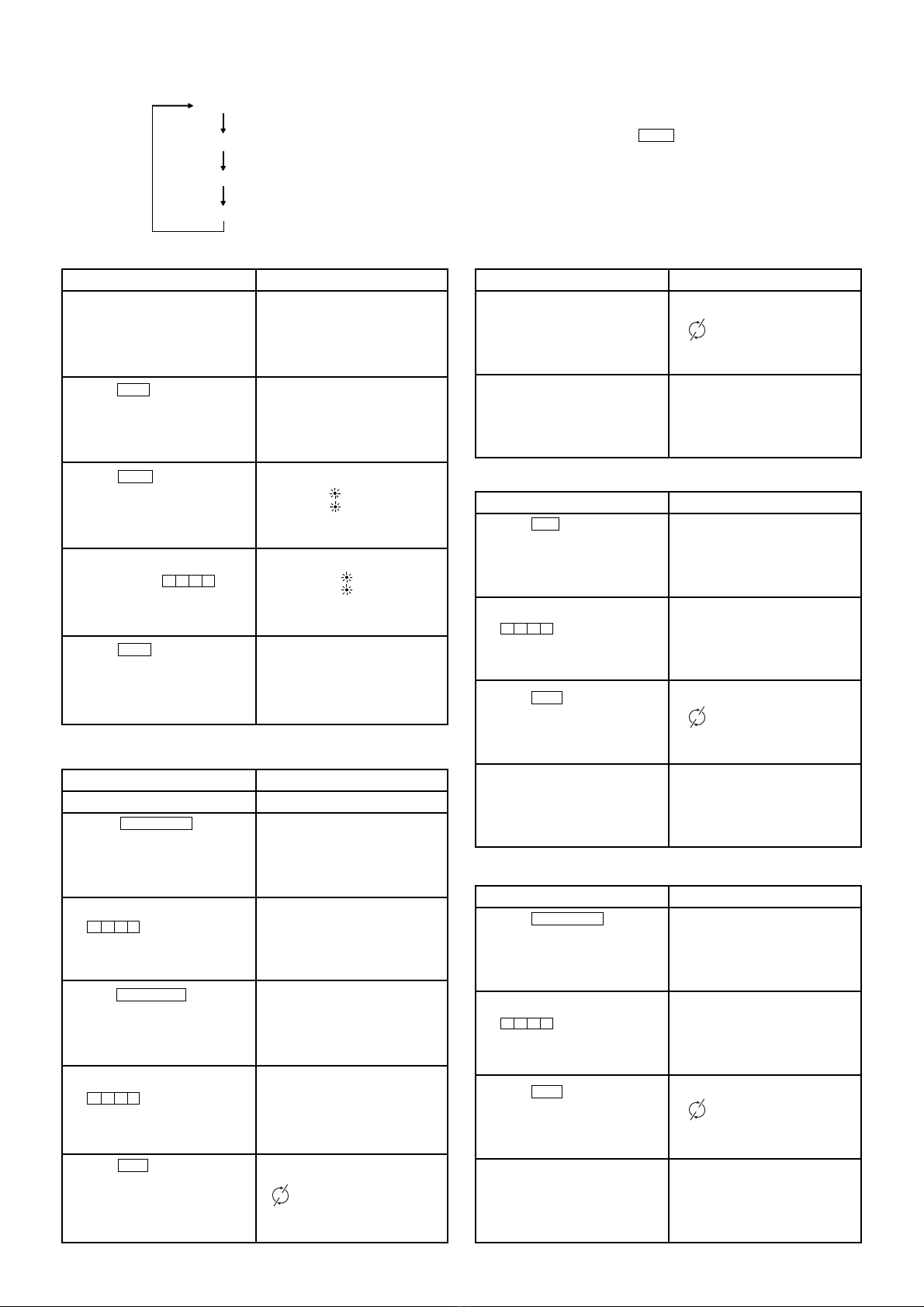

This service manual covers products for following markets.

When troubleshooting or replacing parts, please refer to the country/area identifications shown below for your

applicable product specification.

HNE ......................................... For Hong Kong KKE .................................... For UAE, Egypt, Iran

YNQ ......................................... For Singapore KNQ ................................... For Kuwait, Doha, Quatar

MNQ ......................................... For Malaysia Oman, Bahrain, Pakistan

TNE .......................................... For Thailand, Indonesia SNM ................................... For Saudi Arabia

YKE .......................................... For Others ZPE .................................... For CIS Countries

WNT ......................................... For Tai Wan

FEATURE CHART ............................................................................... 4

CONTROL PANEL ............................................................................... 4

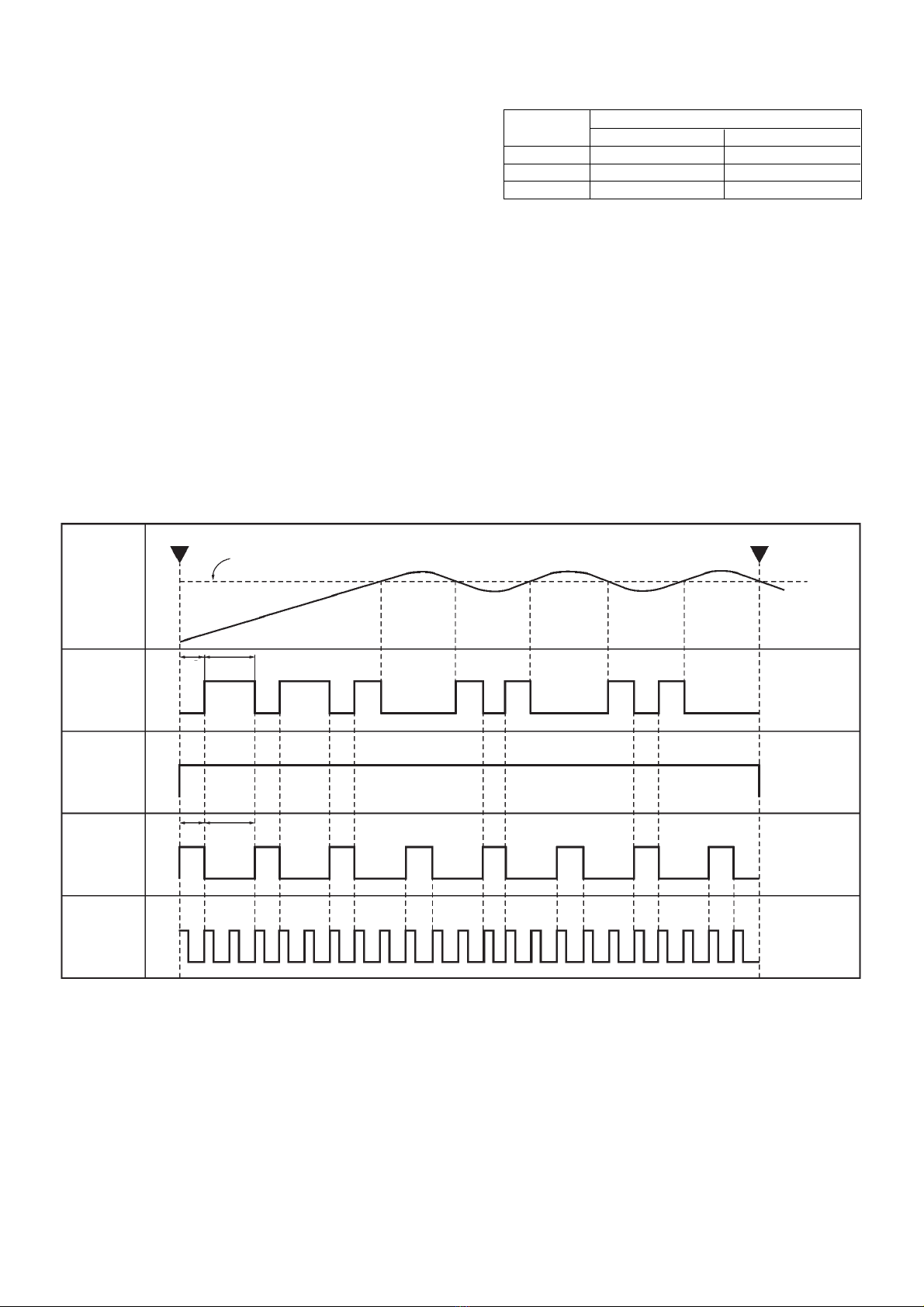

OPERATION AND DIGITAL PROGRAMMER

CIRCUIT TEST PROCEDURE ............................................................ 5

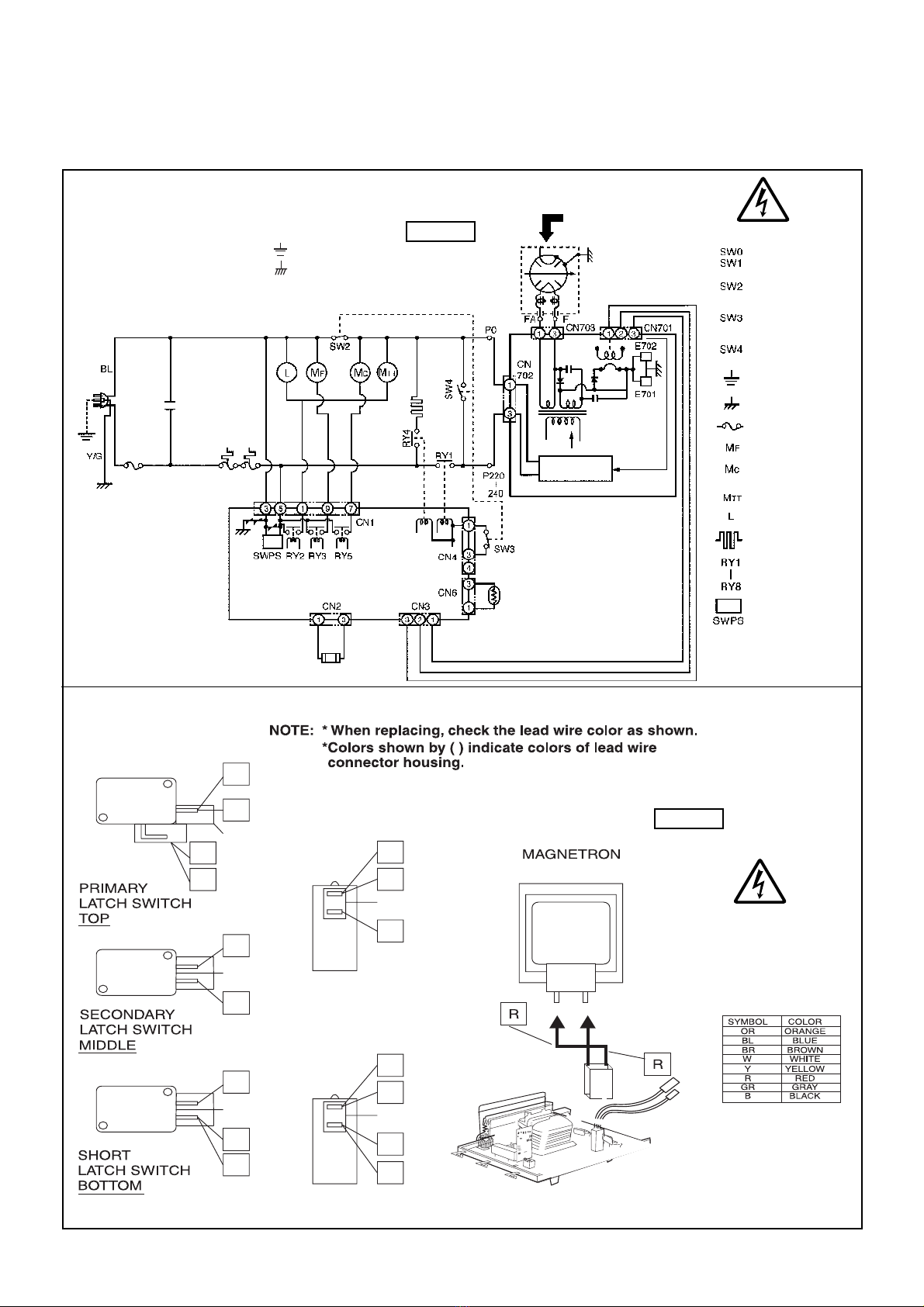

SCHEMATIC DIAGRAMS .................................................................... 7

DESCRIPTION OF OPERATING SEQUENCE ................................... 9

CAUTIONS TO BE OBSERVED WHEN TROUBLESHOOTING ......... 11

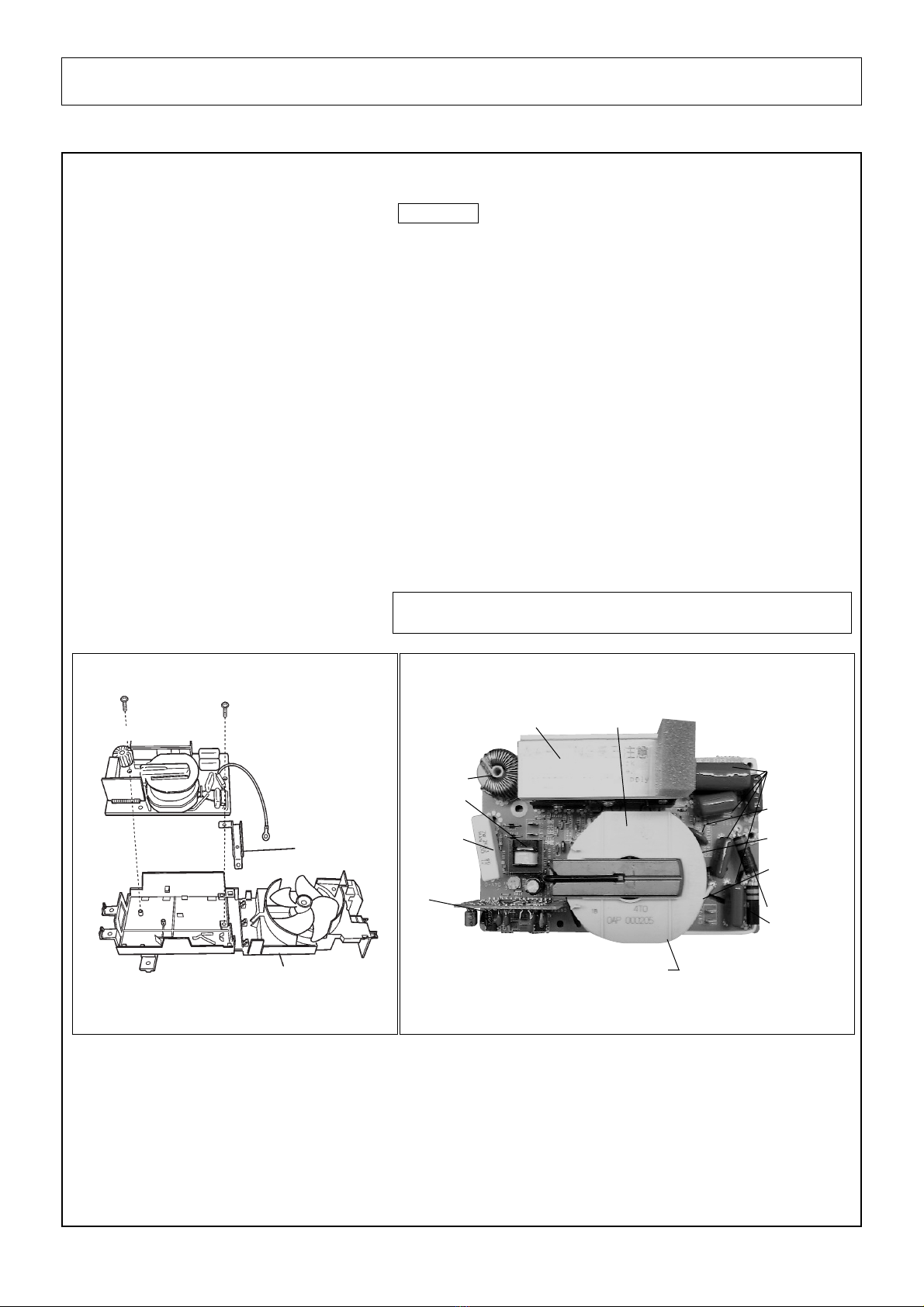

DISASSEMBLY AND PARTS REPLACEMENT PROCEDURE ........... 13

COMPONENT TEST PROCEDURE .................................................... 17

MEASUREMENTS AND ADJUSTMENTS ........................................... 20

PROCEDURE FOR MEASURING MICROWAVE ENERGY LEAKAGE ...

21

TROUBLESHOOTING GUIDE ............................................................ 22

EXPLODED VIEW AND PARTS LIST .................................................. 28

SCHEMATIC DIAGRAM &

PARTS LIST OF DIGITAL PROGRAMMER CIRCUIT ......................... 34

!

!