A

A1

A3 A2

H

B2

B1

H1

B

07

06

V. Troubleshooting

Malfunction

Low

Vacuum

Oil leak

Start-up

problems

Oil spray

Possible Cause

1. Secondary air inlet connection cap loose on the

air inlet port.

2. Damaged rubber o-ring inside the secondary air

inlet connection cap.

3. The volume of oil is insufficient.

4. Pump oil becomes opaque or absorbed too

many impurities.

5. The pump’s oil entry hole is clogged or the oil

supply is insufficient.

6. The pump connecting hoses, manifold or

system has a leak.

7. The pump selection is wrong.

8. The pump has been used for too long, damage

and wear to components caused increased

gaps between parts.

1. Damaged oil seal.

1. Oil temperature is too low.

2. Motor, power source or circuit board

malfunctions.

3. Foreign objects entered the pump.

4. Voltage supply is excessively low or high.

5. Overload trips.

1. Excessive oil volume.

2. Inlet port pressure is excessively high for a long

period.

2. Loose or damaged oil box connections.

Remedy

Tighten the cap.

Replace the rubber o-ring.

Add oil to the center line of the oil display.

Replace with new oil.

Clean the oil entry hole, clean the oil filter.

Inspect the connecting hose gaskets and

system, repair leaks.

Check the size of the container to be evacuated,

recalculate and select an appropriate pump

model.

Inspect and repair, or replace the pump.

Inspect and repair.

Inspect and remove.

Inspect the power source voltage.

After overload trip occurs, switch kept On.

Remove battery, wait for approximately 30

seconds before inspecting and repairing.

Replace the oil seal.

Tighten the connecting screws, replace O-rings.

Remove oil until the oil position line is reached.

Select an appropriate pump, increase the

pumping speed.

Warm up the pump.

Notes:

1. The pump is inverter driven and the motor has over-current / overload protection, please

troubleshoot after overload resets.

2. If the above methods cannot resolve your problems, please contact your nearest distributor. We will

do our best to provide you with a quick turnaround to keep you working.

Requirements For Warranty Coverage

Product warranty is provided for product quality problems for one year from date of sale. For

warranty to be valid, the following conditions must be met:

1. Products issues due to manufacturing defects confirmed by qualified agents.

2. Products which have not been maintained or dismantled by unauthorized parties.

3. Products that have been used in accordance with the User Manual. All maintenance services shall

be performed during the warranty period.

Statement: Other than repairing the defective product , the manufacturer of this product will not be

liable for any other costs, such as time spent in fixing the issue, refrigerant consumption,

refrigerant disposal costs, as well as unauthorized transportation and labor costs.

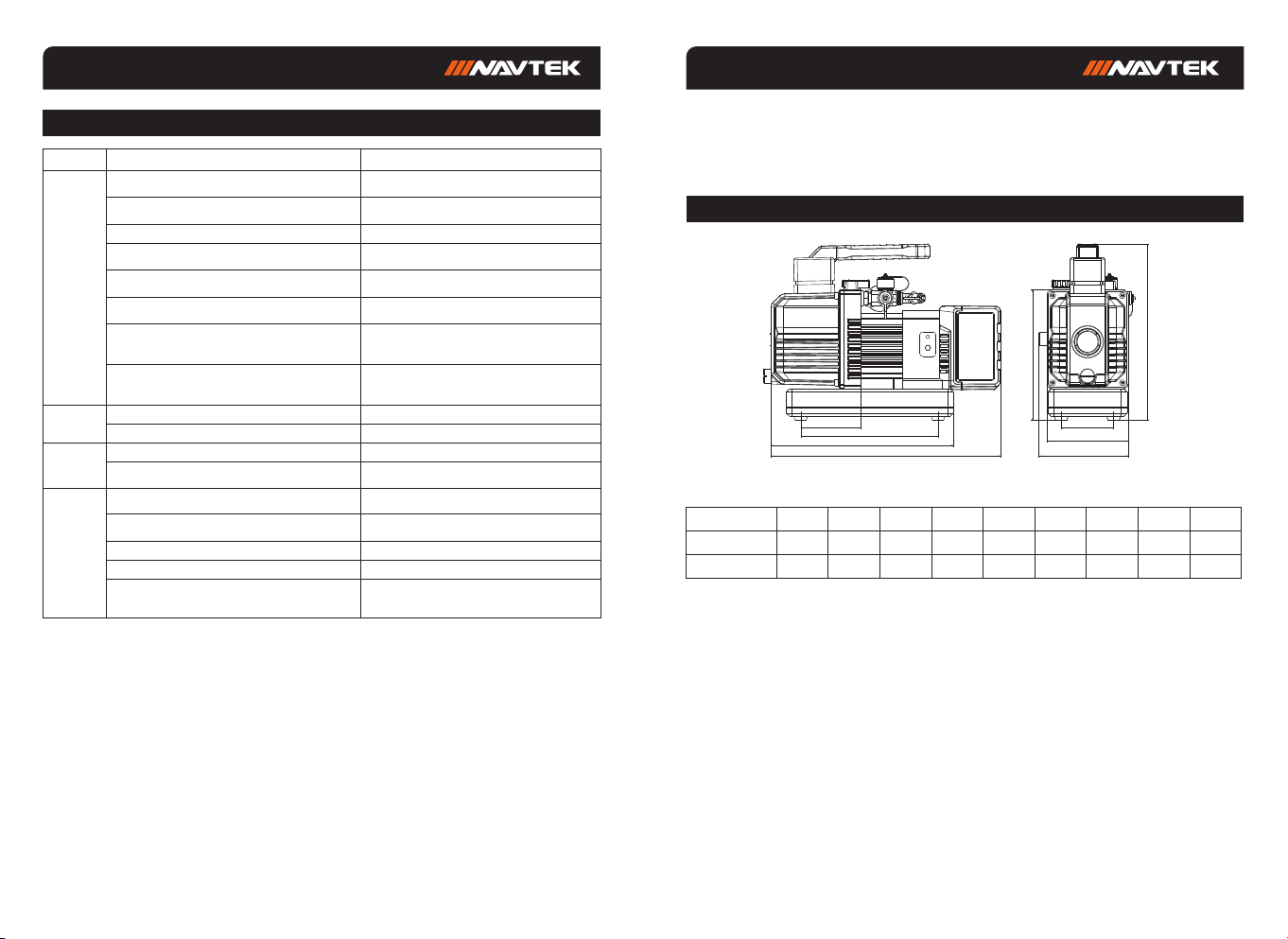

VI. Dimension

Model

NP2DLM

AA1 A2 A3 BB1 B2 HH1

9.6" 7.7" 4.9" 2.8" 3.5" 2.2" 2.4" 7.6" 5.9"

NP4DLM 12.8" 10.3" 7.4" 3.2" 4.8" 4.4" 2.8" 9.5" 7.1"