3

IMPORTANT SAFETY INSTRUCTIONS

IMPORTANT: Read the assembly instruction section and safety precautions of this

booklet carefully before removing the contents of this carton.

1. This appliance is not intended for use by persons (including children) with reduced physical, sensory or mental capabilities,

or lack of experience or knowledge, unless they have been given supervision or instruction concerning the use of the

appliance by a person responsible for their safety. Children should be supervised to insure that they do not play with the

appliance.

2. After removing the packaging, make sure to check if there is any damage to the appliance. If there is any damage, never

attempt to use the appliance and immediately contact your Authorised Service Centre. As packaging materials can be

dangerous to children, they need to be collected immediately and put out of reach.

3. In certain circumstances electrical appliances may be a danger hazard. The unit MUST be connected to the electrical

supply before operation to enable the electronic ignition to work.

4. Do not place heavy objects on this appliance, use for storage or as a cutting surface as sharp edges can damage the surface.

This appliance is designed for cooking food only. Do not drop heavy items onto the ceramic glass cooktop. If any damage,

such as chips or cracks, are seen in the glass, turn off all control knobs and do not use until the appliance has been inspected

by an authorised Service person or replaced.

5. This appliance is designed for domestic household use only and for the cooking of domestic food products. Use as a

commercial appliance will void the warranty. It should not to be used in a marine environment or outdoors and must be fully

built in. Do not use the appliances until fully installed.

6. Damage can occur to bench tops if pots and pans are able to overlap the bench top. This can result in heat being transferred

to the bench top. Ensure that correct sized pots and pans are used. Refer to guide in booklet.

7. Do not allow pot handles or utensils to be placed near gas burners which are operating, as they can cause the handles to

become hot to touch. Always turn handles away when small children are nearby. It is recommended that children are kept

away from the cooktop at all times.

8. Do not leave the cooktop while cooking with solid or liquid oils. There may be flaming up in conditions of extreme heating.

Never pour water onto the flames occurring from oil. Immediately turn the cooktop off and cover the pan with a lid or fire

blanket in order to smother the flame.

9. If the electrical supply cord is damaged, either when being installed or after installation, it must be replaced by the

manufacturer, it’s service agent or similarly qualified persons in order to prevent a hazard.

10. The electrical connection must be accessible after installation. The appliance must be electrically isolated before any

maintenance can be performed.

11. The appliance is not intended to be operated by means of an external timer or separate remote control system.

12. Electrical connection must be made as per local wiring rules and regulations. Do not disconnect the appliance with wet hands

or bare feet, and do not disconnect the power cord with extreme force.

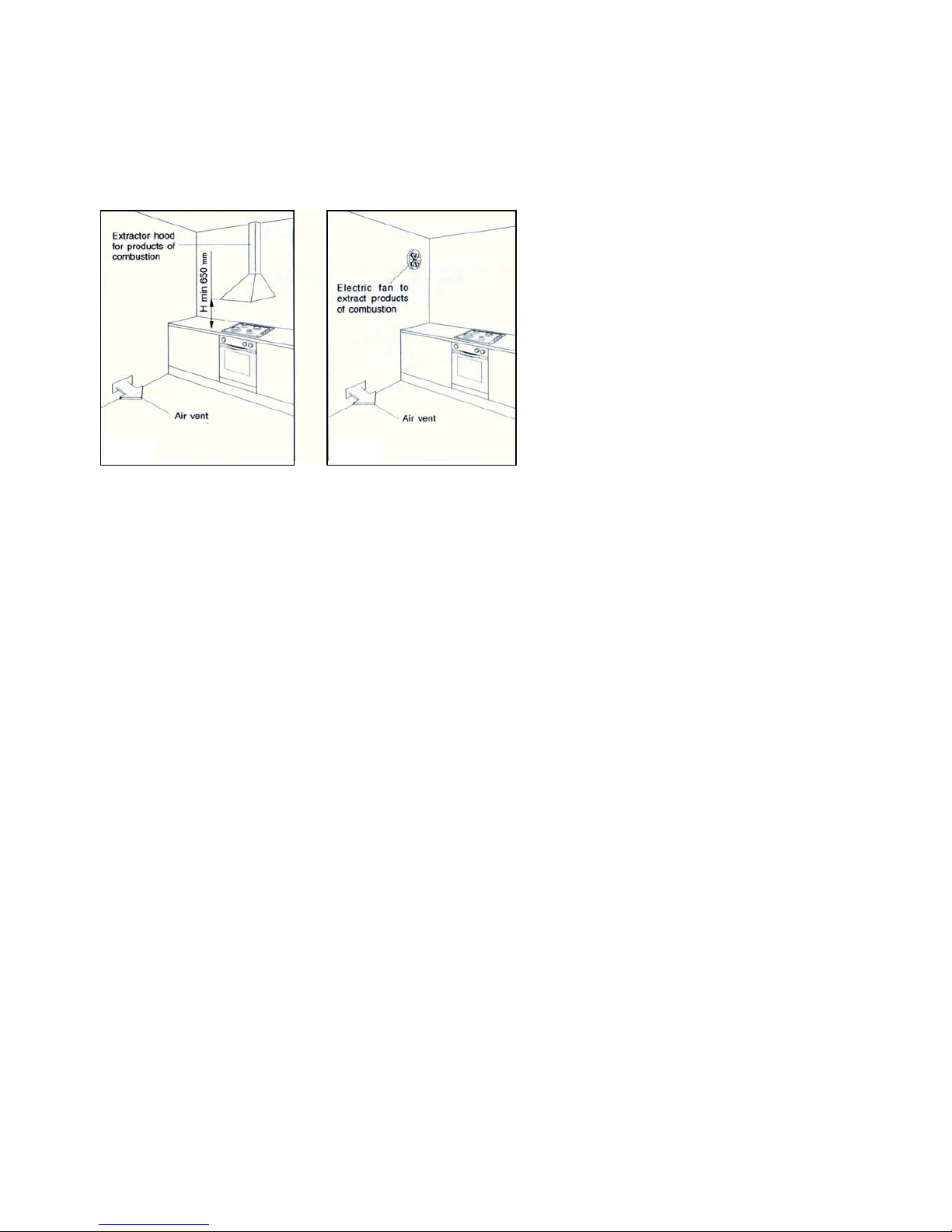

13. Ensure that the kitchen is well ventilated or mechanical ventilation is in use while cooking on the gas cooktop. Items made

from aluminium, plastic, plastic film and sugar based foods should also be kept away from the appliance, as they may fuse to

the surface.

14. DO NOT USE OR STORE FLAMMABLE MATERIALS IN THE APPLIANCE STORAGE DRAWER OR NEAR THIS APPLIANCE.

DO NOT SPRAY AEROSOLS IN THE VICINITY OF THIS APPLIANCE WHILE IT IS IN OPERATION.

15. WARNING - The cooktop will become hot during and directly after use. Do not touch any components during this time, as

they may be hot and can cause burns. To avoid burns, children should be kept away.

16. Cleaning may only be commenced on the appliance once it has cooled down and is turned off. Failure to clean properly can

damage the unit. Do not use a steam jet or any other high pressure cleaning equipment to clean the appliance.

17. Do not use harsh abrasive cleaners or sharp metal scrapers to clean the glass surface as they can scratch the surface, which

may result in the glass shattering. Clean the glass using a warm damp cloth (e.g. dishcloth) and dry it with a soft dry tea towel.

18. When the appliance is not being used, the knobs must be kept in the ‘OFF’ position.

19. Not to be used in a marine environment.

20. WHERE THIS APPLIANCE IS INSTALLED IN MARINE CRAFT OR CARAVANS, IT SHALL NOT BE USED AS A SPACE

HEATER.

21. The appliance must be installed and put into operation by an authorised person under the conditions provided by the

manufacturer in this manual. The manufacturer cannot be held responsible for any damage that might occur due to faulty

installation.

22. DO NOT MODIFY THIS APPLIANCE. This appliance is not suitable for use with aftermarket lids or covers.

DO NOT OPERATE THIS APPLIANCE BEFORE READING THE

INSTRUCTION BOOKLET

DO NOT PLACE ARTICLES ON OR AGAINST THIS APPLIANCE

DO NOT STORE CHEMICALS OR FLAMMABLE MATERIALS OR

SPRAY AEROSOLS NEAR THIS APPLIANCE