PLEASE READ THESE INSTRUCTIONS CARFULLY. NOTE THE SAFETY INSTRUCTIONS

AND WARINGS. USE THE PRODUCT CORRECTLY AND WITH CARE FOR THE PURPOSE

FOR WHICH IT IS INTENDED. FALURE TO DO SO MAY CAUSE DAMAGE TO PROPERTY

AND/OR SERIOUS PERSONAL INJURY. PLEASE KEEPTHIS INSTRUCTION MANUAL

Max. Spring Diameter:180mm

Max Working Length: 570mm

Base size: 36.1cm x 50.2cm

2. SAFETY INSTRUCTIONS AND WARNINGS

1. Use a qualified person to maintain the strut spring compressor in good condition. Keep it

clean for best and safest performance.

2. The maximum load is 1ton. DO NOT exceed this rated capacity.

3. Use the compressor only on passenger cars and pickup truck. DO NOT use it for any other

purpose it is not designed to perform.

4. Keep children and unauthorized persons away from the work area.

5. Remove loosen clothing. Remove ties, watches, ring and other loose jewelry, and contain

6. Wear ANSI approved safety goggles when using the strut spring compressor.

7. Keep proper balance and footing, DO NOT overreach and wear non-skid footwear. Always

keep your fingers, hands and feet away from compressing area.

8. Only use this compressor on a surface that is stable, level, dry and not slippery, and capable

of sustaining the load. Keep the surface clean, tidy and free from unrelated materials and

ensure adequate lighting.

9. Inspect the tool before each use. DO NOT use if bent, broken, cracked, leaking or otherwise

damaged, any suspect parts are noted or it has been to a shock load.

10. Use extreme caution when applying or releasing a load. Never allow the load to suddenly

drop. Slowly and carefully apply and release the load.

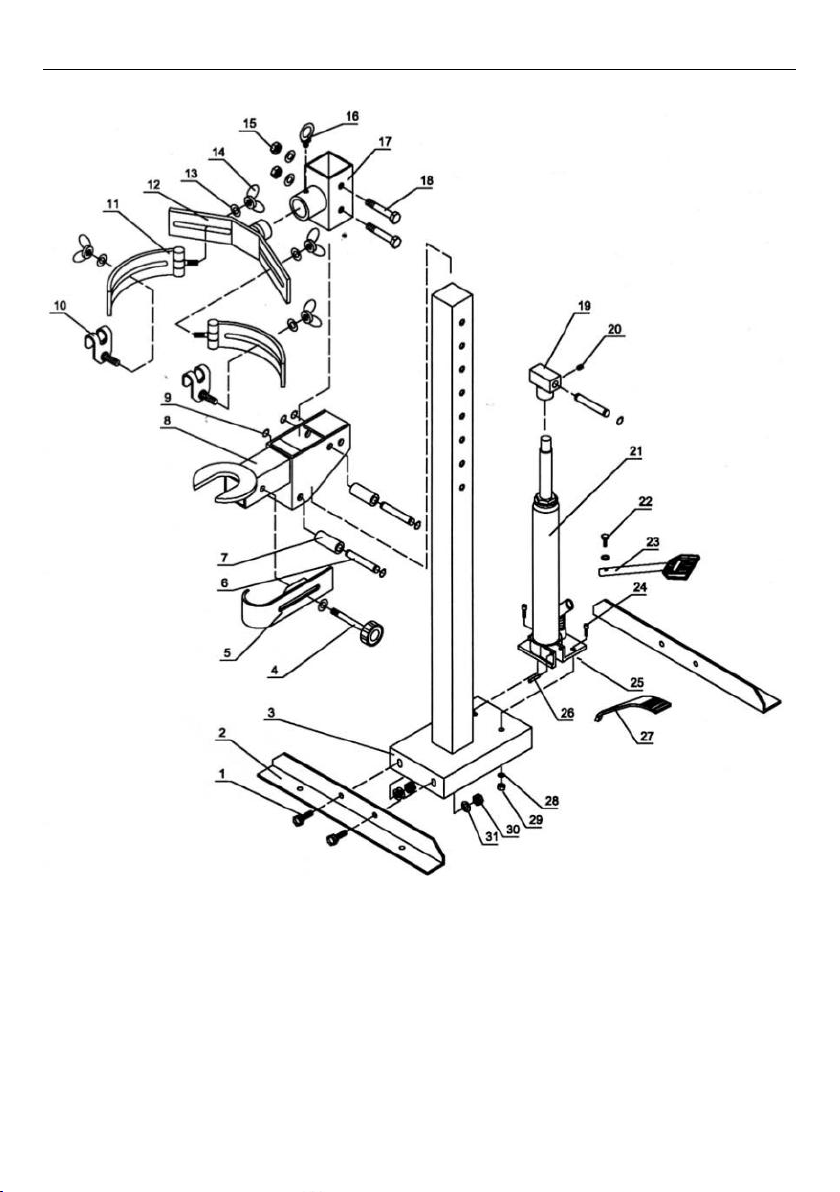

11. DO NOT allow any lubricants to contact the spring clasp bracket (12), spring clasp holder

(11), spring clasp/claw (10), lower strut support (8), adjustable strut shaft clasp (5) as that

will diminish the ability of the strut spring compressor to firmly and safely grip and hold a

strut spring in position, which may result in personal injury and/or property damage.

12. DO NOT operate the compressor when you are tired or under the influence of alcohol,

drugs or any intoxicating medication.