IMPORTANT

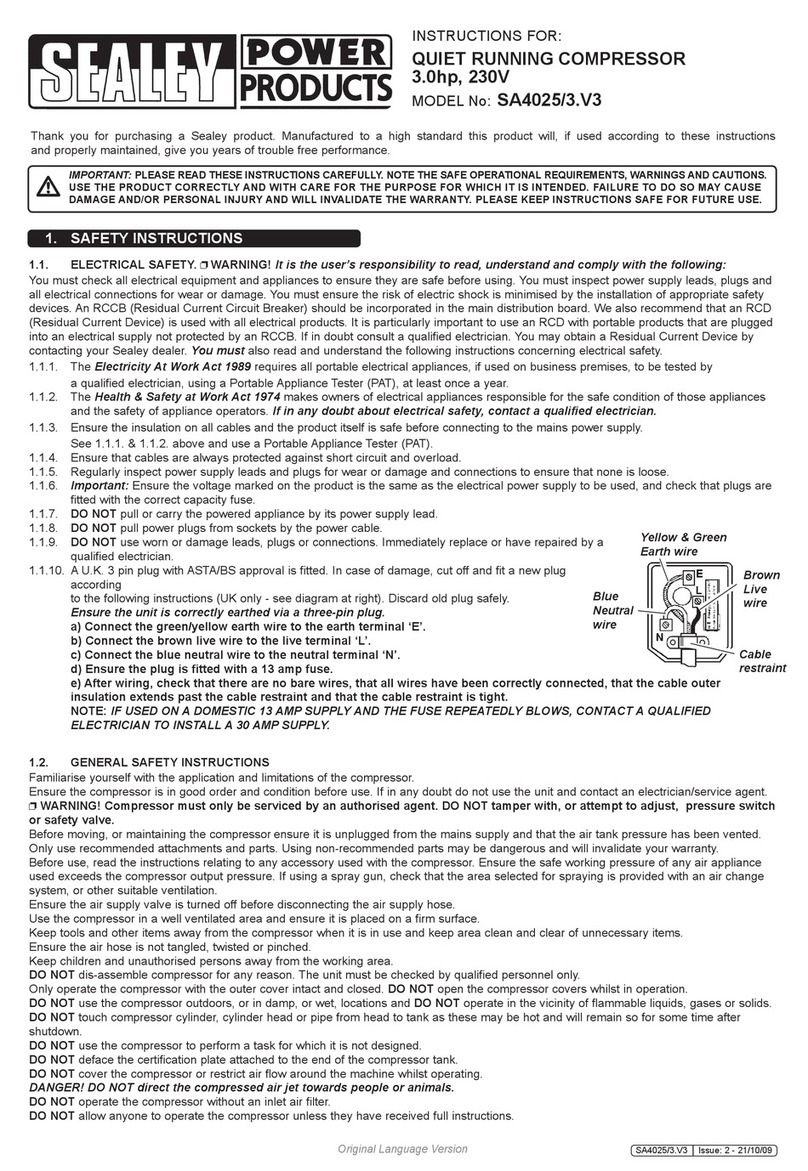

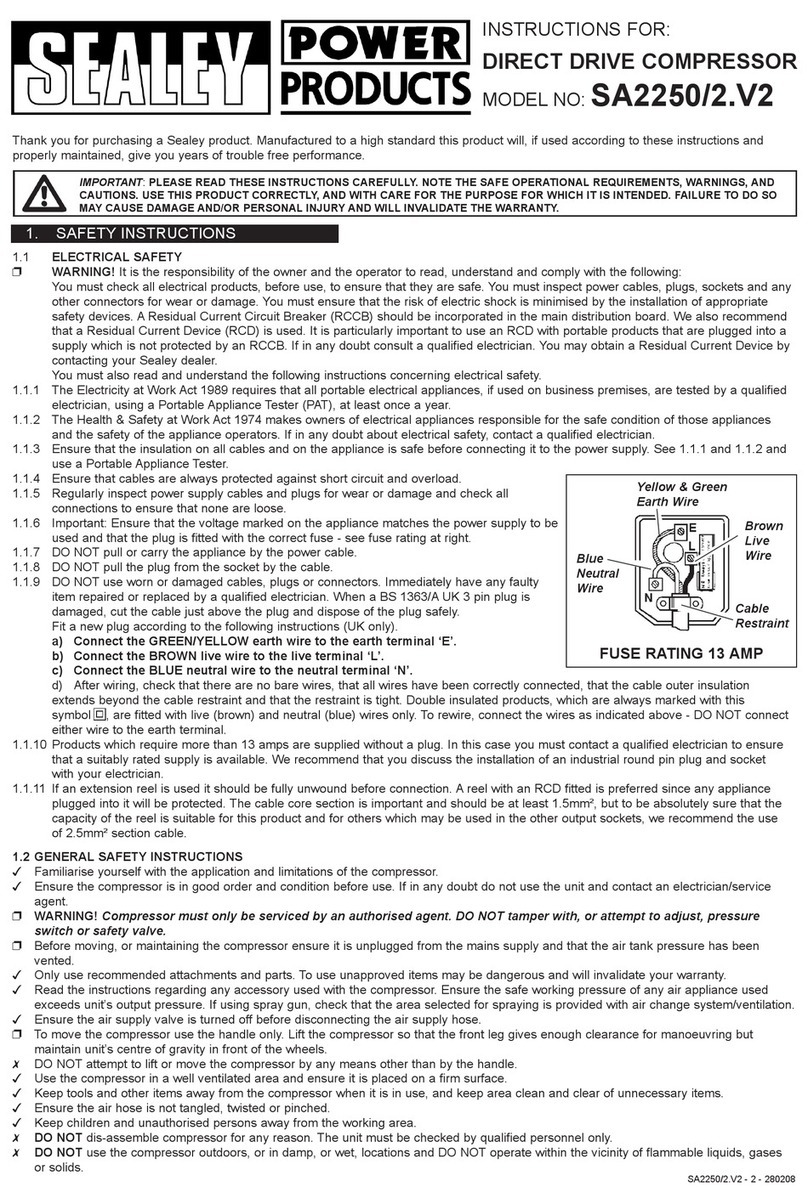

a. The motors on these compressors are 3HP/230V and at normal mains voltage will start within the capacity of a 13 amp fused

circuit. Certain local conditions relating to electrical supply in the UK can result in the voltage varying between a low of 216

volts and a high of 253 volts. At such times of fluctuating voltage the 13 amp fuse in the compressor plug may blow. This is

normal and is not a fault with the compressor. However if it happens regularly we recommend that you consult an electrician

with a view to installing a 30 amp supply, with contact breaker, to avoid the inconvenience of frequent fuse replacement.

WARNING! Extension lead MUST NOT be used to connect compressor to the mains as the resulting voltage drop would

reduce motor output, and pump performance causing the 13Amp fuse to blow.

b. Take care when selecting tools for use with the compressor. Air tool manufacturers normally express the volume of air

required to operate a tool in cubic feet per minute (cfm). This refers to free air delivered by the compressor (‘air out’) which

varies according to the pressure setting. Do not confuse this with the compressor displacement which is the air taken in by

the compressor (‘air in’). ‘Air out’ is always less than ‘air in’ - due to losses within the compressor - and so it is important

that, before choosing equipment, you study the ‘Free Air Delivery’ figures shown in the Specifications chart, section 2.

WARNING! Ensure that you have read, understood and apply section 1 safety instructions.

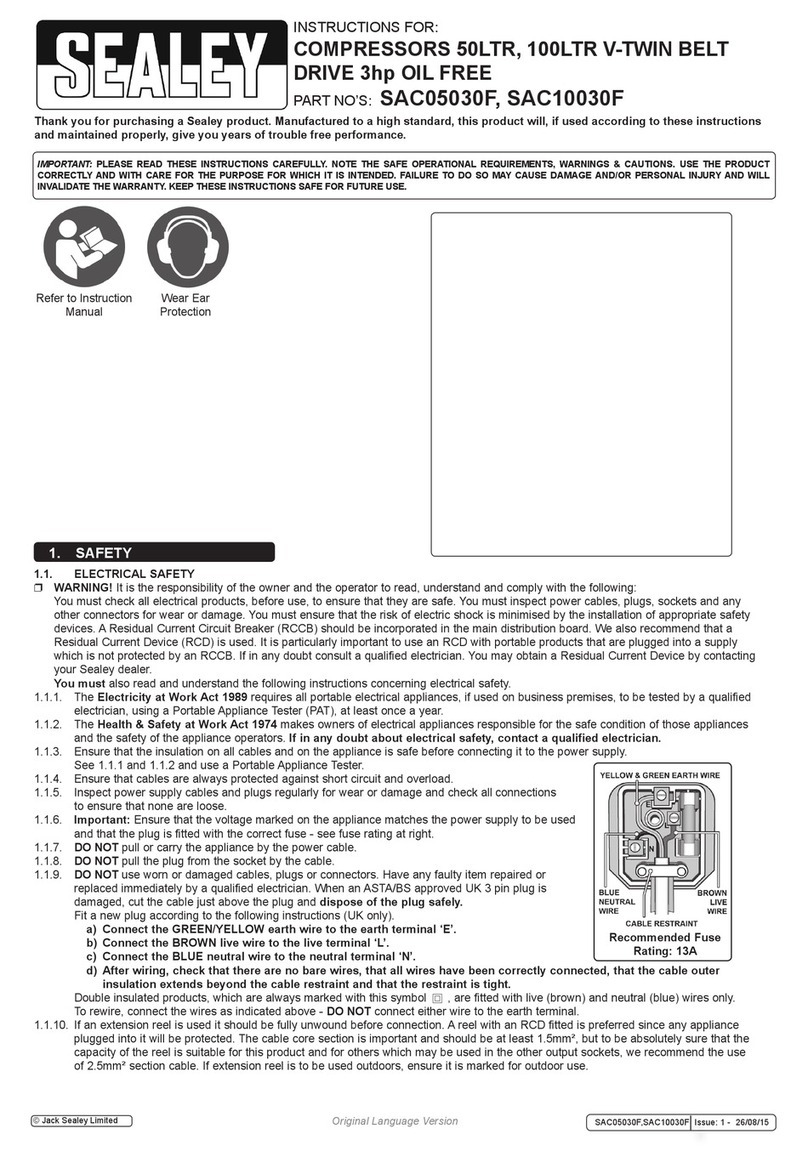

4.1. Make sure the main switch (fig.4.1) is in position "O”, off (fig.4).

4.2. Plug the lead into mains supply and start the compressor by turning the main switch to “I”, on.

4.3. When starting the compressor for the first time, leave it running with air outlet (7) closed and

reducer (fig.4.3) set to maximum pressure. Make sure that pressure in the tank rises and

that the compressor stops automatically when the max. pressure value allowed - written on the plate and

shown on the gauge (fig.4.2) - is achieved.

Note: SA2015/3 and SA2020/3 are not supplied with an integral pressure regulator.

The compressor will now operate automatically. The pressure switch stops the motor when the maximum

tank pressure is reached and restarts it when pressure falls below the minimum threshold - approx. 2 bar

(29psi) less than the maximum pressure.

4.4. Stop the compressor by turning the main switch off (fig.4). The compressed air inside the compressor

head will flow out, making the restart easier and preventing the motor from being damaged.

DO NOT, other than in an emergency,stop the compressor by switching off the mains socket, or by

pulling the plug out, as the pressure relief will not then occur and motor damage may result upon restart.

When the compressor runs correctly and is stopped correctly there will be:

(a) a whistle of compressed air when the motor stops,

(b) a protracted whistle (about 20-25 seconds) when the compressor starts with no pressure in the tank.

4.5. The compressor is equipped with an overload cut-out to protect the motor. The manual reset ‘D’ (fig.6) should

not be operated until 3 minutes after cut-out, to allow the motor to cool. To restart, turn main switch off, reset

‘D’ and then turn main switch on. If, after restarting, the compressor again automatically cuts out turn off at the

main switch and contact Service Agent.

4.6. SA2050/3 & SA2010/3 - The output pressure is regulated by the pressure reducer (fig.4. 3.).

Lift and turn the knob clockwise to increase pressure, anticlockwise to reduce - push knob down to lock in

required position. The gauge will show the output pressure. To determine the correct output pressure for any

piece of equipment check the manual.

When the compressor is not being used set the regulated pressure to zero so as to avoid damaging the pressure reducer.

NOTE: a) If the motor does not cut in and out, but runs continuously when using an air appliance, the capacity of the compressor may be too

small for the equipment or tool.

b)The gauge (fig.4.2) indicates the pressure inside the main tank, NOT the pressure supplied to the air equipment. Note: only model

SA2050/3 also has an output gauge (fig 4.X). Should the pressure in the tank exceed the pre-set switch (6) maximum, a safety

valve (5) will activate. WARNING! for this reason DO NOT tamper with or adjust the switch or safety valve.

4. OPERATION

In order to keep the compressor in good working condition, periodic maintenance is essential.

IMPORTANT! Failure to carry out maintenance tasks may invalidate the warranty on your compressor.

WARNING! Before performing any maintenance operation, switch off compressor, disconnect from power supply and vent air

from tank.

5.1. After the first 50 working hours. Operations to be carried out:

a) Check that all bolts/nuts are tight, particularly those retaining the crank case and cylinder head.

b) Replace the lubricating oil - see para 5.6.

5.2. Daily. Operation to be carried out :

a) Drain condensation by opening the valve ‘C’ located under the tank.

5.3. Monthly (or more frequently, if the compressor operates in a very dusty atmosphere):

a) Check oil level and, if necessary, top up. b) Remove the filter element (fig.2) and clean by blowing

through, with an air line at low pressure, from the clean side. Do not operate compressor without filter

as foreign bodies or dust could damage the pump. c) Check belt tension. d) Check for oil leaks.

5.4. 3-monthly. Operation to be carried out a) Check tank for internal corrosion.

5.5. Every 500 hours. Operations to be carried out :

a) Change air filter element

b) Check the automatic cut-out at max. pressure and the automatic cut-in at 2 bar below.

5.6. Every 1000 hours. Operations to be carried out :

a) Replace the lubricating oil. For oil specifications see 5.8.

Remove the oil breather ‘A’ and screw ‘B’, draining the oil into a container. Drain when the compressor

is hot so that oil drains rapidly and completely. Wash breather in kerosene, fuel oil or similar.

Replace screw ‘B’ and refill through the filler aperture. Do not overfill. Replace breather.

WARNING! Never mix different oils and do not use non-detergent/low quality oils as compressor may be

damaged.

WARNING! Dispose of waste oil only in accordance with local authority requirements.

5. MAINTENANCE

fig. 4

fig. 6

A

B

C

X

Original Language Version

SA2010/3, SA2015/3, SA2020/3, SA2050/3 Issue: 5 - 06/10/10