NetherLocks PROCESSINTERLOCKING Operator's manual

Quick Fix Guide

PROCESSINTERLOCKING

Quick Fix Guide

PROCESSINTERLOCKING

Congratulations on your purchase of a

Netherlocks valve interlock!

Netherlocks valve interlocks are manufactured

with care and are renowned for their high

quality. They do not need greasing, neither

do parts have to be replaced.

For support please contact

or call +31 (0)172 471 339.

We will assist you in the best possible way.

The Netherlocks team

2

Contents Quick Fix Guide

How are valve interlocks used? 4

Basic principles of valve interlocking 6

Valve interlock components 8

NDL exploded view 8

NDL GA drawing 10

MRL exploded view 12

MRL on gearbox exploded view 14

MRL GA drawing 16

Interlock tag plates 18

Key tag plates 19

Key cabinet tag plates 20

How to operate valve interlocks 21

How to reset a MRL valve interlock 22

Reset procedure (open side) 23

Reset procedure (close side) 25

Q-cards - Commissioning keys 27

How to remove a Q-card 28

Troubleshooting valve interlocks 30

Key stuck (key cannot be removed) 30

Key does not t (key cannot be inserted) 31

Key lost 32

Valve is replaced 33

Netherlocks Support programs 34

Service products 34

support: +31 (0)172 471 339

3

How to use the Quick Fix Guide

Welcome to the Netherlocks Quick Fix Guide, your reference

to valve interlocks! With this guide, you will be able to:

>Quickly understand the basic functionality of

valve interlocks

> Identify dierent valve interlock types, their

components and related products

>Operate valve interlocks

>Reset valve interlocks

>Quickly solve simple issues related to valve interlocks

The nal section of this guide explains how Netherlocks can

support you maintaining your valve interlocks, by oering

maintenance programs, site services and training.

The Quick Fix Guide oers 4 colour coded sections:

Basic principles

Operate and reset

Troubleshooting

Support programs

Each section has its own colour for easy navigation. If you

need more support, please do not hesitate to contact us.

Our dedicated engineers are specialists in the eld of valve

interlocks and can directly provide advice and support.

Quick Fix Guide www.netherlocks.com/support

4

How are valve interlocks used?

The main functions of valve interlocks are to:

> Enforce a predened valve operating sequence

- Create a safer working environment

- Save costs and prevent production spill or loss due to

incorrect switchovers

>Guide operators safely through strict work procedures

Some common applications for valve interlocks are:

Pressure Safety

Valves

To guarantee that only one relief

valve can be oine/in maintenance

Pig launching and

receiving

To guarantee the closure door can

only be opened when the vessel is

depressurized, free from toxic

gasses and isolated

Decoking To guarantee safe change over from

cracking to de-coking of the furnace

Inert gas systems To prevent that inlet and outlet of

tank are closed at the same time

Pump startup To guarantee that during startup

suction valve is open

support: +31 (0)172 471 339

5

Flare lines To guarantee that there is always

an open path to the are

Boiler blow-down To prevent that the drain and vent

are opened at the same time

2 out of 3 To guarantee that always two out of

three instruments (i.e. pressure

gauge, level gauge) are online

Chemical dosing To guarantee that the pot is isolated

before lling

Amine absorber To guarantee that the drain can

only be opened when the vessel

is isolated

Basic principles

Valve interlocks are permanently mounted to the valve and

guide the operator through a predened sequence with

unique keys for each step.

Quick Fix Guide www.netherlocks.com/support

6

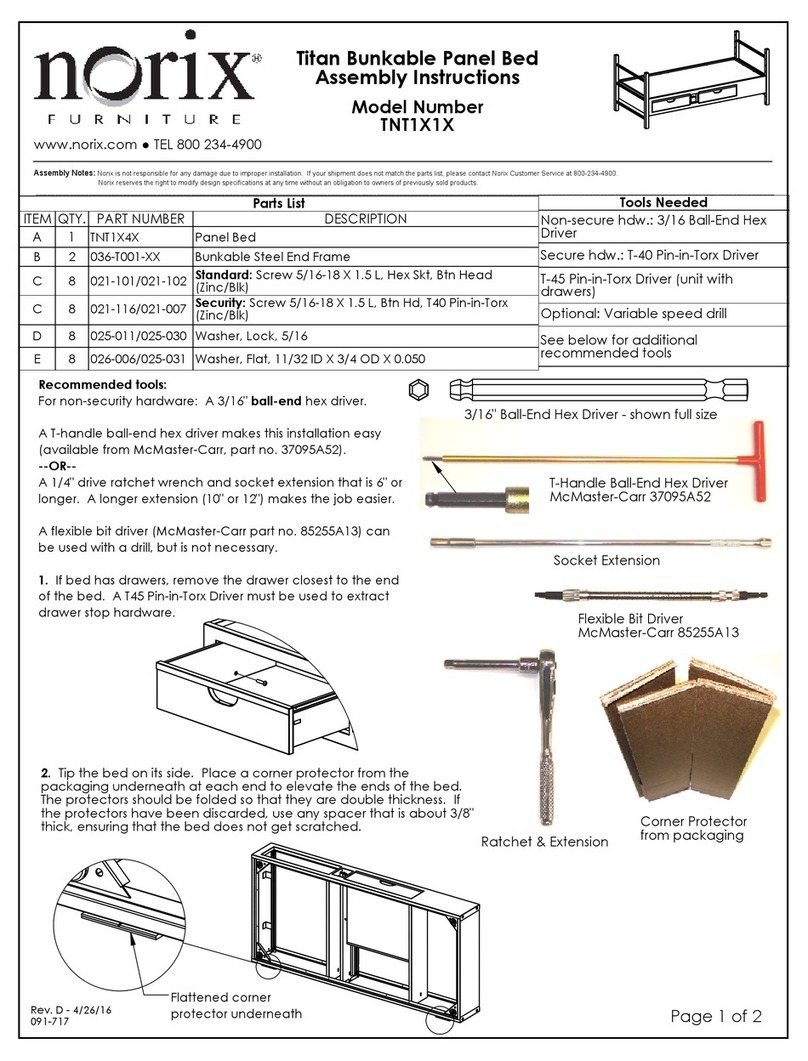

Lock A Lock BKey cabinet Situation

Basic principles of valve interlocking

Green start

key from key

cabinet to

lock A

Yellow switch

key from

lock A to lock B

Red end key

from lock B to

key cabinet

Operable Locked closed

Operable

Locked open

Locked open Locked open

support: +31 (0)172 471 339

7

1

1

Basic principles

Key code on lock

Key code on key

Position for open key

Position for close key

>Green start key is inside the key cabinet in its

dedicated position (green = normal operation)

> Yellow keys in locks in the eld are trapped and

designated to stay in the eld

> A key only ts in lock with the same key code

>Insert key to unlock, operate and after operating

remove the other key

>After last valve operation, insert end key into

dedicated position in the key cabinet.

Quick Fix Guide www.netherlocks.com/support

8

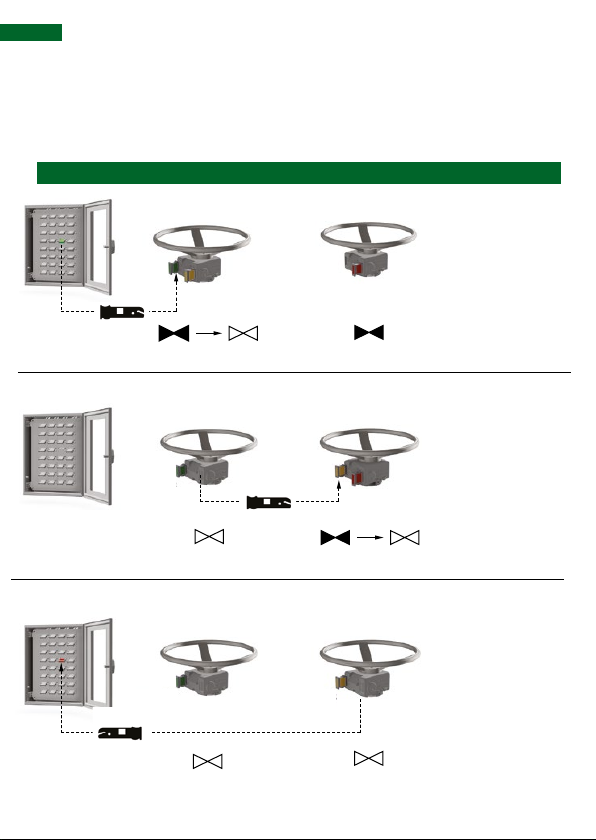

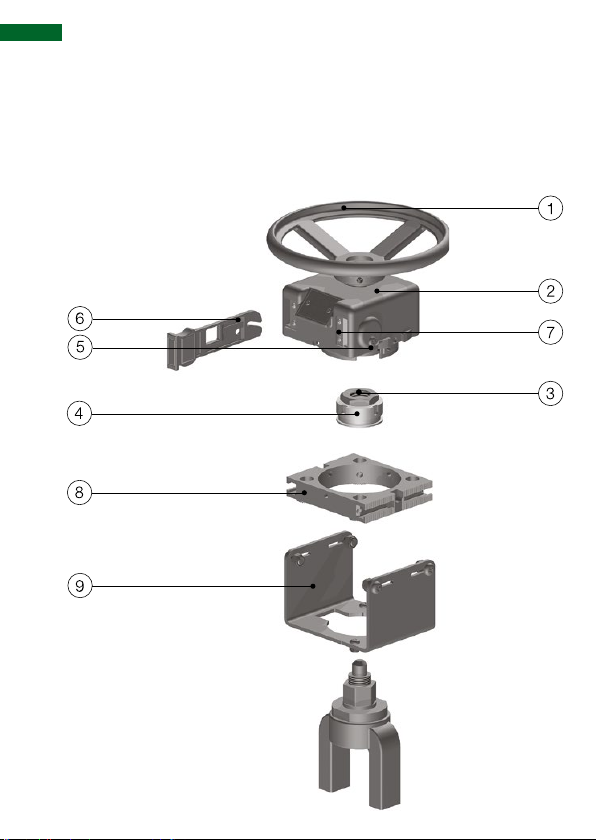

NDL exploded view

Valve interlock components

support: +31 (0)172 471 339

9

Ninety degree lock, for all types of lever operated valves.

Legend

1. AISI 431 sliding lever for optimum exibility

2. AISI 316 body

3. AISI 316 Adaptor - purpose machined - with 4 keyways

4. Linear key for operator friendly use

5. Key slots protected with self sealing weather strips

6. Mounting plate to connect bracket to interlock

7. AISI 316 bracket - purpose machined

8. Fixing means

Basic principles

Quick Fix Guide www.netherlocks.com/support

10

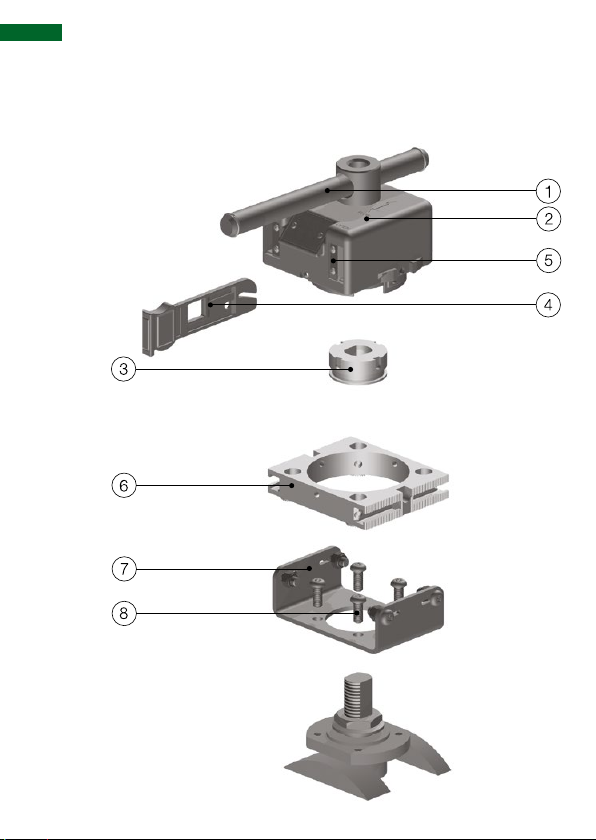

NDL GA drawing

Valve interlock components

support: +31 (0)172 471 339

11

Legend

1. Lever

2. Tube NDL

3. Lock body NDL

4. Operating key

Dimensions

Length (mm) 133

Width (mm) 115

Height (mm) 107

Mass of lock (kg)* 2,9

Lever sizes (mm) Dierent lever sizes from 230 to

730

* Without bracket- and adaptor

Quick Fix Guide www.netherlocks.com/support

12

Valve interlock components

MRL exploded view

support: +31 (0)172 471 339

13

Multi rotation lock, for all types of handwheel and gear

operated valves.

Legend

1. CS powder coated hand wheel / optional AISI 316

2. AISI 316 body

3. Original nut will be used if possible

4. AISI 316 Adaptor - purpose machined - with 4 keyways

5. Easy to set and reset counters behind counter cover plate

6. Linear key

7. Key slots protected with self sealing weather strips

8. Mounting plate to connect bracket to interlock

9. AISI 316 bracket - purpose machined

Basic principles

Quick Fix Guide www.netherlocks.com/support

14

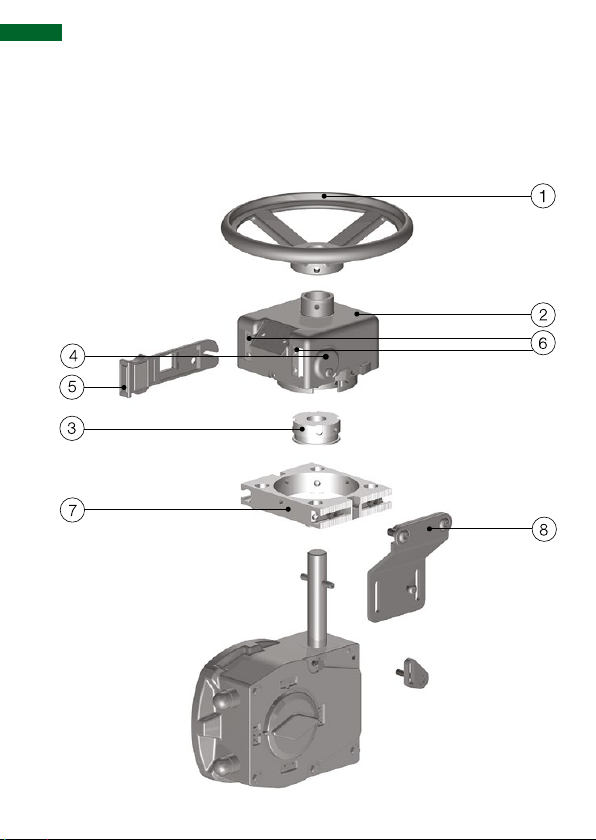

MRL on gearbox exploded view

Valve interlock components

support: +31 (0)172 471 339

15

Legend

1. CS powder coated hand wheel

2. AISI 316 body

3. AISI 316 adaptor - purpose machined - with 4 keyways

4. Easy to set and reset counters behind counter cover plate

5. Linear key

6. Key slots protected with self sealing weather strips

7. Mounting plate to connect bracket to interlock

8. AISI 316 purpose machined bracket

Basic principles

Quick Fix Guide www.netherlocks.com/support

16

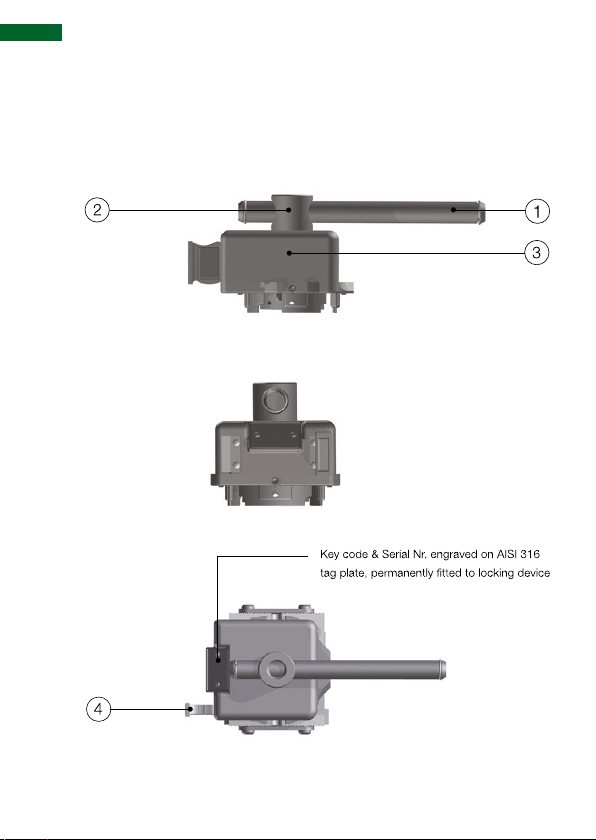

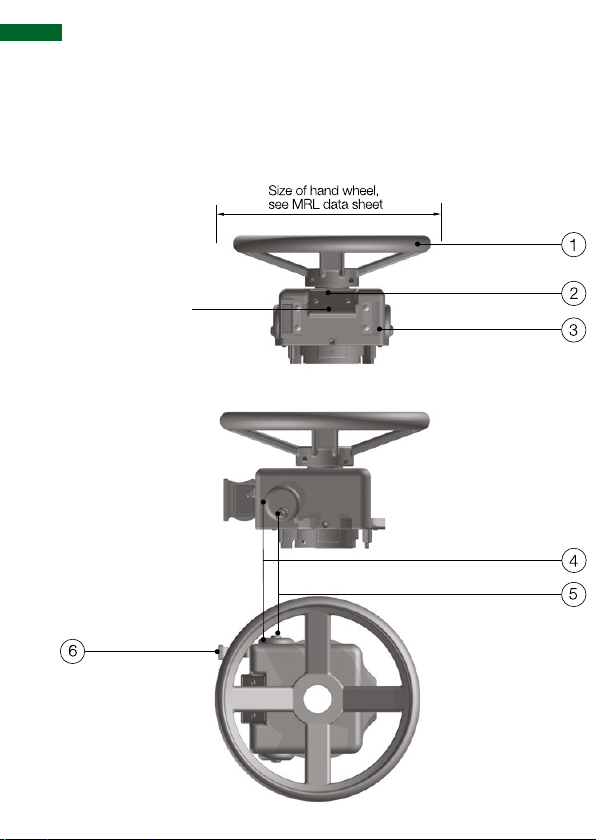

MRL GA drawing

Valve interlock components

Key code & serial

number engraved

on AISI 316 tag

plate, permanently

tted to locking

device

support: +31 (0)172 471 339

17

Legend

1. Handwheel

2. Tube

3. Lock body

4. Adjustment cover

5. Tamper proof M6 screw

6. Operating key

Basic principles

Dimensions MRL-S (small type)

Length (mm) 133

Width (mm) 115

Height (mm) 82

Mass of lock (kg)* 3

Handwheel sizes Dierent sizes between 200 and 700

Max. valve spindle diameter (mm) 26

* Without bracket, adaptor and hand wheel

Dimensions MRL-L (Large type)

Length (mm) 152

Width (mm) 144

Height (mm) 100

Mass of lock (kg)* 4.7

Handwheel sizes Dierent sizes between 380 and 700

Max. valve spindle diameter (mm) 68

* Without bracket, adaptor and hand wheel

Quick Fix Guide www.netherlocks.com/support

18

1. Key code open key

2. Key code close key

3. System tag number

4. Serial number (netherlocks-year.serialnumber)

Interlock tag plates

Table of contents