NetWave NW6000-7001 User manual

NW6000-7001 QIG

-1- -2- -3-

1. Overview

NW6000-7001 DNV GL Managed Industrial Ethernet Switch is

designed for harsh environments to withstand vibration, shock,

free fall and power surges. The switch provides layer 2+ software

features required in marine systems and is DNV GL certied. It

includes 8-port 10/100Mbps RJ45 downlink, 2-port GbE SFP uplink

and supports Modbus TCP communication.

2. Package Checklist

Panel view

4. Grounding the switch

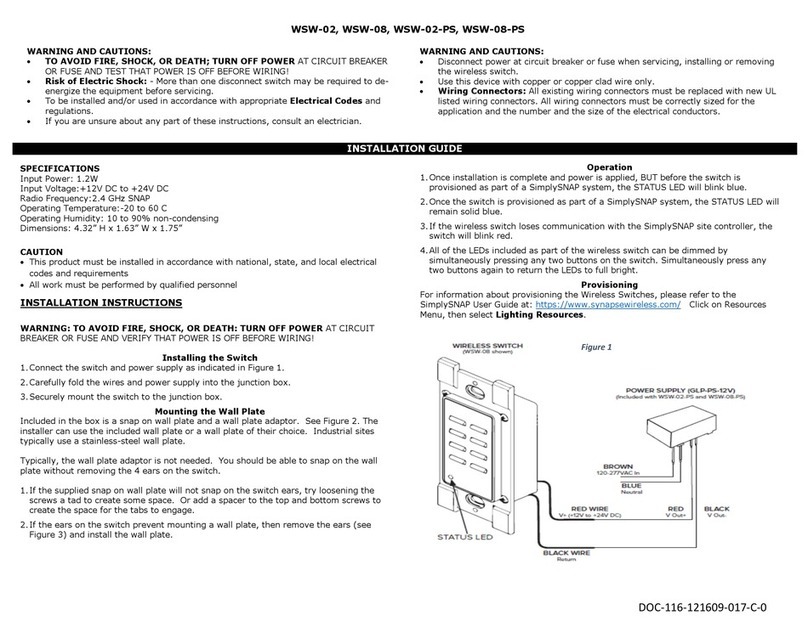

5.1 Wiring Power Input

5.1.1 The Switch with terminal block

You can use “PWR” for Primary Power input and “RPS” for Redundant

Power Input. Check the polarity while connecting.

Top view of Terminal Block is shown in the gure below:

Grounding and wire routing help limit the eects of noise due to

electromagnetic interference (EMI). Run the ground connection from

the ground screw to the grounding surface prior to connecting

devices.

!ATTENTION:

A corrosion-free mounting rail is advisable. When installing,

make sure to allow for enough space between devices to

properly install the cabling. And provide ample space for

air ow.

3. Mounting and Dismounting to DIN-Rail

!ATTENTION:

The Switch is an open type device and shall be DIN-Rail

mounted or wall mounted (optional) in cabinet or enclosure

and the ambient temperature should not exceed 70°C (75°C

is not certied by UL).

!ATTENTION:

This product is intended to be mounted to a well-grounded

mounting surface such as a metal panel.

!

Terminal Block

Caution:

• Use copper conductors only

• Wiring cable temperature should

support at least 105°C

• Tighten the wire to a torque value 5lb

• The wire gauge for the terminal block

should range between 12~24 AWG

To insert power wire and connect the specied voltage range at a

maximum of 1.5A DC power to the power terminal block, follow the

steps below:

1. Use a at-head screwdriver to loosen the wire-clamp screws

2. Insert the negative/positive DC wires into the PWR-/PWR+

terminals, respectively

3. Tighten the wire-clamp screws to prevent the wires from loosening.

!ATTENTION:

Please use a power supply from 12~60VDC, the device

power shall be supplied by SELV circuit.

!WARNING:

Safety measures should be taken before connecting the

power cable. Turn o the power before connecting

modules or wires. The correct power supply voltage is

listed on the product label. Check the voltage of your

Please read and follow these guidelines:

• Use separate paths to route wiring for power and devices. If

power wiring and device wiring paths must cross make sure the

wires are perpendicular at the intersection point.

NOTE: Do not run signal or communications wiring and power

wiring through the same wire conduit. To avoid interference,

wires with dierent signal characteristics should be routed

separately.

• You can use the type of signal transmitted through a wire to

determine which wires should be kept separate. The rule of

thumb is that wiring that shares similar electrical characteristics

can be bundled together

• You should separate input wiring from output wiring

• We advise that you label the wiring to all devices in the system

Mounting the switch

Place the switch on the DIN-Rail from above using the slot, push the

front of the switch toward the mounting surface until it snaps into

place with a click sound.

5. Wiring requirements

Dismounting the switch

Press the switch from top and pull out the lower edge of the switch

and then remove the switch from the DIN-Rail.

The switch is shipped with the following items*.

If any of these are missing or damaged, please contact your customer

service representative for assistance.

• The Switch x 1

• DIN-Rail kit x 1

• Console Cable x 1

• Quick Installation Guide x 1

power source to make sure that you are using the correct

voltage. DO NOT use a voltage greater than what is

specied on the product label. Calculate the maximum

possible current in each power wire and common wire.

Observe all electrical codes dictating the maximum

current allowable for each wire size. If current exceeds

the maximum rating, the wiring can overheat causing

serious damage to your equipment.

Mounting the Switch

Click

Removing the Switch

Front ViewTop View

DIP Switches

9 10

CONSOLE

1

3

5

7

2

4

6

8

Reset

PWR RPS

ALM

POST

SFP

SFP

100Mbps

(Green)

LNK/ACT

(Green)

LASER ON

SPD

ALM

P9

P10

A

B

1 PWR

RPS

P1

P2

P3

P4

P5

P6

P7

P8

P9

2

3

4

5

6

7

8

9

10

11

12 P10

12~60VDC

+

+

PWR

RPS

ALM

Grounding

Screw

Power Input

Terminal Block

OFF ON

OFF

100M

ON

1000M

A

B

1

2

3

4

5

6

7

8

9

10

11

12

-4- -5- -6- v1.0

M64-0001080-000

Connect one end of an Ethernet cable into the Ethernet port of the

switch and the other end to the attached networking device.

• Ports 1-8 supports 10/100/1000Mbps speed

• Ports 9-12 supports 100FX/Gigabit speed

• All the RJ45 ports on the switch support auto-negotiation and

auto MDI/MDI-X to eliminate the need for crossover cabling.

* Category 5e cable or above should be used.

5.3 Cabling RJ45

Load External

Power

5.2 Wiring the relay contact (ALM)

The switch has one set of relay alarm

output. This relay contact uses two

contacts of the terminal block on the

switch top panel. The two contacts of

the terminal block connector are used

to detect user-congured events. The

two wires attached to the fault

contacts form an open circuit when a

user-congured event is triggered. If a

user-congured event does not occur,

the fault circuit remains closed.

Relay rating: 24V, 1A

6. DIP Switch Setting

Connect through Web Browser:

• Connect your computer to one of the Ethernet ports.

• Use the default IP-address 192.168.100.254 to login to the

switch.

9. Conguration

Default Username

Default Password

admin

netwave

NOTE: For more details on conguration please refer user manual.

8. Environmental limits

-40°C~75°C (-40°F~167°F)

-40°C~85°C (-40°F~185°F)

5 to 95% (non condensing)

Operating Temperature

Storage Temperature

Ambient relative humidity

!ATTENTION:

This device complies with Part 15 of the FCC rules.

Operation is subject to the following conditions:

1. This device may not cause harmful interference.

2. This device must accept any interference received

including interference that may cause undesired operation.

!ATTENTION:

If the equipment is used in a manner not specied by

Netwave, the protection provided by the equipment may

be impaired.

!ATTENTION:

Please leave at least 5cm of space at the left and right of

the unit for ventilation.

ON: Fiber port 1000Mbps support

OFF: Fiber port 100Mbps support

A

B

ON:

Primary power alarm reporting is enabled

OFF:

Primary power alarm reporting is enabled

1PWR

ON: Redundant power alarm reporting is enabled

OFF: Redundant power alarm reporting is disabled

2RPS

ON: Port 9~12 (SFP) link alarm reporting is

enabled per dip

OFF: Port 9~12 (SFP) link alarm reporting is

disabled per dip

3

~

12

P1

~

P10

P9

~

P10

A

B

OFF ON

1

2

ON

1

2

3

4

1

2

3

4

ON DIP

1

2

3

4

5

6

7

8

ON DIP

1

2

3

4

9

10

11

12

ON DIP

7. LED Indicators

Illuminated

O

PWR

(Green)

Primary power on

Primary power o or failure

Illuminated

O

RPS

(Green)

Redundant power on

Redundant power o or failure

Illuminated

O

ALM

(Red)

Alarm triggered for abnormal power status

and anomalous features.

Normal operation or DIP switch OFF

Illuminated

O

OFF LINE

(Red)

(9~10th

Fiber port)

No ber transceiver insertion

Fiber transceiver is ready on port

POST

(Green)

Switch is ready or running

Self-testing the device when power on

Switch is not ready

Illuminated

Blinking

O

SFP

(Green)

(9~10th

Fiber port)

Port link-up

Activity (receiving or transmitting data)

Port disconnected or link failed

Illuminated

Blinking

O

Illuminated

O

LASER ON

(Yellow)

Fiber transceiver is plugged into port 9 or 10

Both ber transceivers are not ready on

port 9 & 10

100

(Green)

(1~8th

RJ45 port)

Illuminated

O

Link speed at 100Mbps

Link speed at 10Mbps

LNK/ACT

(Green)

(1~8th

RJ45 port)

Port link-up

Activity (receiving or transmitting data)

Port disconnected or link failed

Illuminated

Blinking

O

Netwave Systems BV

Blauw-roodlaan 100, 2718 SJ Zoetermeer, The Netherlands.

+31 (0)6 215 021 67 (24/7)

Popular Switch manuals by other brands

Cabletron Systems

Cabletron Systems 9E423-36 owner's manual

MACOM

MACOM MADR-011022 manual

Brocade Communications Systems

Brocade Communications Systems 7840 quick start guide

Buffalo

Buffalo BS-GS20 Series user manual

FORTEC Elektronik AG

FORTEC Elektronik AG Epsilon-8100 user manual

Ametek

Ametek RFB 6000A user manual