Neutec Studio Plus Series Service manual

MAN00080-01-EN

IMPORTANT:

Please read this handbook before using

the Neutec/USA® Studio™ Plus

Laser Welder

MIDI00SP

This device has been designed in compliance with IEC EN 61010-1 and IEC EN 60825-1 safety standards to prevent injury to the

operator if used correctly and properly. However, no engineering design can make this device safe if it is not used and maintained

properly and in compliance with safety standards. This manual should be read carefully and in its entirety before performing any

operation. Failure to follow instructions and safety standards may cause injury to the operator and the device.

MAN00080-01-EN

Contents

General I nfo rmati on ......................................................................................................................................................................................4

Identification.........................................................................................................................................................................................................................................................................................4

Safety information ........................................................................................................................................................................................5

General safety rules..........................................................................................................................................................................................................................................................................5

Safeguards.............................................................................................................................................................................................................................................................................................6

Interlock...........................................................................................................................................................................................................................................................................................6

Leather cur tains ..........................................................................................................................................................................................................................................................................6

Resonator shutter......................................................................................................................................................................................................................................................................6

Infrared microscope filter......................................................................................................................................................................................................................................................7

Infrared welding c hambe r filter.........................................................................................................................................................................................................................................7

Emergency button.....................................................................................................................................................................................................................................................................7

Enabling ke y /PI N........................................................................................................................................................................................................................................................................7

Danger zones and residual risks...............................................................................................................................................................................................................................................7

General r u le s.................................................................................................................................................................................................................................................................................7

Before every u se of the de v ice ..........................................................................................................................................................................................................................................7

Transport precautions.............................................................................................................................................................................................................................................................8

Precautions for packaging material.................................................................................................................................................................................................................................8

Installation ................................................................................................................................................................................................. 10

Transport..............................................................................................................................................................................................................................................................................................10

Unpacking............................................................................................................................................................................................................................................................................................10

Positioning...........................................................................................................................................................................................................................................................................................10

Preliminary checks...........................................................................................................................................................................................................................................................................10

D e vi ce specifications...................................................................................................................................................................................11

Technical specifications.................................................................................................................................................................................................................................................................11

Electrical connections....................................................................................................................................................................................................................................................................12

Power supply tolerances......................................................................................................................................................................................................................................................12

D e vi ce specifications...................................................................................................................................................................................12

Technical specifications................................................................................................................................................................................................................................................................12

Applicable standards and directives:............................................................................................................................................................................................................................12

Intended use.......................................................................................................................................................................................................................................................................................12

I m pr ope r use......................................................................................................................................................................................................................................................................................13

Labels and safeguards:.................................................................................................................................................................................................................................................................13

Op e r at o r inte rface ......................................................................................................................................................................................14

Controls and indicators................................................................................................................................................................................................................................................................14

Back connection...............................................................................................................................................................................................................................................................................14

Inside welding chambe r...............................................................................................................................................................................................................................................................15

Use............................................................................................................................................................................................................ 15

Recommendations..........................................................................................................................................................................................................................................................................15

Positioning and e r g onom ic s......................................................................................................................................................................................................................................................15

Microscope eyepieces...........................................................................................................................................................................................................................................................15

Turning on the de vic e...................................................................................................................................................................................................................................................................16

Emergency Stop...............................................................................................................................................................................................................................................................................16

E x am ple of practical u se ..............................................................................................................................................................................................................................................................16

PIN me nu......................................................................................................................................................................................................................................................................................16

USE OF THE ROTARY............................................................................................................................................................................................................................................................16

Operator’s Handbook

Capitolo:

3

MANUAL PRIMING OF THE PUMP................................................................................................................................................................................................................................17

Accessory functions........................................................................................................................................................................................................................................................................17

Use of the air dispenser/shielding gas.........................................................................................................................................................................................................................17

Regular inspections.........................................................................................................................................................................................................................................................................18

Checking the coolants...........................................................................................................................................................................................................................................................18

Checking the filters.................................................................................................................................................................................................................................................................18

Checking the p r o te c t iv e glass slide ...............................................................................................................................................................................................................................18

Routine Maintenance.....................................................................................................................................................................................................................................................................18

Removal of the liquid............................................................................................................................................................................................................................................................18

Filling/refilling the liquid.......................................................................................................................................................................................................................................................19

Cleaning the filters..................................................................................................................................................................................................................................................................19

Replacing the protective glass slide..............................................................................................................................................................................................................................19

Checking alignment................................................................................................................................................................................................................................................................19

Correcting the alignment...................................................................................................................................................................................................................................................20

Repairs...................................................................................................................................................................................................................................................................................................20

Recommendations.........................................................................................................................................................................................................................................................................20

D i agno st ic s................................................................................................................................................................................................. 21

Errors and Warnings......................................................................................................................................................................................................................................................................21

Warnings.......................................................................................................................................................................................................................................................................................21

Operator’s Handbook

Capitolo: General Information

4

General I nformation

T h is manual is intended for: Transporters - Installers - Users - Maintenance and Disposal personnel

Please read this manual carefully and in its entirety, as it contains important information relating to the safe and efficient operation of the device.

This manual is an integral part of the product and is included only for the device to which it relates.

This manual should be stored securely for the entire useful life of the device so that it may be referred to as needed.In the event a used device is

sold, it must be sold together with the manual and any appendices. The manufacturer assumes no liability for direct or indirect damages to

persons, property or animals caused by use of the device in conditions other than those set out in this manual. The manufacturer reserves the

right to make changes without notice to this documentary material or to the device to which it refers.

Safety pictograms:

Dan ger

indicates a condition or situation that may

c au se death or serious injury

.

Warning

indicates a condition or situation that may

c au se mod e rate injuries

.

N ote

indicates

additional information, explanations or hints.

Identification

Manufactured in Italy for:

Neutec/USA® Phone:505.839.3550

7500 Bluewater Road NW Fax: 505.839.3525

Albuquerque, NM 87121

USA e-mail: neutecusa@neutec.com

Device:

MIDI00SP STUDIO PLUS 25,UNIV MINI L-WELDEQUIP.

The identification plate on the device displays its electrical characteristics and complete identification information.

Operator’s Handbook

Capitolo: Safety information

5

Safety information

General safety rules

Touching live electrical parts can cause fatal damage or serious burns.

Improper installation or improper grounding of this appliance can be dangerous. Do not touch live electrical parts. R e mo ve the

power plug from the mains before installing or making repairs to the machine. Properly install and earth this device per the instruction

manual and in accordance with local standards and regulations. Always turn off the machine after use. Do not use weak or damaged

cables, or cables of insufficient diameter or that are poorly connected. Make sure that cables are not near heat sources. Use the

device only if in perfectcondition. Repair or replace damaged parts immediately.

Never open covers, or attempt to repair or modify the device.

These ac ti ons m ay lead to electric shock andfire. Do not attempt to perform work on the d ev ic e except as described in the maintenance section.

Always keep all covers tight andin their proper location.

Do not look at or touch the laser beam.

Class 4 laser product: uncontrolled reflections of the laser beam may result in burning or, in the worst cases, irreparable damage to

the eyes.

•Never use mirrors or reflective objects while the device is in operation

•Objects inside the welding chamber should be viewed exclusively through the viewing window located on the front of the

device or through the microscope.

•Accidental eye exposure to laser radiation can cause cataracts and, in the worst cases, burning of the retina.

•Do not remove the hand curtains for any reason.

•Persons of small stature should not be near the hand curtains when the device is in use.

Operators are advised to protect hands by wearing appropriate UV protection gloves.

Wear provided safety glasses.

When the welding chamber is open or the bottom of the chamber is removed,the safety glasses MUST be worn, in order to prevent

damage to the retina. Safety glasses must have an OD 7 optical density and an L9 protection levelfor pulsed lasers with a wavelength

of 1064 nm, in compliance with the relevantEN 207 standard.

Laser welding can be dangerous.

Protect yourself and others from possible serious injury or death. Keep children away. Keep persons wearing pacemakers away,

unless they are provided with specific medical consent. Welding, as with most work, involves risks. Welding is safe if pr oper

precautions are taken. The welding risk is limited to manipulation of objects within the welding chamber. The process is safe; in any

case, it is important that the device be operated only by authorized personnel. INSTALLATION, MAINTENANCE AND RE PAIR

SHOULD ONLY BE PERFORMED BY HIGHLY QUALIFIEDPERSONNEL.

Do not touch objects during or immediately after welding.

Recently welded objects can be hot

Stop operations immediately if an unforeseen problem arises.

Stop the device immediately in the eventa problem involving a burning smell, abnormal noise, abnormally hot parts, smoke, etc.

occurs. There is a risk of electric shock or fire. Contact NEUTEC USA immediately.

Welding processes produce fumes and gas. Breathing these can be hazardous to your h ealth.

Keep your head out of the fumes. Do not breathe fumes. Do not cover the vents on the device. Carefully read the instructions

concerning the various types of metals, detergents and shielding gas. The device should optimally be installed in a large, specially

dedicated room. If the room is small, please ensure that it is sufficiently ventilated. The shielding gas used for melting can gradually

saturate the air causing discomfort or death. Do not weld near areas used for degreasing, cleaning, or spraying. Heat may react with

vapors, producing toxic and irritating gases. Ensure that the metals are free from impurities that may cause fumes or gases d u r ing

melting. Provide for the use of an auxiliary intake system or, alternatively, the use of a face mask.

Laser welding can cause fire or explosion.

Sparks and weld splashes can cause fire or burns. Never place gas or flammable liquids in the welding chamber. Bottles and o bj e c ts

containing gas or highly flammable liquids should be moved a safe distance away from the welding chamber. Keep a fire

extinguisher nearby in case of fire.

Operator’s Handbook

Capitolo: Safety information

6

Do not use water to clean the device.

Do not use water near the device when it is in operation. Do not place liquid containers above the device.Do not place the d e vice

in a moist environment (acceptable relative humidity is between 30% to 80%)or near sources which produce heat or moisture.

Protective clothing should be worn.

Wear protective clothing such as gloves, long-sleeved jackets, leather aprons, etc. Sparks and molten metal splashes can cause burns

on the skin.

Do not cover the laser with blankets or fabric materials.

Do not cover the device during operation with blankets or fabric materials, as these may overheat and burn.

Perform regular maintenance.

Refer to the specific chapter in this manual and perform the suggested maintenance. In the eventa problem arises, do not use the

device;consult the manual and call for service.

The manufacturer assumes no liability for direct or indirect damages to persons, property or animals resulting from failure to c o mply

with safety standards and the instructions contained in this manual.

Safeguards

Safeguards include all safety measuresthat employ the use of specific technical means (guards, safety devices) to protect people from dangers

that cannot be reasonably limited by design.

Tampering with the safeguards or any modification of the device may cause risks to users and other exposed persons.

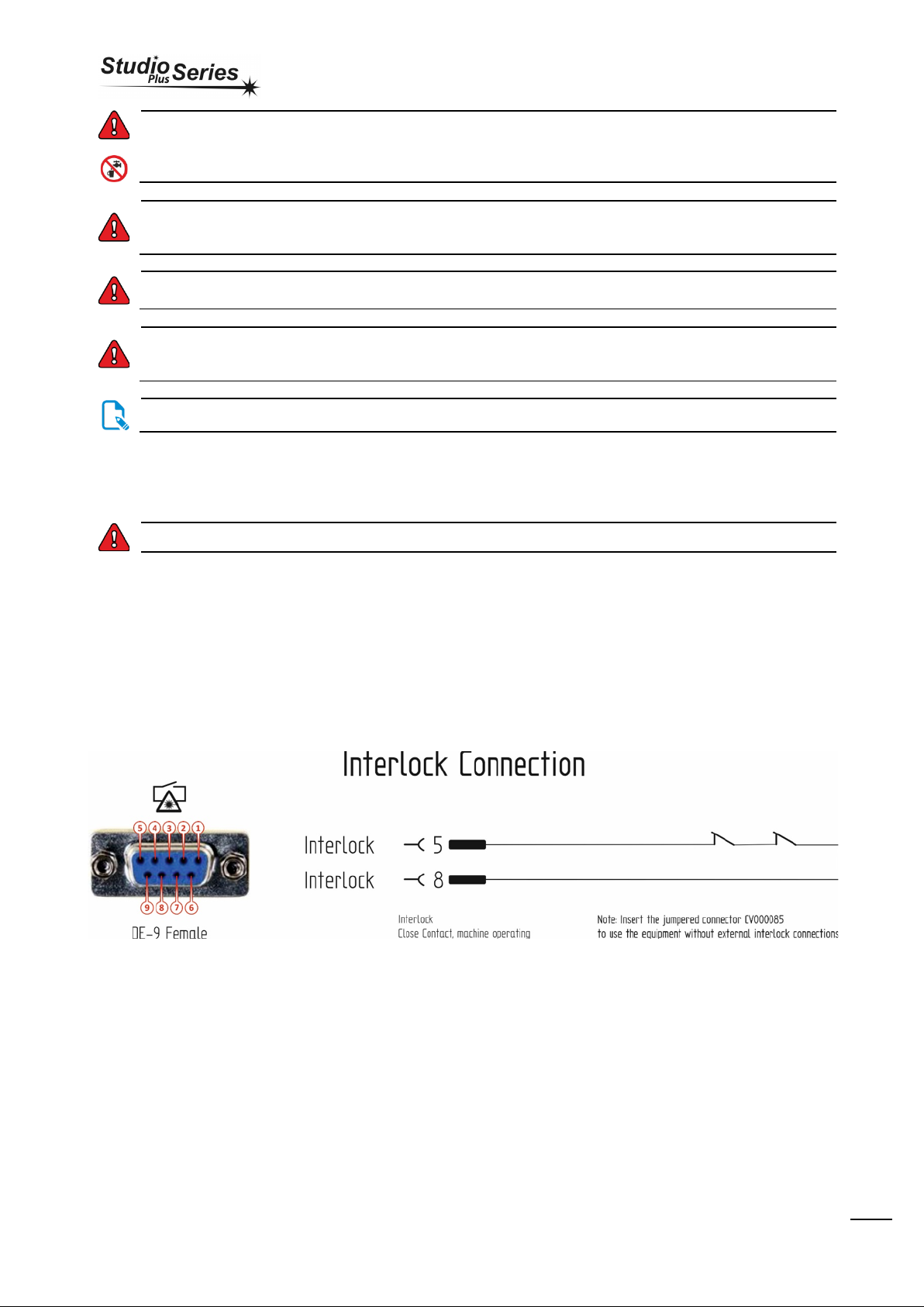

Interlock

Description

The interlock is a normally closed switch that should be placed on the access door(s) to the room where the

device is located. The interlock switch electrical connections are shown in the figure below.

Purpose

The Interlock switch serves to prevent operation of the laser when safety issues arise. This precaution is

mandatory if working with the welding chamber open or when the bottom of the welding chamber is r e m oved.

A blind interlock connector is provided for use on the device with the bottom of the welding chamber i n se rted

and under normal operating conditions.

Operation

When the switch is opened normal device functions are disabled and a warning message is displayed on the

screen until the switch is closed again.

The DB9 male connector, cables and switches are provided only upon request.

Leather curtains

Description

Several layers of leather strips form a movable and permanent barrier at the access openings to the we lding

chamber through which the operator can insert hands and objects to be welded.

Purpose

This safety device is necessary to prevent any potential radiation escaping from the welding chamber, and to

prevent the operator or people close by from exposure to the flashes produced during welding operations, as

well as to preventany leakage of shielding gas in use.

Operation

The leather curtain, which blocks the passage of laser radiation, is easily replaceable in the eventmost the strips

are damaged, bent, broken or cut through usage.

Resonator shutter

Description

This device consits of motor-driven flag located inside the laser resonator system. The shutter cuts off the laser beam

path within the resonator when the welding machine is in stand-by or in the event of an anomaly.

Purpose

The purpose of this device is to prevent the generation of unwanted laser radiation.

Operator’s Handbook

Capitolo: Safety information

7

Operation

The shutter is activated when the power is turned on, before the device is activated.

Upon activation, the shutter clears the laser path, and the device is ready for normal operation. A m ic r o p r o c e ssor

control checks that the shutter is disabled in a timely manner: any anomalies are indicated by a warning on the

display.

When the machine is turned off the shutdown procedure closes the shutter; a check to ensure proper closure is then

performed. Any anomalies will be shown on the display.

The resonator shutter movements are detected by an infrared sensor controlled by the movement of the motor

shaft. Failure of the infrared sensor is detected by the microprocessor, which puts the system on alert, preventing

normal operation of the device and showing the anomaly on the display.

Failure of the motor or its control driver is detected by the microprocessor by checking the ON/OFF movement

times of the flag and showing an appropriate warning message on the display.

Infrared microscope filter

Description

This filter is a 1.064 nm optical glass that is opaque to laser radiation. It appears clear and transparent grey to

our eyes.It is located inside the microscope.

Purpose

The purpose of this filter is to protect the operator's eyesfrom laser radiation leaks along the optical path of the

microscope.

Operation

Opaque at a wavelength of 1.064 nm, it prevents the passage of laser radiation.

Infrared welding chamber filter

Description

This filter is a 1.064 nm optical glass that is opaque to laser radiation. It appears transparent light-green to our

eyesin compliance with EN 207 and EN 208 standards and is classified as OD6 for 800-1090 DIR LB6 protection.

It forms the viewing window of the welding chamber and is replaceable in case of breakage.

Purpose

The purpose of this filter is to protect the operator's eyesfrom laser radiation during normal operation of the

device and permit inspection of objects in complete safety.

Operation

Opaque at a wavelength of 1.064 nm, it prevents the passage of laser radiation.

Emergency button

Description

The emergency button is a red, mushroom-shaped switch positioned on the device for easy access by the user.

Purpose

The button immediately stops the device,and is for use in the eventof danger to the operator or the device.

Operation

The button cuts power to all electrical parts/electronic equipment instantly.

Enabling key/PIN

Description

An enabling switch operated by key or, alternatively, by an electronic PIN.

Purpose

It prevents operation of the device by unauthorized personnel.

Operation

Once the key is turned, or the PIN is entered, the device starts charging the internal circuitry and enabling laser

emission.

Danger zones and residual risks

A danger zone is defined as any area within or near the device in which a person is exposed to risk of injury or damage to health. Residual risks

for the operator exist during some device operation procedures. These risks can be eliminated by following basic work and behavior rules or,

more specifically, the procedures in this manual, and by using personal protective equipment if indicated.

This device should be installed solely and exclusively by personnel trained in its handling and who have completely read the saf e ty

instructions in this manual.

General rules

Before beginning regular use of the device, it is recommended checking to ensure that it is in suitable working conditionand that

there are no defective or worn parts. Perform any necessarymaintenance o p e ra ti ons .

•Pay attention to the danger of electric shock from both direct and indirect contact caused by unexpected failures of the electrical

system.

•Do not subject the device to severe impacts.

•Do not expose the device to fire, weld splashes, or extreme temperatures.

•Do not allow the device to meetcorrosive substances.

•Do not wash the device with water jets.

Before every use of the device

For proper use of the device,keep in mind the following guidelines:

•Never insert objects into the slots on the device.

•Always stop the machine by using the red button on the display after each work session, and turn off the main switch only after the

machine has shut down.

•Perform the maintenance operations indicated in the maintenance section.

•If the laser output nozzle is dirty, clean it with a dry or slightly damp cloth. If it is very dirty, use a mild detergentsuch as alcohol. N e ver

use thinner, gasoline, etc., as these may discolor or otherwise damage plastic parts. If the protective glass is damaged or overly saturated

with metal, replace it with a new one.

Operator’s Handbook

Capitolo: Safety information

8

•Use fingers delicately on the buttons and touch-screen.The use of metal or plastic points can damage the device.Press buttons one

at a time; if multiple buttons are pressed simultaneously, the device may not respond properly or may even get damaged.

Transport precautions

•Make sure that the equipment is properly supported at the lifting point when moving.

•Do not stand directly in the path of applied force and do not place personnel where loads are not adequately supported by

mechanical means.

Risk or Danger

PPE available

Crushing of the hands or limbs

Work gloves, protective overalls

Abrasion, cuts

Protective eyewear

Eye damage due to projected material

Precautions for packaging material

Keep the original packaging for future use.

•Always pack the device during transport and/or movement.

•The packaging consists of a cardboard box, a bottom and top layer of cell or expanded foam.

•Inspect the packaging when the device is delivered. In the event,any anomaly is found, the customer should "conditionally accept" the

delivery and provide an explanation.

•The customer should be careful when using box cutters or other cutting tools when opening the package.

Operator’s Handbook

Capitolo: Safety information

9

Package content

The package contains the following items:

Plastic cone for Argon output LE100100

3

PZ

Stainless steel sheet kit test 710140 ”NEUTEC” LVBEA002 1 PZ

Protective glass BK7 AR @ 1064 nm D.40 2 mm ATE00043 1 PZ

Hex keys LTS 2,5 - 3,0 GAL01000 e GAL01001 1+1 PZ

Microscope oculars LEI00050 1 PZ

Bidistilled water (avaiable only if the shipping period is in winter time) FIR03002 2 LT

Syringe for liquid refill C/Cat 50x50 LXA10004 1 PZ

RL 3/8 – 4 FOX adapter for air/argon MWW00240 e MWW00241

+ MWW00707

1 +1 PZ +

15 cm

USB Pendrive OME00337 1 PZ

Rilsan blue tube Ø 8x6 MWW00710 4 mt

Power cord LE000008 1 PZ

Footswich pedal RIC0056M 1 PZ

Protective ring spacer ring and glass holder flange D2109234 – LS000670 1 PZ

Conical flange (usually already mounted in the machine) D2103650 1 PZ

Interlock key display wiring CV000085 1 PZ

INOX wire Ø 0.3mm LXA10002 30 cm

Operator’s Handbook

Capitolo:

Installation

10

Installation

Transport

The information in this section must be followed when the machine is in one of the transport phases below:

•Equipment storage;

•Initial installation;

•Relocation;

The machine is normally supplied complete with special packaging that allows for easy transport and handling.

In the eventthe packaging has not been provided, the machine must be moved using a forklift capable of lifting the machine mass (refer to the

plate located on the machine), with the lifting forks positioned under the plate at the base of the device.Secure the machine to the lifting for ks

and ensure that it is perfectly balanced before lifting.

The crates should be moved using the lifting equipment taking the proper precautions and strictly observing the sense of d ir e c t ion

indicated on the packaging. Please take normal and logical precautions to avoid collisions and overturning.

When storing the welding machine in its packaging, do not tilt it, place it in the upright position or turn it upside down. Doing so

may cause the coolant to spill out.

Protect the device and any accessory equipment from the elements. Water and moisture can oxidize some parts of the device,

causing irreversible damage.

Unpacking

After removing the packaging, check to ensure that the machine is complete and that there are no missing or damaged parts. If in doubt DO

NOT USE THE DEVICE, and please contact the manufacturer.

Please keep all packaging materials for future use

Positioning

The device should be positioned in a location and environment suited to the use for which it was designed (laboratory use sheltered fr om the

weather); such positioning should be performed by qualified personnel.

Acceptable temperatures from + 10 °C to + 40 °C

Acceptable relative humidity from 30% to 90%

Maximum height above sea level 2000 m

When positioning the laser welding machine, please take the following recommendations into consideration:

•Position the device on a flat, stable surface that extendsbeyond the base of the machine in all directions. Position the device so that

there is more than 10 cm between the back of the machine and the wall.

•Leave enough space around the welder to permit adequate ventilation.

•Do not position the machine in places subject to rapid changes in temperature and humidity. Keep the device away from direct sunlight,

strong light or heat sources.

•Do not position the welding machine near appliances that produce moisture, dust or heat (sanders, vaporizers, EDMs, ovens etc.).

•Position the device no farther than 1.5 m from an electrical outlet.

Preliminary checks

The device is delivered with liquid inside the cooling circuit. During the winter months, the liquid is not placed inside the machine, rather a rinse is

made with a 20% alcohol solution for the inspection. In this case a container of liquid coolant (deionized water) is placed in the package with an

attached note.

In this case it is necessary to:

•run two rinses in the following manner: fill the tank half full with the supplied liquid (with the machine off), turn the machine on and

the "on" button under the option H2O (Options > H2O), wait one minute and then drain the tank.

•Fill the tank completely with the machine turned off.

Operator’s Handbook

Capitolo: Devi ce specifications

11

Device specifications

Technical specifications

Ch aracteris tic / Model

MIDI00SP

Power supply

1-ph, 115-230 VAC ± 10%,50/60Hz, 16 A

Max. Pulse-power and Duration

2.5 J at 6 mS

Peak Pulse-po we r

2.5 kW

Average Power

25 W

Frequencyof Repetition

0.5 – 3 Hz

Spot Size

0.3 to 1.5 mm

Stereomicroscope

10X at 45° binocular and cross – hair by Leica

Weight

30 Kg

Operator’s Handbook

Capitolo: Devi ce specifications

12

Electrical connections

Make sure that the power outlet is appropriate before connecting the power cable. Checkthe information on the plate located on the back of the

machine for more information.

Make sure that the electrical outlet of the mains supply has a Schuko socket; the welder absorbs 10A at 230Vac.

Install a general duty safety switch upstream of the device'scable connection with the power grid.

The safety switch should be used in combination with a surge protection device equipped with an emergency shut-off switch (S P D).

The features of these devices should be designed to meet the regulations of the country where the device is being installed, and

sized per the specifications of the device.

Power supply tolerances

•Voltage at ± 10% of the rated voltage.

•Frequency: ± 1% of the rated voltage for continuous use ± 2% of the rated voltage for short periods

•Harmonic distortion for the sum of the second to fifth harmonics no more than 10% of the total voltage RMS between live conductors.

Further distortion is permitted for the sum of the sixth to thirtieth harmonics up to 2% on the total RMS between live conductors.

•The voltage pulses should be no longer than 1.5 ms with a rise/fall time of between 500ms and 500μs and a peak value that does not

exceed 200%of the effective value of the nominal supply voltage.

•The power supply should not be interrupted nor go to zero for longer than 3ms at any moment during power. There should be no

more than 1s between two successive interruptions

•The voltage dips should not exceed 20% of the peak voltage for more than one cycle. There should be no more than 1s between

voltage dips.

Device specifications

Technical specifications

Power supply:

110V–230V

Maximum working cycle (shots/hour):

7200 (±10%)

Frequency:

50/60 Hz

(with m ac hi ne setti ngs at: 1.2kW 1.3m s 2Hz and ambient r oom tem perature: 25°C/77°F)

Phases:

single

Working temperature:

10°C–40°C

Max. input current:

15 Amps

(50°F–104°F)

Max. noise level:

dBA <70 LwA

Storage temperature:

0°C–60°C

Approx. net weight:

88.2 lbs. (40kg)

(32°F–140°F)

Laser class:

Type 4

Humidity:

30%–90%

Cooling system:

Water and forced air

Maximum altitude:

2000m

Microscope:

10X power (Leica)

For indoor use only

Applicable standards and directives:

The device has been constructed in accordance with the provisions of the directive lowvoltage (LVD) 2014/35/CE,directive EMC 2014/30/CE

and the following referencestandards:

EN60825-1 Safety of laser products

Part 1: Product classification and requirements.

EN61326-1 EMC standard for measurement,control and laboratory use.

EN61010-1 Safety requirements for electrical equipment for measurement, control, and laboratory use.

Intended use

Use the device for the welding of specific metal alloys. Only the following alloys may be used:

•Gold

•Silver

•Platinum

•Palladium

•Titanium

•Steel

•Cobalt chrome (CoCr)

The metals and alloys listed above must not contain any of the metals listed in the section "Improper use".

The shielding gas recommended for the welding process is Argon. Use only genuine parts and consumable materials from Neutec USA

For technical assistance, please contact Neutec USA Consumable materials should be replaced after use. Follow all regulations and safety

instructions in this manual.

Operator’s Handbook

Capitolo: Devi ce specifications

13

Improper use

Do not modify the device.Do not weld any metals or alloys that include any of the following materials: Beryllium, Uranium, Plutonium,

Cadmium, Magnesium, Sodium, Mercury,Potassium, Lead, Arsenic.

Do not usetoxic orinflammable gasessuch as: Hydrogen, Oxygen, Fluorine, Chlorine, any form ofhydrocarbon gas, anymixtureof Hydrogenand

Nitrogen.

Do not use Nitrogen when welding. Do not place any flammable materials along the path of the laser beam. Do not use any toxic materials or

materials that emit explosive gas. Do not stare at the laser beam without protective eyewear.

Do not leave clothing of any kind along the laser beam path. Do not place any living or dead organisms in the laser beam. Do not use the laser

welder to heat up food. Do not use the laser welder to dry clothes and materials.

Labels and safeguards:

1. Emergency button, use only in case of emergency.Disconnects the power supply from the

device turning it off instantly when pressed.

2. LASER aperture warning label located near the laser beam output inside the welding

chamber (ETI00129):

LASER APERTURE

This label indicates the laser beam output side

3.

Laser emission characteristics label (ETI00493):

This label provides information about the emission characteristics of the laser beam,

including:

•Energy emitted (E)

•Wavelength (λ)

•Pulse duration (t)

•Average power (P)

It also displays the reference standard for laser product safety.

4. Laser product classification label (ETI00131):

LASER RADIATION AVOID EYE OR SKIN EXPOSURE TO DIRECT OR SCATTERED

RADIATION. CLASS 4 LASER PRODUCT:

This label indicates the dangers that might arise if the laser system is used improperly. In

fact, the energy levelof the laser generator used in this device is Class 4.

1

2

3

4

Operator’s Handbook

Capitolo: Operator interface

14

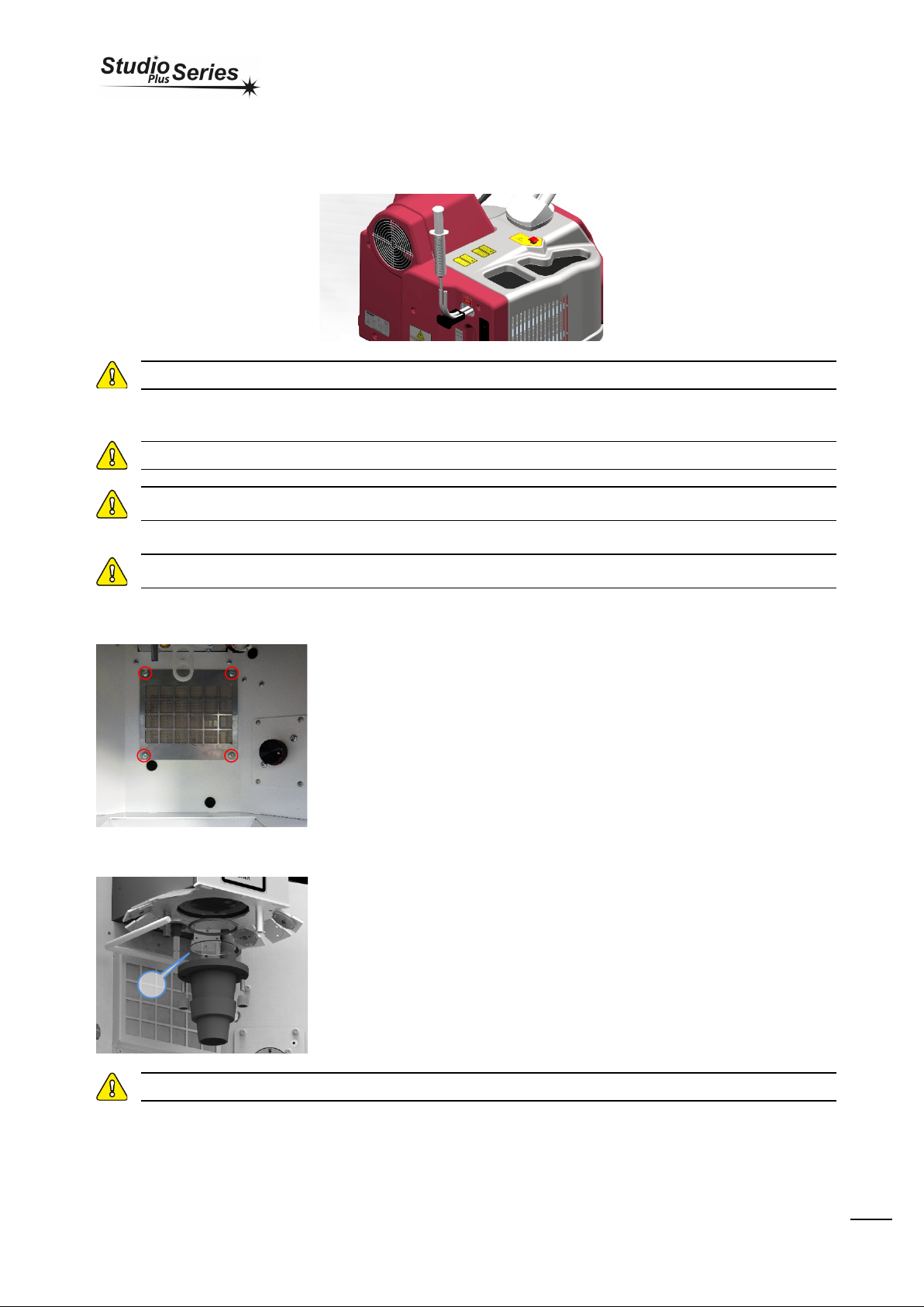

Operator interface

Controls and indicators

1. Stereo-microscope.

2. Inspection window with 1064 nm LASER ray filter.

3. Working chamber access doors.

4. Display with touch-screen for user setup parameters.

5. Emergency switch

6. USB key

7. Back connection (see paragraph)

8. Radiator cooling, do not cover, leave at least 5cm of free

space between the rear side and the wall.

9. Water level, for the proper equipment functioning,the

cooling level must always reach the MAX. Use bi-distilled

water ONLY for refilling/filling up.

10. Opening hosting pipes for filling/empting water tank.

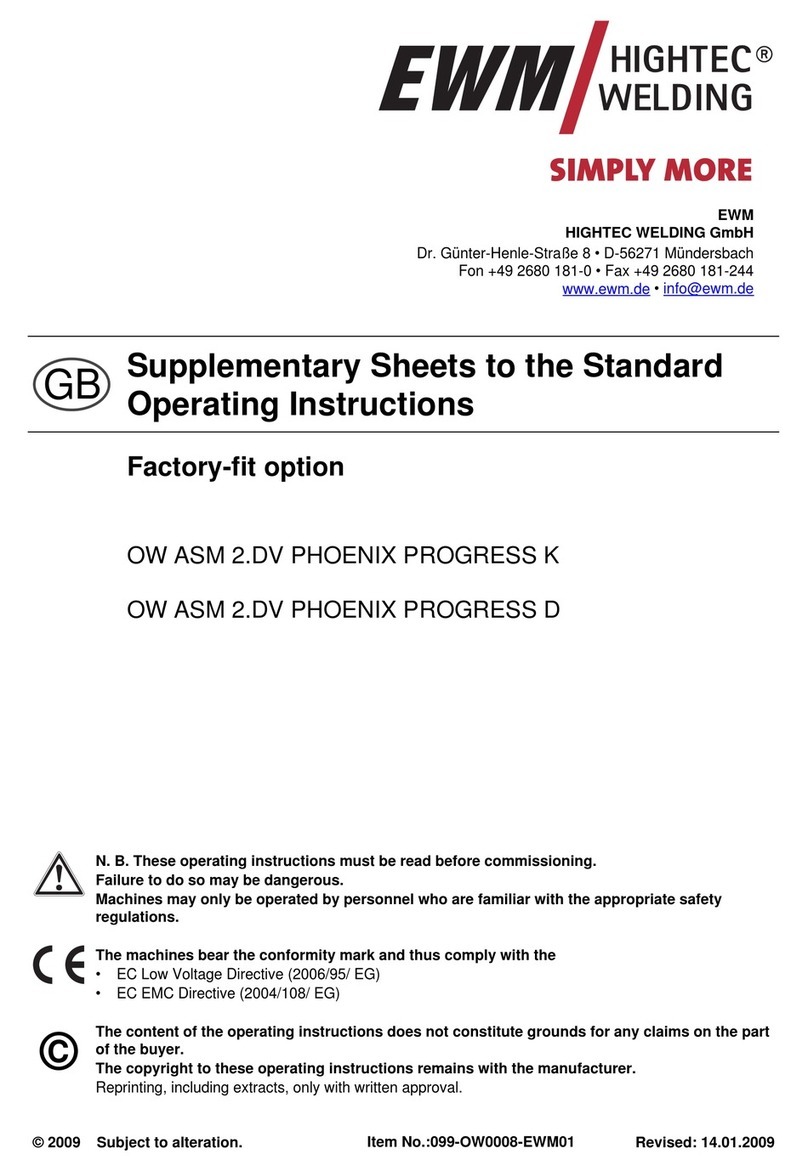

Back connection

1. Resettable fuses

2. Power outlet

3. Main power switch

4. Shielding Gas/Air input

5. Foot switch connector

6. Remote interlock

2

6

4

5

1

3

1

2

3

4

5

6

7

8

9

10

Operator’s Handbook

Capitolo:

Use

15

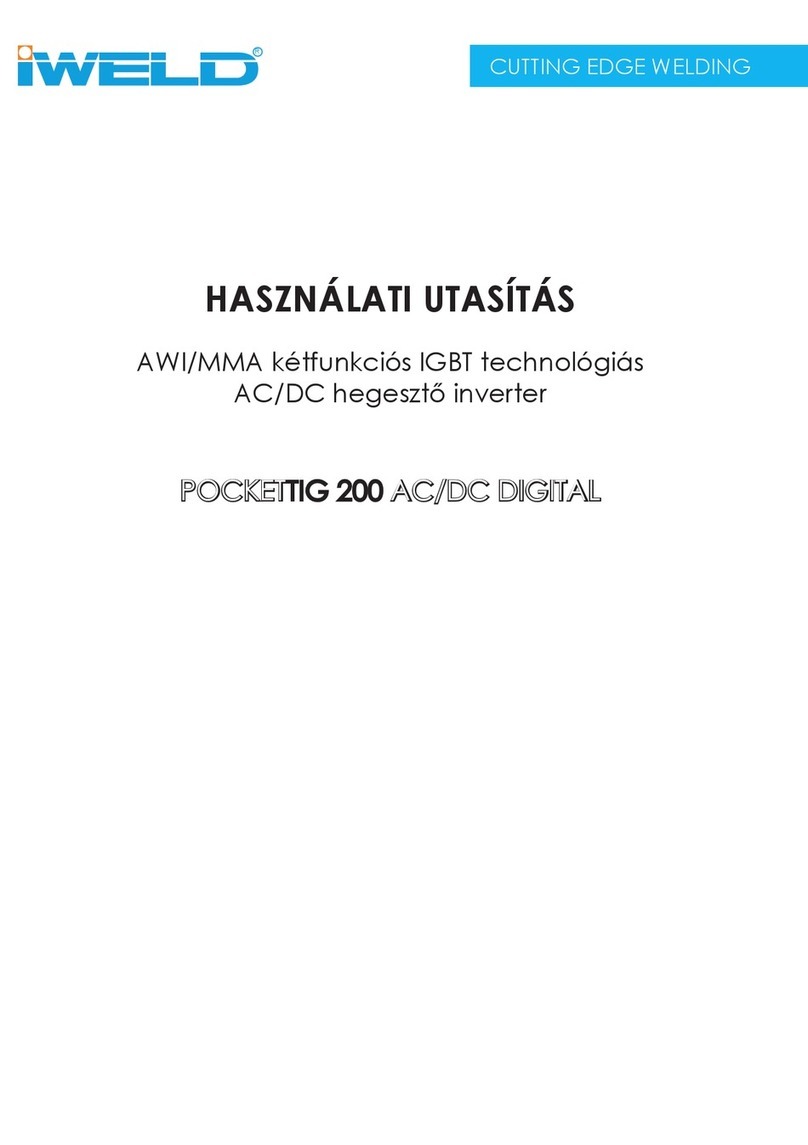

Inside welding chamber

1. LED lamp

2. SPOT diameter regulator

3. Rotary for settings the working parameters

4. Exhaust vapour grid

5. Plastic cone for Argon/Air output

Use

Please read the Safety Informationsection before using the device.

This paragraph explains how to use and the meaning of each menues loaded into the LASER welding unit.

Recommendations

Before beginning re gular use of the device it is recommended checking to ensure that it is in suitable working condition and that there are no

defective or worn parts. Perform any regular maintenance or repairs that may be required.

Positioning and ergonomics

Microscope eyepieces

Remove the caps that protect the stereo microscope, insert the eyepiecesand, once positioned properly in the housing, tighten the fixing screw.

Store the caps and eyepiece wrappers for future use.

One of the eyepieceshas a crosshair for sighting, this is usually positioned on the right tube of the stereo microscope. The diopter

dial may be adjusted: once the eyepiecesare positioned properly, rotate the dial clockwise or counterclockwise depending on the

focus you wish to achieve.Refer to the scale printed on each eyepiece.

1

2

3

1

4

5

Operator’s Handbook

Capitolo:

Use

16

Turning on the device

Move the power switch located on the front of the device to position I. Wait until the display shows the PIN entry screen.

Emergency Stop

The emergency button (see page. 14) is used to immediately switch off the device;This button is equipped with a safety feature,once it is

pressed it must be released to power the unit up again. Use the button only in case of danger or failure.

Example of practical use

This section describes practical use of the device and explains the laser welder menu.

PIN menu

In PIN Menù screen it’s possible to read the follow informations:

-Serial number of the unit

-Firmware revision of the display’s board

-Firmware revision of the microprocessor board

-Laser shots counter

Digit the numeric code “0000” and press “OK” to enter the stand-by

mode.

To make the machine operational, press and hold fo a second the

GREEN-key icon (Pic.1) and wait for it to become RED (Pic.2).

Operators may always interact with working parameters using the

touch-screen display. On the left side of the screen we can selectthe

energy of the impulse (intensity X duration of the impulse). On the

lower side of the display we can change the frequency of the shot in

time(shots per second). The maximum frequency is limited according

to the energy of the selected pulse.

USE OF THE ROTARY

Pressing the rotary switch (Pic.1), changes the val ue of the shot

frequency (l ower part of the di spl ay). I f operator spi n the rotary

instead, the val ue of the power set will be changed (l eft si de of the

display).

Operator’s Handbook

Capitolo:

Use

17

Tochange the spot diameter,the white lever must be slid up and

down. The smallest size of the spot diameter is the slider position

towards the machine. If the slider will be set towards the operator,

the spot diameter will be the biggest.

MANUAL PRIMING OF THE PUMP

In stand-by mode ONLY it’s possible to activate the pump making the water running in the circuit without starting the machine. This

operation is useful when tank is refilled after a full draining or in the first start up of the machine. Release the rotary to stop the pump work.

Press the rotary switch for 3 seconds, triggering the pump that turns

the water in the hydraulic circuit.

Accessory functions

Use of the air dispenser/shielding gas

All devices are equipped with:

1. A pipe jointed to the orientation of the air or protective gas.

2. Metal cone for protective gas coaxial flow.

3. Metal frame holding a protective glass.

If you wish, you can use one system or the other for the supply of shielding gas or air cooling.

The output of the gas / air is controlled by a solenoid valve, which is activated by depressingthe pedal every first frequency shot chain.

The inlet pressure must not exceed 4 bar. Do not connect pressure higher than the maximum allowed as this may damage the solenoid valve.

Example of use of the door slide door with cone:

This configuration is recommended for welding titanium, cobalt

chromium and steels in general.

The recommended pressure for use with protective gas (argon) is

0.1 / 0.2 bar, a soft blow is sufficient for the protection of articles

made of titanium, cobalt chromium and steels in general. Use the

special transparent cone inserted in the cone holder for conveying

the flow at the point of welding, as shown in Figure 1

Example of use of the slide door without dispenser:

This configuration is recommended for welding of objects in Silver

or Gold. It’s also advisable to connect compressed air (up to 4 bar)

to cool the metal during welding prolonged.

1

2

3

Operator’s Handbook

Capitolo:

Use

18

Maintenance

Please read the chapter on Safety Information before proceeding

Every maintenance operation, even minor ones for machine parts and the electrical system, requires the use of professionally

qualified personnel with training on the featuresof the device.

Original spare parts should be used. The use of non-original spare parts releasesthe Manufacturer from any liability.

Regular inspections

Check the integrity of the laser radiation safety glass on the KG3 viewing window and the leather curtains for hand access to the welding

chamber daily; if they need to be replaced, contact the manufacturer. Using the device with broken glass or without the curtains is DANGEROUS

and can cause health damage. Check the status and the integrity of the safety labels and IDplate every six months, contact the manufacturer if

they are discolored or illegible.

Checking the coolants

The equipment is provided of a cooling system working with bi-distilled water. The water shall be replaced at least every 12 months to avoid

having algae or limestone, which along time may deposit in the cooling pipes or in the LASER pool cavity.

Open up the rear pipes seat and pull out the 2 pipe caps. Pour the water (around 2 lts) into a basin.

Checking the filters

Air filter must be checked every month. Refer to ”routine maintenance” chapter for more ifnormation

Checking the protective glass slide

Verify at least once in a month the state of the glass placed inside of the welding chamber.

Routine Maintenance

Removal of the liquid

Pull the small pipe located underneath the LASERbase,remove the cap (see picture);place the basin under the opened pipe andwait the water

tank to be fully emptied (around 2 lts).

Operator’s Handbook

Capitolo:

Use

19

Filling/refilling the liquid

Use the syringe provided as a standard accessory with the equipment. Insert the syringe with double distilled water into one of pipes (any pipe)

and fill up to the level indicated on the panel. The equipment holds roughly 800ml of bi-distilled water. If overfilled the water will drain out from

the other pipe

Before closing the rear panel, verify the presence of the stoppers on the 2 small tubes.

Cleaning the filters

Failure to maintain these filters can impair the device's performance.

Do not cover the vents on the device with cloth or other materials. Leave at least 10 centimeters of space between the v e n ts and

walls or obstacles. Failure to do so may compromise the efficiency of the device.

Do not cover any of the exhausting grids with clothes or other things and leave enough space (at least 10cm) from the rear grid and

the wall..

Cleaning of air filter

Unscrew the 4 screws shown in the photo. Clean up the filter with compressed air.

Replace the filter when it is very dirty;replace with a filter of the same type (Code RIC00041).

Replace regularly this filter because when full of dust and dirt may compromise the proper

functioning of the equipment.

Replacing the protective glass slide

Verify at least once in a month the state of the glass placed inside of the room (see photo).

To remove the door glass, unscrew the 2 screws indicated in the figure. In case the glass is

saturated of metal sprays or damaged, replace it with one new (Code ATE00018). 1 - Check

also the black paper (Code D2139193) cone inside the plastic light diffuser, to get the best

performance of the illumination this paper must be in good condition, replace it when

necessary.

If the glass is very dirt or damaged, the power of the equipment can go down until to 80% regarding the normal performances.

Checking alignment

•Set the following parameters 1.0KW, 1.0mS 0Hz and minimum SPOT size.

•Insert a piece of flat metal and fire a shot.

•Check the location of the spot produced against the crosshair; if the spot intersects the crosshair in the center is not necessary to correct the

alignment.

1

Operator’s Handbook

Capitolo:

Use

20

Correcting the alignment

Take great care to avoid inadvertently activating laser emission when performing realignment operations.

With the device in standby, locate the screws close to the cone

slide holder as shown in the illustration.

Never touch the screw no. 3, the one between the other two

screws without a guide. This screw has been placed there by the

manufacturer. Using the 3 mm hex key, loosen screws 1 and 2.

•Turning screw no. 1 moves the welding point

horizontally.

•Turning screw no. 2 moves the welding point

vertically.

Use slight movements and small shots on a piece of metal to

verify the correct positioning of the crosshairs. Continue until the

crosshairs coincide perfectly with the welding spot.

The screws for the alignment have brass guides to make them

easier to identify.

To facilitate the alignment procedure, the crosshairs bear the symbol ▲, which indicates the highest point. make sure th is

symbol is pointed upwards and complete the alignment as described above.

Only use the viewing window to inspect the inside of the welding chamber, it is a good rule to put the device in standby before

adjusting the screws to preventaccidentally activating the laser.

Repairs

Repairs should only be made in the eventof an anomaly, see the chapter Diagnosticsfor more information.

Repairs should only be performed by Neutec USA personnelor personnel it has authorized.

Recommendations

The following recommendations will optimize the efficiency of the device:

•The device should be stored in a location that is not too hot and away from heat sources; the higherthe temperature of the envir onment,

the lower the efficiency of the cooling circuit/heat exchanger.

•Keep away from equipment that produces moisture or dust, such as sand blasters, vaporizers,etc.

•Follow the directions in the manual, and read the sections on safety and maintenance.

•Use only original spare parts specified in this manual.

•Only use deionized water as a cooling liquid, the use of water or liquids different from that indicated may affect device operation.

•Ensure that safety devices are working properly.

1

2

3

This manual suits for next models

2

Table of contents

Popular Welding System manuals by other brands

Lincoln Electric

Lincoln Electric BURNY KALIBURN Spirit II 275 user manual

Miller

Miller Dynasty 280 owner's manual

Magmaweld

Magmaweld SMART Series user manual

EWM

EWM OW ASM 2.DV PHOENIX PROGRESS K operating instructions

ESAB

ESAB ET 186i AC/DC operating manual

iWeld

iWeld POCKETTIG 200 AC/DC DIGITAL user manual

Lincoln Electric

Lincoln Electric RANGER GXT IM856 Operator's manual

Metal Man

Metal Man M190 Operator's manual

WIELANDER+SCHILL

WIELANDER+SCHILL Inverta Puls IP6-2 ACT Operation manual

stud welding products

stud welding products StudPro 2500 Operation manual

CIGWELD

CIGWELD WeldSkill 120 Turbo Operation manual

ESAB

ESAB ESABMig 325 Service manual