Newasia NA8820 User manual

1

NA8820 User Guide

3Main Function and Technique Index

Main Function:

) Refrigeration Controlling (Refrigeration / heat): temperature display, temperature controlling

(refrigeration/heat mode can be set),compressor start delay protection, temperature sensor error alarm.

)Defrost Controlling: 2 defrost modes (electric heat, hot gas), 2 defrost start mode (time alternation,

accumulative compressor running time), 2 defrost end mode (timing, controlled by both temperature and

time) dripping, manual defrost, defrost sensor error alarm.

)External alarm: one external alarm input, it can be set to 5 modes: always open, always open locked,

always closed, always closed locked or forbidden.

Main Technique Index:

2Temperature display range: -50~150℃(The resolution is 0.1℃)

-58~302℉(The resolution is 0.1℉)

2Power supply: AC 220V±10% or AC 380V±10% 50Hz (Refer to the wiring diagram)

2Operating environment: temperature -10℃~50℃, humidity≤85%.

2Relay contact capability: compressor 20A/250VAC, defrost 8A/250VAC (pure resistive load)

2Temperature sensor: NTC R25=5kΩ, B (25/50) =3470K

2Executive standard: Q/320585 XYK 01 (NA8820-CTDA)

Operating Guide

Panel:

* What’s the meaning of the index lights on the panel?

The function of the LED on the panel is showing below:

Index Light Name Light Flash

Temp Setting In the state of temp setting -

Refrigeration Refrigerating Ready to refrigerate, in the state of compressor start delay

protection

Heat Heating

Ready to heat, in the state of compressor start delay

protection

Defrost Defrosting Dripping or the state of compressor start delay protection

- - -

Alarm - Alarm state

* The meaning of the LED display

The LED usually shows temperature, if it shows “SHr”, it means the temperature sensor is short,

and “OPE” means the temperature sensor is open. The temperature and the alarm code (Axx) will show

alternately when in the alarm state.

The code is showing below:

Code Signification Explanation

A11 External alarm Alarm from external alarm signal, please refer to the internal parameter code “F50”

A21 Temperature sensor error Open or short(showing “OPE” or “SHr”)

A22 Evaporator sensor error Open or short(showing “OPE” or “SHr” when press the key “”). If you don’t

need to use the evaporator sensor, you can use the F59 to close the alarm.

* How to set the temperature?

Press the key “set” for at least 2 seconds, then enter the state of temperature setting, here the LED

displays the setting temperature, then using “” key or “” key can change the parameter(the

2

key“”adds 0.1°C, the key“”minuses 0.1°C, press and hold it over 0.5 seconds can add or minus

rapidly). After setting, press “set” again, then exit the state of parameter setting. (The setting temp range is

limited by the parameters F13 and F14, please refer to the advanced operation). Pressing the key “M” in the

setting process means cancel and exit, but the setting value will not be saved.

*How to defrost manually?

When in the state of displaying current temperature, press the key “” and hold it at least 5 seconds,

then the controller enters the defrosting state. In defrosting state, press the key “” and hold it at least 5

seconds again, this can finish the defrosting forcibly.

*How to read the temperature of the evaporator sensor?

When displaying current temperature, press “” key, Controller will display defrosting temperature.

Loose “” key, then return to current temperature. Notice that if you press the key and hold it for 5

seconds, the controller will enter or exit the defrosting state forcibly.

* How to refrigerate (or heat) forcibly?

When displaying current temperature, the temperature is between “setting temperature-temperature

difference” and “setting temperature+temperature difference”, the system may or not refrigerate, here you

press the key “” and hold it for 5 seconds, the controller will enter the refrigeration state forcibly when in

the refrigeration state, and stop refrigeration when the temperature is below “setting temperature-

temperature difference”; the controller will enter the heat state forcibly when in the heat state, and stop

heating when the temperature is above “setting temperature+temperature difference”.

9 Advanced Operation

Press the key “M” and hold it for 5 seconds, and if you have set the password, the LED display the

“PAS” to hint you to enter the password, you can use the key “” and “” to enter the password, if the

password is correct, the LED will display the parameter code, use “” or “” to select the parameter

code,Pressing the “set” key can make it to show the value of the parameter after select the parameter, here

you use “” or “” to set the parameter(pressing the key and not release can add or minus rapidly), then

press the “set” key to return to the state of showing parameter code after finishing setting. Pressing the key

“M” can exit the parameter setting state when display the parameter code, pressing the key “M” means

cancel when in the process of setting parameter, and the parameter will not be changed.

Internal parameter code is showing below:

Sort Code Parameter Name Range Factory

setting Unit Remark

F11 Setting temperature F14 – F13 0 ℃/℉The setting range is limited by

F13 and F14

F12 Temperature difference 0.1 – 20 1.0 ℃/℉

Control the temperature

difference, please refer to the

temperature controlling

F13 Max setting temperature -58 - 302 302 ℃/℉

F14 Min setting temperature -58 – 302 -58 ℃/℉

Notice: the controller will

follow the rule of

F14<F11<F13 forcibly, if you

find out that one parameter can

not be adjusted, it is because

the parameter is limited by

other parameters, you must

first adjust other parameters

F18 Evaporator sensor adjustment -20 – 20 0.0 ℃/℉Adjust the evaporator sensor

bias

Temperature

F19 Temp sensor adjustment -20 – 20 0.0 ℃/℉Adjust the temperature sensor

bias

F21 Compressor delay time 0 -- 10 3 min

Compressor F29 Compressor controlling mode

(temp controlling mode) COOL / HEAT COOL - COOL: refrigeration mode

HEAT: Heat mode

F31 Defrost alternation time

(Enable when F35=1 and 2) 0.1 – 99.9 12 hour

F32 Defrost end temperature 0.0 – 100 15.0 ℃/℉

F33 Defrost time 1 -- 99 15 min

F34 Dripping time 0 -- 99 5 min

Defrosting

F35 Defrost start mode OFF

1 -- 2 1 -

OFF: defrost is off

1: time alternation start

2:time alternation start, the

alternation is compressor

accumulative running time

3

F36 Defrost stop mode 0 or 1 1 -

0:only controlled by time

1:controlled by both time and

temp

F37 Defrost heat mode 0 or 1 0 - 0: electric heat 1: hot gas

F50 External alarm mode 0 -- 4 0 -

0: without external alarm

1: always open, unlocked

2: always open, locked

3: always closed, unlocked

4: always closed, locked

Alarm

F59 Whether use the evaporator

sensor error alarm YES / NO YES -

F80 Password OFF

0001 -- 9999 OFF -

OFF means no password

0000 means clearing password

System

setting F81 Temperature unit C/F C - C: Centigrade

F: Fahrenheit

F98 Reserved

Testing F99 Test self This function can attract all relays in turn, and please don’t use it

when the controller is running!

End Exit

7 Basic Operating Principle

Temperature controlling

The controller has 2 temperature controlling mode: Refrigeration and Heat(F29).Temperature

controlling point is controlled by “setting temperature (F11, or press the “set” key for some time to set)”

and “temperature difference(F12)”.In refrigeration mode, the controller begins to refrigerate when the

temperature of the temperature sensor is over “setting temperature +temperature difference”, and it stops

refrigerating when the temperature is under “setting temperature -temperature difference”; In heat mode,

the controller begins to heat when the temperature of the temperature sensor is under “setting temperature

-temperature difference”, and it stops heating when the temperature is over “setting temperature +

temperature difference”

Compressor delay time

The compressor delay time is set by F21, for example, 3 minutes. The controller contains a

“compressor halt calculagraph”, and it begins to time when compressor stops, the program first check the

calculagraph before booting the compressor next time, the program will immediately boot the compressor

if the calculagraph reach 3 minutes ,if the calculagraph doesn’t reach 3 minutes ,it will boot again when the

calculagraph reaches 3 minutes. Thus you can ensure that the boot alternation is over 3 minutes after halt,

so it can prevent to breaking the compressor as a result of frequent boot. In addition, the controller doesn’t

boot the compressor within 3 minutes after turning on the power supply, thus the compressor can also be

protected in the state of power cut and then power on.

Auto defrosting principle

The controller has 3 defrost start modes which can be selected(F35):

OFF: Defrost is off.

1. Time alternation: the controller will start defrost according to the setting alternation time which can

be set in “Defrost alternation time (F31)”.

2. Accumulative compressor running time: if compressor accumulative running time reaches the time

which set in “defrost alternation time (F31)”, the controller starts defrost.

The controller has 2 defrost end modes which can be selected(F36):

0: time control: the defrost time can be set by F33, the controller will stop defrosting when it reaches

the defrost time.

1: controlled by both time and temperature: the controller will check the defrost effect through

evaporator sensor after starting defrost, If the sensor temperature reaches the “Defrost end temperature

(F32)”, the controller will turn off defrosting, if the defrost time is longer than “defrost end time (F33)”,

the defrosting will be turned off forcibly.

You can select 2 defrost heat modes (F37):

0: electric heat: the compressor stops and the defrost output is turned on (the defrost output controls

the electric heater);

1: hot gas: the compressor and defrost output is turned on (the defrost output controls the valve).

Dripping

A dripping time can be set (F34). For example, set the dripping water with 5 minutes, after finishing

4

defrosting, in 5 minutes, compressor doesn’t run, in this state, “Defrost” indicator light will flash. But in

two conditions the controller can’t enter the dripping state: one is finishing the defrosting manually, and the

other is defrosting temperature sensor’s error.

External alarm

The controller can connect a switching value as external alarm source (Pin 4, 5), when the external

alarm occurs, the controller stops, displays the alarm code “A11” and generates alarm output. External

alarm signal has 5 modes (F50):

0: without external alarm

1: always open, unlocked

2: always open, locked

3: always closed, unlocked

4: always closed, locked

“Always open” means in normal state, external alarm signal is open, if closed, the controller will give

an alarm; “Always closed” is on the contrary. “Locked” means that when external alarm signal becomes

normal, the controller is still in the alarm state, and it needs to press any key to resume.

Password

In order to prevent irrespective persons from changing the parameters, you can set a password (F80),

and if you have set a password, the controller will hint you to enter the password after you press the key

“M” for 5 seconds, you must enter the correct password, and then you can set the parameters. If you don’t

need the password, you can set F80 to “OFF”. Notice that you must remember the password, and if you

forget the password, you can not enter the set state.

Wiring Diagram:

Notice:

1. Please read the guide carefully before using, and set the parameter accurately.

2. Please place the temperature sensor at the place of air return of the air-cooler.

3. The evaporator sensor must be fixed on the air return pipe of the evaporator, and if you don’t

use the evaporator sensor, please set the F59 to NO, or the controller will generate alarm.

4. Please use the temperature sensor which is supplied by our company.

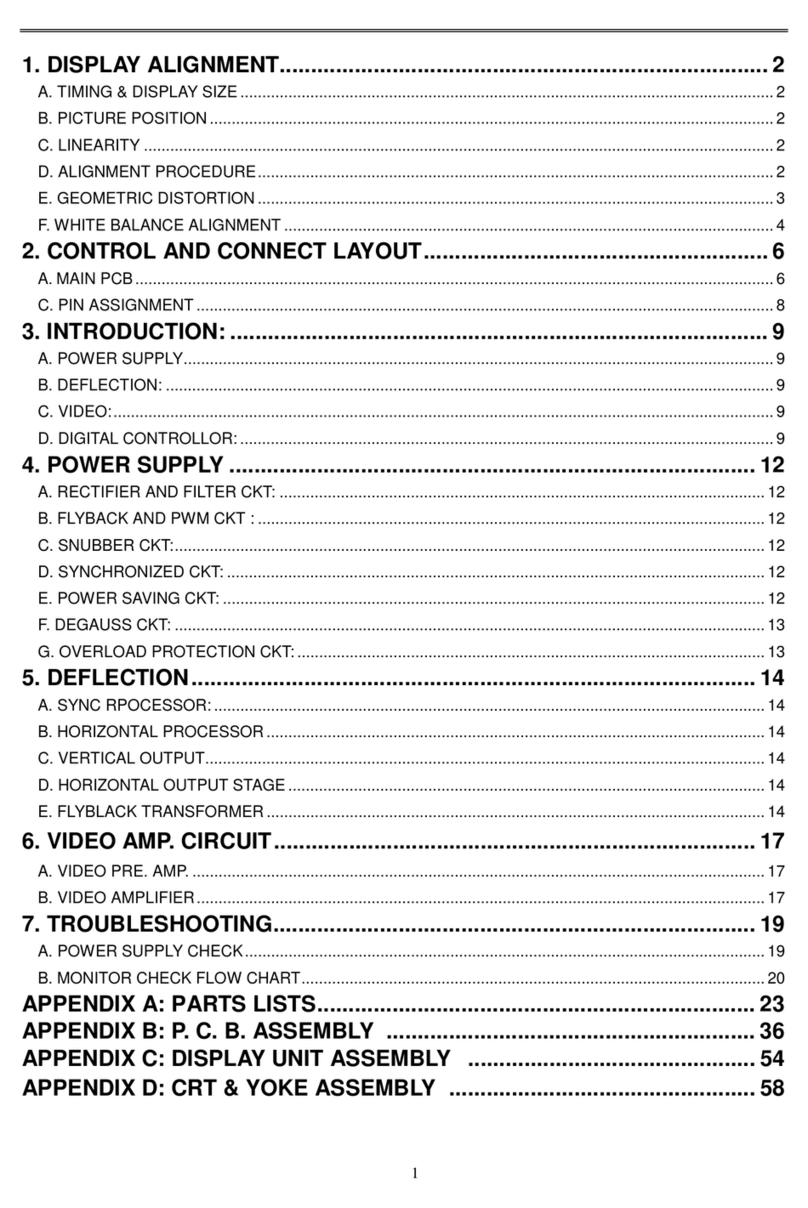

Table of contents