NEWCOMB SM-310-4 User manual

PnoTo FACT' FolJ"t

S

ff9

o€

-t_

OE

rr ul

|a

dT

oo

:s

5e

(J('

i; r*

Fg

E;

oe

I rrr

FrUI

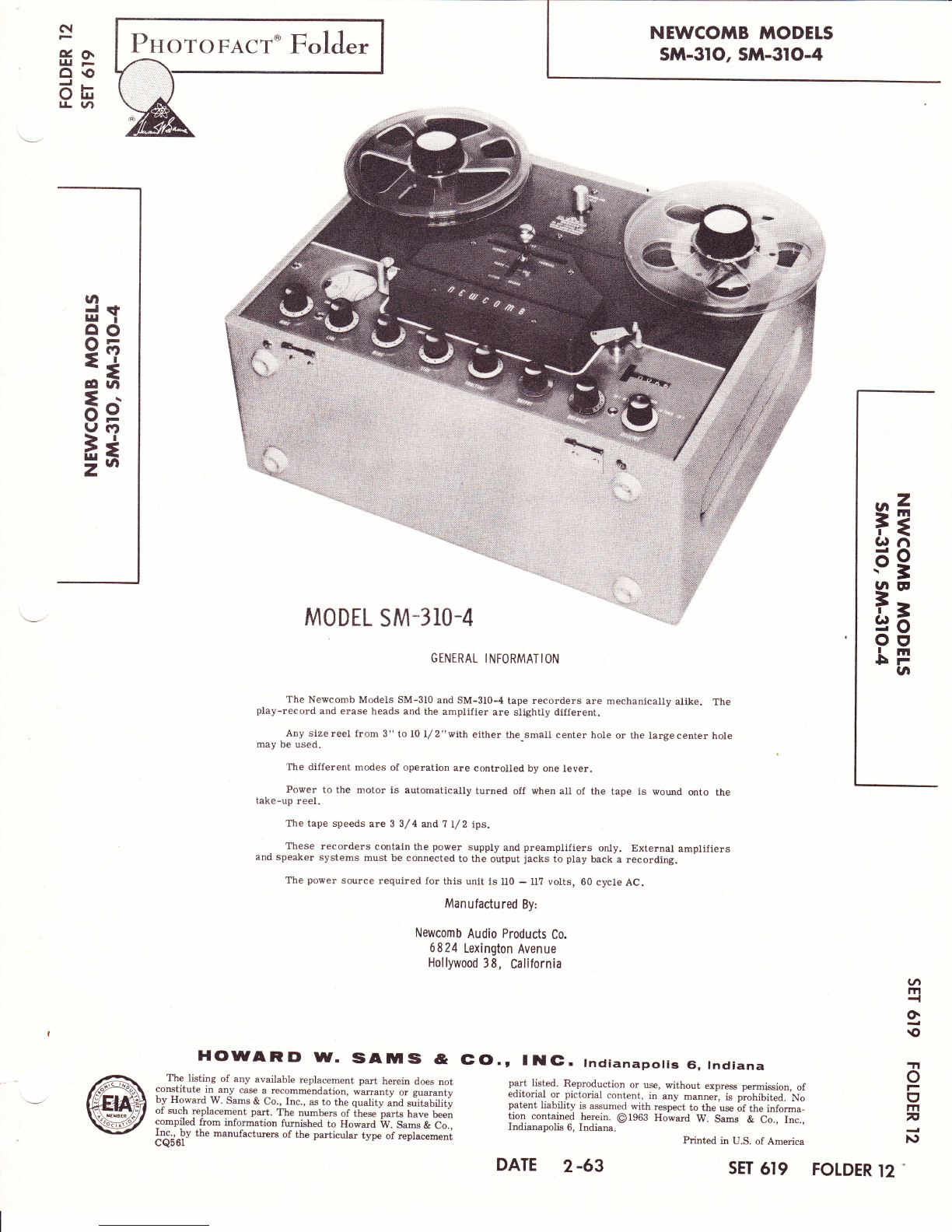

M0D[L SM-3r0-4

GENERAL INFORMATION

The Newcomb Models SM-3I0 and SM-3I0-4 tape recorders are mechanically alike. The

play-record and erase heads and the amplifier are slightly different.

Any sizereel from 3" to l0 l/2"with either the small center hole or the largecenter hole

may be used.

The different modes of operation are controlled by one lever.

Power to the motor is automatically turned off when all of the tape is wound onto the

take-up reel.

The tape speeds are 3 3/ 4 and ? I/2 ips.

These recorders contain the power supply and preamplifiers only. External amplifiers

and speaker systems must be connected to the output jacks to play back a recording.

The power source required for this unit is lI0 - U? volts, 60 cycle AC.

Manufactured By:

Newcomb Audio Products Co.

6824 Lexington Avenue

Hollywood 38, California

HCDWARD W. ISAIUlts &

The listing of any available replacement part herein does not

constitute r! .ny case a_recommendation, warranty or guaranty

by Howard W. Sams & Co., fnc., as to the quality ana sriitanUty

of such replacement part. The numbers of ihese parts have beeir

compiled from information furnished to Howard W. Sams & Co.,

L"!r -!V the manufactwers of the particular type of replacemeni

cQ56l

(GO., ltG. tndianapolis Gi, Indiana

part listed. Reproduction or use, without express permission, of

editorial or pictorial content, in any -a'nei, is piohibiied. No

patent liability is assumed with respect to the use of th" i.rfor-"-

tion contained herein. 01963 Howard W. Sams & C;., i;".,

Indianapolis 6, Indiana. Prinied in U.S. of America

(

m

{

O.

€

TI

o

|-

I

m

F

}\)

NEWCOMB MODELS

sM-31o, stl^-3lo-4

DATE 2-63 sET 619 FOTDER 12

13

33

14

16

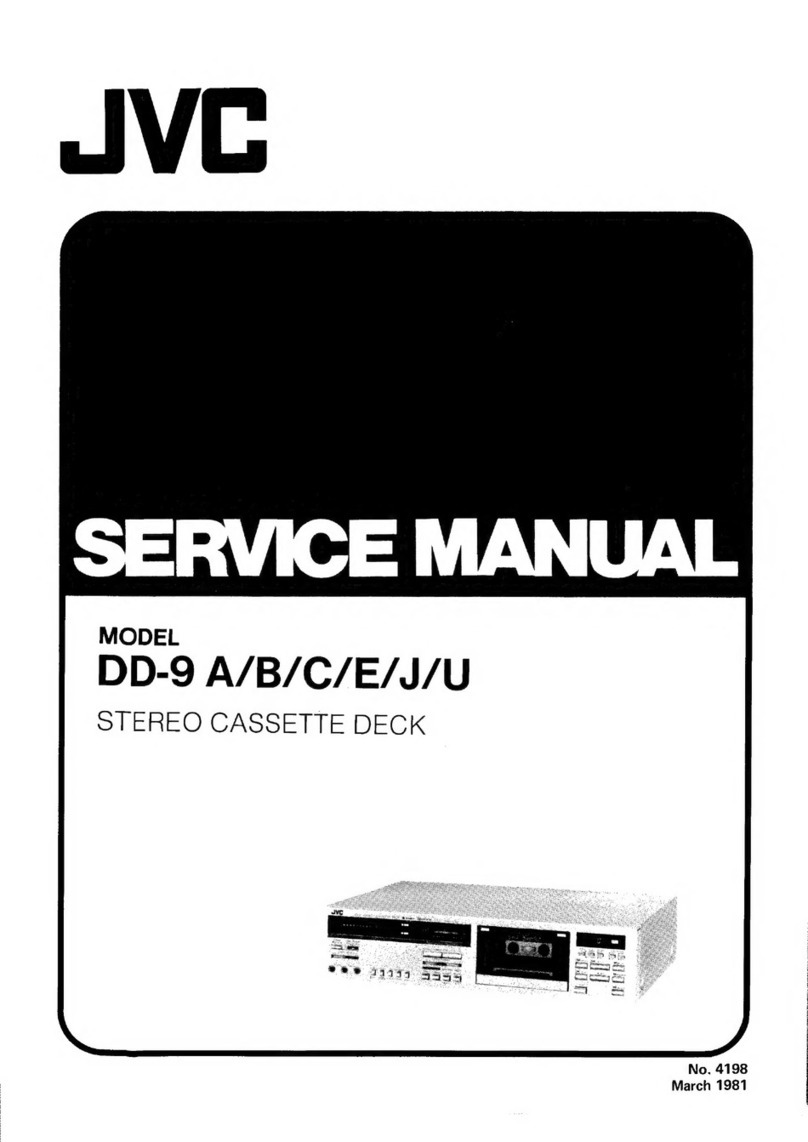

FIG. I TOP VIEW OF MECHANISM WITH COVERS AND DRIVE ASSEMBLY REMOVED

FUNCTION OF CONTROLS

Tape Control Lever Channel I and Channel 2 - Line

Sel€cts themode of operation whenplaced in the Controls the record Level when recording from

marked positiona on the head cove!. an external source.

Speed Fu nction

Depress thls button while tie motor is running Selects either the record or playback mode of

to select tlte correct speed. operation.

Left-Hand Take-up Guide outPut

The take-up guide is connected to the automatic Turns the power on to the recorder and regu-

motor swltchald holds the switch closed when tape is late6 the output volume.

threaded on the recorder. When no tape is on the re-

corder, the take-up guide is pulled forward by spring Balance

tenslon and opens the automatic motor snritch.

channel I and channel 2 - Mike Balances the two channels when plaving stereo'

controls the record level v/hen recording from Sglgctor

a microphone. Selects the channel or chalnels for recording

or playback.

FUNCTIONS OF JACKS

Mike I channel 2lnput

Connect microphone to this jack for Channel I Fo" cormecting an external Gource to make a

recordlngs. recording on Channel2.

Channel I lnput Channel 2 output

connect an external recording source for chan- For connecting an external ampliJier tor pl.ay_

ne1 I recording. back.

Channel I Output Mike 2

For connecting an external ampliJler for play- For making recordings on Channel 2.

back.

Monitor

Fo! connecting headphones to monito! a re-

cordlng.

PAGE 2

128 141 107 1 13 1 14 115 160 106

. a:r:

{*B

\:v

137 118 IT7 136

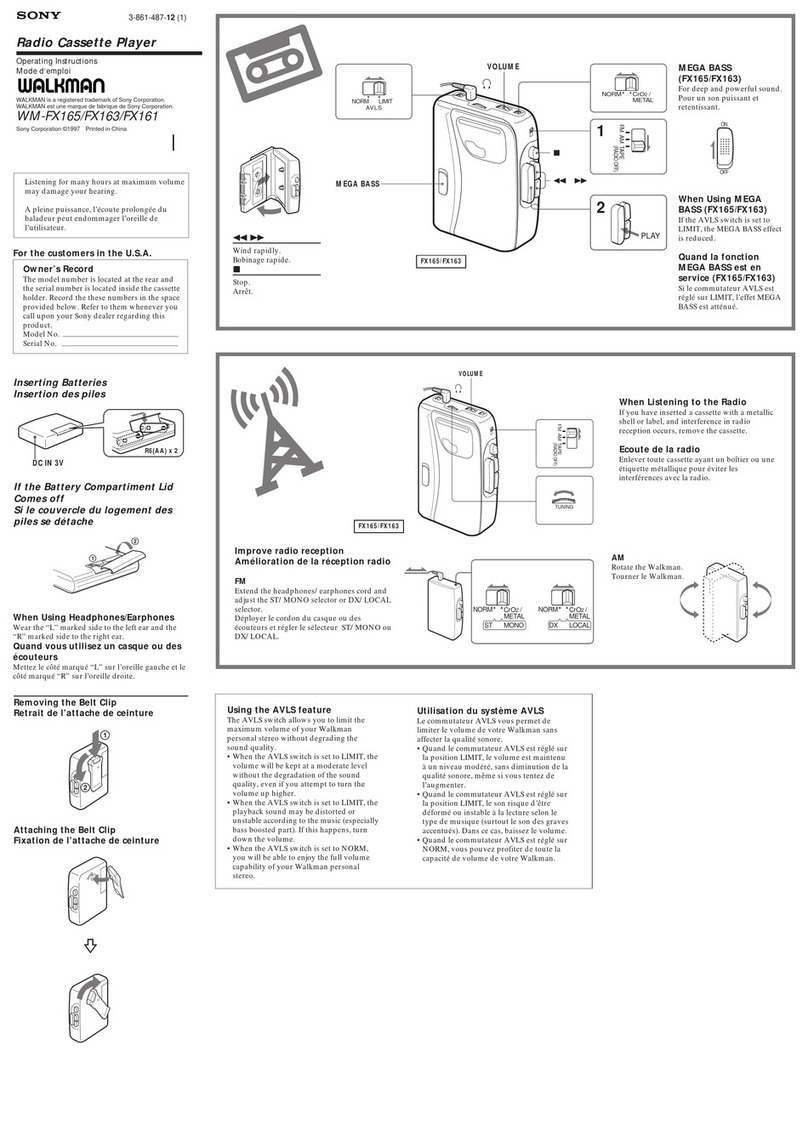

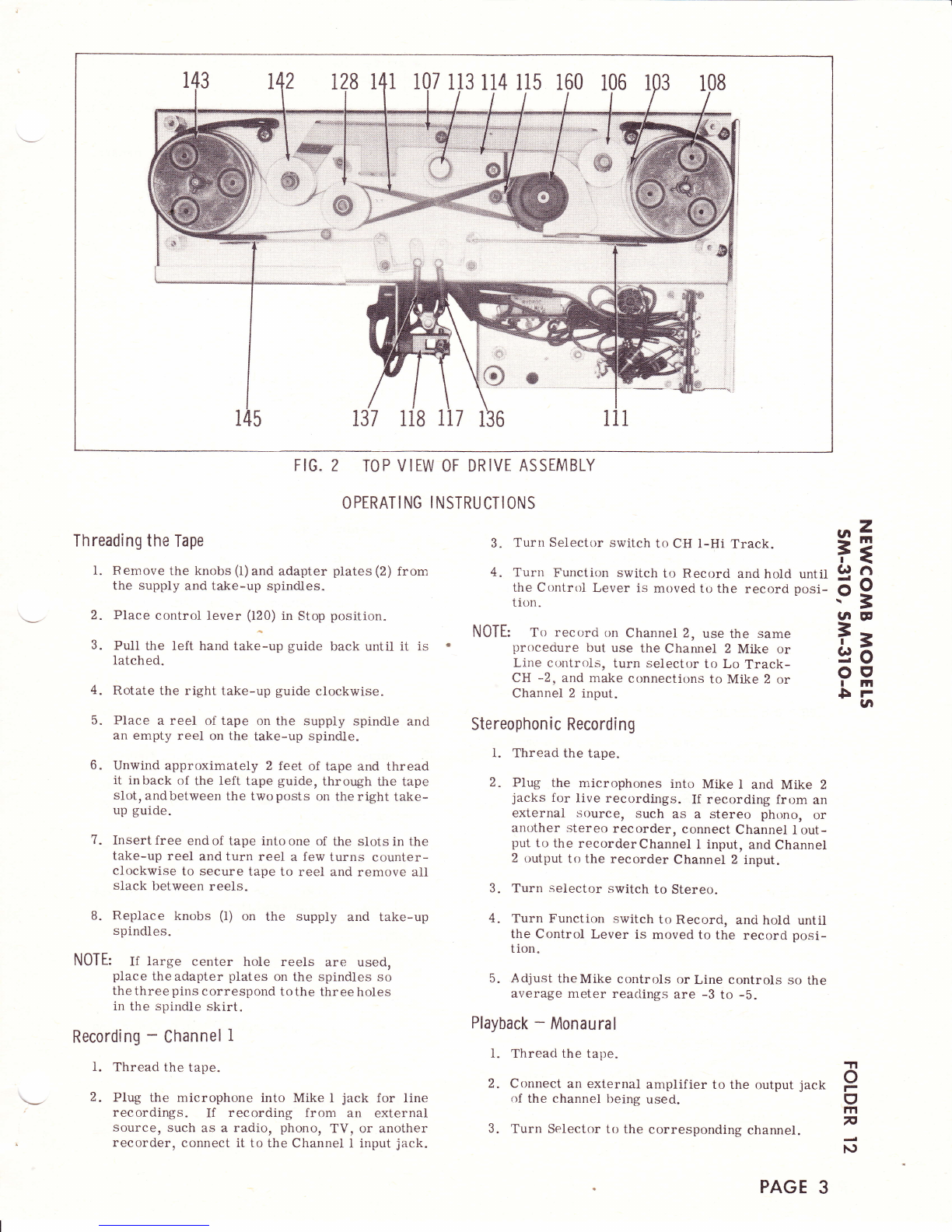

FIG. 2 TOP VIEW OF DRIVE ASSEMBLY

OPTRATI NG I NSTRUCTIONS

Threading the Tape

l. Remove the knobs (I)and adapter plates (2) from

the supply and take*up spindles"

2. Place control lever (120) in Stop position.

3. PuII the left hand tat<e-up guide back until it is .

latched.

4. Rotate the right take-up guide clockwise.

5. Place a reel of tape on the supply spindle and

an empty reel on the take-up spindle.

6. Unwind approximately 2 feet of tape and thread

it inback of the left tape guide, through the tape

slot, andbetween the twoposts on the right take-

up guide.

7. Insert free end of tape into one of the slots in the

take-up reel and turn reel a few turns counter-

clockwise to secure tape to reel and remove all

slack between reels.

8. Replace knobs (l) on the supply and take-up

spindles.

NOTE: If large center hole reels are used,

piace the adapter plates on the spindles so

the three pins correspond tothe three holes

in the spindle skirt.

Recording - Channel I

I. Thread the tape.

2. Plug the microphone into Mike I jack for line

recordings. If recording from an external

source, such as a radio, phono, TV, or another

recorder, connect it to the Channel I input jack.

3. Turn Selector switch to CH l-Hi Track.

4. Turn Function switch to Record and hold until

the Control Lever is moved to the record posi-

tiott.

NOTE: To record on Channel 2, use the same

proceciure but use the Channel 2 Mike or

Line ct_rntrols, turn selector to Lo Track-

CH -2, and make connectit.rns to Mike 2 or

Channel 2 input.

Stereophon ic Recordi ng

l. Thread the tape.

2. PIW the microphones into Mike I ancl Mike 2

jacks for live recordings. If recording from an

external source, such as a stereo phono, or

ar"rother stereo recorder, connect Channel I out-

put to the recorderChannel I input, and Channel

2 output to the recorder Channel 2 input.

3. Turn selector switch to Stereo.

4. Turn Functicln switch to Record, anci hold untii

the Control Lever is moved to the record posi-

tion.

5. Adjust theMike controls or Line controls so the

average meter reaclings are -3 to -b.

Playback - Monaural

l. Threaci the tape.

2. Connect an external amplifier to the output jack

of the channel being used.

3. 'Iurn Selector to the corresponding channel.

.^z

FE

G)fl

.69

rN CE

Ee

oe

rm

Frta

TI

o

r

I

1Tl

F

N

PAGE 3

4. Pull Control Lever to Listen,

5. Adjust the Output control to the desired listening

le v eI.

Playback - Stereo

I. Thread the tape.

2. Connect external amplifiers to the output jacks.

3. Turn Selector to Stereo.

4. PuIl Control Lever to Listen.

5. Adjust the Output control to the desired listening

Ievel.

6. Adjust the Balance control so the output of each

channel is equal.

Dual-Track Recording

When all the tape has been wound onto the take-

up spindle, remove the full reel; turn it over and

place it on the supply spindle. Place the empty reel

on the take-up spindle, rethread the tape, and pro-

ceed with ttrerecording. The first track canbe played

back without rewinding.

Quarter-Track Recording

Turn the Selector to CH i Hi Track. Thread the

tapeon the recorder. When theiirst track isrecorded

remove the full reel from the take-up spindle, turn it

over and place on the supply spindle. Rethread the

tape and record the second track. After the second

track is recorded, turn the Selector to Lo-Track -

CH 2. Remove the full reel of tape, turn it over and

place on the supply spindle. Rethread the tape and

record the third track. After the third track is re-

corded, remove the full reel, turn it over and place

on the supply spindle. Rethread the tape and record

the fourth track.

The tape can be played back in the same manner.

Reverse

When the Control Lever is moved tethe Reverse

position, the tape will be rewound onto the supply reel,

Forward

Portions of program material may be skipped

over toadesired spot when theControl Lever ismoved

to the Forward position,

ListenTo play back a recording, move the Control

Lever to Listen.

Record

To set the tape in motion for recording, move

the Control Lever to Record.

Erasi ng

A recording is automatically erasedwhile a new

one is being made. To erase a tape without putting a

new recording on it, unplug all input connections, turn

ali controls to their lowest level, turn the Function

switch to record and hold until the Control Lever is

pulled into Record position. The tape will now run by

the erase head and any material on the tape will be

erased.

DISASSEMBLY

To Remove Recorder from Cabinet

I. Remove two screws from the front and back of

cabinet and lift recorder out.

To Remove Tape Transport and Power Supply

I. R.emove the spindle plates (3).

2. Rem.ove the knob (3I) from toggle section (lI?).

3.

R

8.

Remove head covers (B) and (9) and belt access

cover (6).

Lift push-pull rod (98) out of the slot in the idler

carriage (]07).

Unplug the equalizer plugs from the amplifier.

Unhook the supply drag brake cord.

Unhook the motor switch cord.

Unhook spring from take-up tensioner (24).

Remove flywheei drive belt (71) from motor

pulley (160).

Remove counter drive belt (65).

Il. Remove the screw holding the tape transport

and power supply to the amplifier.

12. Remove four screws from the top assembly.

13. Remove the hex nut and lockwasher holding the

power supply chassis to the lower flywheel

mounting piate.

14. Slide the transportback andunplug theamplifier

power plug.

15. Lift the transport and power supp).y from the

top assembly and amplifier.

To Remove Amplifier

1. Remove control knobs.

2. Remove monitor switch from top assembly.

3. Remove four screws from amplifier shield and

remove shield.

4. Unsolder head leads.

5. Unpiug meters.

6. Remove twoscrews from top assembly and then

lift ampiifier from top assembly.

4.

6.

7.

9.

I0.

PAGE 4

I

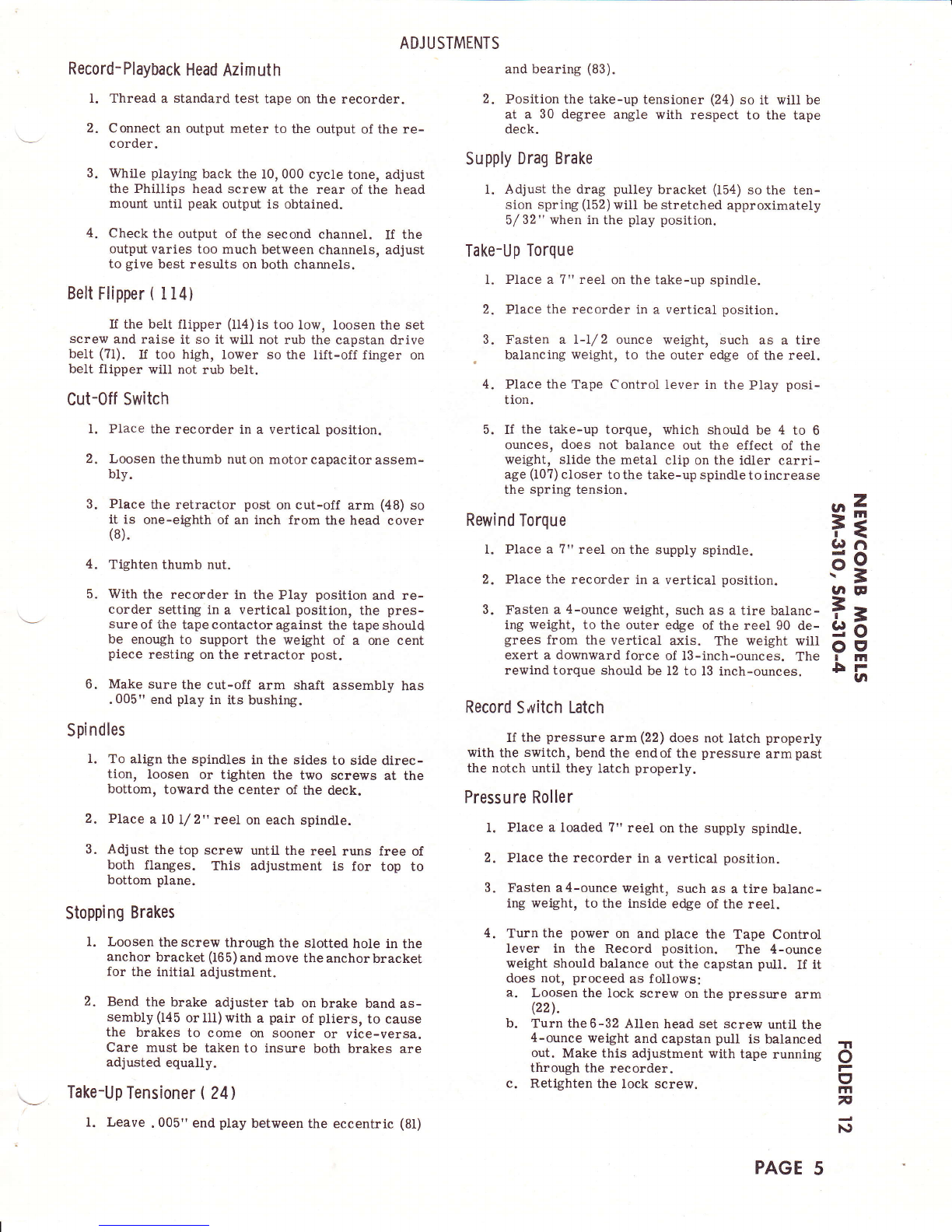

ADJUSTMENTS

Record- Playback Head Azim uth

l. Thread a standard test tape on the recorder.

2. Connect an output meter to the output of the re-

corder.

3. While playing back the I0,000 cycle tone, adjust

the Phillips head screw at the rear of the head

mount until peak output is obtained.

4. Check the output of the second channel. If the

output varies too much between channels, adjust

to give best results on both channels.

BeltFlipper(ll4)

If the belt flipper (114) is too low, loosen the set

screw and raise it so it wiII not rub the capstan drive

belt (71). If too high, Iower so the lift-off finger on

belt flipper will not rub belt.

Cut-0ff Switch

l. Place the recorder in a vertical position.

2. Loosen the thumb nut on motor capacitor assem-

blv.

3. Place the retractor post on cut-off arm (48) so

it is one-eighth of an ineh from the head cover

( B).

4. Tighten thumb nut.

5. With the recorder in the Play position and re-

corder setting in a vertical position, the pres-

sure of the tape contactor against the tape should

be enough to support the weight of a one cent

piece resting on the retractor post.

6. Make sure the cut-off arm shaft assembly has

.005" end play in its bushing.

Spindles

I. To align the spindles in the sides to side direc-

tion, loosen or tighten the two screws at the

bottom, toward the center oi the deck.

2. Place a l0 L/ 2" reel on each spindle.

3. Adjust the top screw until the reel runs free of

both flanges. This adjustment is for top to

bottom plane.

Stopping Brakes

l. Loosen the screw through the slotted hole in the

anchor bracket (165) and move the anchorbracket

for the initial adjustment.

2. Bend the brake adjuster tab on brake band as-

sembly (145 or lll) with a pair of pliers, to cause

the brakes to come on sooner or vice-versa.

Care must be taken to insure both brakes are

adjusted eqr-rally.

Take-Up Tensioner ( 24)

l. Leave .005" end play between the eccentric (81)

and bearing (83).

2. Position the take-up tensioner (24) so it will be

at a 30 degree angle with respect to the tape

deck.

Supply Drag Brake

l. Adjust the drag pulley bracket (l5a) so the ten-

sion spring (I52) will be stretched approximately

5/32" when in the play position.

Take-Up Torque

l. Place a ?" reel on the take-up spindle.

2. Place the recorder in a vertical position.

3. Fasten a L-L/2 ounce weight, such as a tire

. balancing weight, to the outer edge of the reel.

4. Place the Tape Control lever in the Play posi-

tion.

5. If the take-up torque, 'which should be 4 to 6

ounces, does not balance out ihe effect of the

weight, slide the metal clip on the idler carri-

age (107) closer tothe take-up spindletoincrease

the spring tension.

Rewind Torque

l. Place a ?" reel on the supply spindle.

2. Place the recorder in a vertical position.

3. Fasten a 4-ounce weight, such as a tire balanc-

ing weight, to the outer edge of the reel 90 de-

grees from the vertical axis. The weight will

exert a downward force of 13-inch-ounces. The

re'wind torque should be 12 to 13 inch-ounces.

Record Switch Latch

If the pressure arm (22) does not latch properly

with the switch, bend the endof the pressure armpast

the notch until they latch properly.

Pressure Roller

l. Place a loaded ?" reel on the supply spindle.

2. Place the recorder in a vertical position.

3. Fasten a4-ounce weight, such as a tire balanc-

ing weight, to the inside edge of the reel.

4. Turn the power on and place the Tape Control

lever in the Record position. The 4-ounce

weight should balance out the capstan pu1l. If it

does not, proceed as follows:

a. Loosen the lock screw on the pressure arm

(22).

b. Turn the6-32 Allen head set screw until the

4-ounce weight and capstan pull is balanced

out. Make this adjustment with tape running

through the recorder.

c. Retighten the lock screw.

.-z

F3

G)6

.69

UIF

ia

ott

r |tt

5rUI

.n

o

F

(f

m

F

N

PAGE 5

z.

l.!J

o

E,

O

tf,

./t

lJ.j

E

I

=

u.l

=

o

o

6

VI

L/t

at'l

(J

o-

=

PAGE 6

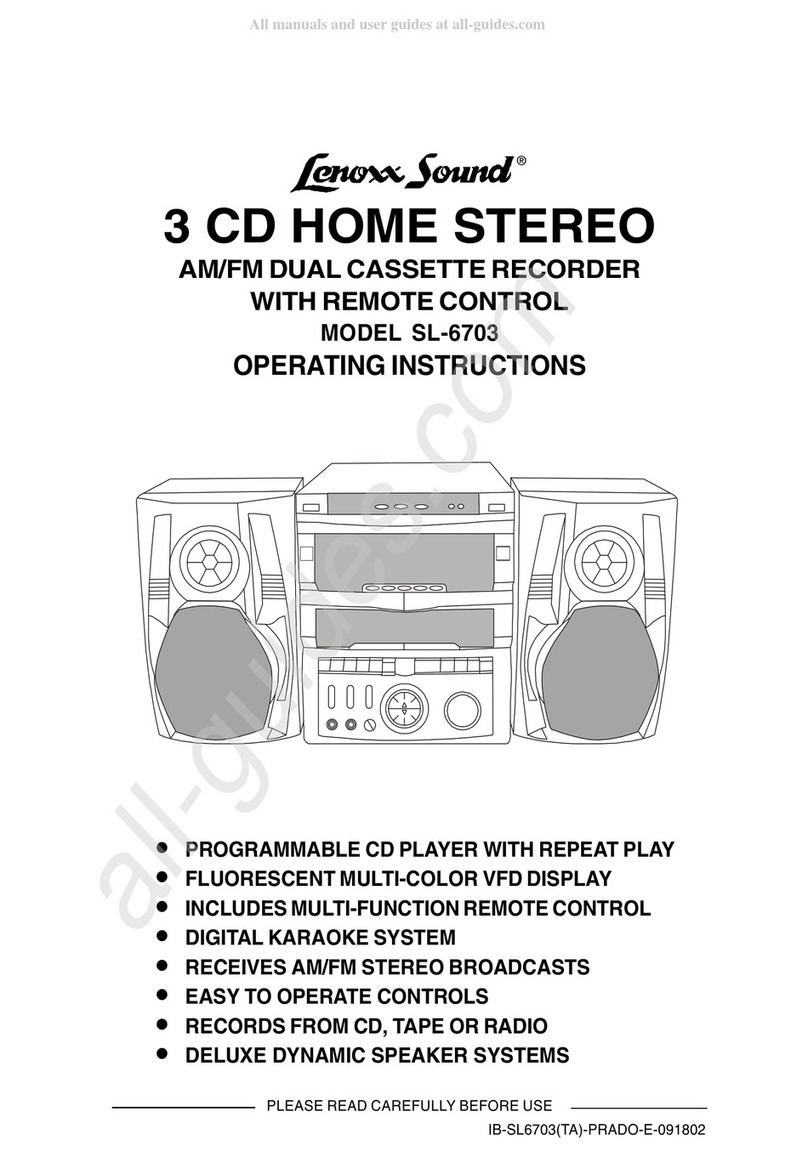

AMP CHASS IS BOTTOM V IEW.CAPACITOR & MISC. IDENT.

BOTTOM

DR IVE MECHAN I SM

PAGE 7

FIG. 3BONOM V IEW OF MECHAN ISM W ITH DR IVE ASSEMBLY REMOVED

138 139 154

ry*#

FIG. 4BOTTOM V lEW OF DR IVE ASSEMBLY

CLTAN ING

Pressure roller (20), erase head (33), record-

playback head (14), and tape guides (16) accumulate

tape oxide as it passes these parts. Use a soft cloth

and alcohol to remove it. After long periods of oper

ation, a buildup of dirt and brake lining fuzz will

accumulate on the brake drums. Use a cloth and al-

cohol to remove it.

LUBRICATION

The bearings are the setf-lubricating type and

t3

..69

gtE

Ea

oe

Itll

5rIa

should not need lubrication for a long period of time

under normal operating conditions. Need for lubri-

cation will be evident by mechanical noise or slow

operation. Use SAE30-type motor oiland lubricate as

follows:

Motor - l0 drops at each end.

Belt idler pulleys - I drop each.

Capstan - l0 drops at top and bottom.

Counter - I drop on shaft at bearing.

Pressure roller - I drop to shaft.

CAUTI0N: Do not overtubricate.

TI

o

F

I

m

F

J

N)

PAGE 13

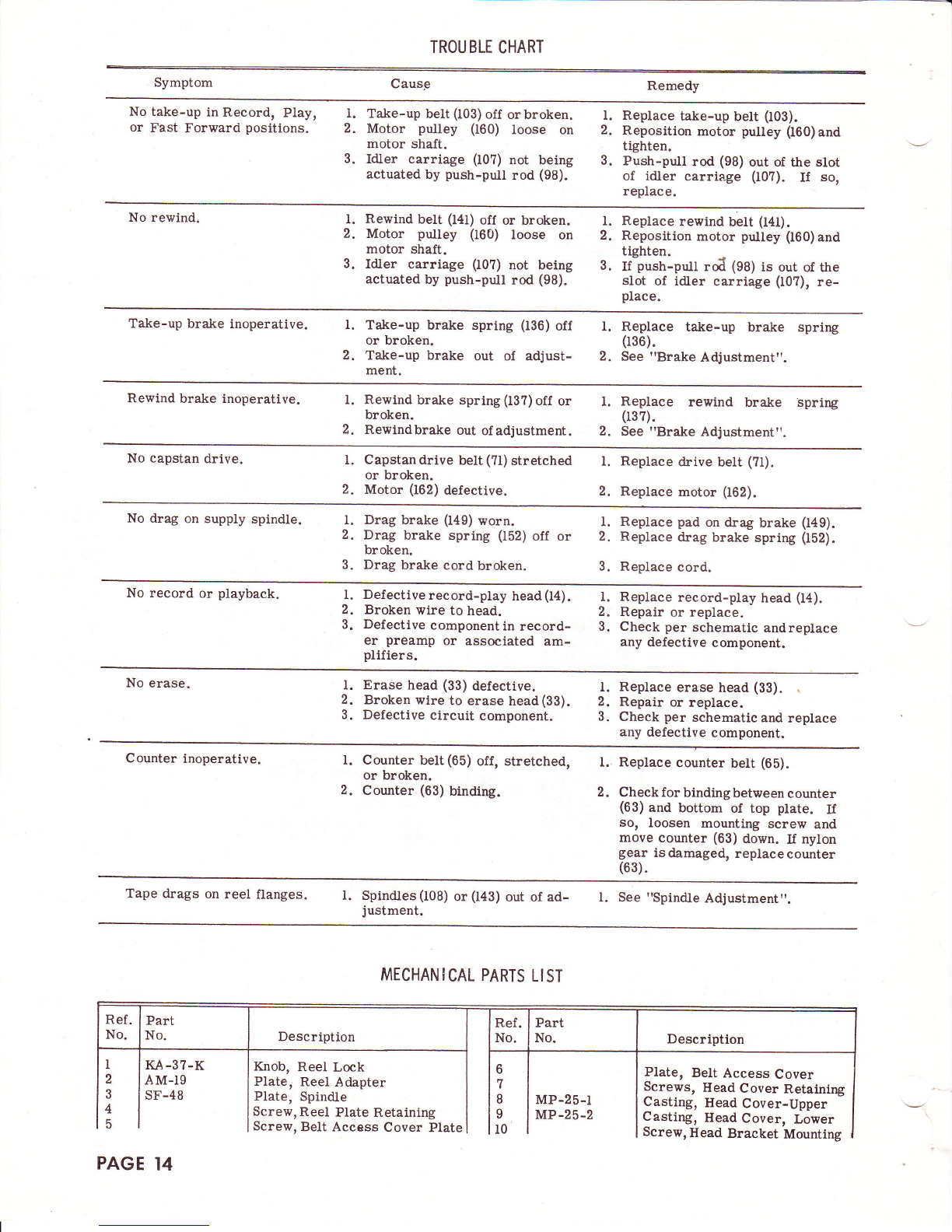

TROUBLE CHART

Symptom Cause Remedy

No take-up in Record, Play,

or Fast Forward positions. Take-up belt (103) off orbroken.

Motor pulley 060) loose on

motor shaft.

Idler carriage (10?) not being

actuated by push-pull rod (98).

Replace take-up belt (I03).

Reposition motor pulley (160) and

tighten.

Push-pull rod (98) out of the slot

of idler carriage (10?). If so,

replace.

I.

2.

3.

1.

2.

3.

No rewind. I. Rewind belt (l4l) off or broken.

2. Motor pulley (160) loose on

motor shaft.

3. Idler carriage (107) not being

actuated by push-pull rod (98).

l. Replace rewind belt (l4t).

2. Reposition motor pulley (160)and

tiEhten.

3. tf'push-pil rd (98) is out of the

slot of idler carriage (10?), re-

place.

Take-up brake inoperative. Take-up brake spring

or broken.

Take-up brake out of

ment.

Replace take-up brake spring

036).

See "Brake Adjustment".

I.

2.

1.

2.

(136) off

adjust-

Rewind brake inoperative. I.

2.

Rewind brake spring (13?) off or

broken.

Rewindbrake out of adjustment.

Replace rewind brake spring

037).

See "Brake Adjustment".

1.

2.

No capstan drive. Capstan drive belt (?1) stretched

or broken.

Motor (162) defective.

Replace drive belt (?l).

Replace motor (162).

l.

2.

l.

2.

No drag on supply spindle. Drag brake (149) worn.

Drag brake spring (t52) off or

broken.

Drag brake cord broken.

Replace pad on drag brake (149).

Replace drag brake spring (152).

Replace cord.

l.

2.

3.

I.

2.

3.

No record or playback. Defective record-play head (14).

Broken wire to head.

Defective component in record-

er preamp or associated am-

plifiers.

Replace record-play head (I4).

Repair or replace.

Check per schematic andreplace

any defective component.

l.

2.

3.

l.

2.

3.

No erase. I.

2.

3.

l.

2.

3.

Erase head (33) defective.

Broken wire to erase head(33).

Defective circuit component.

Replace erase head (33). \

Repair or replace.

Check per schematic and replace

any defective component.

Counter inoperative. Counter belt (65) off, stretched,

or broken.

Counter (63) binding.

Replace counter belt (65).

Check for binding between counter

(63) and bottom of top plate. U

so, loosen mounting screw and

move counter (63) down. If nylon

gear is damaged, replace counter

(63).

t.

2.

I.

2.

Tape drags on reel flanges. l. Spindles (108) or (143) out of ad-

justment. l. See "Spindle Adjustment"

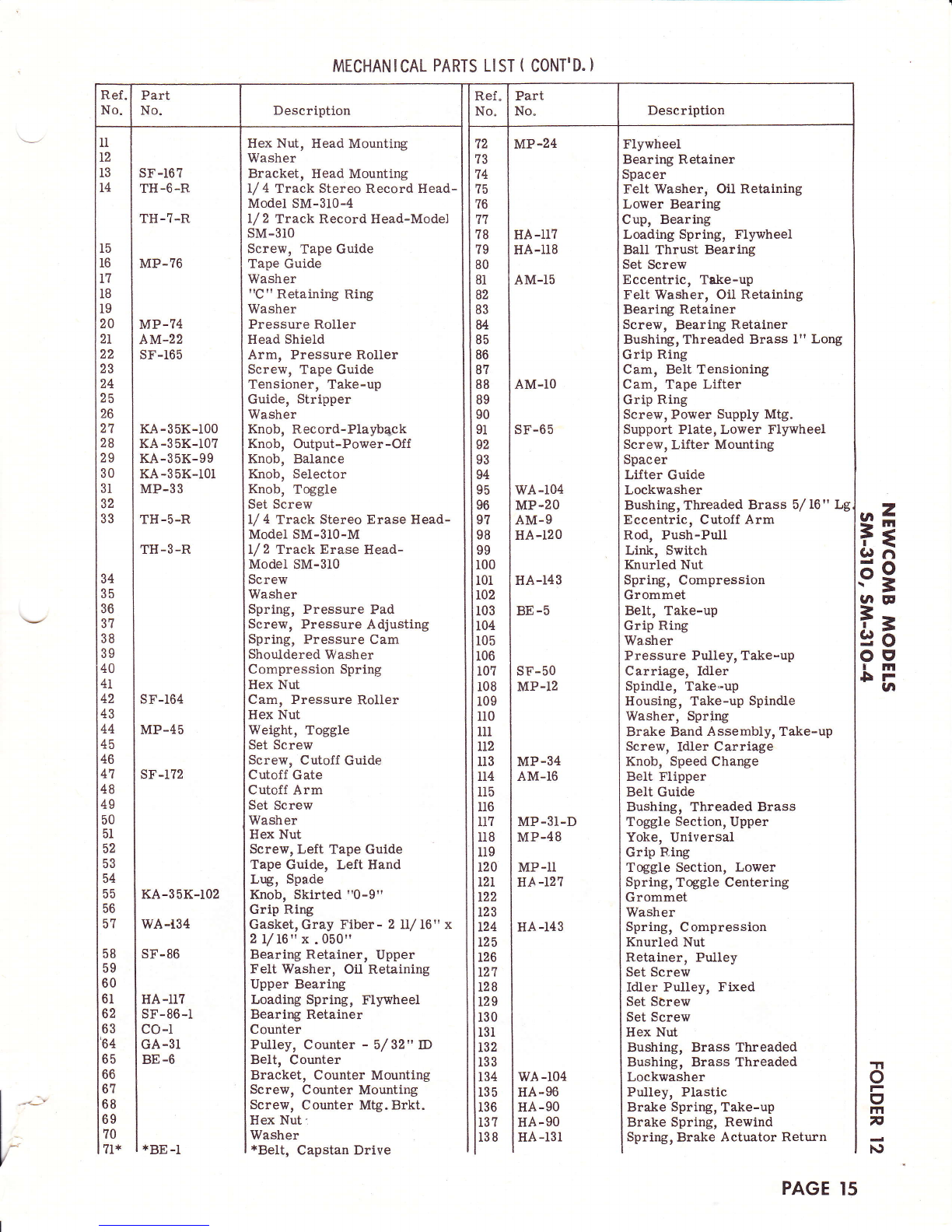

MECHANICAL PARTS LIST

6

7

I

I

i0

I

2

3

4

5

KA-37-K

AM-Ig

sF-48

Knob, Reel Lock

Plate, Reel Adapter

Plate, Spindle

Screw, Reel Plate Retaining

Screw, Belt Access Cover Plate

Plate, Belt Access Cover

Screws, Head Cover Retaining

Casting, Head Cover-Upper

Casting, Head Cover, Lower

Screw, Head Bracket Mounting

MP-25-1

MP-25-2

Description

PAGE 14

MECHANICAL PARTS LIST ( CONT'D. }

l5

I6

l?

IB

l9

20

2L

22

23

24

25

26

27

28

29

30

31

32

33 r*

.69

(aE

Ee

o9

rI'l

5rUI

'n

o

I

m

n

N)

72

?3

74

75

?6

11

78

?9

80

8l

82

83

84

85

86

87

88

89

90

91

s2

93

94

95

96

91

98

99

100

l0l

r02

103

r04

r05

106

t0?

r08

109

lr0

lll

LLz

113

114

tl5

116

1l?

118

ll9

120

I2r

122

123

t24

125

126

t27

lrza

lrzs

| 130

I 13t

I rsz

I rss

I rs+

lrss

I rso

lrsz

lrsa

34

35

36

3?

38

39

40

4L

42

43

44

45

46

47

48

49

50

5l

52

53

54

55

56

5?

58

59

60

6l

62

63

64

65

66

67

68

69

?0

?l*

sF-167

TH-6-R

TH-?-R

MP.?6

MP-?4

Al0'I-22

sF-165

KA-35K-100

KA-35K-10?

KA-35K-99

KA-35K-lot

MP-33

TH-5-R

TH-3-R

sF-r64

MP-45

sF-l?2

KA-35K-IO2

wA-134

SF-86

HA-II?

sF-86-1

co-r

GA-3I

BE-6

Hex Nut, Head Mounting

Washer

Bracket, Head Mounting

L/ 4 Track Stereo Record Head-

Model SM-310-4

l/ 2 Track Record Head-Model

SM-3IO

Screw, Tape Guide

Tape Guide

Washer

"C" Retaining Ring

Washer

Pressure Roller

Head Shield

Arm, Pressure Roller

Screw, Tape Guide

Tensioner, Take-up

Guide, Stripper

Washer

Knob, Record-Playbqck

Knob, Output-Power-Off

Knob, Balance

Knob, Selector

Knob, Toggle

Set Screw

I/ 4 Track Stereo Erase Head-

Model SM-310-M

L/ 2 Track Erase Head-

Model SM-310

Screw

Washer

Spring, Pressure Pad

Screw, Pressure Adjusting

Spring, Pressure Cam

Shouldered Washer

Compression Spring

Hex Nut

Cam, Pressure Roller

Hex Nut

Weight, Toggle

Set Screw

Screw, Cutoff Guide

Cutoff Gate

Cutoff Arm

Set Screw

Washer

Hex Nut

Screw, Left Tape Guide

Tape Guide, Left Hand

Lug, Spa.de

Knob, Skirted t'0-9rr

Grip Ring

Gasket, Gray Fiber - 2 lI/ 16 " x

2 L/L6" x .050"

Bearing Retainer, Upper

Felt Washer, Oil Retaining

Upper Beariry

Loading Spring, Flywheel

Bearing Retainer

Counter

Pulley, Counter - 5/32" D

Belt, Counter

Bracket, Counter Mounting

Screw, Counter Mounting

Screw, Counter Mtg. Brkt.

Hex Nut:

Washer

*Belt, Capstan Drive

MP-24

HA-II?

HA-ll8

AM-I5

AM-10

SF-65

wA-r04

MP.2O

AM.9

HA-120

HA-143

BE-5

sE-50

MP-12

MP-34

AM-16

MP-3I-D

MP-48

MP-II

HA -I2?

HA-I43

FlywheeI

Bearing Retainer

Spacer

Felt Washer, Oil Retaining

Lower Bearing

Cup, Bearing

Loading Spring, Flywheel

Ball Thrust Bearing

Set Screw

Eccentric, Teke-up

Felt Washer, Oil Retaining

Bearing Retainer

Screw, Bearing Retainer

Bushing, Threaded Brass l" Long

Grip Ring

Cam, BeIt Tensioning

Cam, Tape Lifter

Grip Ring

Screw, Power Supply Mtg.

Support Plate, Lower Flywheel

Screw, Lifter Mounting

Spacer

Lifter Guide

Lockwasher

Bushing,Threaded Brass 5,/16" Lg

Eccentric, Cutoif Arm

Rod, Push-Pull

Link, Switch

Knurled Nut

Spring, Compression

Grommet

BeIt, Take-up

Grip Ring

Washer

Pressure Pulley, Take-up

Carriage, Idler

Spindle, Take-up

Housing, Take-up Spindle

Washer, Spring

Brake Band Assembly, Take-up

Screw, Idler Carriage

Knob, Speed Change

Belt Flipper

BeIt Guide

Bushing, Threaded Brass

Toggle Section, Upper

Yoke, Universal

Grip R.ing

Toggle Section, Lower

Spring, Toggle Centering

Grommet

Washer

Spring, Compression

Knurled Nut

Retainer, Pulley

Set Screw

Idler Pulley, Fixed

Set Screw

Set Screw

Hex Nut

Bushing, Brass Threaded

Bushing, Brass Threaded

Lockwasher

Pulley, Plastic

Brake Spring, Take-up

Brake Spring, Rewind

Spring, Brake Actuator Return

wA-104

HA-96

HA-90

HA-90

HA-l3l

_i-

*BE-I

PAGE 15

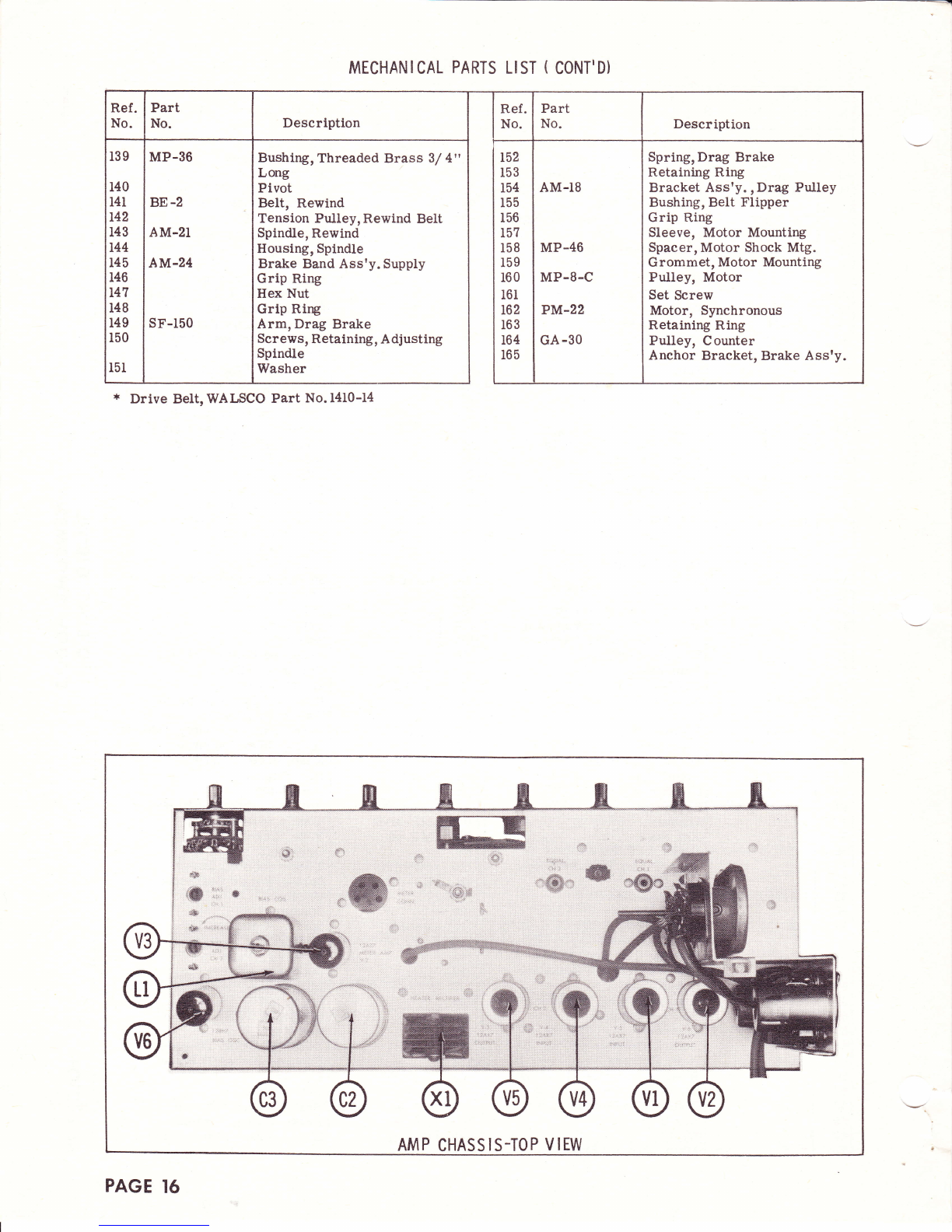

MECHANICAL PARTS LIST ( CONT'D)

..*

ffi

,;ffi;

4Fp:

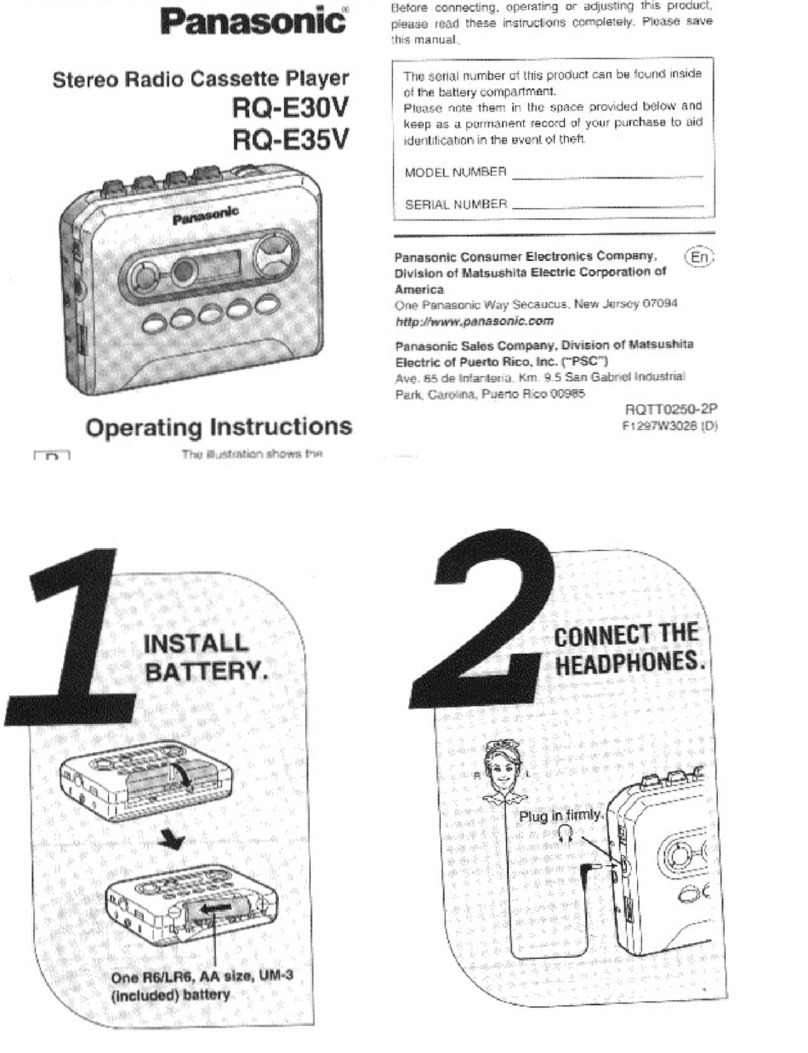

AMP CHASSIS-TOP VIEW

Description Description

MP-36

BE-2

AM-2I

A M.24

sF-150

Bushing,Threaded Brass 3/ 4"

Long

Pivot

BeIt, Rewind

Tension Pulley, Rewind BeIt

Spindle, Rewind

Housing, Spindle

Brake Band Ass'y. Supply

Grip Ring

Hex Nut

Grip Ring

Arm, Drag Brake

Screws, Retaining, A djusting

Spindle

Washer

AM-I8

MP-46

MP-8-C

PM.22

GA -30

Spring, Drag Brake

Retaining Ring

Bracket Assty. , Drag Pultey

Bushing, Belt Flipper

Grip Ring

Sleeve, Motor Mounting

Spacer, Motor Shock Mtg.

G rommet, Motor Mounting

Pulley, Motor

Set Screw

Motor, Synchronous

Retaining Ring

Pulley, Counter

Anchor Bracket, Brake Ass'y.

* Drive BeIt, WALSCO Part No.l4I0-14

PAGE 16

F

o

F

U

:

U

I

J

c

U

4

tt,

Y

E

=

u

e

z.

<o

iz

v-

&n

o?

='d

QZ

ej-

r

o

z

F

d,

F-

xEEgExExs-EENE

=BSE33SB=5sBE

Et g!q!At!?qlF6oodNolll

6ldNNNNNNOOOOO

etr &Etrtrdddcdd!d

F

6

F

z

u

2

U

U

J

G

u

e

v,

Y

e

=

U

e

x

N

@

z

i2

!zL

5i

)"

ct

z

U

dl-

-d c

o

z

F

d, :gEFxHsxsHsse

fre -OHNO$66eOOO*

e.iiHdiH----NN

trtr!ttrtrtrtrtre&e&t,

F

o

F

z

r

=

U

(J

I

A.

U

4

t9

o'

=5

-s

'1 Fl "1 ":,1

<r$sssFl

u;^ ;{ ;; X d (o

sE!333N

a€ ?^?^9^?-s d E

s.,^ o-B o-t "-g ogEgd-g{g

:':J' g@<{ntf @{16€t@QnO@

*;$ $o$oso$@@oNoNo

HB Sd$dgd$d$d$d$d

ed

d, z-

Ia

Uf;

55545555*Aar ?i

tq(Jn(Jtrl(Jooxr-)(a ch

xnhFlhFlhFlYn= H

##fni3sgi"3,.

PiliHiHiHgHHEHE

oo @q) 0() @o oosasn

F

<d

uiz

Op

e, c,

JL

IiAi*i*{*{u{*

ro.

<o

4t

22

ud

E+ E H F E g

^-f; T .r c'\ ct d

qHF:"EdtEd

E;X.Y?Y;EA

3;Hs333s:-s33iRx F

@-u, !N6N@N@NONFi)-.

AgEB dBABABAAd'E F

g,

o-

B<

Ho-

XvMXM!4

;jjiSJoo

? ???????

ccccfr&&d

iur

32

p< 8E58EMx

@6@@a:@@

NNNNN6TN

v14

oo

oo

60

u

o

)

N

4;-l;

i:55 N

AE* E E "+;

HltF'lg<

-: tD ! o d o a

g5g5Effff

o

I

o

rN

iDo

EE

at

oo

fe StQdo<.n@r@

frtrtrdddtr&

d

qt

:€,

,2

.

q,

o

rnE

4,=

o;

b-E

t/t o

ul E'

s=

C{

(9

EI

E

ct

'

-t

Q'

6

:o

6

'=

€t

-ct

6

v!8

A=

v

4A

hs

Za

Os

r,l i

'Ft

\.

I

q,

a

E

!E

o''

F:

.:

o

k

C)

-' c)

OE

-oo

tro

LO

f,B

!o

EZ

o

o.

rD ru

zE

+z

?

g

o

g

rtl

c,

o

ts

I

G

I

o

tlt

x

u-

z

o

F

L

-

e,

(J

rn

tlt

o

o

z

=

Fl

o

&

ti

A

z

ID

:

*r*

Fg

(aE

Ee

?H

DFla

.--J

tt

F

c,

4

o-

=

r/t

c,

o

=

(J

il

I

o

tlt

x

l!

tt

c

o

E

I

4

I

I

t-

J

o

c

l-

(J

tlt

J

tlt

vt

llt

cl

o

o

J

z

I

l,I

06

vt

I

ut

-

IL

=

(,

llt

4

4

ul

3

o

4

rt!

tlt

to

f

F

TI

o

F

g

ttt

F

}9

F

6

F

z

u

=

u

U

I

A

U

d

!!d

o'

<t

C.d

A<

rrd ERFEEEFfiHFFqrf.;

HiigiiEEEE6HggEH*E

ai

o2

-{ts

=3

6O NN

H(o.O NN

O ONN dN

ltr :l|@O 6@

oioiiioiioooog9o

s>d::>6>E5ddsET9

P{H P{ tsl H f4 AHFI A P{ A F<A E A

uoo(5o(,o(J()o(,(5()(,0(J

Oc

Yz

UF

=:

uA

$ $NN NN

-d 6;dEd eili r

q;HiEEFiiEF++$ T

ari.ari clci aricia aaoa d,

848S4888888888 B

-rc c

dv2

z4

g:! €@ NN F

sd aEE EE ---*s

@$n$o@n@@t Fi.r.:'o@

*ggBBBEBBEEEEEET

Eo'l o oo l.l o o i "1Fl i'l X o

!A

JJ

<L

E--

6f 9?$NsNNTNN:a*:fi 9?

T???EE?SS??TFfi E

OEOrr@@A@oAAAAA A

aaooaaaoanaaoa n

!,

8?

<e

@@ NN F

si-i33 3E gi

A6EEEEaEEgegEEdE

HEaEEEadEaaaaaEE

,1,

!z

d

z

g

d

o

t

tr

&

o

oo oo a>

oo

o o€o dN

$H$@@ NN ET

8.18.18.q g qt g gEEFS 3.

Ei F@OOTNO:[email protected]€6rO<d

NNNOOOO@OOOOO:tr$<.

oooau()()oouu(.)(J()()()

ts

o

F

z

u

=

u

lJ

J

4

U

e

u;

o"

<F

ee

A<

U'4

6aO- @ @ O

@=@!:?O=O oO oOF= Oo

t?eqEfr td tE#q qe

HggHiiHti gii g*iiE Hg

FO

ilq

6u

AE

$@

TJ

oL

+ts

=3

;;

\)z

z-

qF

=t

uC

55 5 6

EE H*RAT*T fiE glq* ER

AU EOSsEUE 3E BsUg 33

$o;xseHsH =H =H$o rB

aeugeeeeea s**e**euee

-4eo

d9lz

z=

g:5 f,; EssHflgs Ef, EEf,3;e

6

<ci

<L

EL

=a

6.o Hg SgHHEgH Eg gEHg EH

lltllttttttttlttt

OA OnnOF.Ok QIr OFiOO OO

QO AaOAoea Aa aanh ci a

5e

8?

<G seE:Eea Fs egEe EE

aaaHEat aE;EEa Ed

r

oo

tt

zz

@@

o6

AF{

an

V

e

=

q

eN99N

!B T B B TIA

O+ O + + +OO

zzzz

o

z_

F

e3 in..E:a - FE. Fq- H ;.n iE

??e B ??? r? '':i 3':i S '':??E ??

E: @ F @ o) 9 =s 9s 99 = 99R FS R XRR

()(JC)UOOO()UAOOC)QOO()OOO()

F

6

F

z

U

2

U

(J

J

4.

q

4

Hct

o'

TE

a-<

OL

€ i o@

= ?o oo

i f ?F

Fl '1 <<

tr tr tr tr

ad

=z

{r

44

LC $ +rs

a ^ NN

= E AA

F. F E{E{

t_d

oL

+F

=s' fr nFep

3vt

qF-

sH5 @ 6 I on

-!-' i T 1't

* H HEE

ie d

dsz

&,68

gdf oo

6@

O!!

Y O = 66

H H HHH

F,

fi5

6

r

o.l

H (o X oo

! r - tf $

{ N N oo

E Ei r AA

F{ tr F< dd

co.

UO

3t

H3

lal a

2

(0@o

<{ $ 6 00

1 ! ! rt

Fl tsl H rrl F]

uoooo

o

z

F

d

i

ooooooo

@@6@n@.^.^oo

:l.Qr{lo{s==@6

4

uqqEe qeHEn *

#s

FZ llqon*tr*E*-

o o () ()L)

ar',

ll|

o

z,

<t

o

k

)

s

&

rll

g

a6' 3

EEE H

,:e- 6t

6bE:

Egg E

E*o 6

f;;; E

hU() n

tJ/

tn

t,

d,

=

se2

xEF o

tq

!n

o

o

<2.

(JF

e, e,

CL

o

o

o

6

e

-l

{rci

z,6z

gES

o

o

?11

>NN

P. fr t-.

=

-r^ O

6>>

5=E o

6

N

Ee dNo

XXX

o

=

=

.

ct)

a

z,

o

U

e,

t

(.)

&

a

(J

&

F

O

r

J

u

J

E

U

=

U

(J

I

x

u

E

r

o-

=

o

FF

XX

Nd

oo- 6

66!-6

()oq()

H HfiH

h

o

Ed,

=!H

Ei-ct < d,

EtxE

<-d;<

r"t 3r"

f?Ex

. _.Jl .

EHr B

d< o d

o- o o

Lla o L

A<dA

PAGE T7

F

a

o

z

-

d

=

3

o

I

ol

3

u

rtt

F-6

d,n

f:

_=

llr E

z6

Ed

sio

06f

o6

i! cd

22

o.=

<t

(Jeo

E

o

T

o

c

o

,E

=

ctl

:)

o

trl

z

J

J

trl

L/

92

o

tII

3

z

-

l-

z

o

(J

z

I

F

o-

-

c,

I

vl

tl|

o

o

z

F

vt

I

J

rr'l

F

c,

o-

G

Ea

;

4

o

l-

g!

vt

tlt

c,

t/t

o

tlt

t

EI

A

F

rn

ut

u,

3

l!

e

EI

=

o

a

c,

tll

=

E

o

t!

rt

z

c,

F

I!I

1!

e

rtl

o

\J

o

a

6

rll

d

li

Q)

{

z

a

F

e

&

U

V'

u

o

o

r45

ir

.. F ,3

" 53ibre

bnx- ! 6I .:

'Y#$fr8#gF

o

z

F

4

d

-OdNr

Y:OOOO

esFH****-

.?TOOOOOO@

d,d,i..l;lli-i

>>xycrd!4uci

U

:

z.o.o.o.o -o .Q -o -o o

ooooooooo

tcccE=dEd

XXYMXvVVo

6

r

o

z

6

o

E{^

oP

g.x

H iis

tr €Fl

rD Od

dal o

a &sE

_^e, E "l

!EEH

$#xFe

't >A -->

sehghl

x3 tA 5

fiESE?

d^ !/ cd'n o

#sgss

gt

BJ

(.)

}E

Ef $ssxEEs

H I I t I I -:

F).f.).'.).El

11 u)aa(h.Av) a

tg

z

F

c,

4

>,

p

E

o

o

o

h

ID

Io

u,C,e t,c.CZ

Q39-9.9.9r

=di;i;6

;Ft'''p

aa)V)rAU)./)l)

d* * -oe-o9

>=>E>>>

z

o

F

A

d

U

v,

q

6

€

d6,

s#

ro

^o

Hd

\k

tr14

oo

oo

h;{

oo

au)

!.4

oo

dl .l

kt<

F{Fr

tt

kk

oo

ht

dd

))

@@

,n

(J

-O

oL

E3

zoo

@6

o{l

go

6z

9?

frl a

z

frfr

tl

o6

It

HF.

a

u

e

n)

q

{

?g

aLd (JO

XV

oo

@@

u6

2=

ee

u

\U)

6ts

sd

e>

oo

oo

(o@

<t@

U

(,

z

F

U

J

6

zHs

oa

o6

@r

f;ci

tsz NO

>=

ts

6

F

z

g

{

q

(,

J

A

u

4

o

vrz

.n

a3

G

4

u

o

J

o

E

o

?

A

M

a

v7

D

go

(,

He

?z

EoE

=a

4

U

o

o

4

tll

o

N

{

o

g

t>

r

o

a

jd

8s

N

do

s3

trl

Ea

o3

PE

B<

A4

4

q

o

J

o

!

q

.n

r

o

I

fa

ltlI

h

o

tr

d, <b

d6 N

u

E(,

6

#s

>z-

v,

u

F

o

z

F

a

F

z

U

=

u

(J

J

4

u

e

c;

az

3-

e'av

F<A

z

&z

d=

d=

ol

F

6e

0L

Z*

ft

v)a

d

EZ

d

UF

=tc

tr

Eg

r.l-

FE

Ef 6

o

N

I

c

F

(}

z

F

d

ot

I

u

tn ts*

N< (9

(,

U

!,

E{<

irS

>o

o.

3@

e

e3q

,I(o

fi* t{

rn

q

ts

o

z

E_d

Ez-

IF

j3

.ci

gz

CL

oir

(;<

{

C,

oL

=

<d A

o

-7

Oq

{tc

rl

=

Oc;

oz

>,

l{L

2<

4

oI

o

c

llt

o

D

q)

o

o

o

ol

n

Ei Fl

EEEEEEE$EEHEEEEEE

ggHHXFgHgFEHSEHHH

ffE Ef ff38 tE tgEEg 3 E E

PAGE T8

This manual suits for next models

1

Table of contents