Guarantee/Service Policy

13 NEWTEAM SHOWER PUMPS

Guarantee

Thank you for purchasing a NewTeam product, which has been designed, manufactured and

tested, in the U.K., to the highest standards.

Guarantee. Varispeed 50 and Varispeed SI - 1 Year - Parts and Labour

Duraspeed, Duraspeed 2 and Singlespeed - 2 Years - (Second Year - Parts Only)

This guarantee applies to products purchased within the United Kingdom or Republic of

Ireland, but does not apply to products used commercially.

This is provided that:

1. The guarantee registration card is completed and returned within ten days complete with a copy

of proof of purchase.

2. The product is installed and operated in accordance with our instructions and has not been

misused or damaged.

This in no way affects your statutory rights as a consumer.

The information on the Guarantee card helps NewTeam to process any claims and contact you

about your product and its maintenance if required. The registration of your personal details is

purely for NewTeam use, and the other information helps us to make products for the future.

NewTeam Shower products are designed, manufactured and tested to the highest standards.

Should a complaint arise, products are guaranteed against faulty workmanship and materials for a

period of 12 months from the date of purchase, when in domestic use (second year guarantee is

parts only and only applies to Duraspeed, Duraspeed 2 and Singlespeed). For your guarantee to

be valid, your shower pump must be installed by a competent person, in accordance with the

instruction manual. Failure to do so will result in a service call charge being levied.

Home visits are made between 8.30am and 5.00pm Monday to Friday. Visits may be available

outside these hours at our discretion, in which case a premium will be charged.

NewTeam will repair or replace (at our option), free of charge, any faulty components during the

guarantee period, provided it has been maintained and operated in accordance with our

instructions, and has not been misused or damaged.

Modification or repair of this product by person(s) not authorised by NewTeam will invalidate this

guarantee.

This guarantee does not affect your statutory rights.

Service Policy –Replacement Parts Policy

IMPORTANT:

In the event of product or component malfunction, DO NOT tamper with or remove the

product from site. Telephone NewTeam Customer Service Department on 01536 264 012 and be

prepared with the date of purchase, model number and a description of the complaint.

Our service staff are fully qualified to advise on correct installation procedures and will be able to

diagnose whether the fault will require a replacement part or a visit from a NewTeam engineer.

If required, a service call will be booked, and either yourself or an appointed representative (who

should be a person of 18 years or over) must be present during the visit.

All site visits to product within the guarantee period will be carried out free of any parts or

labour charges provided the conditions of the guarantee have been adhered to. (Second year

guarantee is parts only and only applies to Duraspeed, Duraspeed 2 and Singlespeed.)

All site visits to product out of guarantee will be subject to charges for parts and labour which is

payable by you or your appointed representative at the time of the visit. Charges will also be levied

on cancelled appointments, unless advised to NewTeam at least 24 hours in advance of the agreed

date and time.

We reserve the right not to undertake work where payment cannot be made to our engineer at the

time of the visit.

NewTeam hold stocks of components for all their range of products and these will be

maintained for the duration of their life.

Should a product be discontinued, spare parts stocks will be maintained, but in the event of a part

becoming unavailable NewTeam reserve the right to supply a substitute of equal quality.

The following payment methods can be used to obtain spare parts:

By post, pre-payment of proforma invoice by cheque or postal order.

By telephone quoting credit card (Mastercard, Visa or Visa Delta) details.

Part No. 404-0131 05/04

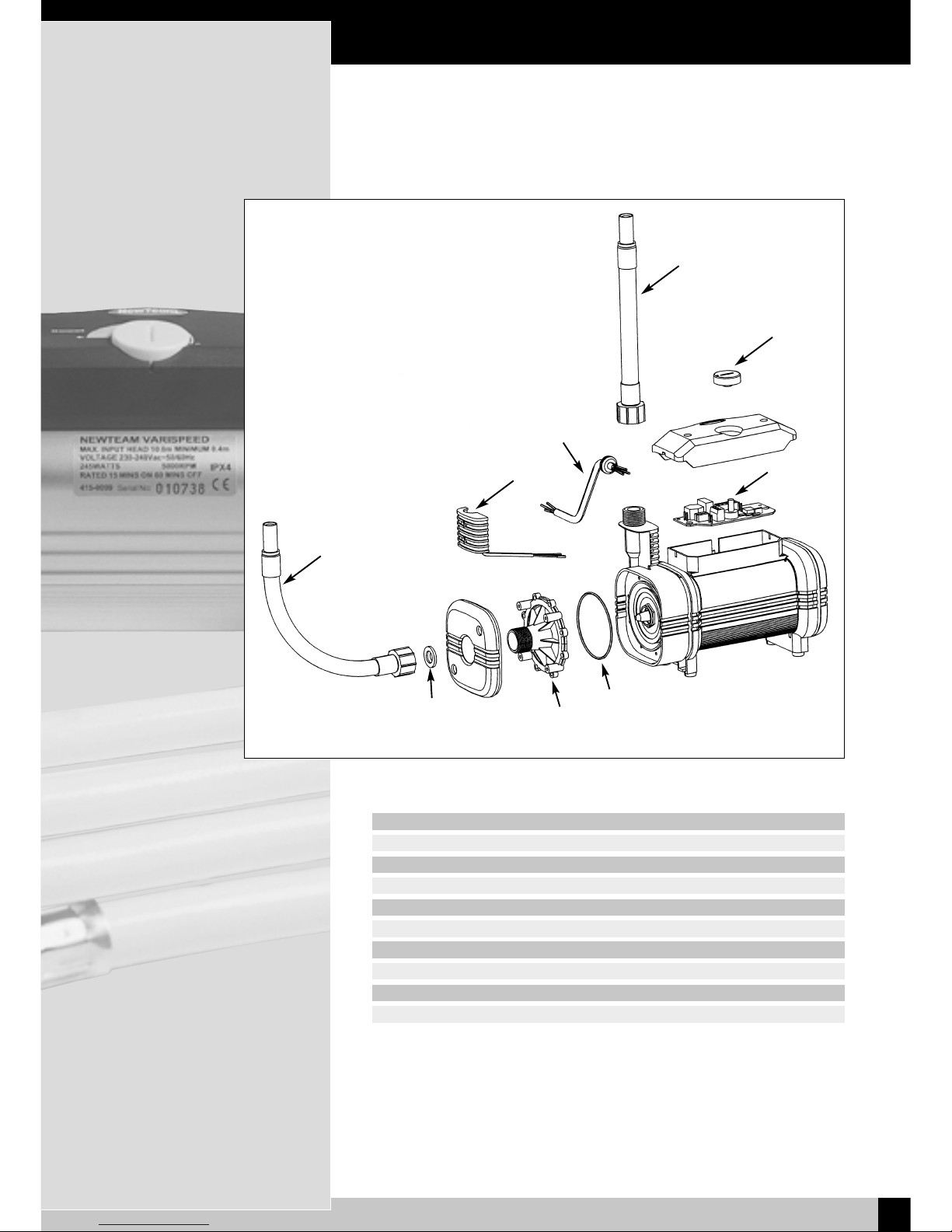

REPLACEMENT PARTS:

CUSTOMER SERVICE HOTLINE: