About NexSens Technology, Inc.

NexSens Technology, Inc. was founded in the late 1990s with a mission to advance the capabilities and

simplify the development of environmental monitoring systems. The company specializes in

environmental sensors, remote data acquisition and communications technology, easy-to-use computer

software, and web-based datacenters.

iChart Software is an easy-to-learn, easy-to-use Windows-based software program designed to interface

with the industry’s most popular environmental monitoring sensors and systems. A large, multi-vendor

instrument library makes setup quick and easy. iChart automates much of the tedious programming,

data collection, and manual data processing common with other environmental data collection systems.

The SDL500 (Submersible Data Logger) and iSIC (Intelligent Sensor Interface and Control) are state-of-

the-art data loggers that simplify the collection of real-time data from environmental sensors and

monitoring instruments. The data loggers support multi-vendor sensor connections and are specifically

designed for environmental data monitoring.

WQData LIVE is an enterprise class and business critical web-based software solution for environmental

data management. It assists with collecting, storing, analyzing, interpreting, sharing and publishing

environmental data. The datacenter effectively manages a wide variety of biological, physical, and

chemical parameters, along with many other environmental observations and project information.

Smart USB-based WQ Sensors include: Temperature, pH, ORP, Dissolved Oxygen, Ammonium, Bromide,

Calcium, Chloride, Fluoride, and Nitrate. An integral USB connector on the sensor cable offers a simple,

hassle-free connection to a computer without the need for a meter or batteries.

T-Node FR temperature systems, based on RS-485 Modbus technology, provide a simple, yet effective,

plug-and-play solution for developing multi-sensor networks and temperature strings. The T-Node FR

offers pass-through signals for SDI-12 and RS-485, allowing the user to connect Nodes and other

environmental measurement sensors along a string. This sensorBUS architecture has been designed so

researchers can easily build and customize multi-point temperature strings for more powerful

environmental monitoring networks.

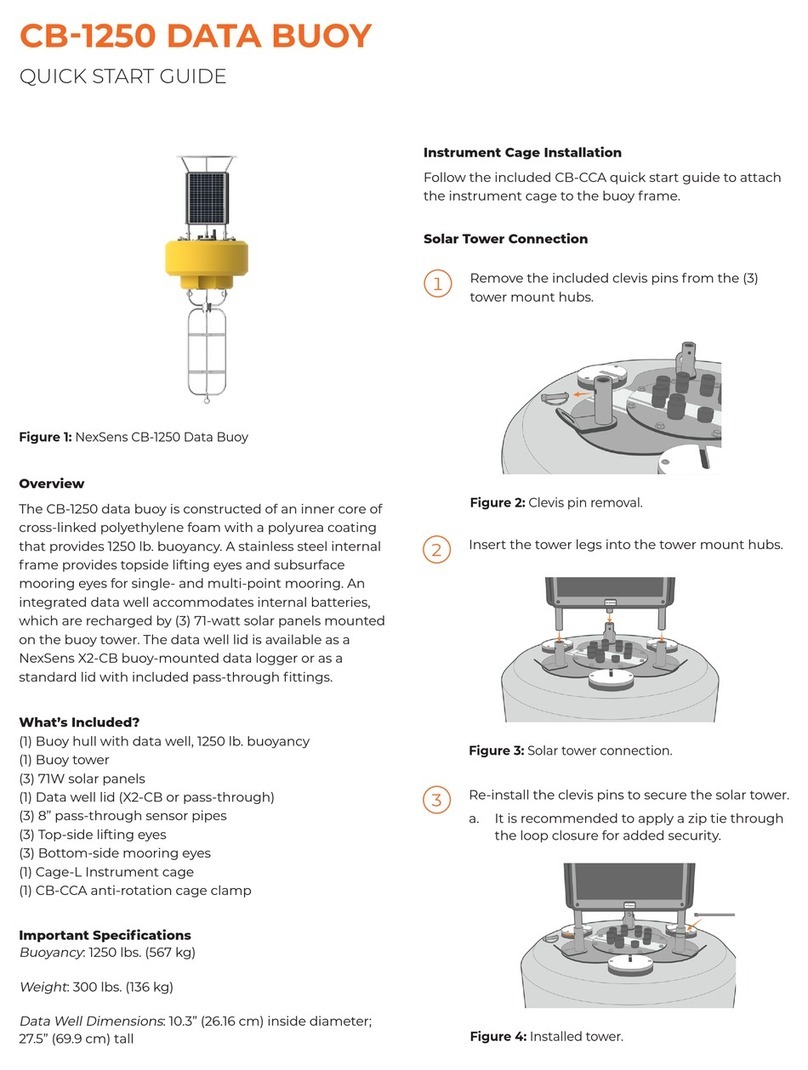

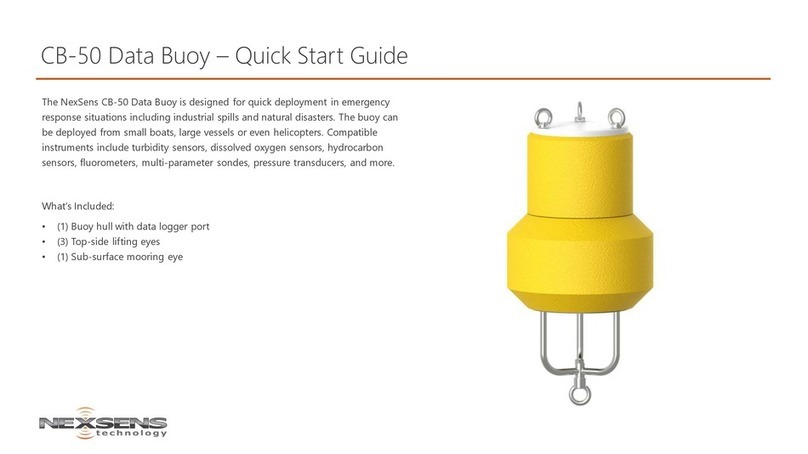

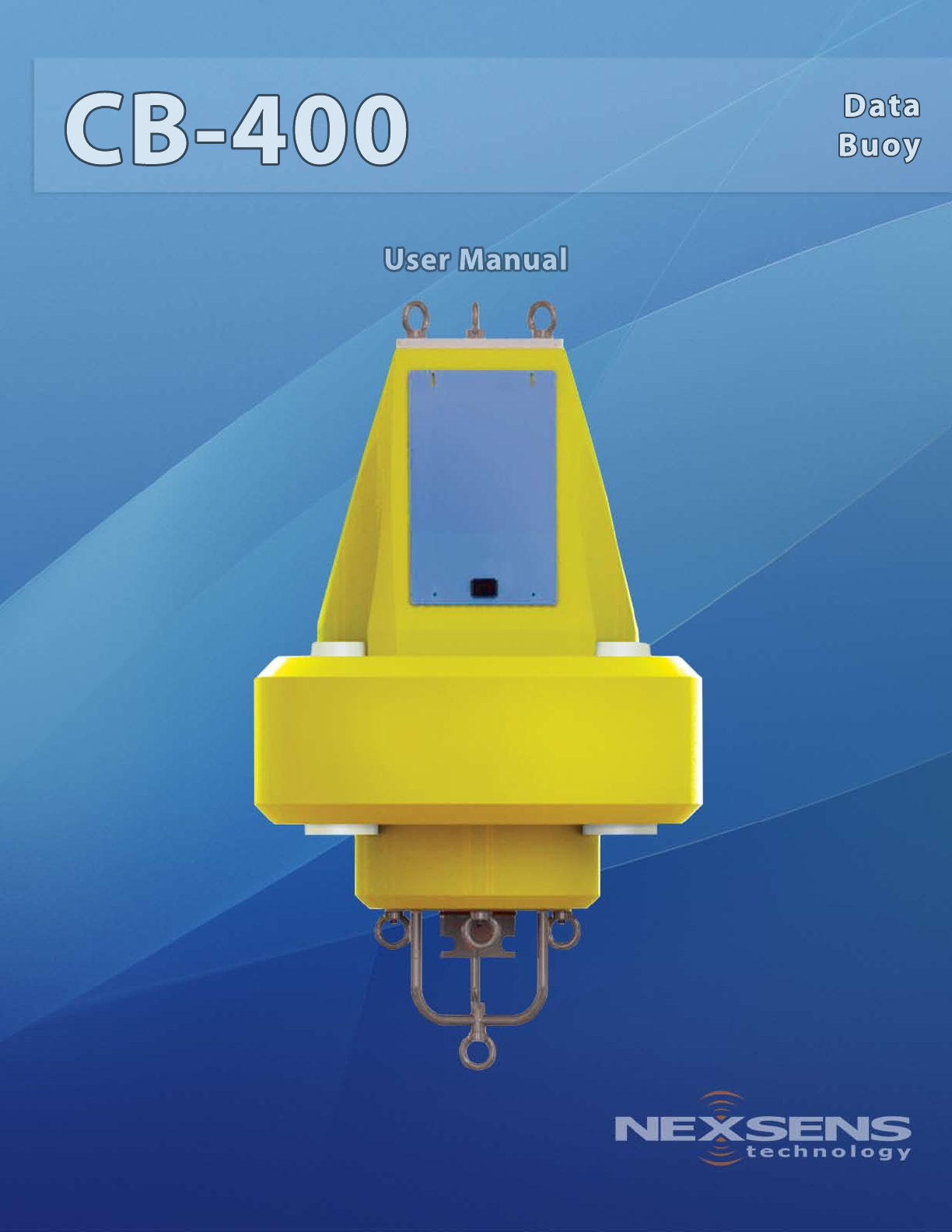

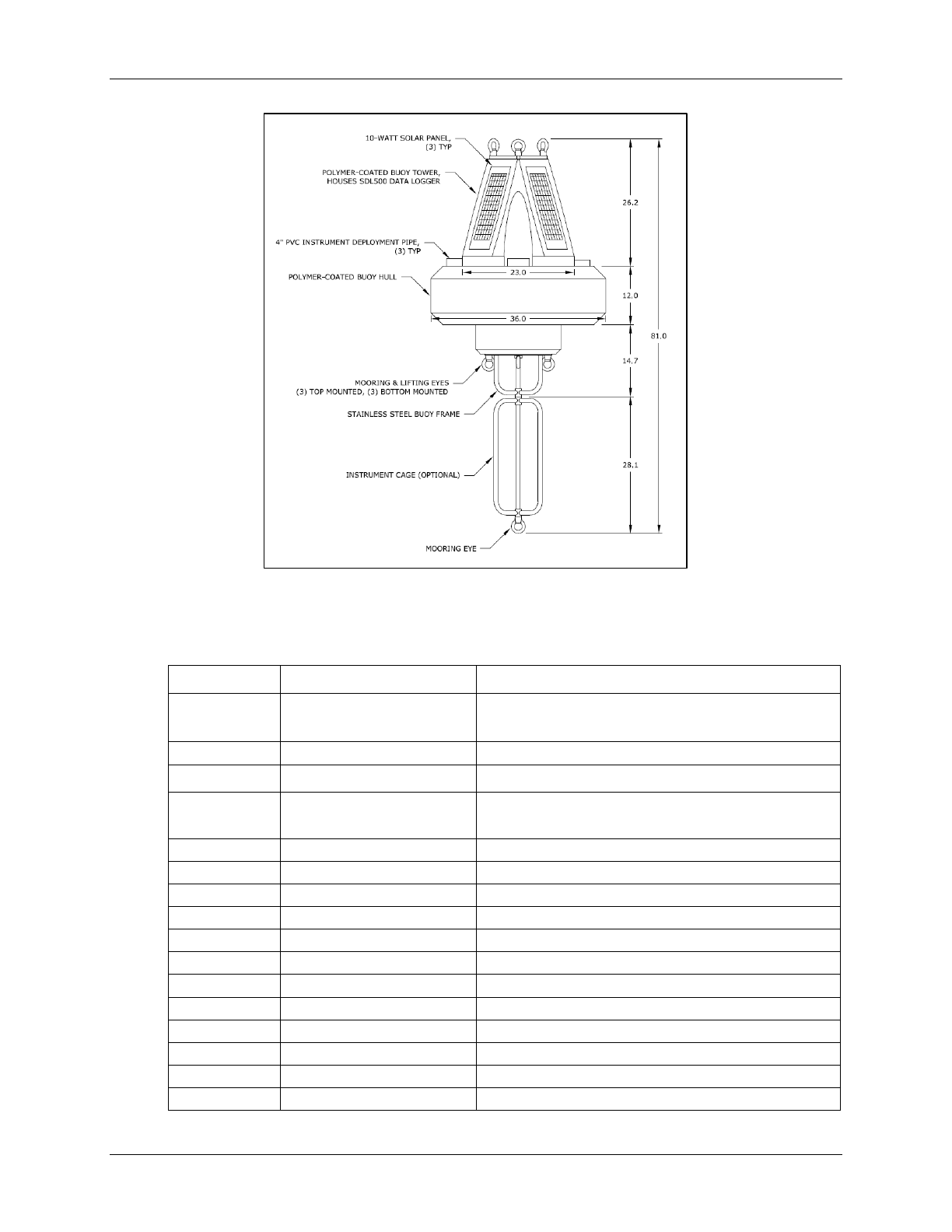

Coastal Buoys are designed to support offshore monitoring systems. These buoys provide a robust

floating platform for coastal water or lake monitoring projects.

NexSens products and systems simplify the setup and operation of environmental monitoring networks

and help ensure quality data.