NextGen DB-1 User manual

DB-1 DI-Boost Pedal Kit

(V1.0-2020)

INSTRUCTIONS

This DB-1 DI-Boost Pedal Kit by Next Gen Musical Ltd. is a boost pedal at its core that

can also be ade into a 70's style distortion pedal. It contains instructions for both

configurations, as well as so e advanced distortion odding discussion. It was originally

designed by To Free an of To Free an Audio Effects, a Canadian pedal aker.

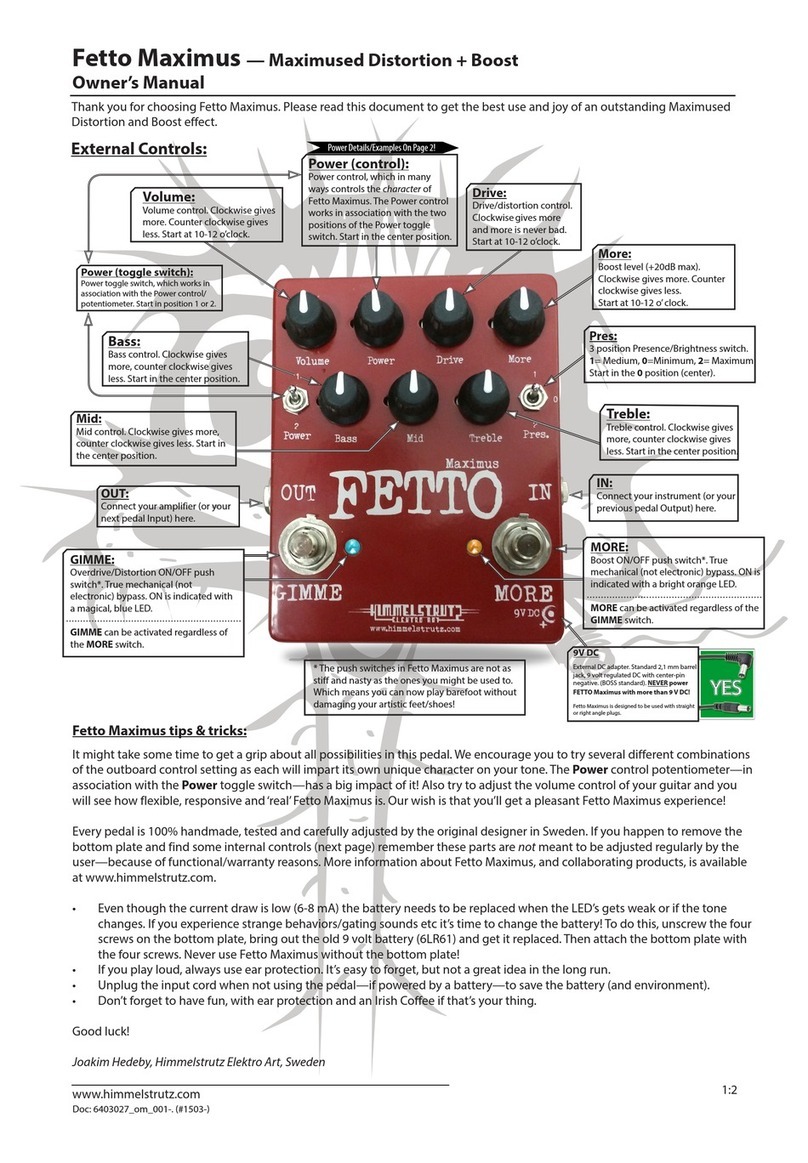

BOOST CONFIGURATION

As a boost pedal, the level control is a clean control that can reduce volu e or add a

slight clean boost. The gain control increases the volu e significantly, and introduces a little

grit as it's turned up past 12 o'clock. We suggest running it with the level axed, and the gain

to taste for the a ount of boost you want.

Using an op-a p as the core of the circuit, the pedal can be powered by up to 18V.

The higher the voltage used to power the pedal, the ore clean volu e there is available

before it gets gritty. Note that when built in the "boost" configuration, this is NOT a high gain

pedal. Even with the gain axed out, it adds very little grit to the signal on its own. Boost

pedals are used to overdrive your a p's tubes, or to increase your level a bit for things like

solos.

DISTORTION CONFIGURATION

As a distortion pedal, it's very raw sounding with a lot of attack, si ilar in design to the

classic MXR Distortion+ and Ross Distortions. We have added an advanced odification and

experi entation section that describes how you can experi ent to find the perfect distortion.

Depending on your choice of co ponents, it can be anything fro a subtle distortion to a high

gain onster. See the distortion od section for details, if you're brave enough.

Page 1

TABLE OF CONTENTS

Page 3-4 Kit Contents

Page 4 Reco ended Tools

Page 5-6 PCB Soldering Tips

Page 7 PCB Co ponent Layout

Page 8-15 Pedal Asse bly Instructions

Page 8 - Written Instructions

Page 11 - PCB - Boost Configuration Photo Guide

Page 12 - PCB - Distortion Configuration Photo Guide

Page 13 - Enclosure Asse bly Photo Guide

Page 14 - 3PDT Footswitch Wiring

Page 15 - Finished Product Photo Exa ple

Page 16 Advanced Distortion Modding & Experi entation Discussion

Page 19 Sche atic

Page 20 Basic Troubleshooting

Page 2

KIT CONTENTS

MAIN CONTENTS

PCB's:

1x - Next Gen DIY Kits DB-1 PCB

Resistors:

1x - 100Ω 1/4W Metal Fil Resistor

2x - 1KΩ 1/4W Metal Fil Resistor

2x - 4.7KΩ 1/4W Metal Fil Resistor

3x - 100KΩ 1/4W Metal Fil Resistor

3x - 2.2MΩ 1/4W Metal Fil Resistor

Capacitors:

2x - 0.1uF Polyester Fil Box Capacitor (25V ini u )

4x - 4.7uF Electrolytic Capacitor (radial lead; 25V ini u )

1x - 47uF Electrolytic Capacitor (radial lead; 25V ini u )

1x - 100uF Electrolytic Capacitor (radial lead; 25V ini u )

Diodes:

1x - 1N5817

1x - 5 LED (red)

ICs:

1x - TL072

1x - IC Socket

Potentio eters:

2x - A100K Alpha Mini Solid Shaft Pot (Right Angle PCB)

Jacks & Switches:

1x - Switchcraft #11 Mono Jack

1x - Switchcraft #12B Stereo Jack

1x - Pre iu 3PDT Footswitch

1x - Pre iu External DC Jack (2.1 )

Hardware & Wire:

1x - Ha ond 1590N1 Enclosure

1x - 9V Battery Clip (holder)

1x - 9V Battery Snap

1x - 5 LED Bezel

2x - Knobs for Pots

1x - Bundle of hookup wire (2' black; 2' red, 2' green, and 2' blue)

1x - Set of Adhesive Rubber Feet

Page 3

*ADDITIONS FOR DISTORTION CONFIGURATION*:

1x - Capacitor - 47pF Cera ic Disk Capacitor (25V ini u )

1x - Capacitor - 470pF Cera ic Disk Capacitor (25V ini u )

1x - Capacitor - 4.7nF Polyester Fil Box Capacitor (25V ini u )

1x - Capacitor - 47nF Polyester Fil Box Capacitor (25V ini u )

1x - Capacitor - 1uF Electrolytic Capacitor (25V ini u )

2x - Capacitor - 2.2uF Electrolytic Capacitor (25V ini u )

4x - Diodes - 1N914

1x - Potentio eter - A250K Alpha Mini Solid Shaft Pot (Right Angle PCB)

2x - Resistor - 10KΩ 1/4W Metal Fil

1x - Resistor - 2.2KΩ 1/4W Metal Fil

1x - Resistor - 220Ω 1/4W Metal Fil

RECOMMENDED TOOLS

•Soldering iron

◦Preferably one that can reach and aintain 350°C (digitally controlled is ideal)

◦S all flat tip is preferred, but a pencil tip will also work

•Solder station (with a da p sponge and steel wool)

•Solder (flux/rosin core; 22 gauge or thinner)

◦63/37 "eutectic" solder is easiest to work with and provides excellent long ter

reliability, but 60/40 will also work

•Solder braid (or a de-soldering pu p)

•Wire stripper

•Needle nose pliers

•Wire cutter

•Adjustable wrench

•Electrical tape, or heat-shrink tubing and heat gun

•Phillips head screwdriver

•A digital ulti eter that can easure continuity, resistance, capacitance, and voltage.

•A clean, well organized work surface with plenty of ventilation

◦Solder fu es are very hazardous to your health. Avoid breathing in the fu es.

Page 4

PCB SOLDERING TIPS

These instructions assu e that you are already fa iliar with basic soldering technique

and aintenance. Wiring electronics can be tedious work. It's i portant to take your ti e

and follow good soldering procedures to ensure a solid joint at each connection. This not only

ensures long ter reliability for you to enjoy the fruits of your labour, but it helps avoid any

hours of potential frustration while trying to figure out why your pedal isn't working.

Assu ing your soldering iron is clean, well aintained, and that it's up to te perature

and pre-tinned; Follow these steps to ake a good solder joint ounting a co ponent onto a

PCB:

1. Bend the leads of the co ponent you're installing just outside the body of the part, not

at the body. This helps avoid potentially da aging the casing of the part you're

installing (this is especially i portant with diodes.)

2. Push the leads through the holes so they co e out the other side, and then bend the

outwards slightly so the co ponent can stay in place on its own.

3. Make the solder joint:

a) Touch the soldering iron to the pad on the PCB and the lead of the part you're

installing (at the sa e ti e) and hold for 2-4 seconds. This will heat up the pad

and the lead for the solder to flow easier.

*Always take care to avoid making contact with any solder joints already soldered to

the board. Doing so will cause a solder bridge between the two pads, which will

prevent the pedal from functioning correctly.*

Page 5

b) Flow so e solder onto the lead and pad (not directly to the soldering iron) and

continue holding the soldering iron in place for another 1-2 seconds. This allows

any re aining flux/rosin to burn off, and for the solder to flow through to the other

side of the pad.

*Do not hold the soldering iron in place for too long, as this may damage the

component or the PC .*

c) Re ove the soldering iron. The result should be a s all bead of solder with a

irror-like sheen that flows through to the other side of the PCB pad. The picture

shows a little ore flow-through than needed. You just want it flowing through to

the other side to ensure a strong and stable connection.

4. Clip off the re aining co ponent leads or excess wire. Keep it aside for PCB ju per

wire aterial.

5. Clean and re-tin the iron as needed. So e do this between every joint, which ay be

needed for a beginner who is taking a lot of ti e between joints.

Page 6

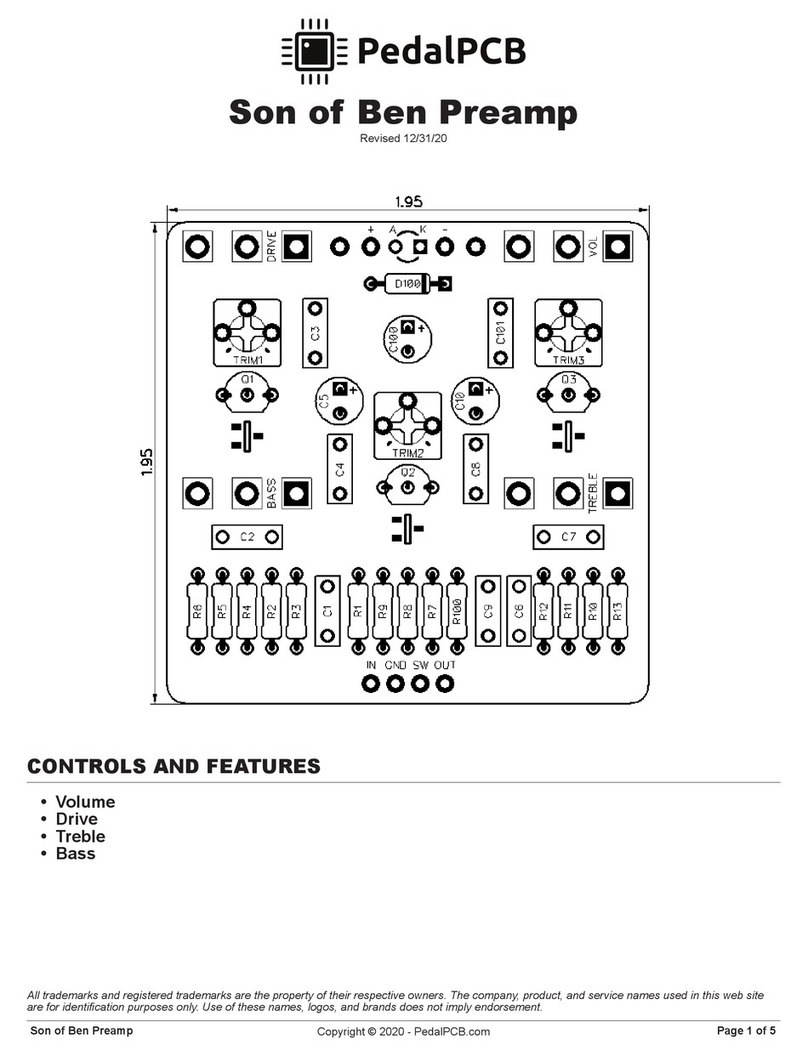

PCB COMPONENT LA OUT

Location Boost Distortion

C1 100uF Electrolytic 100uF Electrolytic

C2 0.1uF Polyester 0.1uF Polyester

C3 47 uF Electrolytic 47uF Electrolytic

C4 OMIT 470pF Ceramic

C5 0.1uF Polyester 47nF Polyester

C6 4.7uF Electrolytic 1uF Electrolytic

C7 OMIT 47pF Ceramic

C8 4.7uF Electrolytic 2.2uF Electrolytic

C9 OMIT 4.7nF Electrolytic

C10 4.7uF Electrolytic 4.7uF Polyester

C11 4.7uF Electrolytic 2.2uF Electrolytic

D1 1N5817 1N5817

D2 OMIT 1N914

D3 OMIT 1N914

D4 OMIT 1N914

D5 OMIT 1N914

GAIN A100KΩ Pot A250KΩ Pot

VOLUME A100KΩ Pot A100KΩ Pot

R1 100KΩ 100KΩ

R2 100KΩ 100KΩ

R3 4.7KΩ 4.7KΩ

R4 2.2MΩ 2.2MΩ

R5 1KΩ 10KΩ

R6 2.2MΩ 2.2MΩ

R7 1KΩ 2.2KΩ

R8 4.7KΩ 220Ω

R9 JUMPER WIRE 10KΩ

R10 2.2MΩ 2.2MΩ

R11 100Ω 100Ω

R12 100KΩ 100KΩ

IC1 IC SOCKET IC SOCKET

Page 7

ASSEMBL INSTRUCTIONS

The PCB:

1. Open the kit package and confir all contents are present as listed in the KIT

CONTENTS.

2. Be sure to start with a clean and well organized workstation that is static-free.

3. Asse bly of the PCB usually starts with the shortest co ponents and ends with the

tallest. This is for ease of asse bly. We reco end this order:

a) Resistors & Ju per Wires (ju per wires can be actual wire, a very low value

resistor, or the clipped off lead fro another co ponent used in place of a wire)

b) Diodes (be sure to place the in the proper orientation; the line on the co ponent

should be on the side of the line on the PCB)

c) IC Sockets (be sure to place the in the proper orientation; the gap and/or dot on

the socket should line up with the gap and/or dot on the PCB)

•IC's the selves are not generally soldered directly to the board as they are

highly susceptible to heat da age. Instead, an IC socket should be used. To

install the IC, carefully position the legs into the sockets with the correct

orientation, then apply flat even pressure to the top of the IC until it's all the way

down. You ay need to bend the legs inward slightly to get the to slide into

the socket initially.

d) Tri Pots (not in this kit/build)

e) Non-polarized Capacitors (Mylar, Fil Box, Cera ic, etc.)

f) Transistors (not in this kit/build)

g) Press-fit IC's into their respective sockets (be sure to place the in the proper

orientation; the gap/dot on the IC should be on the sa e side as the gap on the

socket)

Page 8

h) Electrolytic Capacitors (be sure to place the in the proper orientation; the longer

leg is typically the positive lead)

i) Potentio eters (you can break off and discard the extra little tab on the side of the

pot's body using a pair of pliers before installing)

4. Using the PCB COMPONENT LAYOUT as a guide, position and solder the proper

co ponents into place one at a ti e, following the SOLDERING TIPS provided. You

can follow along with the photo exa ples provided in the next section.

5. Once the PCB is fully populated, set it aside and proceed to the next stage.

The Enclosure:

1. In this order, ount the LED holder ( etal part only), DC jack, footswitch, and audio

jacks into the enclosure.

2. Wire up the footswitch and audio jacks for true bypass by cutting the appropriate length

of each colour wire, stripping the wire ends back by approxi ately 1/4", and hooking

the wire around each intended lug. DO NOT solder yet.

a) Test signal flow with your ulti eter. There should be continuity between the

hot/signal lugs of each jack. There should be continuity between the ground lugs of

each jack. There should be NO continuity between a hot/signal lug and a ground

lug. Upon a successful test of the bypass wiring, solder each of the prepared

connections.

3. Place the LED through the s all plastic support piece of the LED bezel. Bend both

legs and attach hookup wire to each lead. Red goes to the longer lead, black to the

shorter lead. Solder the wires into place on the LED and clip off the excess leads. You

ay choose to add electrical tape or heat-shrink to these joints.

4. Push the LED into place within the LED holder and solder the negative/black lead to

the designated lug on the PCB based on the picture provided. Solder all re aining

wires to the jacks and footswitch as per the pictures provided. Make sure each piece

of hookup wire is at least 2 inches long. Do not solder anything to the PCB yet.

a) Battery Snap = Black wire to Input Jack (sleeve lug). Red wire to DC Jack ( iddle

lug).

You can ignore the battery snap and battery clip if you don't plan to add battery

capability. attery is not included.

5. Grab the PCB and begin connecting the hookup wires fro the ounted hardware to

the appropriate pads on the board. Start with the DC jack and LED, then ove on to

the re aining wires on the footswitch.

a) DC Jack = Red wire to PCB(J1-DC). Black wire to PCB(J1-GND).

b) LED = Red wire to PCB(LED1-A).

c) 3PDT Footswitch Wires = Follow the diagra provided.

Page 9

6. Once everything is connected, you can then ount the PCB by sliding the pot shafts

through the holes in the enclosure and attaching the washers/nuts on the other side.

Just be careful to keep the loose wires out of the way of the pots.

7. You're done (hopefully)! Connect the appropriate power supply or 9V battery, then

plug in and test your pedal. If everything is connected correctly, it should function as

expected. The LED should go on when the pedal is on, and off when the pedal is off.

LEVEL should increase and decrease the volu e. GAIN will also i pact volu e, but

should also increase and decrease the a ount of "grit" introduced (especially in the

distortion configuration).

If you bought this kit with an unfinished enclosure, now would be a good ti e to re ove the

jacks, switch, and PCB to do any painting/finishing of the enclosure. Then re-asse ble, add

the adhesive rubber feet to the botto plate, congratulate yourself on a job well done, and

ROCK OUT!

If something is not functioning correctly, proceed to the ASIC TROU LESHOOTING

section.

Page 10

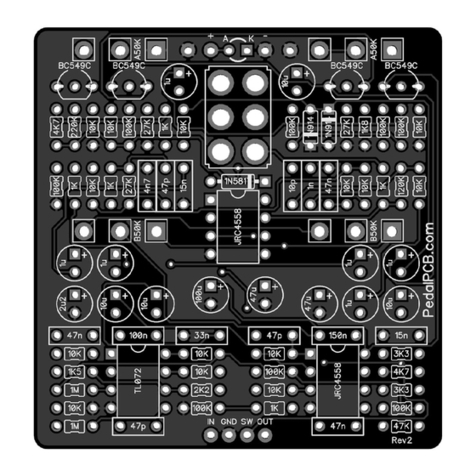

PCB - BOOST CONFIGURATION (photo guide)

E pty PCB - 1 Resistors Added - 2

Diodes Added - 3 IC Socket Added - 4

Fil Box Caps Added - 5 Electrolytic Caps Added - 6

IC Pressed Into Place - 7 Potentio eters Added - 8

Page 11

PCB - DISTORTION CONFIGURATION (photo guide)

Resistors Added - 1 Diodes Added - 2

Cera ic Caps Added - 3 IC Socket Added - 4

Fil Box Caps Added - 5 Electrolytic Caps Added - 6

IC Pressed Into Place - 7 Potentio eters Added - 8

Page 12

ENCLOSURE ASSEMBL (photo guide)

LED Bezel Added - 1 DC Jack and Footswitch Added - 2

1/4" Jacks Added - 3 True Bypass Wiring Done - 4

LED Preparation - 5 Co pleted Enclosure Wiring - 6

Page 13

3PDT FOOTSWITCH WIRING

(1)

Black to LED

(4)

Green to Input

HOT

(7)

Blue to PCB

13-OUT

(2)

Black to Input

GND

(5)

Green to PCB

12-IN

(8)

Blue to Output

HOT

(3)

Black to PCB

13-GND

&

Ju per to Lug 2

(6)

Black to Output

GND

&

Ju per to Lug 3

(9)

Ju per to Lug 4

Page 14

FINISHED PRODUCT

Page 15

ADVANCED DISTORTION MODDING & EXPERIMENTATION

*Parts and components mentioned in this section are not provided in the kit.*

The default values in the PCB COMPONENT LAYOUT table are a good starting point

for a fine distortion pedal. However, you can do a lot to further odify the sound to your liking

if you go beyond the basics. Many of the concepts discussed in this section can be applied to

other si ilar distortion circuits, though the actual part locations ay vary.

How Distortion Pedals Work (in layman's terms):

The two stages in a distortion circuit that interact ost to deter ine the a ount and

character of your distortion are the gain stage and the clipping stage. The gain stage co es

before the clipping stage, and is essentially a volu e boost. It increases the level of the

signal it receives. It increases everything it's fed, including loud playing, soft playing,

background noise, etc. Here's what it looks like in the sche atic, and what it's affect is via a

wavefor exa ple:

Most people associate "gain" with the gritty/fizzy/crackly sound that is introduced as

you turn up the "gain" knob on ost a ps and pedals. However, that gritty sound is actually

the result of the clipping.

The clipping stage, which co es after the gain stage, is where that newly louder signal

is then "clipped", reducing the peak level of the signal. To our ears, those clipped peaks

sound like little crackles and pops, and they happen so fast that it turns into that gritty/fizzy

sound we call distortion. Here's what it looks like in the sche atic, and what it's affect is via a

wavefor exa ple:

Page 16

The ore the signal is clipped, the less clarity each note has and the ore grit you'll

hear. The signal can be clipped at any levels and in any ways, all i pacting how it

sounds to our ears. This distortion circuit uses diodes to clip the signal. The point at which

they begin to clip is rated by their forward voltage. Diodes with a lower forward voltage will

begin to clip sooner than diodes with a higher forward voltage.

Finally, the "level" control in ost distortion pedals typically co es after the gain stage

to control the volu e of the fully clipped signal. Think of it like a aster volu e control for the

pedal.

Understanding these parts of the circuit, you can understand just how interactive the

gain and clipping stages can be. The hidden dance going on underneath your foot. Moderate

gain with less clipping will leave you with a ore dyna ic result, where quieter playing won't

get clipped as uch as louder playing (quiet parts sound cleaner, louder parts sound grittier).

Increase the gain or the a ount of clipping, and you'll lose those dyna ics, leaving a ore

consistent distortion like that of a rock/ etal sound. Different levels of gain and clipping will

sound different, and this is where pedal tinkering can quickly turn fro a hobby into an

obsession.

*Please note: Even the best PC s aren't meant to be soldered/de-soldered/re-soldered

over and over again and can become damaged when overused. If you plan on

experimenting a lot by adding and removing components multiple times in the same

location, just be aware that you do run the risk of irreparably damaging the PC . So,

please take caution.*

Modifying the gain and clipping stages:

By default, the distortion configuration of this circuit gives you a oderate a ount of

gain and clipping, si ilar to so e of the classic distortion pedals. You can do an awful lot to

the character of this distortion by using different co binations of gain pot values, diode types,

and the diode arrange ent in the clipping section. The options are nearly li itless, but here

are the broad strokes:

1. GAIN = A250K (experi ent with A100K up to A500K)

The potentio eter's resistance is pri arily what i pacts the a ount of gain in this

circuit. A100K won't add too uch gain, where as, A500K will ake it a high gain

onster.

2. D2-D5 = 1N914 (experi ent with other diodes)

The stock 1N914 diodes in this kit are the " iddle ground" of clipping diodes, with a

forward voltage of ~630 V. You can try BAT41 or 1N34A diodes for a little ore

clipping (~350 V). Or, go the opposite way and replace the clipping diodes with

LEDs (~1400-1600 V, depending on the colour.) Co bine those changes with

changing the pot values to taste. You ay want ore gain (A500K pot) if you use

LEDs in the clipping section, or less gain (A100K pot) if you use diodes with a lower

forward voltage. The shape that the signal is clipped also varies between the

different types of diodes. Silicon is sharp/harsh. Ger aniu is softer. LEDs have

a nice crunch, but require ore gain. Experi enting with these factors alone can

keep a builder/ odder busy for years finding the sweet spot that hits their ears just

right.

Page 17

3. D2-D5 (experi ent with diode arrange ent)

By default, the distortion configuration of this circuit uses 2 diodes per side. This

arrange ent is called "sy etrical clipping", because it clips both sides of the

wavefor equally. However, you can try different clipping arrange ents. Co bine

changing the arrange ent with using different diodes in different positions, and

you'll be busy for a while. Here are so e exa ples of different arrange ents in a

sche atic, and what the happens in each exa ple via a wavefor :

Tone Shaping By Changing Capacitor Values:

1. C9 = 4.7nF (experi ent with 0.001uF up to 0.01uF)

This is the final post-clipping high frequency roll-off in the circuit, which eans it's

the first place to go to odify the treble response. This reduces the unwanted high

end fizz/hair fro the final output of the distortion circuit, like a fixed tone knob.

Increasing the value of this capacitor will bleed ore high end to ground, leaving

you with a darker tone.

2. C4 = 470pF (experi ent with 470pF up to 0.01uF)

This cap's pri ary function is to reduce unwanted RF (radio frequencies) fro the

signal. It also helps to reduce ESD (electrostatic discharge.) When solely used for

those purposes, the value is generally quite s all. It can be as low as 22pF, or

even o itted co pletely in lower gain circuits. However, in higher gain circuits like

distortion pedals, pedal builders often use this as a place to shape the high end

before it hits the gain and clipping stages. Increasing the value of this capacitor will

bleed ore high end to ground, leaving you with a darker tone.

3. C5 = 47nF (experi ent with 0.01uF up to 0.1uF)

This is the coupling capacitor. It blocks potentially dangerous DC voltage fro the

signal and reduces pops and clicks when turning the pedal on and off. However, it

can also i pact the low frequencies that reach the gain stage of the circuit. Having

too uch low-end prior to the gain stage can produce undesirable results (very

uddy/ uffled tone.) Try lower values for tighter bass and higher values for thicker

bass.

4. C7 = 47pF (experi ent with 22pF up to 100pF)

This cap provides stability in the feedback loop of the IC. It bleeds extre ely high

frequencies to ground so they aren't a plified when you turn the gain knob up.

Increase the value to bleed ore high frequency to ground. However, going too

high here can really kill the clarity, so don't go crazy.

Page 18

SCHEMATIC

Page 19

BASIC TROUBLESHOOTING

If you've built your pedal and so ething isn't working, you now get to experience the

true joy of aking/ odding things that all of us have experienced: Troubleshooting to figure

out what went wrong. Get your ulti eter handy, you ay need it.

*Please note: If you contact us for troubleshooting assistance, we can only take you

through the troubleshooting steps we've already provided in this document. If you've

completed these steps and still can't get your pedal working, try posting about it on

our Facebook group, DIY Musicians Canada. If the group is unable to assist, in-person

assistance from a local tech may be required at your own expense.*

Pedal doesn't turn on:

1. The ost co on reason for this is a bad power supply. First thing to do is check that

the correct type of power supply is connected to the pedal. It's designed for the

standard 9V pedal power supply with a center negative (though up to 18V can be

used). This pedal draws <10 A and ost power supplies do 300 A or ore, so that

shouldn't be an issue.

a) If running on a battery, ake sure your battery has juice. Set your ulti eter to

read DC voltage, and put one lead on each battery ter inal. You should be reading

~9V (+-10%). If you're reading significantly less than 8V, your battery is either

dying or defective and it should be replaced.

2. If neither of those are the issue... The issue is likely with the soldering or asse bly of

the pedal.

a) Using the photos provided, double check that all of your parts/co ponents are

connected in the right places, in the right orientation, and that the proper coloured

wires are soldered in the right locations. Check all of the , but pay particular

attention to the DC JACK, LED, BATTERY SNAP, and the PCB ter inals

associated with each of those.

b) Check that each of your solder joints have that nice irror-like finish, and that the

PCB solder joints flow through to both sides of the PCB pad.

c) Ensure that any parts of exposed wire are not touching anything but what they're

supposed to touch and that none of the PCB pads have solder flowing to an

adjacent pad by istake.

Pedal turns on, but there's no sound: (or there's intermittent failure, or something sounds

ery wrong)

1. First, you need to ensure that everything else in your signal chain is working correctly.

Take the pedal out of the chain and test your guitar into your a p using both of the

cables that were connected to the pedal. Wiggle the cable a little at the guitar and at

the a p to see if there are any inter ittent issues. If the guitar, a p, and both cables

are all working, only then can we take a look at the pedal.

Page 20

Table of contents