Nibco RHP-1 User manual

Installation and Operation Manual Radiant Heat Panel

1

RHP-1&2 0511

NIBCO®Radiant Panel

Models RHP-1 & RHP-2

Installation and Operation Manual Radiant Heat Panel

2

RHP-1&2 0511

Table of Contents

Cover Page 1

Table of Contents 2

Warning Symbols 3

Safety Warnings 4

Definitions 5

Introduction 6

Specifications and Restrictions 7

Panel Picture with Parts Legend 8

RHP Schematic 9

Installation Instructions 10-12

Control Sequence 13-14

Component Descriptions 15

Specifications 16

Thermostat Instructions 17

3/4” TMV Instructions 18-19

1” TMV Instructions 20-23

Pump Instructions 24-28

General Terms and Warranty 29

Installation and Operation Manual Radiant Heat Panel

3

RHP-1&2 0511

Warning!

The following symbols are used throughout this document. For your safety please pay attention.

Treated Water,

Do Not Drink

When used with a boiler, fluid in

panel is typical

of fluids found in boilers.

Not for human consumption or for

washing, cleaning or as a dilution

fluid.

Warning

Pay Attention, Health Hazard

Do Not Take Risks

Possible Dangers

If In Doubt, Contact

NIBCO INC.

Danger

Live Power

24 Volt and 110 Volt

Qualified Electrician Only

Do Not Touch

Danger

Explosion

Electrical sparks could

cause explosion.

Do not operate near

flammable substances

such as, but not

limited to:

Gas, Oils, Propane,

Solvents, Paints,

etc.

Do Not Touch

Hot Pipes, Corrosive Liquids

Scalding is Possible

Corrosive

High or Low pH

Do not store corrosives

near this panel

Safety First -

Always!

NIBCO shall not be responsible for errors in catalogs, brochures or printed materials. NIBCO reserves the right to alter its

products at any time without notice. All trademarks are property of the respective companies. NIBCO®PEX is a trademark

of NIBCO INC. All Rights Reserved.

Installation and Operation Manual Radiant Heat Panel

4

RHP-1&2 0511

Warning!

Safety First -

Always!

This product must be installed, used, stored and operated strictly in accordance with the terms set

out in this manual and in accordance with all laws, rules, codes and regulations of the jurisdiction

wherein the product is located. Failure to follow the terms set out in this manual, or the foregoing

laws, rules, codes or regulations may result in property damage, serious injury or death.

In the event this product is not installed by a qualified person, as defined herein, or in the event this

product is not installed, used, stored or operated in accordance with the terms set out in this manual

or in accordance with all laws, rules, codes or regulations of the jurisdiction wherein the product is

located, or in the event this product is repaired or altered without the written consent of NIBCO, any

and all warranties offered by NIBCO in relation to this product will be void, and NIBCO will not

be responsible for any direct or indirect damage to this product or to any other property, personal

injury, and/or death, regardless of whether NIBCO advised of the possibility of such damage, injury

or death.

WARNING SYMBOLS:

This panel contains electrical devices which could ignite flammable vapors. Do not connect power to,

nor operate this equipment in the presence of flammable vapors.

The heated fluid supplied to this panel could be hot enough to cause personal injury should skin

remain in contact with pipes. Do not mount this panel in any area or manner which could lead to

injury. Treat like any other boiler room equipment. Keep children away.

The power to be connected to this panel has dangerous capabilities with potential to cause fatal

injury. The capability to injure continues to exist whether the power is on or off. No persons should

attempt to connect, service, repair or alter this equipment. Only a competent electrician, qualified by

local jurisdictions having authority should connect power to the panel. It is the responsibility of the

person installing this equipment to provide proper grounding.

Improper handling and installation of this product may cause equipment failure, serious injury or

death. Follow this manual, National Electrical and Plumbing Codes and Local Codes.

Motors and valves mounted on this panel require continuous air circulation. Overheated equipment

will lead to premature failure.

This panel does not come with pressure control equipment such as a pressure relief valve or expan-

sion tank. This panel is only to be connected to a heating plant which contains safety devices.

Do not use petroleum based products in or on this panel. Damage to seals can occur resulting in

personal and/or property damage.

This product is not protected from freezing. In applications where freeze protection is required, use

antifreeze solutions suitable for hydronic systems such as 50/50 mixture of propylene glycol and

water. Installing contractor to meet all local environmental and plumbing codes governing backflow

prevention. With Glycol, use a stabilized type, a separate stabilizer, or change fluids annually to

avoid a buildup of corrosive glycolic acid. See note on Page 7.

Brass products such as the valves supplied with this product are adversely affected by media that

contain - or that during the process of treatment could develop, agents aggressive to brass. This could

include Ammonia, Mercury, Oxygen, Carbon Dioxide, and Chloride. Further, the pH-value of the

fluid in the hydronic heating system in contact with the brass products should not exceed 9.5 .

Neglecting the above restrictions may in some circumstances cause damage to the brass in the panel

allowing the heating fluid to escape, possibly causing damage to property and/or persons.

Installation and Operation Manual Radiant Heat Panel

5

RHP-1&2 0511

Definitions

ASTM

ASHRAE

American Society for Testing and Materials

American Society of Heating, Refrigeration and Air-Conditioning Engineers

BTU British thermal unit. A unit of measuring the amount of energy required to raise one pound of

water by 1°F.

Btuh British thermal unit per hour. The rate at which energy is transferred.

Circuit

CSA

Pipe that is connected from supply manifold to the return manifold.

Canadian Standards Assosiation

Design

Temperature

The temperature of the system needed to be maintained under extreme outside

temperature conditions.

Zone Area with one or more loops controlled by single thermostat.

RFH Radiant Floor Heating

Thermostatic

Control An internal mechanical element which reacts to temperature changes.

RHP NIBCO®PEX Radiant Heat Systems Panel Model RHP

USgpm Gallons (US) per minute of liquid flow.

UL Underwriter’s Laboratory

Thermostatic Non electrical temperature control

Heat Source A source of heated fluid for the RHP. This could be electric, gas, or wood-fired heat from a

boiler or water heater.

Loop Single piece of PEX pipe connected to a manifold.

Installation and Operation Manual Radiant Heat Panel

6

RHP-1&2 0511

Thank you for purchasing a NIBCO®Radiant Heat Panel. The RHP unit is the easiest way to link a

properly sized heat source to the radiant system using time tested control technology. Backed by years

of experience designing components for the heating industry, the NIBCO®RHP is a reliable choice

for radiant system control.

Features: Benefits:

Pre-engineered Designed for Dependable Performance using Proven Components

Pre-assembled Tested for Installation Leak Free Consistency.

Pre-wired Facilitates Quick Trouble Free Start Ups.

Compact Minimal area needed for installation.

Modular Systems of any size can be assembled.

Warranty 12 months from purchase.

The RHP-1 model will serve up to five loops. The RHP-2 model will serve up to ten loops.

Each loop is capable of handling no more than 0.5 USgpm.

Each loop is to be ½” PEX (or BARRIER-PEX).

Each loop is not to exceed 250 ft.

The RHP moves heated fluid to the Radiant Floor Heating (RFH) system and allow you to raise or lower

the room temperature. As long as the circulator is moving water according to instructions from the

thermostat, the RHP is operating as intended.

The delivery of heat to your floor and room is based on the temperature of the fluid, the capacity of

the RHP circulator and design of the RFH. Restriction to water flow such as the radiant floor heating

pipes in your floor, temperature of the heated water, and the design/installation of your RFH system

will have an impact on the system. Most RFH systems need a minimum of 110oF water to work prop-

erly, while some need temperatures of 150 oF.

The proper design of a RFH system will make the difference between your satisfaction or

dissatisfaction. Several factors such as slab insulation, tube length, spacing, floor covering and heat loss

will affect the performance of your system. The RHP has no control over these important factors.

The RHP simply moves the heated water to the RFH(s) based on instructions from the thermostat. There

is no need to modify, cut, change, or otherwise alter the RHP. Doing so will void warranty.

Introduction

Introduction

Features/Benefits

Capacity

Function

Performance

Expectations

Disclaimer NIBCO shall not be responsible for any errors in catalogs, brochures or printed materials. NIBCO

reserves the right to alter its products at any time without notice. NIBCO®PEX is a trademark of

NIBCO INC. All Rights Reserved.

Installation and Operation Manual Radiant Heat Panel

7

RHP-1&2 0511

Specifications & Restrictions

Circulators

Material Properties

of Components

The parts used on the RHP are composed of non-ferous material. The types of materials used that

are in contact with water are brass, TP 304/TP 304L stainless steel, and EPDM rubber.

The NIBCO®RHP is pre-assembled and pre-wired using our standard products. The circulator has

been selected to handle the flow requirements for a typical system plus a marginal allowance for any

additional pressure capacity not considered. The circulator will be undersized if there are more than

the maximum loops, if the loops are longer than 250 ft. or if they are smaller than 1/2” in diameter.

Manifold Connections

Boiler vs. Domestic

Water Heaters

The RHP-1 is designed for 3/4” PEX piping to and from the heat source and to and from the distri-

bution manifold. The RHP-2 is designed for 1” PEX piping.

Any heat source such as a domestic water heater, cast iron boiler, outside wood

furnace or other heat source is compatible with this RHP.

NOTE: The circulators supplied with the RHP are suitable for potable ap-

plications. If any type of glycol is used in the system, it must be isolated

from domestic water use. Propylene glycol is posionous and ethylene

glycol is toxic. Follow codes and standards of authorities having jurisdic-

tion. With Glycol, use a stabilized glycol, a separate stabilizer, or change

fluids annually to avoid a buildup of corrosive glycolic acid.

Pressure losses have been dimensioned based on design flows through ½” nominal PEX tubing at

a rate of 0.5 to 0.7 USgpm. A nominal 9 ft. of head for the radiant tubing and 4 ft. of head for

control valves, pipe and fittings has been allowed for in the circulator selection.

If system requires a larger circulator, you should consider a modular approach and use multiple

RHP’s. Mixing valves have been selected to provide sufficient flow for a minimum and maximum

case.

The RHP utilizes an electronic thermostat, which is placed within the room where temperature is

monitored by an internal room sensor.

Control Format

Hydraulics

Installation and Operation Manual Radiant Heat Panel

8

RHP-1&2 0511

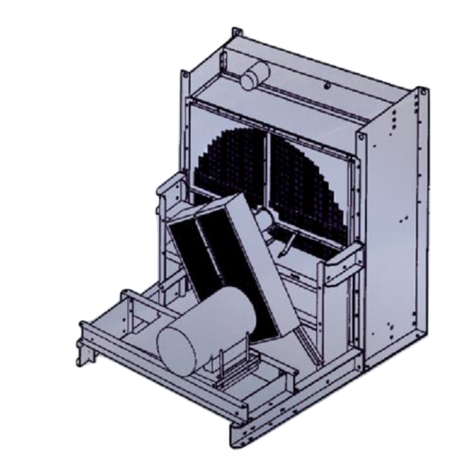

Parts Legend :

1. Thermostat

2. Pump

3. Power Box with transformer, relay and integral timer

4. Temperature Gauge

5. Mixing Valve

6. Thermostat jack and auxiliary contacts

The room thermostat is the controller that signals the circulator and has an internal air sensor

which monitors the temperature. Some thermostats include a limitation sensor which should be in a

protective sleeve (such as a short piece of PEX) when placed in a slab. If your thermostat has a floor

sensor, you have two options when controlling temperature. One option is to use the floor sensor to

ensure the set maximum temperature is not exceeded. The second option uses the sensor to keep a

constant set temperature in the floor. For either option when there is a call for heat the thermostat

signals the circulator which causes heated fluid to enter the radiant system.

NIBCO®Radiant Panel Model RHP-1

Room Temperature

Control

<<< (Hs) Heat Source

>>> (Hr) Return to Heat

This is a representative panel. Your model may differ slightly.

RHP-2 Panel is very similar but utilizes 1” TMV instead of 3/4”.

Return from Floor >>>

Supply to Floor <<<

5

4

3

2

1

6

Installation and Operation Manual Radiant Heat Panel

9

RHP-1&2 0511

RHP Schematic #1

Model Shown: RHP-1

Description: Shown with 4

Loop Manifold and 3 Loops,

Closed system .

Water heater shown is a

representative model.

PEX Pipe

Installation and Operation Manual Radiant Heat Panel

10

RHP-1&2 0511

Examine carton for visible damage that may have occured during shipping. If damage is

visible notify your courier and supplier immediately.

Open carton carefully, pull tape off carton, do not cut tape or you may damage the finish on

the panel.

Remove the panel from the carton, lift panel by base, and do not lift by circulator or other

components.

Locate and verify that the items shown below are packaged in the carton or in the panel.

Before discarding carton, check carefully for any loose components or accessories that may

be located in the box.

It is recommended the piping distance between the RHP and the heater should be no greater

than 20ft. and central to RFH manifolds. In addition, the components on the RHP must be easily

accessible should repair or service be required.

Give careful consideration to the mounting location of your RHP panel. You must ensure you

have adequate room to connect the heat source supply and return as well as the system

supply and return to the panel. To minimize piping, locate the panel as close as possible to the

heat source (max. 20 ft.). The electrical feed into the panel is through a 6 foot factory wired cord

and plug that requires a dedicated 15-amp receptacle. Locate the panel near the receptacle

or in an area where such a receptacle can be easily installed.

Dimension lines are to a pipe velocity between 2 and 5 ft/s. (see chart below). The circulator

supplied with the RHP has differential pressure available for some limited distribution piping.

Exceeding the available differential pressure could cause under-performance. Please refer to

specification sheet or contact NIBCO.

1. Unpacking

2. Location of Panel

Installation Instructions

3. Distribution Pipe

Installation and Operation Manual Radiant Heat Panel

11

RHP-1&2 0511

Use 3/4” PEX or 3/4” copper (use 1” on RHP-2) to connect from the RHP panel

to the manifolds and from the panel to the heat source (page 9).

Panel connections consist of a union nut, washer, and a FPT adapter. These

components must be used on every installation. System connections will consist of

a 3/4” MPT x PEX adapter or 3/4” MPT x copper adapter, depending on the

material used (the adapters will be 1” on RHP-2).

Follow these steps and refer to picture below.

Screw 3/4” FIP adapter (D)(supplied with panel) into adapter (E) or (H) using appropriate

thread sealant.

Without disturbing gasket (C) place assembly against flanged steel pipe (A)

Slide nut (B) over adapter (D) and finger tighten.

Use 2, 30mm or adjustable wrenches. Attach 1 to adapter (D) and hold it firmly in place.

Attach other wrench to union nut (B) and tighten 1/4 turn.

Pipe Connections

Step 1

Step 2

Step 3

Step 4

A - Flanged pipe on panel

B - Nut on panel

C - Rubber gasket

D - 3/4” FIP adapter

E - PEX x Male thread adapter

F - Copper crimp ring (SS clamp or SS sleeve)

G - 3/4” PEX

Installation Instructions

Installation and Operation Manual Radiant Heat Panel

12

RHP-1&2 0511

It is required to install an in-line expansion tank in the supply from heat source. This allows for

contraction and expansion of the fluid.

The objective in filling the RHP and related equipment is to purge air from the piping network.

To allow proper filling and purging, it is necessary to install fill and purge valves as seen in the

example schematic on page 9. The fill and purge valves are not included with the RHP. Allow suf-

ficient time and flow for air bubbles to be flushed from the system. An air eliminator (not included)

will facilitate the final purging of air. The RHP has no ability to deal with air locks, which impede

the performance of the system and can cause the pump to fail. Installer will need two hoses to

complete the following procedure. Hoses must each have a female connection to attach to ap-

propriate valves. (Installer takes responsibility and liability to meet all local environmental codes

for discharging fluids).

Purging Instructions

1. Turn off power to RHP and fill heat source with fluid. Open all isolation and drain valves

(except the one between the fill and purge valves).

2. Close all individual loop isolation (balancing) valves on manifold except one. Connect hose to

water source outlet and the other end to fill valve. Connect another hose to purge valve and to a

suitable discharge (such as a large bucket) and begin filling. Flow will be in reverse of normal.

3. When flow appears free of air bubbles, close the open loop and move to the next loop - thus

filling and purging each loop in turn.

Note:

If using a glycol mix, pump in the mix from a large container and purge back into the same con-

tainer.

Locate room thermostat. Use a suitable 3 conductor wire and connect the N,L, and Signal terminals

on the thermostat to the corresponding terminals on the RHP wiring block. The room thermostat

should be located in an area representative of the most commonly used space, between 50 and

60 inches above the floor, away from doors, curtains, draughts, direct sunlight, air registers, fire-

places, or any other form of heat, which may influence the control.

If you desire to use the RHP to signal a boiler to fire, use the auxilary contacts. This pair may be

connected to a boiler and the circuit will close when heat is called for by the panel.

Finally, connect 110V power to RHP.

To reduce heat transfer from RHP to room, insulate with standard grade pipe insulation. Do not

insulate electric motors.

8. Fill and Purge

Installation Instructions

9. Wiring

Running the circulator

dry voids

warranty. Ensure the

system is filled

before operating the

circulator.

10. Pipe Insulation

Installation and Operation Manual Radiant Heat Panel

13

RHP-1&2 0511

Control Notes

Control Sequence

The RHP does not control the heat source (however see note at bottom of page 11)

The heat source requires its own control system, according to local codes independent of the RHP.

1. When room thermostat calls for heat the dry contacts in the thermostat are closed.

2. The radiant circulator will begin to pump heated fluid to the system.

3. For the RHP-1 and RHP-2 models, the limitation sensor (if in use) monitors the temperature of the

floor to ensure the maximum temperature is not exceeded or the target temperature is maintained.

4. When the room temperature is met, the dry contact opens which turns the radiant circulator off.

Control Sequence

Field Setting of the

Limitation Sensor

Thermostat for the

RHP-1 and RHP-2

Models.

Some thermostats include a floor sensor. If in use, there are two available options when setting the

limitation sensor. From the factory, the thermostat is set not to utilize the floor sensor.

Option 1 - Allows the use of the sensor as a limitation to the maximum temperature allowed for

the floor. For example, the placement of the limitation sensor in a radiant wooden floor. Typically

the floor should be under 85oF. With the limitation sensor set to the first option (maximum sensor),

a temperature reading above 85oF will cause the thermostat to close the actuator ensuring an over-

shoot will not occur.

Option 2 - Which can be chosen uses the limitation sensor as a temperature set point. With this

setting a particular temperature can be set for the floor, which the thermostat will maintain. For

example, the floor in the bathroom might requires a constant temperature of 80oF for comfort. All

one has to do is adjust the temperature in the thermostat to the 80oFand the limitation sensor will

maintain the desired set temperature.

To adjust the temperature setting of the sensor or to change from one option to another, it is neces-

sary first to open the thermostat cover. Second, gently pry out the inside cover.

The switch on the bottom left of the thermostat has two sections. The top portion, labelled “MAX”,

allows setting of the thermostat as a limit switch. This corresponds to option one above i.e. limiting

the temperature under a wood floor. The white portion of the scale, labelled “MIN”, allows settting

of the thermostat as a minimum set point. This corresponds to option two above i.e. setting the

minimum floor temperature of a bathroom ceramic floor.

The blue square in the upper right hand corner has an slot for turning with a screwdriver and an indi-

cator arrow pointing to a series of temperature settings. Refer to page 17 for instructions.

Field Setting of

the Mixing Valve

for the RHP-1 and

RHP-2 Models.

The Thermostatic Mixing Valve (“TMV”) mixes hot water from the heat source and return water from

the floor. This enables tempering of the hot water supplied to the floor and the return water going

back to the heat source. This is particularly important when utilizing a boiler or with a wooden floor.

Please consult your boiler manufacturer or installer to determine the correct return water temperature

for your heat source.

Installation and Operation Manual Radiant Heat Panel

14

RHP-1&2 0511

An example: Your supply temperature is 140 degrees F and your target return temperature is 100

degrees F. (100 - 50) / 10 = 5 and 100 + 5 = 105. Referring to the chart yields a TMV dial

setting just below 2.

Timer for the RHP-1

and RHP-2 Models

The TMV has six settings which are changed by turning the knob under the square cover on top of the

TMV on the RHP 1, the RHP-2 does not have a cover. Remove the cover by prising against the small

tab on either side. In order to adjust the TMV to the proper setting, determine the supply temperature

to the RHP and the desired return temperature. [Some boilers require a minimum return temperature

to protect against flue gas condensation, consult your boiler provider if applicable] Subtract 50 from

the return temperature and divide by 10. Add this number to the return temperature to determine the

target temperature as seen on page 18 (RHP-1) and page 20 (RHP-2)

Start Up 1. Set thermostat(s) 5 to 10 degrees above actual room temperature.

2. If a floor sensor is used make sure the minimum setting (if used) is at least

5 to 10 degrees higher than the actual floor temperature.

3. If you are using the auxilary contacts to bring on the heat source, make sure

they are connected.

4. Plug power cord into a 110V outlet.

5. Observe the panel to ensure it follows the proper sequence of operation.

6. After the system temperature stabilizes, verify mixed fluid temperature

is within a few degrees of the desired set point by checking with a temperature

gauge. If the temperature is off, re-adjust the 3 way thermostatic valve.

The integral timer’s purpose is to circulate water for a short period each day within the system.

If you are employing an open system (sharing the heat source with domestic uses) this prevents

any “stale” water from accumulating in the pipes during the summer period. The timer will activate the

system for 15 minutes every 24 hours. You should leave the panel turned on with the thermostat

turned down even in the summer to allow the timer to activate this circulation. If you are operating

a closed system, you may turn the panel off in summer or even disconnect the power cord.

Installation and Operation Manual Radiant Heat Panel

15

RHP-1&2 0511

Thermostat

Type: RHP-1 &

RHP-2:Danfoss FH-WS

PX

Description/Function:

The Danfoss thermostat is designed to be flush mounted.

It has an adjustable limit sensor which can be set to

maintain a minimum floor temperature or to protect the

floor via a maximum temperature setting. Please refer to

the instruction sheet that comes with the thermostat.

Specifications:

• Temperature range 50 -86oF

• 24V AC, 60Hz

• Dry Contact, Max 2A

• Fully electronic

• LED status indicator

1

Mixing Valve

Type: TMV

Model: RHP-1:

065B8876

PX10292

Description/Function:

The TMV (Thermostatic Mixing Valve) is

a 3-way brass valve which regulates the

temperature in the radiant system.

Specifications:

• Maximum flow temperature 180°F

• 3/4” BSPP

• Maximum working pressure 145 psi

5

Type: TMV

Model: RHP-2

065B8999CA

PX10293

Description/Function:

The TMV (Thermostatic Mixing Valve) is

a 3-way brass valve which regulates the

temperature in the radiant system.

Specifications:

• Maximum flow temperature 180°F

• 1” BSPP

• Maximum working pressure 145 psi

Installation and Operation Manual Radiant Heat Panel

16

RHP-1&2 0511

Specifications

6 Amp Inductive Load

Transformer

110 Volt Circulators

Single Zone 0.9 L

Dry: 10lb (4.5kg)

Filled: 15lb (6.5kg)

136 BTU/hr @120 °F AWT

205 BTU/hr @140 °F AWT

280 BTU/hr @160 °F AWT

Control Valves**

TMV: Brass body.

Ball Valves

Hose bib/ Pet cock: Brass body, PTFE, FKM, EPDM rubber seals

Circulator

Standard Models Grundfos: PES composite,Composite Pump Housing, EP Rubber

Piping

Type TP304/TP304L Stainless

180°F

125 psi

180°F

Electrical Specifications

Weights

(RHP-1)

Thermal Output

to Room

(RHP-1)

Materials in Contact

with Water

Maximum Ambient

Temperature

Maximum Operating

Pressure

Maximum Operating

Temperature

Volume

Installation and Operation Manual Radiant Heat Panel

17

RHP-1&2 0511

Installation and Operation Manual Radiant Heat Panel

18

RHP-1&2 0511

Index

Applications

The Series 30 is a multi-purpose thermostatic mixing valve

designed for ease of installation and a wide variety of uses.

The TMV offers accurate temperature control via a self-regulating

thermostat. The valves are designed to control temperature of

Domestic Hot Water (DHW), Hydronic Radiant Space Heating,

Heat Pump, and Solar Systems for central mixing applications.

Series 30 MR offer the following features:

• Anti-scald function* (see below).

• Listed to meet ASSE 1017 requirements (applies to 85–120°F

and 95–140°F only).

• Purpose: Mixing function.

• Temperature Ranges: 70–110°F (20–43°C),

85–120°F (29–49°C), or 95–140°F (35–60°C).

• Maximum working pressure: 150psi (10 bar).

• Maximum hot water inlet temperature: 194°F (90°C).

• Maximum pressure difference between hot and cold supply:

20% to max. 44psi (3 bar).

• Minimum flow requirement: 0.5USgpm (113.5l/hr).

• Designed for long-life and easy maintenance.

• Minimal outlet temperature fluctuation.

VERY IMPORTANT!

To the Installer:

These installation and maintenance instructions

must be reviewed by all installers and by the owners

of the building or property where the device will

be installed.

* The Serie 30 is designed to respond to a failure of the cold

water supply by a complete closing of the hot water supply port

before the outlet temperature exceeds the setting by 18°F (10°C).

NOTE: To ensure that the anti-scald function works properly, the

pressure difference between inlets and outlet should not exceed

72 psi (5 bar), otherwise minor leakage could occur.

Setting

The Series 30 MR temperature setting is accomplished by

adjusting the setting wheel between 1 and 6 to obtain the

required mixed water temperature. For quick setting refer to the

table below. Series 30 MR valves are not factory calibrated.

For accurate setting, measure the mixed water temperature once

hot and cold supply temperatures are stabilized. Adjust setting as

required to obtain the desired temperature.

Installation

To protect the TMV from excessive heat, and avoid voiding the

warranty, the tailpieces must be soldered before attaching them to

the TMV (see below). Gaskets supplied must be installed as shown.

NOTE: When installing a TMV on plumbing systems using CPVC

piping, always follow the pipe manufacturer’s instructions.

1. Position union nut

over tailpiece

before soldering.

2. Solder tailpiece to

tubing.

3. Insert gasket in nut.

4. Connect to TMV.

Gasket

Adjust temperature setting

between 1–6.

Mount label on cap to seal

valve. Space is provided on the

label to indicate measured

outlet temperature, date and

signature of installer.

Coppertubing

TMV

Solder joint

Installation and Maintenance InstructionsThermostatic Mixing Valve Series 30 MR

© Copyright. All rights reserved.

Over time the temperature setting

may have to be adjusted due to

scaling or dirt deposited in the

valve.

+

F

F

F

F

F

F

–

+

120°F 67 74 81 87 94 109 80 90 97 102 107 115 95 106 115 119 120 120

140°F 68 75 82 90 97 113 81 91 99 104 109 117 97 108 117 126 133 140

160°F 69 76 84 92 100 118 82 93 100 106 112 118 99 109 118 127 135 145

180°F 70 77 86 95 102 122 82 95 102 108 114 120 100 111 120 129 135 149

Hot water 70–110°F 85–120°F 95–140°F

Temperature 1 2 3 4 5 6 1 2 3 4 5 6 1 2 3 4 5 6

Note: Table is based on 50°F cold water and no difference between hot and cold water supply pressures. For other cold water temperatures correct the mixed

temperature by 1°F for every 10°F from 50°F, up or down.

Push pin to remove cap. Remove cap. Replace cap.

Installation and Operation Manual Radiant Heat Panel

19

RHP-1&2 0511

Installation continued

The Series 30 MR valves are not intended to provide final

temperature control at the fixtures or appliances. Use Series 30

HR/HV valves that meet ASSE 1016 for these applications.

The valve should be installed below the storage tank or water

heater as shown in Fig. 3 wherever possible. If the valve is

installed adjacent to, or higher than the storage tank or water

heater, it is important to prevent gravity circulation during times

where there is no consumption of water. This is done by various

methods such as a heat trap loop or a check valve in the cold

water feed line as shown in the examples below.

A check valve should also be installed whenever a high tempera-

ture (uncontrolled) water outlet is included (Fig. 4).

For installation of a TMV in a system providing recirculated

tempered water using a circulation pump refer to Fig. 6.

An aquastat to limit circulation of recirculated water is not

required with Series 30 MR/HR/HV valves.

3

54

21

7

Serie 30 MR

6

* Spare Parts

© Copyright. All rights reserved. Art. nr. 15323 · Ritn. nr. 9097-01 Utg. B

Inspection and maintenance –important!

To ensure proper function, a licensed contractor should verify the

mixed outlet temperature annually. The following maintenance

procedure should be performed each year and at times when

increase in water outlet temperature is observed. Replacement

of the valve insert may be required if maintenance and calibration

of the valve does not result in correct temperature readings.

To clean and/or restore the valve, shut off water and:

1. Remove cap (item 1) and note position of adjustment wheel.

2. Remove wheel and disassemble valve by removing adjustment

bonnet (item 2) and internal parts. (items 3–6).

3. Remove carefully all scaling (calcium deposits) or foreign

particles from all parts. Do not use sharp tools or scratch

surfaces. Regrease all internal components using silicon grease.

4. Assemble the valve and restore water supplies.

5. Calibrate by measuring the mixed outlet temperature.

6. Replace adjustment wheel and cap to prevent tampering.

7. Record service date and valve setting on valve label.

6 –Body

5 –Spring*

4 –Shuttle*

3 –Thermostat*

2 –Adjustment bonnet*

1 –Cap

Primary-Secondary Pumping

Central Mixing

Central Mixing Radiant Floor Heating Recirculated Domestic Water

Central Mixing Central Mixing

Boiler Return Water Temperature Control

Distributed by:

Danfoss Inc.

7880 Tranmere Drive

Mississauga, Ontario

Canada L5S 1L9

Tel. (905) 676-6000

Fax. (905) 676-0279

Distributed by:

Danfoss Comfort Controls

3435 Box Hill Corporate Center Drive

Suite C

Abingdon, Maryland

U.S.A. 21009

Tel. (443) 512-0266

Fax. (443) 512-0270

8

Installation and Operation Manual Radiant Heat Panel

20

RHP-1&2 0511

This manual suits for next models

1

Table of contents

Popular Heater manuals by other brands

Rinnai

Rinnai RHFE-556 FM Service manual

HORNEET

HORNEET HS0116 Instruction for operation and maintenance

Midea

Midea NDK20-21AF owner's manual

Hatco

Hatco HYDRO-HEATER 3CS2 Series Installation and operating manual

Kelvin

Kelvin ROCORE VB Series Installation, operation and maintenance manual

ORIGO

ORIGO FH-T20P instruction manual