NIPPON POP RIVETS AND FASTENERS PRL600A User manual

PRL600A

”POP”RIVETER

INSTRUCTIONMANUAL

NIPPONPOPRIVETSANDFASTENERSLTD.

2000.9.13

Ⅰ.Outline

ThePRL600Aisapneumatic-hydraulictoolwithhighairpressurespecifications,

whichissuitableforsettingPOPrivetsφ4.0mm-φ4.8mm.

1.Models

Selectthemodelaccordingtotherivetsizeandconditionsofuse.(Table1)

Table1 ※Standardparts

Rivetsize

(φmm) Nosepiece Mandrel guide

ass’y Ejectorcomplete

PRL600A-4,5 PRL600A-160/5

PRL600A-4,5-150L PRL600A-160/515

PRL600A-4,5-200L

4:3.2

5:4.0

4:PRN414

5:PRN514 PRL600A-160/520

PRL600A-161/5

PRL600A-6、6S PRL600A-160/6S

PRL600A-6、6S-150L PRL600A-160/6S15

PRL600A-6、6S-200L

4.8

6:PRN610

6S:PRN6S0 PRL600A-160/6S20

PRL600A-161/6S

Model

*Therivetsizecanbechangedbyinterchangingthenosepiece,mandrelguide

assemblyandejectorcomplete.

2.Nosepiece

Useanappropriatenosepieceaccordingtothetypeandsizeofrivet.

(Table2)

Usingadifferentsizenosepiecemaycausefaultyrivetsettingortool

malfunctions.

Table2

Closedend

Rivettype

Rivet

diameter(φmm)

Openend

Steelmandrel Aluminum

mandrel Stainlesssteel

mandrel

4.0 PRN514 PRN524 PRN534 PRN514

4.0(SD5HR) PRN614 − − −

4.8 PRN614 PRN624 PRN634 PRN614

4.8(SD6HR) PRN6S − − −

3.Toolspecifications

ToolspecificationsareasshowninTable3.

Table3

Model Weight

(kg) Length

(mm) Height

(mm) Stroke

(mm)

*Airpressure

(Mpa)

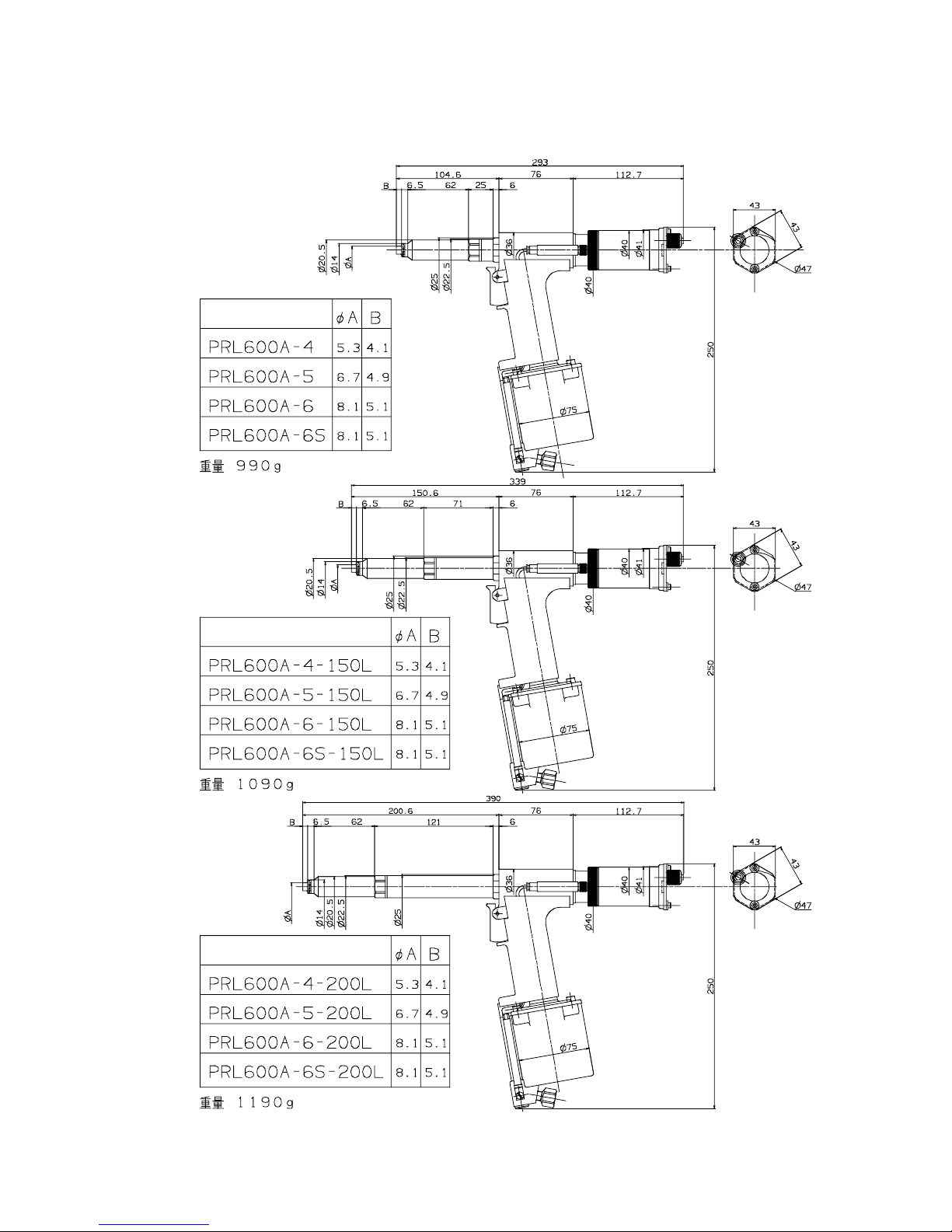

PRL600A-4,5,6,6S 0.99 293

PRL600A-4,5,6,6S-150L 1.09 339

PRL600A-4,5,6,6S-200L 1.19 390

250

18 0.35〜0.8

(3.6〜8.2kgf/cm2)

*ThePRL600Ahashighairpressurespecifications.Itisnormallyusedat

between0.35Mpa

and0.8Mpa,butcanalsobeusedatlowerairpressuresdepending

onthetypeandsizeofrivet.

1

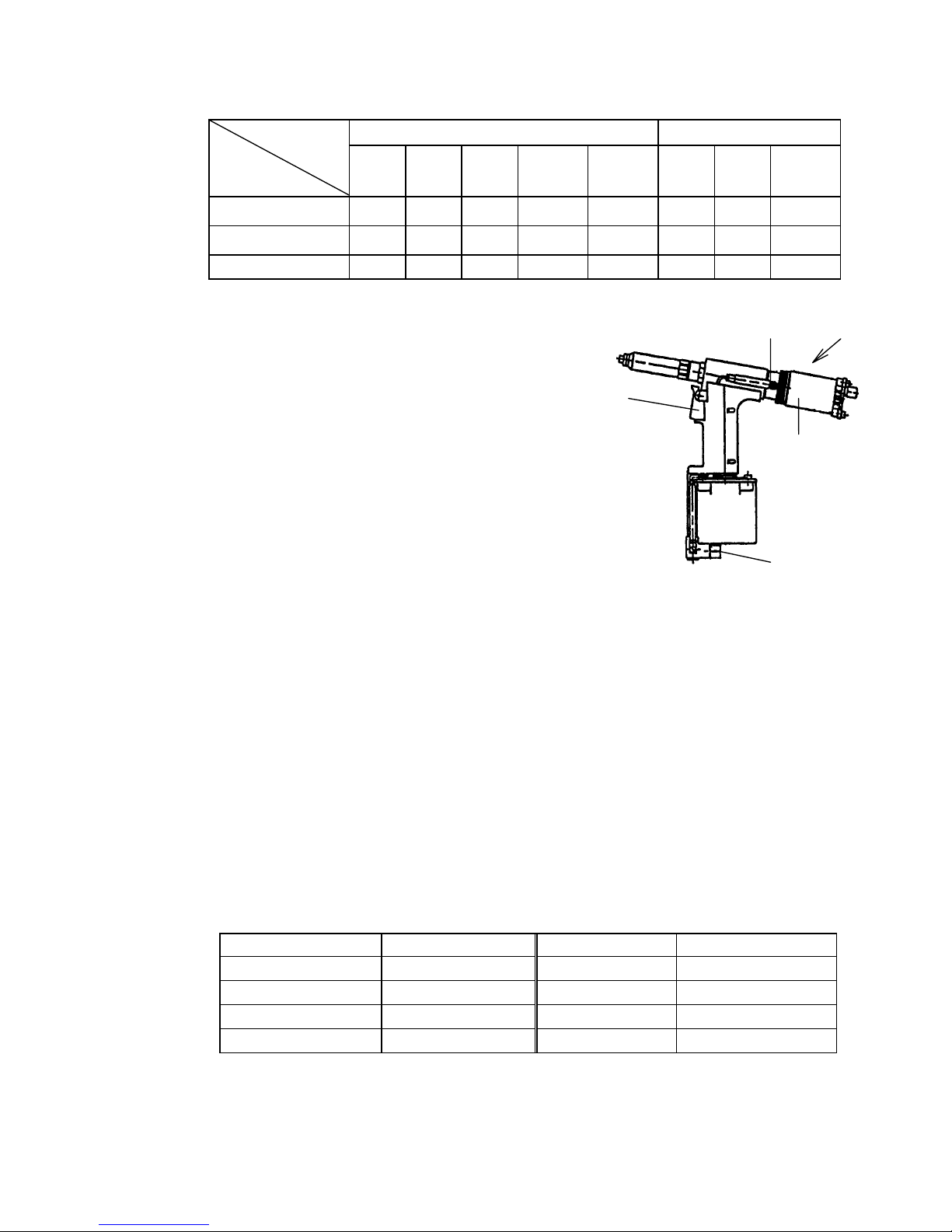

Table4–Minimumrequiredairpressure(MPa)

Openend Closedend

Rivettype

Rivetdiameter

(φmm)

AD-ABS TAP-BS

TAP-HR SD-BS TAP-SSBS

SD-HR SSD-BS

SSD-SSBS AD-AH AD

AD-SSH SSD-SSH

3.2 0.35 0.4 0.45 0.4 0.5 0.35 0.4 0.5

4.0 0.4 0.55 0.5 0.55 0.65 − 0.55 0.65

4.8 0.45 0.65 0.65 0.7 − 0.45 0.65 −

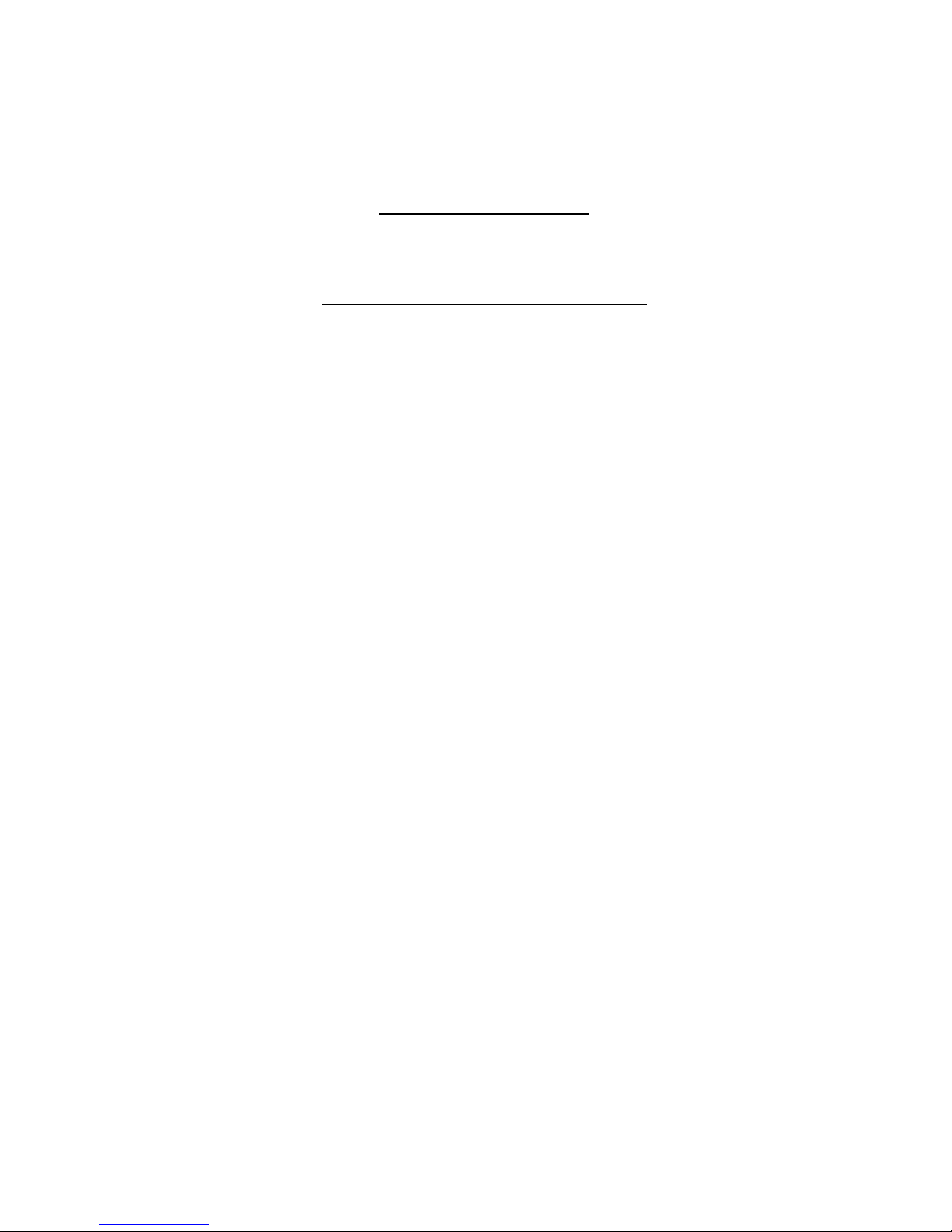

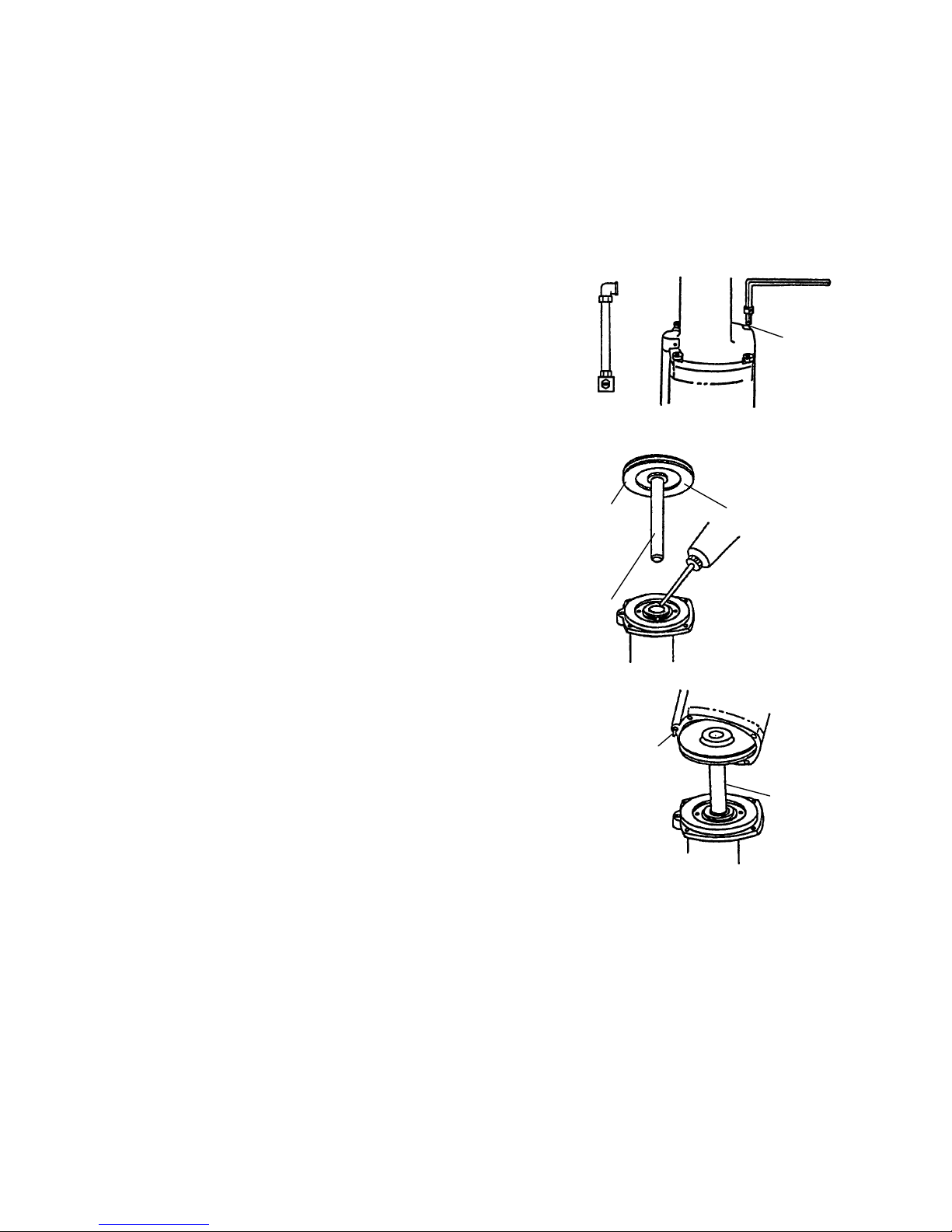

Ⅱ.Methodofuse(Figure1)

1.Connecttheairhosetotheairhosetip

joint(Rc1/4).

2.Whenarivetmandrelisinsertedintothe

nosepiece,therivetwillbedrawninbythe

MCS.

3.Therivetissetbypullingthetrigger.

4.Spentmandreliscollectedinthecatcherby

theMCS.

(Note)TheMCSsuctionpressureisadjusted

(strong-weak)withthevalveshutterscrew

adjustment.TheshuttershouldbeclosedwhentheMCSisnotusedorwhenthe

toolisleftunattendedforlongperiodswiththeairconnected.(Screwthe

valveshutteruntilitstops.)

Valveshutter

(PRL600-25) MCS

Catchercomplet

e

(PRL800-50)

Joint(Rc1/4)

Figure1

Trigger

(PRL600-72)

Ⅲ.Cautionsforuse

1.Airpressure

Alwaysensurethatthetoolhassufficientairpressuretosetrivets.If

thenecessaryairpressurecannotbeensured,useaboostervalve.

(Reference:Theairpressurecanbeboostedfrom0.4MPato0.8Mpawiththe

SMCVBA2100-03GN).

2.Oil

SelectanappropriateoilfromTable5.Usingtypesofoilotherthanthose

listedinTable5maycausemalfunctions.

Table5

Companyname Productname Companyname Productname

EssoStandardOil Tel-Esso52.68 MitsubishiOil DiamondRulerRO68

NipponOil FBKRO68 MobilOil MobilDTE46.68

CosmoOil CosmoHydroRO68 KyodoOil KyosekiHydroW68

IdemitsuPetroleum DuffneyHydro46.68 ShellOil ShellTerraceOilC68

2

3.MCSmandrelholdingcapacity

TheMCSmandrelholdingcapacityfluctuatesaccording Rivetdiameter

(φmm)Maximum

capacity

4.0 100

4.8 70

Table6

totheairpressureandsuctionstrength.Maximum

capacitiesareasshowninTable6.

Themandreldiscardtimingisbestwhenthemandrelsreachapproximatelyhalf

thevolumeofthecatcher.

Figure2 Catcher

(Note)Exceedingthemaximumcapacity

maydamagetheMCSorcausemandrelsto

becomestuckinsidethetool.

Ⅳ.Maintenanceandinspections

Item Frequency Purpose

1 Sprayinglubricantintothe

jaws Every500rivets Maintainsproperjawoperationand

extendstheservicelife.

2 Cleaningthetipparts Every3,000rivets Removesmetalpowderandextends

theservicelife.

3 Addingoil Every30,000rivets Strokerecovery;preventsfaulty

operation.

4 Replacingthejaws Every50,000rivets Replacedduetotheservicelife;

preventsfaultyoperation.

5 Replacingthenosepiece Every100,000rivets ↑↑

6 Replacing the jaw pusher

spring Every20,000rivets ↑↑

7 Replacingtheseals Every100,000rivets ↑↑

8 Replacingthejawcase Every100,000rivets ↑↑

1.Sprayinglubricantontothejaws(Figure3)

Lubricating and rust-proofing agents (CRC type) should be sprayed into the

nosepieceholeapproximatelyevery500rivetsinordertomaintainproperjaw

operation.Alwaysclosethevalveshutterwhensprayingthejaws.(Ifthejawsare

sprayingwiththeairconnected,thelubricatingoilwillbedrawnintotheMCS

andmissthejaws.)

Nosepiec

e

(PRN-□)

Sprayoil

Figure3

(reference)

Manufacturer Productneme

KureIndustriesInc. CRC5-56

ThreeBondInc. 1801B

MusashiHoltzInc. HoltzTopOilMH241

LesupiInc. Pikka

2.Cleaningthetipparts

Cleanthetippartsregularly(twoorthreetimespermonth).Aftersetting2,000–3,000rivets,

metalpowderwilladheretothetippartscausingtoolactiontodeteriorateandthejawsto

slip.Continuingoperationundertheseconditionswillshortentheservicelifeofthejaws

andothertipparts.

(1)Loosenthenosehousingwithawrenchandremoveit.(Figure4)

(2)Releasetheconnectorlockbyhand,andremovethejawcasefromthepullinghead.

(3)ThepartswhichwillcomeoffareshowninFigure5.Cleanthesepartsandthenosehousing

withkeroseneorasimilaroil.Inaddition,blowairthroughthepullingheadandnose

housingtocleanthem.

MandrelguideAss’y

(

PRL60

0

-160

/

□

)

(4)Whenassemblingtheseparts,spraytheinsideofthejawcase(CRCtypeoil).Then,lock

thejawcaseonenotchbackfromthecompletelyclosedposition.

Nosehousing

(PRL600-03) Jawcase

(

PRL60

0

-15

)

Figure4

Connector lock

(PRL600-01) Pullinghead

(PRL600-21,22,112)

Figure5 Jawpusher

(

PRL60

0

-58

)

Jaw

(

PRG54

0

-46B

)

Jawcase

(

PRL60

0

-15

)

Jawpushersprin

g

(

PRL60

0

-20

)

3.Addingoil

Whentheoilbecomeslow,resultinginaninsufficientstroke,orwhentheoilisdrainedout

inordertoreplacetheseals,oilshouldbeaddedaccordingtothefollowingprocedures.There

aretwomethodsofaddingoil;thesimplemethodandthenormalmethod.

(1)Simplemethod(Figure6)

Thismethodisconvenientwhenaddingoilwithoutreplacingtheseals.

(1)First,disconnectthetoolfromtheairsupply,andremovethefillscrewandthe

nosepiecewiththeaccessorywrench.

(2)Addoilwhileusingthehexagonalwrenchtoscrewtheoilreplacementscrewintothe

nosehousing.

(3)Afterscrewingintheoilreplacementscrewuntilitstops,tightenthefillscrew.

Then,removetheoilreplacementscrew.

(4)Loosenthefillscrewandallowtheairandexcessoiltodrainout.Whenthepiston

returnstoitsoriginalposition,oilwillstopdrainingout.

(5)Repeatsteps(2)through(4)twoorthreetimestosufficientlydrainouttheair.Then,

tightenthefillscrew.

4

Fillscrew

(PRL600-23)

Oilreplacementscrew(option)

(PRL540-127)

Nosehousing Hexagonalwrench

(option)(PRL600-81A)

Figure6

(2)Normalmethod(Figures7and8)

Alwaysusethismethodwhenreplacingtheseals,etc.

(1)Removethenosehousing.

(2)Removethetubeassemblyfromthechamberwithascrewdriver.

(3)Removethefourcapscrewswithahexagonalwrench(4mm).Then,remove

thechamberfromthehandleandextracttheairpistonassemblyfromthe

handle.Wipeoffanydirtontheinsideofthechamberandaroundthe

outsideoftheairpiston,andcoattheseareaswithgrease.

(4)Pouroilintothehandleandworktheairpistonassemblytwoorthree

times.Repeatthisprocesstwoorthree

times.

Tubeassembl

y

(PRL600-95A) Chamber

(PRL600-55A)

Figure7

Capscrew

(PRL600-74)

Hexagonalwrench(4mm)

(5)Assemblethehandleandchamber.

(Figure9)

・First,placethechamberoverthehandle

whileslidingitalongtheairpiston.

Thisprocessiseasierifthechamber

istilted.Takecarenottoletthe

valveupperfall.

・Next,facethetoolupwardswhile

holding the handle and chamber

firmly together. Line up the cap

screwattachmentholesandtighten

thehandleandchambertogetherwith

thecapscrews.

・Finally,loosenthefillscrewand

drainouttheairandexcessoil.

Waituntiloilstopsdrainingoutandthen

tightenthefillscrew.

(6)Attachthetubeassemblyandnosehousing.

4.Replacingthejaws

Ifthejawsbeginstoslipshortlyafterbeing

cleaned,itisattheendofitslife.Removeand

replacetheoutlinedinsectionIV-2above.

5.Replacingthenosepiece

Whentheentrancetothenosepieceholebecomes

worn,rivetflangeswillstickupafterbeingset.

Thiscancausefaultyrivetsetting(areduction

instrength).Removethenosepiecefromthenosehousingwiththeaccessory

wrenchandreplaceit.

Airpiston

(PRL600-57)

Oil

Airpiston

assembly

(PRL600-93)

Ram

(

PRL60

0

-56

)

Handle

Ram

Chamber

Valveupper

(

PRL60

0

-68

)

Figure9

Handle

Figure8

6.Replacingthejawpusherspring

Ifthejawsslipevenwhenitisnotworn,thejawpusherspringhasbecome

fatigued.RemoveandreplacethejawpusherspringasoutlinedinsectionIV-2

above.

7.Replacingtheseals

Ifthestrokebecomesdeficientsoonafteraddingoil,thesealsareworn.

Sendthetooltothedealerormanufacturerforrepair.

8.Replacingthejawcase

Ifrivetsarenotsetevenwhenthetooloperates(reciprocatingmotion),the

jawcaseisbroken.Removeandreplacethejawcaseasoutlinedinsection

IV-2above. 5

PRL600A Dimensional drawing

6

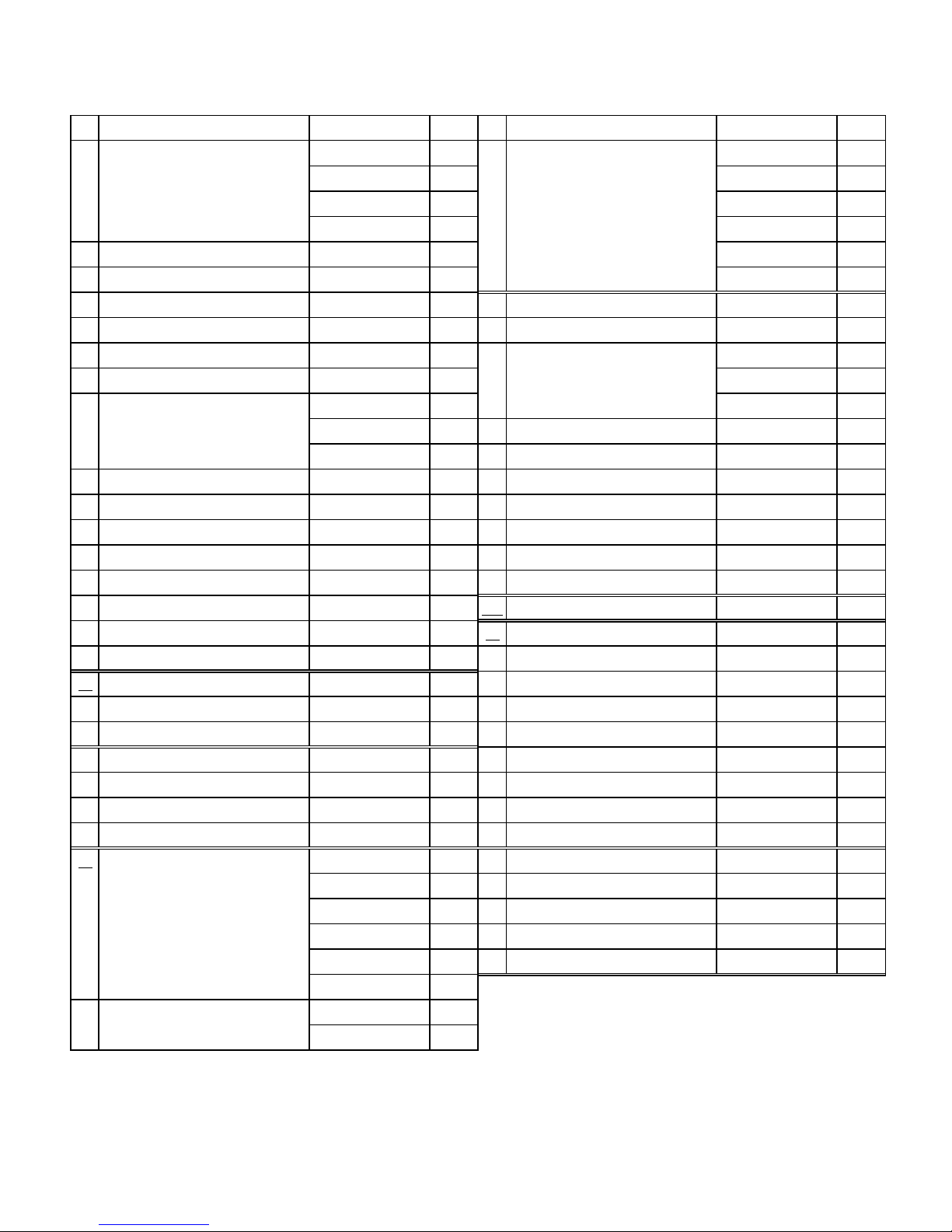

Ⅴ.PRL600APartlist

No. Productname ProductNo. Q'ty No. Productname ProductNo. Q'ty

1 NosepiecePRL600A-4 PRN414 1 23 MandrelguidePRL600A-4,5 PRL500-17/5 1

PRL600A-5 PRN514 1 PRL600A-4,5-150L PRL500-17/515 1

PRL600A-6 PRN614 1 PRL600A-4,5-200L PRL500-17/520 1

PRL600A-6S PRN6S 1 PRL600A-6,6S PRL600-138/6S 1

2 Jaws PRG540-46B 1set(2) PRL600A-6,6S-150L PRL600-138/6S15 1

3 Connectorlock PRL600-01 1 PRL600A-6,6S-200L PRL600-138/6S20 1

4 Lockpin PRM530-53 1 24 Lockring PRL600-19 1

5 Connectorlockspring PRL600-02 1 25 Jawpusherspring#5206 PRL600-20 1

6 Nosehousing PRL600-03 1 26 PullingheadPRL600A PRL600-21 1

7 Hydraulicpiston PRL600-04 1 PRL600A-150L PRL600-22

8 HousingadapterPRL600A PRL600-05 1 PRL600A-200L PRL600-112 1

PRL600A-150L PRL600-06 1 27 Fillscrew PRL600-23 1

PRL600A-200L PRL600-111 1 28 O-ringP5(U565) PRL600-24 2

9 ScraperSER10A PRM530-32 1 29 Valveshutter PRL600-25 1

10 Rodsealcase PRL600-07 1 30 O-ringS4(1A) PRL600-26 1

11 O-ringP20(U565) PRL600-08 2 32 JointPCC4M6M PRL600-28A 1

12 BuckupringT2P10A PRL600-09 1 33 Airtubeφ4×171L PRL600-29A 1

13 PentasealPS10A PRM530-30 1 34 Locknut PRL600-30 1

14 O-ringP6(1A) PRL600-10 1 100 Catchercomplete PRL800-50 1set

15 BuckupringT2P20 PRL600-11 1 91 Shutterassembly PRL800-49 1set

16 O-ringP20(1A) PRL600-12 1 40 Shutter PRL800-36 1

96 Handleupperassembly PRL600-82A 1set 41 Shutterwasher PRL500-39 1

17 Handleupper PRL600-13A 1 42 Pincase PRL500-40 1

31 LockscrewM3×4L PRL600-27 1 89 Pincasecap PRL600-102 1

18 Returnspring PRM530-18 1 43 Shutterpin PRL500-41 1

19 Endcap PRL600-14 1 98 SetringE型4 PRL600-103 1

20 Jawcase PRL600-15 1 44 Grip PRL600-39A 1

21 Jawpusher PRL600-58 1 45 Shutterspring#5113 PRL600-40A 1

90 MandrelguidePRL600A-4,5 PRL600A-160/5 1set 36 Catcherbody PRL800-34 1

assemblyPRL600A-4,5-150L PRL600A-160/515 1set 37 Adapter PRL800-35 1

PRL600A-4,5-200L PRL600A-160/520 1set 35 O-ring1030 PRL800-38 1

PRL600A-6,6S PRL600A-160/6S 1set 38 Shutterspacer PRL500-42 2

PRL600A-6,6S-150L PRL600A-160/6S15 1set 39 CapscrewM4×10L PSL600CJ-30 2

PRL600A-6,6S-200L PRL600A-160/6S20 1set

22 MandrelguidePRL600A-4,5 PRL600A-59/5 1

adapterPRL600A-6,6S PRL600A-59/6S 1

7

No. Productname ProductNo. Q'ty No. Productname ProductNo. Q'ty

92 EjectercompletePRL600A-4,5 PRL600A-161/5 1set 94 Valveassembly PRL600-94 1set

PRL600A-6,6S PRL600A-161/6S 1set 72 Valvelower PRL600-65 1

46 EjecternozzlePRL600A-4,5 PRL600-106 1 73 Valverod PRL600-66 1

PRL600A-6,6S PRL600-41 1 74 Bumper PRL600-67 1

47 Ejecterlock PRL600-42 1 75 Valveupper PRL600-68 1

48 EjecterbodyPRL600A-4,5 PRL600A-162/5 1 76 Springpinφ3×10L PRM530-43 2

PRL600A-6,6S PRL600A-162/6S 1 77 Valvepusher PRL600-69 1

49 EjecterpipePRL600A-4,5 PRL600-137/5 1 78 Handlefront PRL600-70 1

PRL600A-6,6S PRL600-137/6S 1 79 Triggerwire PRL600-71 1

50 Sleeveupper PRL600-45 1 80 Trigger PRL600-72 1

51 O-ringP10A(U565) PRL600-46 1 81 Springpinφ3×18L PRL600-73 1

52 Nutupper PRL600-47 1 82 CapscrewM5×14L PRL600-74 4

53 Handlerear PRL600-48 1 95 Tubeassembly PRL600-95A 1set

54 Sleevelower PRL600-49A 1 83 JointPL4M5M PRL600-75A 1

55 Nutlower PRL600-50 1 84 Tube PRL600-76A 1

56 PentasealPS12.5 PRL600-51 1 85 NippleLN-M5-M5 PRL600-77 1

57 BuckupringT2P12.5(PT) PRL600-52 1 86 JointLH-FM5-M5 PRL600-78 1

58 Handlelower PRL600-53A 1 88 PanheadscrewM3×16L PRL600-80 4

59 SetringISTW21 PRL600-90 1 Accessories

61 Chamber PRL600-55A 1 SprayCRC5-56 PRL600-98 1

67 PanheadscrewM5X6 PRL500-32 1 BrushD-32 PRL600-99 1

93 Airpistonassembly PRL600-93 1set Option

62 Ram PRL600-56 1 Chamberprotecter PRL600-156 1

63 Airpiston PRL600-57 1 Handleprotecter PSL600CJ-101 1

64 Airpistonseal PRT5200-28 1

66 Joint PRL600-89 1

68 Cap PRL600-62 1

69 O-ringS8(1A) PRL600-63 1

70 Valvespring#5082 PRL600-97 1

71 O-ringP4(U565) PRL600-64 1

8

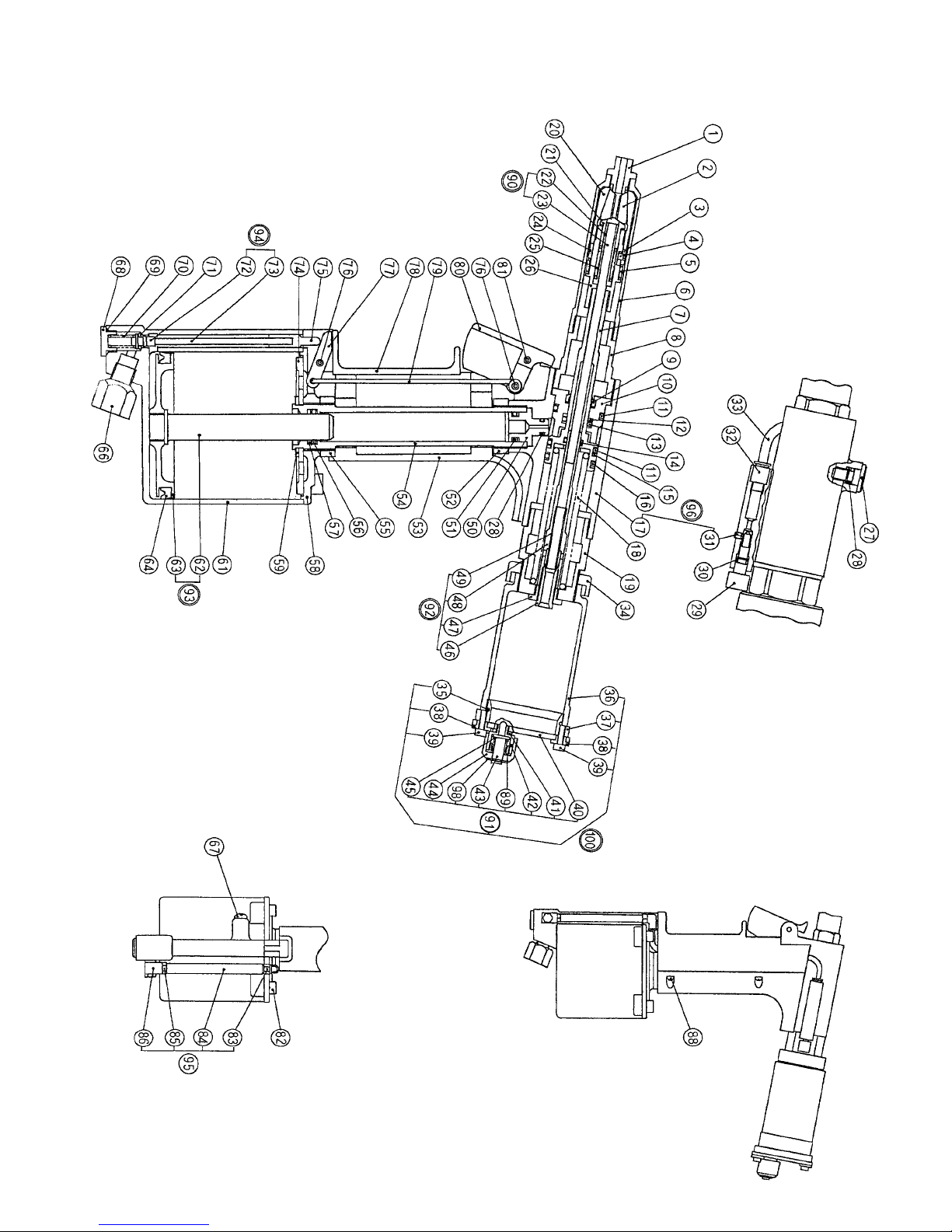

Ⅵ.Cross-sectional diagram

9

Other NIPPON POP RIVETS AND FASTENERS Power Tools manuals