Nitto MYTON MLG-25 User manual

Due to continuous product development/improvement the specifications and

configurations in this document are subject to change without prior notice.

Manufactured by :

NITTO KOHKI Co., Ltd.

2-9-4, Nakaikegami, Ohta-ku,

Tokyo, 146-8555, Japan

TEL : (81)-3-3755-1111

FAX : (81)-3-3753-8791

URL : www.nitto-kohki.co.jp

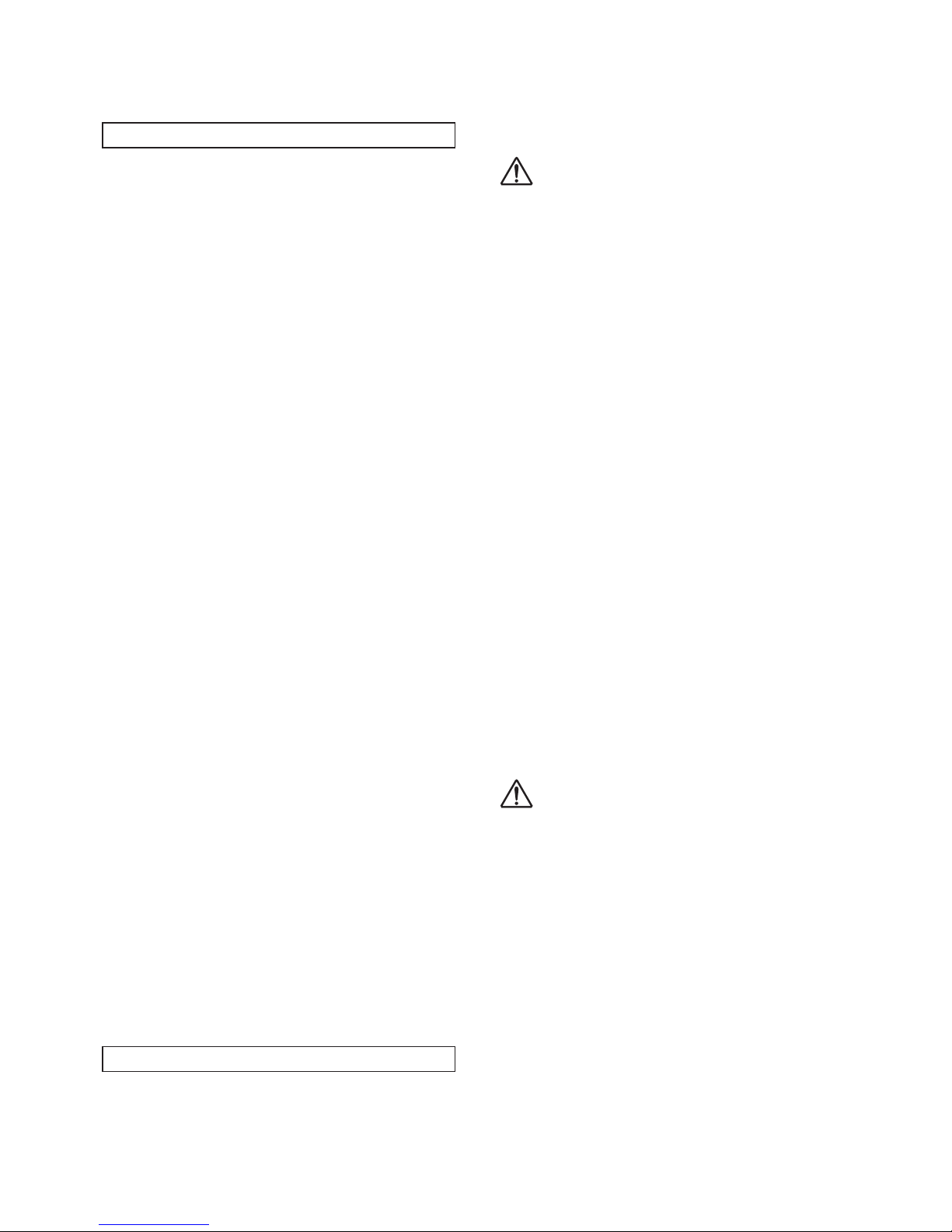

Specifications

Model MLG-25 MLG-40 MLG-50 MLG-70

Maximum Operating Pressure MPa 0.6

Air Consumption (No Load) m3/min 0.42 0.45 0.7 0.7

Maximum Power W 210 710 1,100 1,100

Rated Speed (No Load) r/min(min-1) 19,000 13,000 11,000 7,600

Depressed Center

Grinding Wheel

Diameter mm(inch) 58 (2-9/32) 100 (4) 125 (5) 180 (7)

Hole mm(inch) 9.6 (3/8) 16 (5/8) 22 (7/8) 22 (7/8)

Mass (Weight) kg 0.6 1.4 2.5 2.5

Sound Pressure Level dB(A) 90 88 89 89

Sound Power Level dB(A) 95 99 100 100

Vibration Level

[Uncertainty K]

Body m/s2[m/s2]≦2.5

(1.8 [0.83]) 6.3 [1.10] 3.6 [0.85] 3.8 [0.87]

Handle m/s2[m/s2]−−

4.1 [0.90] 6.2 [1.10]

Thread Size of Air Inlet Rc1/4 Rc3/8 Rc3/8 Rc3/8

PNEUMATIC ANGLE GRINDER

Please read this manual carefully before you attempt to use

your tool so that you may use it properly and safely.

MYTON

Model MLG-25, MLG-40, MLG-50, MLG-70

PROFESSIONAL TOOL

Keep the manual handy – so you can use it whenever necessary.

Original Instructions

MLG-25

MLG-50 MLG-70

MLG-40

1

The following Safety notations are used throughout the manual to highlight safety precautions for the user and for

the tool.

WARNING: Indicates a potentially hazardous situation which, if not avoided by following the

instructions given, could result in death or serious injury.

CAUTION: Indicates a potentially hazardous situation which, if not avoided by following the

instructions given, could result in injury or material damage.

Please note, however, that failure to observe safety precautions under the “ Caution” category could result in a

serious occurrence depending on the situation: please observe all safety precautions in the manual.

Caution: Important precautions for tool setup, operation and maintenance.

Thank you very much for your purchase of this

Nitto Kohki product.

Before using your tool, please read this manual

carefully so that you may use it properly to get

the most out of it.

Please keep the manual handy - so you can

use it whenever necessary.

・English : Please ask your dealer or

distributor for instruction manual

in local language(s).

・German : Bitte fragen Sie lhren Händler

nach eine Betriebsanleitung in

Landessprache.

・French : S'il vous plait, veuillez demandez

á votre foumisseur de manuel

instruction en langue locale.

・Spanish : Por favor, cantacte con su

distribuidor para el manual de

instrucciones en español.

・Portuguese : Por favor pessa ao seo agente

ou distribuidor o manual de

instrucces ih linguagen local.

・Italian : Per Manuale Istruzioni in lingua

locale Vi preghiamo di rivolgervi

al rivenditore o distributore.

・Dutch : Vraag uw handelaar

om een nederladstalige

gebruiksaanwijzing.

・Swedish : Be er lokala Åtreförsäljare eller

distributör om manualer pá

svenska.

・Danish : Venligst henvend Dem til den

danske distributør for instructions

manualer.

・Polish : Prosze pytac swojego dealera

lub dystrybutora o instrukcje

obslugi w jezyku localnym.

・中文 :請向當地供應商或経銷商詢問中

文使用説明書

CONTENTS page

IMPORTANT SAFETY INSTRUCTIONS ……………………2

GENERAL: TOOLS ……………………………………………2

GENERAL: PNEUMATIC TOOLS …………………………3

INSTRUCTIONS FOR THIS TOOL …………………………4

1. USAGE ……………………………………………………5

2. CHECK THE CONTENTS OF THE PACKAGE ……… 5

3. NAME OF PARTS ………………………………………5

4. AIR SUPPLY ………………………………………………6

5. PREPARATION (MLG-50, MLG-70) ……………………6

6. GRINDING WHEELS ……………………………………6

7. MOUNTING AND REMOVING GRINDING WHEEL …7

8. HOW TO OPERATE THE TOOL ………………………8

9. STORAGE ………………………………………………… 9

10. MAINTENANCE ………………………………………… 9

11. ORDERING SERVICE PARTS ……………………… 10

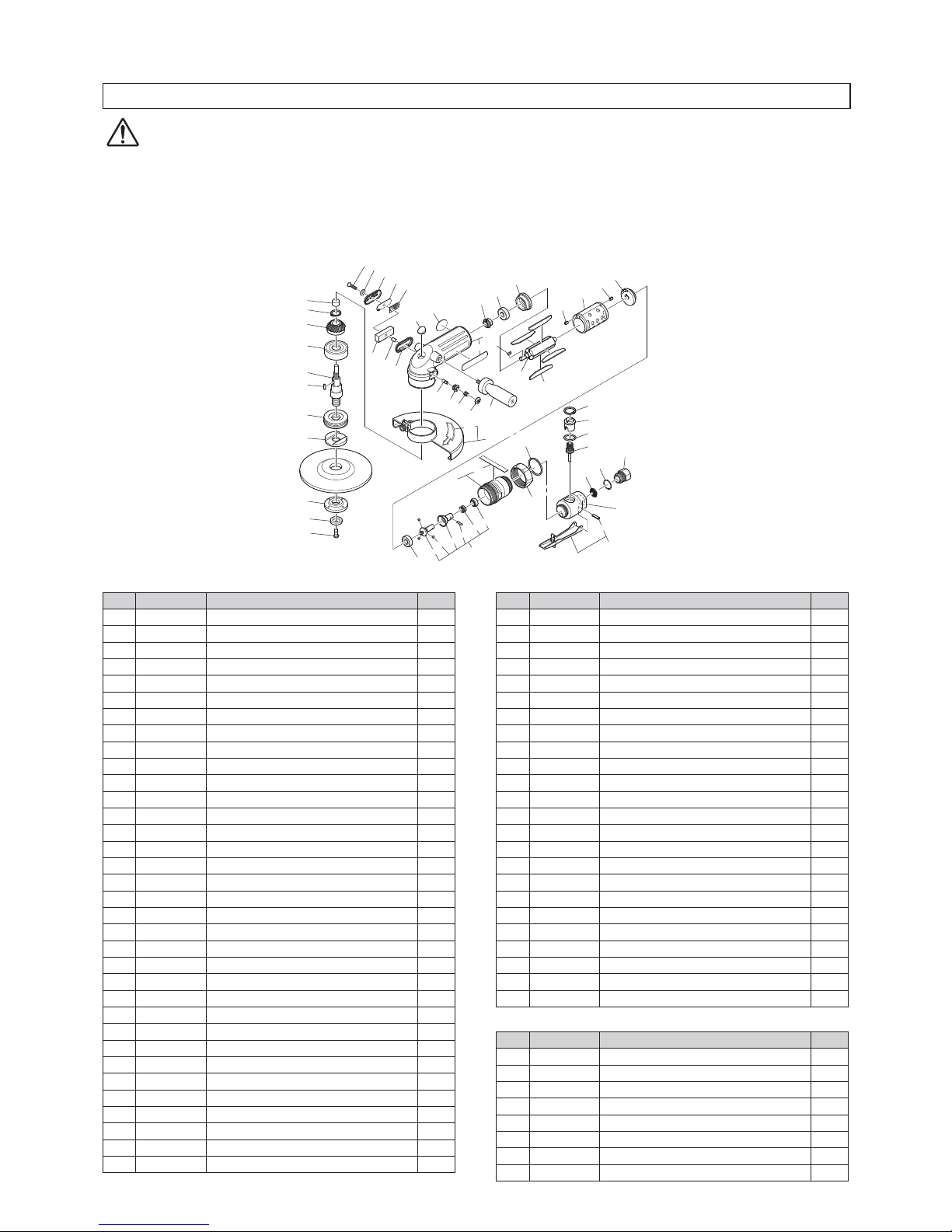

12. EXPLODED DIAGRAM : MLG-25 …………………… 11

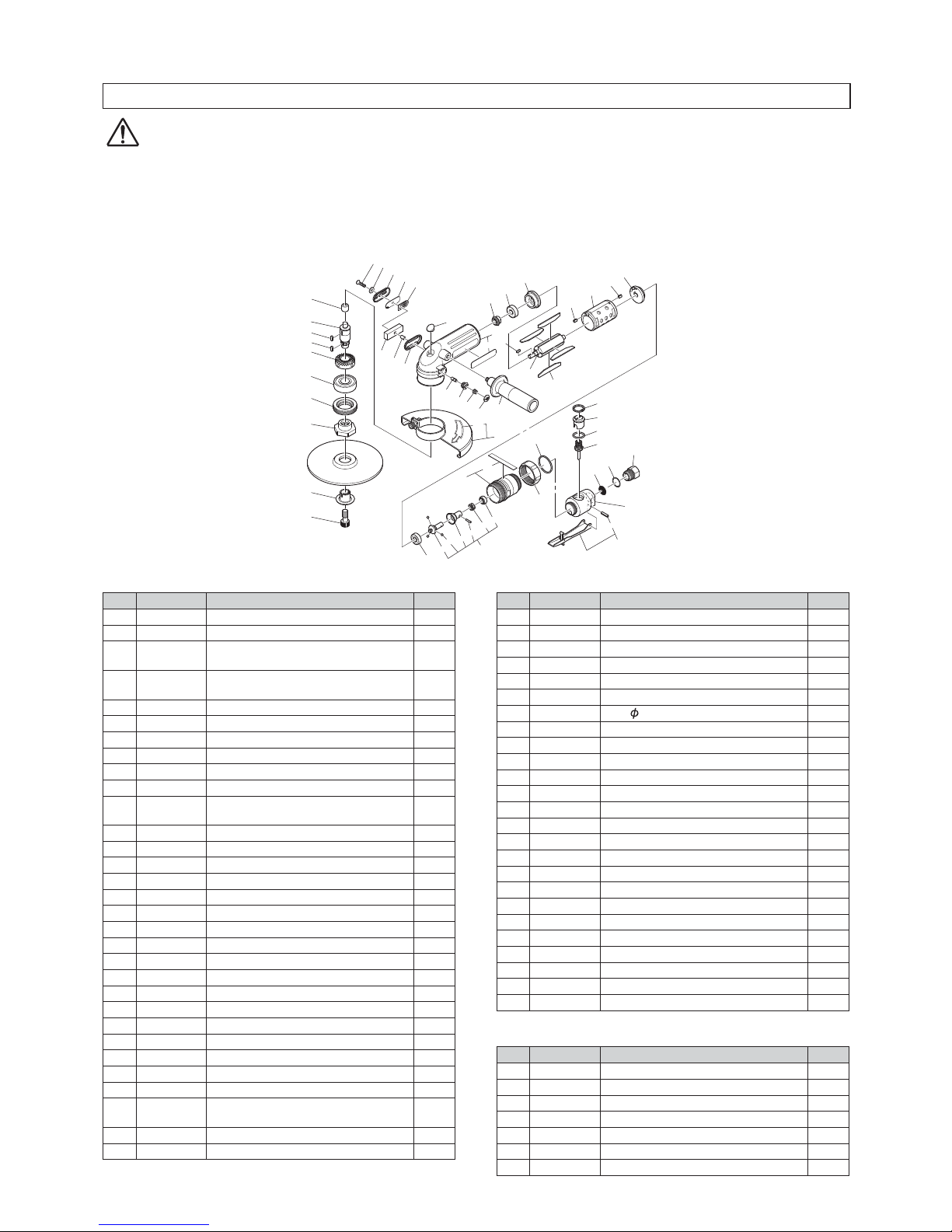

13. EXPLODED DIAGRAM : MLG-40 …………………… 12

14. EXPLODED DIAGRAM : MLG-50 …………………… 13

15. EXPLODED DIAGRAM : MLG-70 …………………… 14

PICTOGRAM

Warning: It might be dangerous to operate the tool if

the instructions supplied are not followed.

Using this tool improperly could result in serious injury.

Read the instruction manual before using.

Always wear suitable eye protection.

Always wear suitable hearing protection.

Always wear respiratory protective equipment (PPE).

2

IMPORTANT SAFETY

INSTRUCTIONS

When using the tool, please observe the safety

precautions below to prevent possible accident or

injury.

GENERAL: TOOLS

WARNING

TO OPERATORS

●Wear proper clothing for the type of work being

done.

Take care to avoid entanglement with the moving

parts of the tool with clothing, ties, hair etc. If items

become entangled it will cause the operator to be

pulled towards the tool and lead to possible cause of

accident or injury.

●Always wear suitable eye protection.

Remember, regular glasses are not safety glasses.

The lenses are only shock resistant, which will not

give you sufficient eye protection you may need in

your working environment.

●Always wear suitable hearing protection.

●Wear respiratory protective equipment (PPE).

Wear respiratory protective equipment (PPE) when

working in an environment where dust particles are

generated in operation.

●Avoid working posture that is too stressful.

Always ensure a firm footing and well balanced

posture.

●Do not operate the tool if you are too tired.

●Never touch any moving parts of the tool when

running.

ABOUT WORK AREA

●Keep the work area clean.

Cluttered work areas (e.g. workbench) invite

accidents.

●Carefully select the work area.

Do not expose tool to rain.

Do not use tool in a wet or soaked area.

See that the work area is adequately illuminated.

●Never work near inflammable liquid or in a

potentially explosive atmosphere.

●Keep children away from the work area.

Keep children and unauthorized people away from

the work area to avoid accident or injury.

●Some tools generate high noise levels.

Check to be sure that the use of this tool conforms

to all local noise regulations.

BEFORE OPERATION

●Inspect tool before use.

Before using, check that screws are securely

tightened, that any protective cover or guard is

securely in place, other parts are free from damage

and that the tool runs as it should.

Check that moving parts are properly adjusted for

positioning and tightened, that parts are free from

damage and properly mounted, and that all other

parts are in good condition for normal operation.

Should you find any damage to the protective

cover or other part, replace it in accordance with

the Operation Manual. If there are no instructions

in the Manual, please contact the sales agent

through which you have purchased your tool or an

authorized dealer near you for repair.

Likewise, if a switch failure occurs, contact sales

agent through which you have purchased your tool

or an authorized dealer near you for repair.

Do not use the tool if it does not start or stop with

the start/stop switch.

●Securely mount cutter

An improperly mounted cutter may fly out, causing

possible damage to the tool or injury to the operator.

●Always remove spanner, wrench, etc., once

adjustment has been made with them.

●Use a tool appropriate for the application.

Avoid heavy-duty application that is beyond the

capacity of tool.

●Do not use the tool for purposes other than what

it is designed for.

●Do not abuse tool.

Use tool in accordance with the specifications: you’ll

get the most out of it while ensuring safety.

●Securely fasten workpiece in place.

Use a vice or clamp to securely fasten the workpiece

in place. It is much safer this way than holding it in

your hand, allowing you to operate the tool with both

hands.

ABOUT HANDLING

●How to store tool.

When the tool is not used, store it in a dry area and

out of reach of children.

●How to carry tool.

Do not touch the start switch while the tool is being

carried.

●Do not leave the tool unattended while it is

running.

Turn off the start switch and disconnect the tool from

power source. Do not leave the work area until the

3

tool comes to a complete stop.

MAINTENANCE/SERVICE

●Do not take apart or modify tool.

Disassembly or modification carried out without

the supervision of a qualified or authorized service

engineer could result in an accident or injury.

●Inspect cutting tool and accessories, etc.

Always check to see that cutting tool and

accessories, etc. are in good operating condition

without damage or deterioration before you mount

them on the tool. Should you find any damage to

an accessory or part, please contact sales agent

through which you have purchased your tool or an

authorized dealer near you for repair.

●Check parts for damage.

When you have found damage to accessory or other

part, carefully check the damaged part to determine

the extent of influence it has upon the functions

of the tool – that is, determine whether it can still

perform its normal functions.

Check to see that the linkage of the moving parts

is OK, that all parts are OK without damage,

that they are properly mounted, and that the tool

functions normally. Should you find any damage

to an accessory or part that may hamper proper

functioning of the tool, please contact sales agent

through which you have purchased your tool or an

authorized dealer near you for repair.

●Have your tool repaired at an authorized Nitto

Service Center.

For repair or parts replacement, please contact the

sales agent through which you have purchased your

tool or an authorized dealer near you.

●Use only Nitto genuine parts.

Use of improper parts may result in serious

occurrence.

To obtain a Nitto genuine part, consult this Manual

or contact the sales agent from which you have

purchased your tool directly.

●Do not detach label or nameplate from tool.

When a label/nameplate gets damaged, worn or

becomes missing, contact the sales agent through

which you have purchased your tool or Nitto Kohki

Co. Ltd, directly for a replacement.

DISPOSAL

●When a tool is taken permanently out of service, it

is advised that the tool is disassembled, degreased

and parts separated by material and recycled locally

in the appropriate manner.

GENERAL: PNEUMATIC

TOOLS

WARNING

●Use appropriate air pressure.

Excessively high air pressure will increase the

number of revolutions or strokes causing not only

potential premature failure/breakage but could also

lead to an unexpected accident or injury.

●Connect tool to air supply line.

There are various types of pipes running in a factory

in addition to the pneumatic line (such as oxygen,

nitrogen, gas and water). For this reason, always

ensure that you are connecting to the pneumatic

line.

●Start tool properly.

Turn the start switch OFF before connecting to the

air supply line.

●Always disconnect the tool from the air supply

line before putting on/taking off any accessory

and prior to carrying out any maintenance work.

●Avoid exposure to exhaust air.

Pneumatic tool exhaust air contains oil and

contaminated moisture. Make sure the exhaust air is

not directed towards your face or anyone else within

the work area.

●Keep tool off electricity.

This pneumatic tool is not electrically insulated. To

avoid a potential electric shock do not use where

there is a possibility of coming into contact with live

electricity.

CAUTION

●Handle tool carefully.

Abusive use of tool could invite failure or accident.

Do not throw, drop or shock the tool.

●Handle connecting hose carefully.

Do not carry the tool by the air hose.

Do not pull the air hose to disconnect.

4

INSTRUCTIONS

FOR

THIS TOOL

About Your Tool

WARNING

●Protect your body from the chips/filings.

Hot chips/filings may fly out from the work piece.

Always wear safety glasses, dust mask, earplugs,

gloves (except knitted gloves) and long-sleeved

garment.

Keep your face well away from the work piece.

●Always use a Grinding Wheel with a maximum

operating speed (m/s) rating equal to or exceeding

the labeled speed of the tool. Make sure the

dimensions of the Grinding Wheel you are using

is applicable to the specification of the grinder.

●Make sure there are no cracks, chips or damage

to the Grinding Wheel prior to use. Do not use

any wheels wet or without labels.

●Use Nitto Kohki’s Wheel Flanges only. However,

do not use any of them which have cracks, chips

or worn. Do not use the alternative flanges or flat

washers.

●Make sure if the Grinding Wheel is adaptable to

the Wheel Flanges.

Do not use reducing bushing to meet the Wheel

Lock unless they are supplied by the Grinding Wheel

manufacturer.

●Make sure there are no cracks, distortion or wear

marks on the thread of the Spindle or Wheel

Lock.

The label on the wheel has to be the same or bigger

diameter than that of a Spindle.

●Make sure if there is any cracks, distortion or

worn on a thread of a Spindle or Wheel Lock.

Do not use the grinder if you ever find one.

●Do not use the side of the Grinding Wheel (except

for specific side use Grinding Wheels)

●Always use the Wheel Guard for the grinder if

the maximum diameter of the Grinding Wheel is

over 50mm.

●Use the Wheel Guard provided.

Failure to do so could result in injury.

●Replace damaged, bent or severely worn Wheel

Guard. Do not use any Wheel Guard which can

damage the Grinding Wheel.

●Air pressure for the grinder must not exceed

0.6MPa (6kgf/cm2).

●Do not start or stop grinders suddenly.

Open a Throttle Lever gradually when you start

operation.

●After a grinder has been repaired and returned,

check the no load speed with a tachometer

before you use to make sure its actual speed

at 0.6MPa (6kgf/cm2) does not exceed the rated

speed printed on the Wheel Guard. Do the same

check after each stage of the work process of

work even in normal use. Set the Adjust Valve to

the maximum speed position when you check

the no load speed.

●Only qualified/trained operators should attach

or replace Grinding Wheels as well as checking/

testing them.

●Release the Throttle Lever when air supply is

stopped.

●Make sure no one is around grinding

circumferences before trial running.

●Run a trial for a minute before start grinding and

for three minutes after replacement of Grinding

Wheels to make sure there is no problem on the

grinder.

●Grind slowly until the Grinding Wheels get

warmer in case Wheels seem cold at the start.

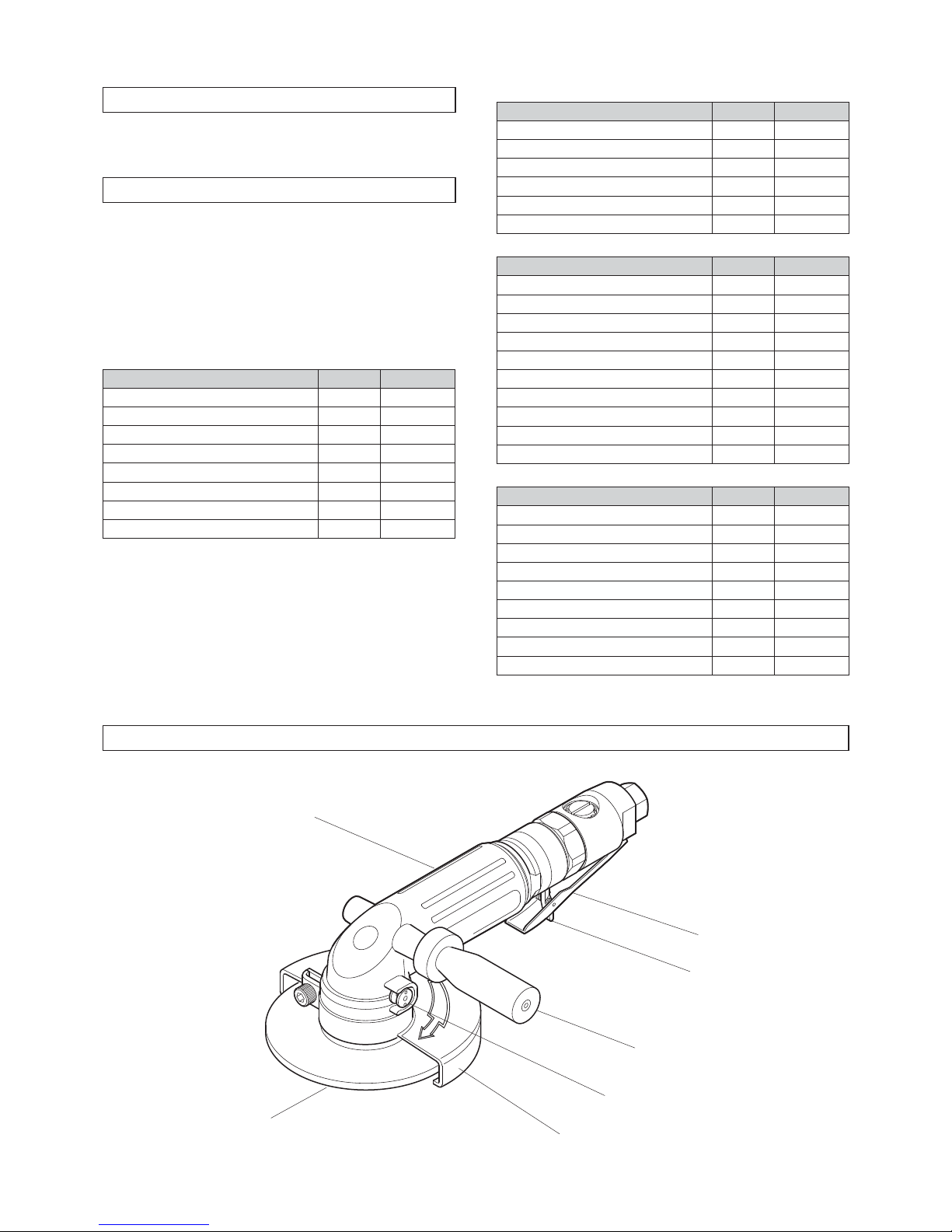

●Always operate the grinder at the correct angle.

(15° 30°) . (Fig.1)

Grinding Surface

15°〜30°

Fig. 1

●Do not put any inflammable liquid or use

the grinding tool in a potentially explosive

atmosphere as there is a possibility of sparks

when grinding which could cause a fire/

explosion.

5

1. USAGE

This tool is for grinding workpieces using a Type 27

Depressed Center Grinding Wheel.

2. CHECK THE CONTENTS OF THE PACKAGE

Check the contents and make sure that the tool does

not have any damage which may have occurred

during transportation. The contents should correspond

to the list as follows. In case of damage/missing

parts, please contact the sales agent from whom you

purchased the tool.

MLG-25

Package Contents Qty Check

MYTON MLG-25 1set

Grinding Wheel GS #80 1

Hex. Socket Screw Key 5 1

Single Ended Spanner 19 1

Bushing R1/4×NPT1/4 1

Instruction Manual 1

Declaration of Conformity 1

Caution for Use 1

MLG-40

Package Contents Qty Check

MYTON MLG-40 1set

Hex. Socket Screw Key 6 1

Bushing R3/8×NPT3/8 1

Instruction Manual 1

Declaration of Conformity 1

Caution for Use 1

MLG-50

Package Contents Qty Check

MYTON MLG-50 1set

Handle Ass’y 1set

Wheel Guard Ass’y 1set

Hex. Socket Screw Key 6 1

Hex. Socket Screw Key 4 1

Pin Face Wrench 1

Bushing R3/8×NPT3/8 1

Instruction Manual 1

Declaration of Conformity 1

Caution for Use 1

MLG-70

Package Contents Qty Check

MYTON MLG-70 1set

Handle Ass’y 1set

Wheel Guard Ass’y 1set

Hex. Socket Screw Key 6 1

Hex. Socket Screw Key 10 1

Bushing R3/8×NPT3/8 1

Instruction Manual 1

Declaration of Conformity 1

Caution for Use 1

3. NAME OF PARTS

Grinding Wheel

Handle Ass’y

Lock Lever

Spindle Lock Button

Wheel Guard Ass’y

Throttle Lever

Housing

6

4. AIR SUPPLY

CAUTION

●Draw off drainage before starting operation. If

the drainage enters into the tool, it can freeze

around the exhaust port of the tool and result in

output power reduction.

4-1. Air Pressure

Adjust air pressure to 0.6MPa (or 6 kgf/cm2) with

the air regulator. Lower pressure may result in

insufficient performance. Higher pressure may result

in premature wornout of parts. It is important to

maintain the proper pressure with pressure regulator

on air line.

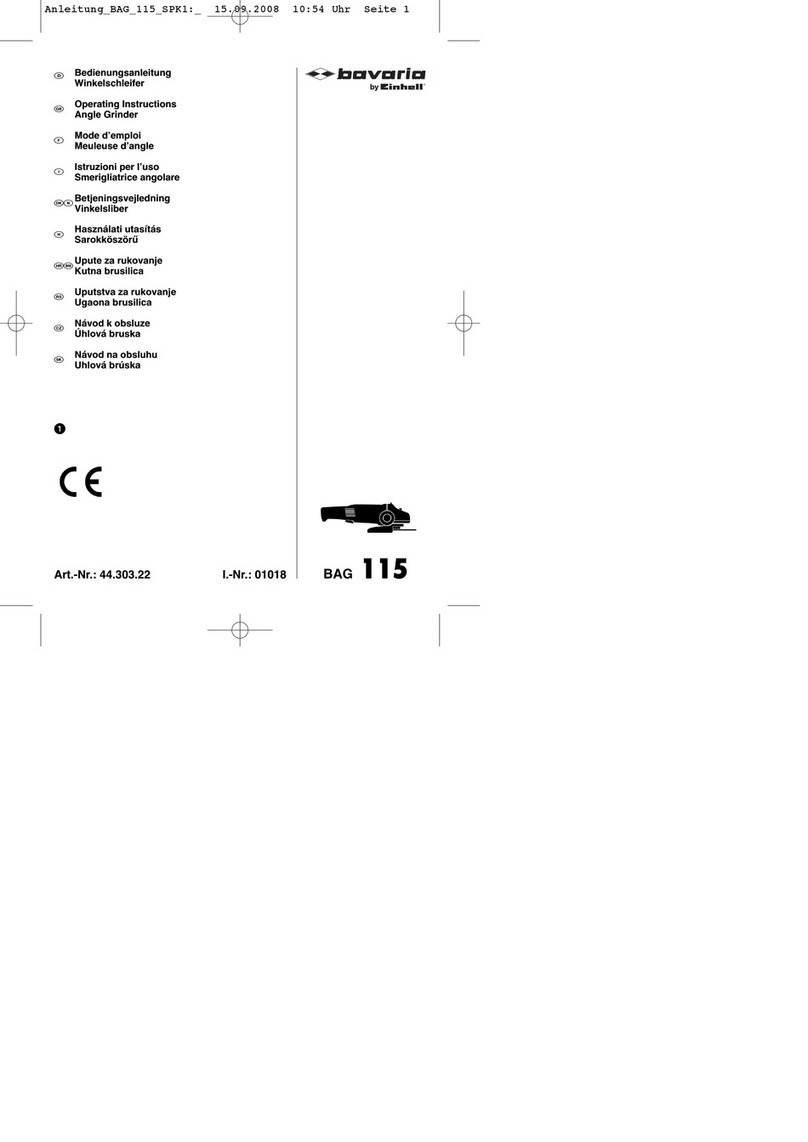

4-2. Air Line (Fig.2)

Use a 9.5mm (3/8”) I.D. [MLG-25] or 12.7 mm (1/2”)

I.D. [MLG-40, MLG-50, MLG-70] air hose between

the compressor and the tool. Compressed air comes

to be cooled down and its drain be separated, as

soon as the air leaves the compressor. The drain,

however , is condensed in the piping, and can

enter into the tool mechanism, and may cause

malfunction. So, install an air filter and an oiler

between the compressor and the tool.

4-3. oiler

Install an oiler between the compressor and the tool.

Use machine oil ISO VG-10 for lubrication and rust

prevention. Negligence of the oil supply may cause

damages on the tool. Lubricating the tool with high

viscosity oil reduces the tool performance.

4-4. Lubrication (Fig.2)

Before starting the tool, disconnect air hose from

the tool and supply a few drops of machine oil ISO

VG-10 to the air inlet port of the tool. Then reconnect

and make idle running for a few seconds so that the

oil should reach every part in the tool.

Air Regulator Oiler

Air Filter

Compressor

Lubrication

Tool 9.5mm (3/8”) I.D. Hose [MLG-25]

or 12.7mm (1/2”) I.D. Hose

[MLG-40, MLG-50, MLG-70]

Cupla

Fig. 2

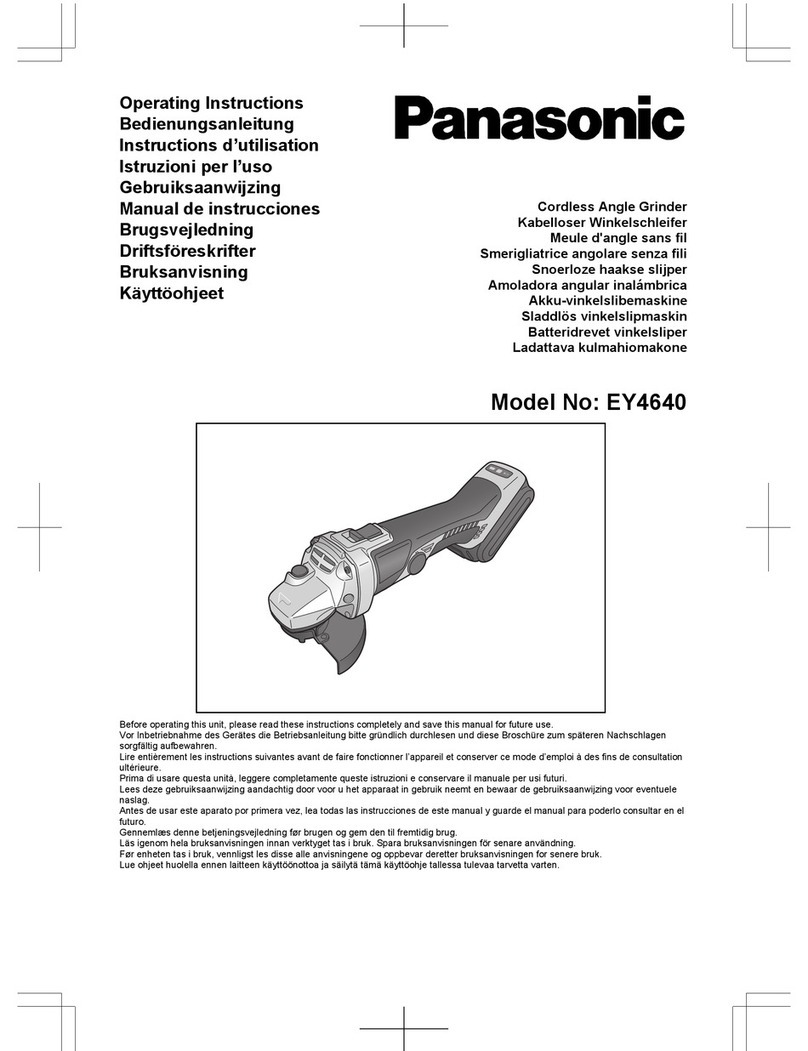

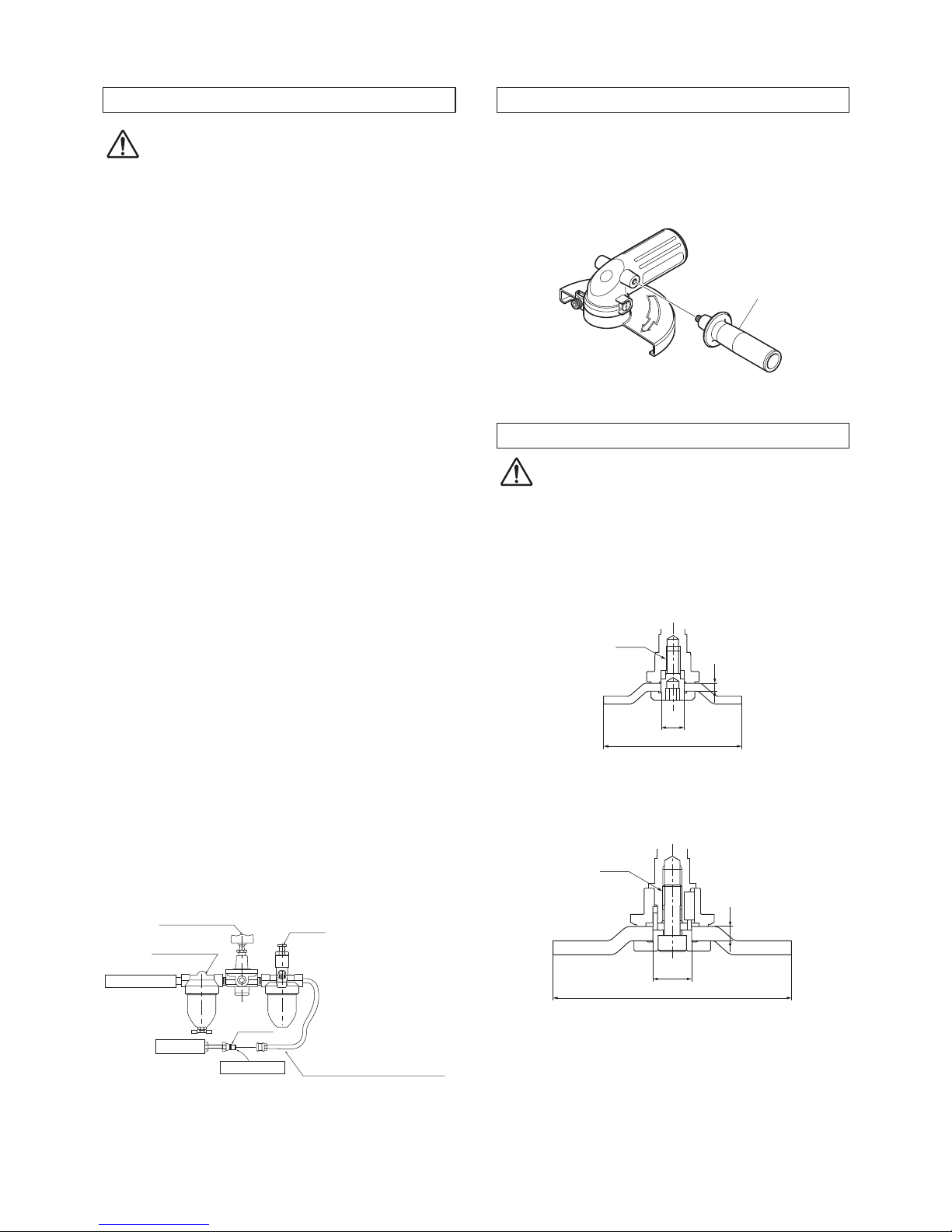

5. PREPARATION (MLG-50, MLG-70)

Mounting the Handle Ass’y

Screw the Handle Ass’y into the Housing Sub Ass’

y. It can be mounted on either right or left side of the

Housing Sub Ass’y. Be sure to mount the Handle Ass’

y before use.

+DQGOH$VVҋ\

Fig. 3

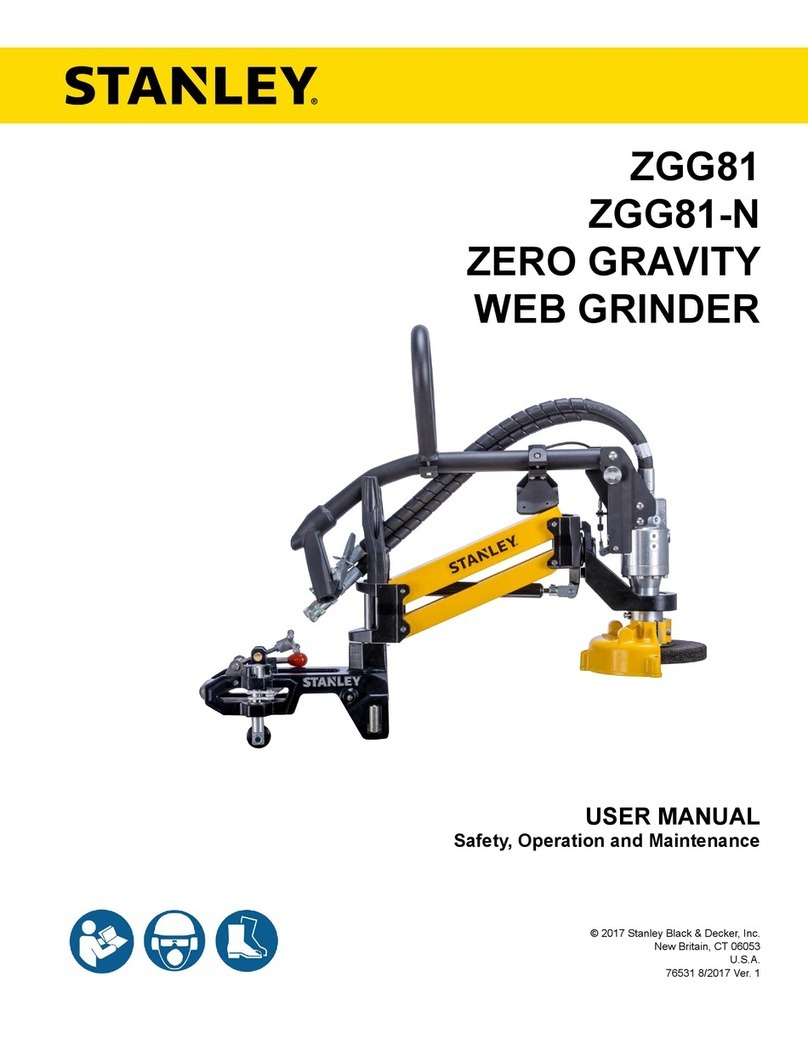

6. GRINDING WHEELS

WARNING

The maximum operating speed marked on the Grinding

Wheel, blotters, or packaging, shall equal or exceed

the rated speed on the grinder.

Use with Type 27 Depressed Center Grinding Wheels.

MLG-25

A

M6

B

C

Fig. 4

MLG-40

0

$

%

&

Fig. 5

7

MLG-50

0

0

$

%

&

Fig. 6

MLG-70

0

$

%

&

Fig. 7

MLG-25 MLG-40 MLG-50 MLG-70

A58mm

(2-9/32”) 100mm (4”) 125mm(5”) 180mm (7”)

B9.6mm

(3/8”) 16mm (5/8”) 22mm(7/8”) 22mm (7/8”)

C3mm

(1/8”)

4mm(5/32”)

~

6.4mm(1/4”)

1mm(3/64”)

~

6.4mm(1/4”)

6mm (1/4”)

~

8mm (5/16”)

A : Diameter of the Grinding Wheel

B : Hole of the Grinding Wheel

C : Thickness of the Grinding Wheel

7. MOUNTING AND DISMOUNTING GRINDING WHEEL

WARNING

Always turn off the air supply and disconnect the air

supply hose.

Read and thoroughly understand IMPORTANT

INSTRUCTIONS FOR GRINDER before carrying out

these operations.

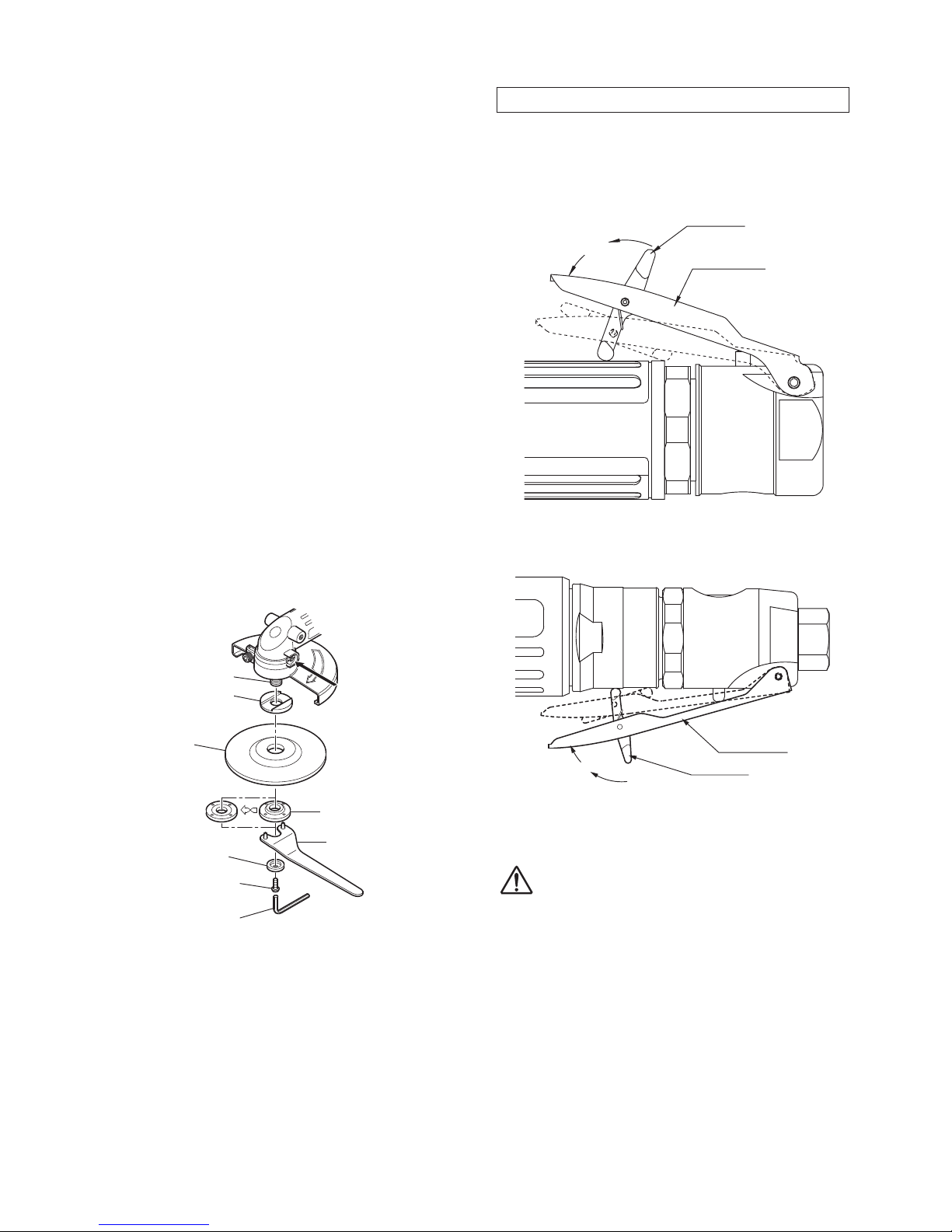

7-1. MLG-25

Mounting

1. Hold the Spindle with Spanner supplied.

2. Insert the Outer Flange into the center hole of the

Grinding Wheel.

3. Secure it firmly to the Spindle by tightening the

Outer Flange with Hex. Socket Screw Key.

Removal

Hold the Spindle with Spanner and loosen Outer

Flange with Hex. Socket Screw Key to remove the

Grinding Wheel.

Spindle

Spanner

Grinding Wheel

Outer Flange

Hex. Socket Screw Key 5

Fig. 8

7-2. MLG-40, MLG-70

Mounting

1. Insert the Outer Flange into the center hole of the

Grinding Wheel.

2. While depressing the Spindle Lock Button lightly,

place the Driving Flange on the Spindle and

rotate it until it comes to stop, then push the

Spindle Lock Button down to the hilt until comes

to lock the position.

3. Align the cutout of the Outer Flange with the

Parallel Key on the Spindle, place the set of the

Outer Flange and the Grinding Wheel on the

Spindle, and tighten it with the accessory Hex.

Socket Screw Key. Releasing your hand from the

Spindle Lock Button will automatically unlock the

Spindle.

Removal

1. While depressing the Spindle Lock Button lightly,

rotate the Grinding Wheel with your hand until it

comes to stop, and then deeply push the Spindle

Lock Button down to the hilt until comes to lock

the position.

2. Loosen the Disk Lock Bolt with the accessory

Hex. Socket Screw Key, and remove the Grinding

Wheel.

'ULYLQJ)ODQJH

6SLQGOH

'HSUHVVWKH6SLQGOH

/RFN%XWWRQ

*ULQGLQJ:KHHO

2XWHU)ODQJH

'LVN/RFN%ROW

+H[6RFNHW6FUHZNH\>0/*@

+H[6RFNHW6FUHZNH\>0/*@

Fig. 9

8

7-3. MLG-50

Mounting

1. Hold the Spindle with pushing the Lock Button.

2. Insert the Driving Flange into the Spindle to fit

the convex on the Spindle and groove of Driving

Flange.

3. Insert the Grinding Wheel and Outer Flange into

the Spindle.

4. In case the thickness of the Grinding Wheel is

4mm or less, attach the Outer Flange up side

down.

5. Secure it firmly to the Spindle by tightening the

Outer Flange with Pin Face Wrench.

6. Secure Washer and Hex. Socket Button Head

Screw 6×15 firmly to the Spindle by tightening

the Socket Button Head Screw 6×15 with Hex.

Socket Screw Key.

Removal

1. Hold the Spindle with pushing the Lock Button.

2. Loosen the Hex. Socket Button Head Screw 6×

15 with Hex. Socket Screw Key and remove the

Washer.

3. Loosen the Outer Flange with the Pin Face

Wrench.

Spindle

Driving Flange

Grinding Wheel

Outer Flange

Pin Face Wrench

4mm or less

Washer

Hex. Socket Screw Key 4

Hex. Socket Button

Head Screw 6×15

Depress the Spindle

Lock Button.

Fig.10

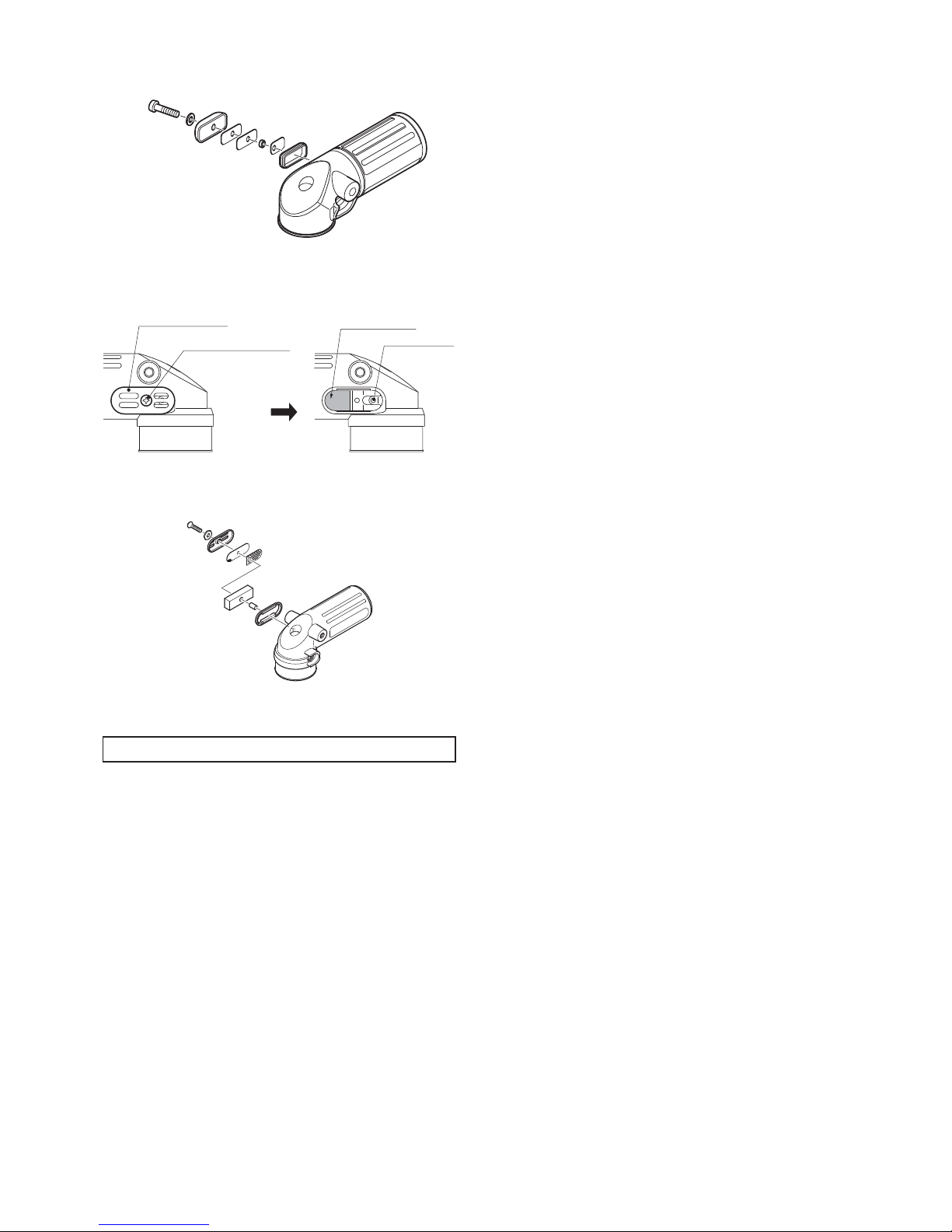

8. HOW TO OPERATE THE TOOL

8-1. Start and Stop

To start, release the lock lever and grasp the throttle

lever.

To stop, release the throttle lever.

MLG-25

Throttle Lever

Lock Lever

Release

Fig. 11

MLG-40, MLG-50, MLG-70

7KURWWOH/HYHU

/RFN/HYHU

5HOHDVH

Fig. 12

8-2. Adjust Valve

WARNING

Be sure to keep hands clear of moving parts.

The desired number of rotation between maximum rpm

and minimum rpm is obtained by turning the groove of

valve clockwise or counterclockwise with screwdriver.

Maximum rotation

Position the groove of Adjust Valve horizontal to main

body.

Minimum rotation

Position the groove of Adjust Valve vertical to main

body.

9

$GMXVW9DOYH

0D[LPXP

0LQLPXP

Fig. 13

9. STORAGE

CAUTION:

When tool is not used, store it out of reach of

children.

Avoid storing the tool in a location subject to high

humidity. If the tool is left as it is used, residual

moisture on the inside can cause rusting. Before

storing, and after operation, oil the tool at the air inlet

with machine oil ISO VG-10 and run it for a short time.

10. MAINTENANCE

Supply additional appropriate amount of Shell Alvania

Grease S#2 into the Gear Case with about once a

month interval.

MLG-25

1. Loosen the Screw 4x12 and remove the Exhaust

Cover, the Toothed Washer CW-4, the Spacer,

the Exhaust Plate, and the Packing Cover.

2. Inject grease with a grease gun into the Grease

Port next to the Exhaust Port.

The outside diameter of the nozzle tip of the

grease gun must be 3mm or smaller. The nozzle

for grease nipple cannot be used for this grease

filling, because the shape of the Grease Port is

different from that of the nozzle for grease nipple.

3. Before putting back the Exhaust Cover, execute

idle running and wipe out excessive grease.

4. For assembly, see Fig.14 and put back the parts

in the reverse order of disassembly.

(M4 Screw)

Grease Port

Exhaust Port

2. Remove

Spacer

Exhaust Plate

Exhaust Cover

1. Loosen

Screw 4×12

Packing Cover

Toothed Washer CW-4

Fig. 14

Fig. 15

MLG-40, MLG-50, MLG-70

1. Loosen the Screw and remove the Exhaust

Cover, the Toothed Washer CW-4, the Spacer,

and the Exhaust Filter.

2. Inject grease with a grease gun into the Grease

Port next to the Exhaust Port.

The outside diameter of the nozzle tip of the

grease gun must be 4mm or smaller. The nozzle

for grease nipple cannot be used for this grease

filling, because the shape of the Grease Port is

different from that of the nozzle for grease nipple.

3. Before putting back the Exhaust Cover, execute

idle running and wipe out excessive grease.

4. For assembly, see Fig.16~19 and put back the

parts in the reverse order of disassembly.

MLG-40

5HPRYH

/RRVHQ

à 6FUHZð

à 7RRWKHG:DVKHU&:

à ([KDXVW&RYHU

à )LOWHU6XSSRUW

à ([KDXVW)LOWHU

à 6SDFHU *UHDVH3RUW

([KDXVW3RUW

Fig. 16

10

Fig. 17

MLG-50, MLG-70

5HPRYH

/RRVHQ

à 6FUHZð

à 7RRWKHG:DVKHU&:

à 6SDFHU

à ([KDXVW)LOWHU

à ([KDXVW&RYHU ([KDXVW3RUW

*UHDVH3RUW

Fig. 18

Fig. 19

11. ORDERING SERVICE PARTS

●For further operational and handling information or

for replacement of parts and components, contact

the company from whom you purchased the tool or

an authorized dealer.

●In ordering parts and components give each part

number, part name and quantity required.

●Use only NITTO genuine parts.

11

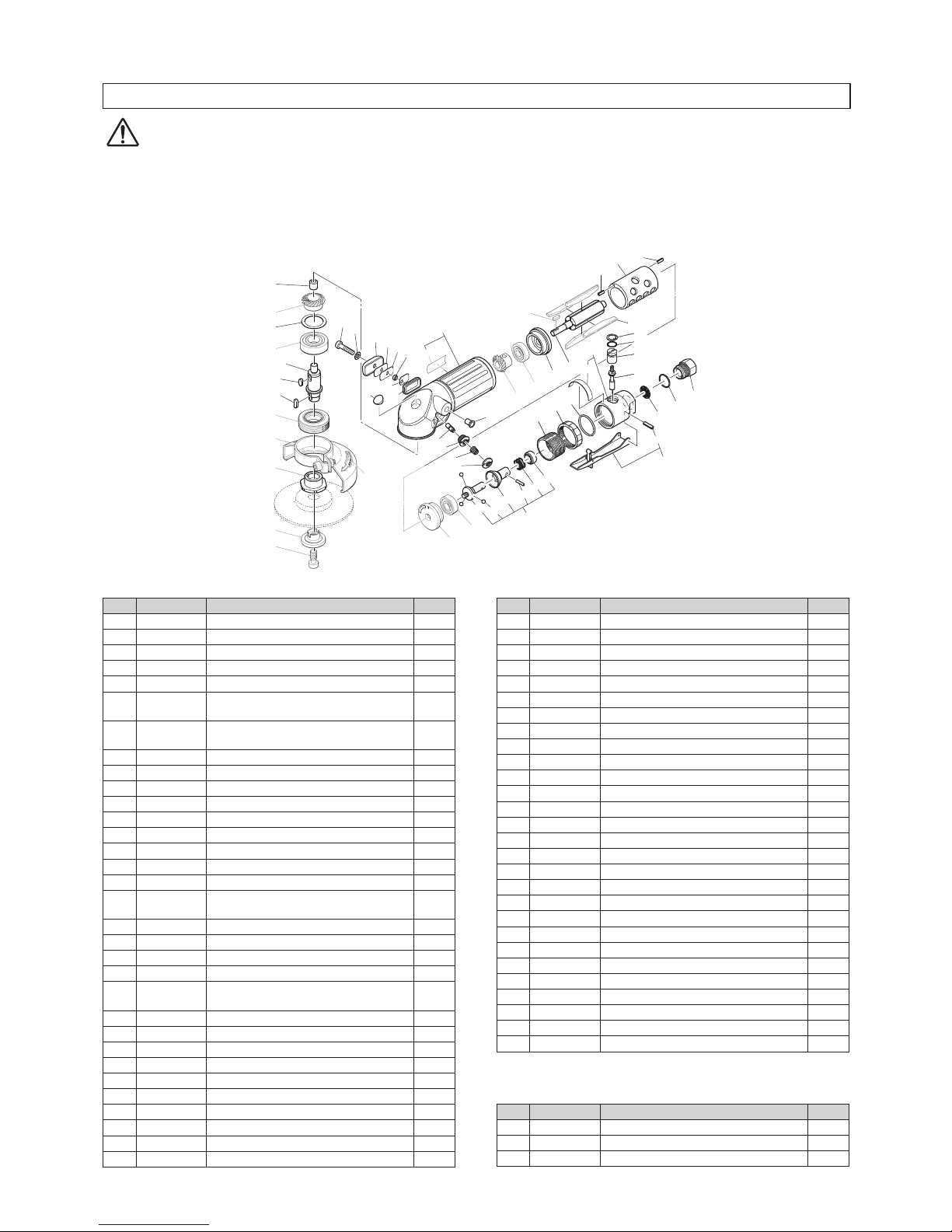

1

24

22 20 19

18

16

15

14

13

12

11

10

9

17

21

2

3

4

5

8

42

76

23

25

26

27

28

29

30

40

38

39

41

36

37

35

34

33

32

31

The part numbers with ( ) are included in the Ass’y parts written above them.

No. PartsNo. Description Qty

Price

1 TQ12638 Needle Bearing BK0609T2 1

2 TQ12986 Gear 1×22 1

3 TP00498 Ball Bearing 6001ZZ 1

4 TB08597 Bearing Set Screw Ass'y 1set

5 TQ12620 Spindle 1

6 TB08893 Wheel Guard Ass'y 1set

7 (TQ13054) Label Warning Wheel Guard 1

8 TP17962 Outer Flange 1

9 TP14222 Cylinder 1

10 TB08602 Blade Ass'y (4 pcs.) 1set

11 TP14224 Rotor 1

12 TQ12622 End Plate B 1

13 TP06322 Spacer 8×11×3 1

14 TP00468 Ball Bearing 608ZZ 1

15 TQ12985 Pinion 1×15 1

16 TB08892 Housing Ass'y 1set

17 (TQ13052) Label Warning CE Mark 1

18 TQ12628 Plug 1

19 TQ12649 Packing Cover 1

20 TQ12630 Exhaust Plate 2

21 TQ12658 Spacer 4EP-3 1

22 TQ12629 Exhaust Cover 1

23 TQ12647 Toothed Washer CW-4 1

24 TQ12739 Raised Countersunk Head

Screw 4×12 1

No. PartsNo. Description Qty

Price

25 TP00496 Spring Pin 2.5×6 AW 1

26 TP10109 End Plate A 1

27 TP03933 Ball Bearing 606ZZ 1

28 TP10110 Cap 1

29 TP10098 Lock Nut 1

30 TP03468 Lock Ring 1

31 TP03695 Internal Retaining Ring C-12 1

32 TP06326 Spacer 6×12×1.2 1

33 TP11997 O-Ring KS-7 1

34 TP06325 Adjust Valve 1

35 TA93070 Valve Stem Ass'y 1set

36 TB08895 Valve Body Sub Ass'y 1set

37 (TQ13053) Label Model 1

38 TB01152 Lever Ass'y 1set

39 (TP00460) Spring Pin 3×22 AW 1

40 (TP05498) Spring Pin 2×16 AW 1

Accessories

No. PartsNo. Description Qty

Price

41 TP02236 Bushing R1/4xNPT1/4 1

42 −Grinding Wheel GS#80×58 1

TQ12633 Single Ended Spanner 19 1

TP04004 Hex. Socket Screw Key 5 1

TQ12673 Instruction Manual 1

12. EXPLODED DIAGRAM : MLG-25

WARNING

This diagram is for your reference only. Do not attempt to service or repair the Tool.

Do not take the Tool apart. Contact an authorized Nitto dealer for all service and repair of the Tool.

Improper service and repair can cause accidents and service injuries.

Never attempt to modify the Tool.

Never attempt service or repair the Tool yourself.

12

13. EXPLODED DIAGRAM : MLG-40

WARNING

This diagram is for your reference only. Do not attempt to service or repair the Tool.

Do not take the Tool apart. Contact an authorized Nitto dealer for all service and repair of the Tool.

Improper service and repair can cause accidents and service injuries.

Never attempt to modify the Tool.

Never attempt service or repair the Tool yourself.

(41)

(42)

(43)

(44)

(45)

(46)

48

1

2

3

4

5

6

7

8

9

11

12

13

(10)

22 23

24

26

25

27

29

28

30

(32)

31

17

21 20

19

18

16

14

14

15

34

35

36

37

38

39

40

47

49

(33)

50

(51)

52

(53)

55

54

56

57

58

59

60

The part numbers with ( ) are included in the Ass’y parts written above them.

No. PartsNo. Description Qty

1 TQ00893 Needle Bearing BK0810 1

2 TQ12725 Gear 1

3 TQ12887 Plate 13.1x30x1.2 1

4 TP01609 Ball Bearing 6202ZZ 1

5 TQ13048 Spindle 1

6 TP00502 Parallel key Both Ends

Round 4x4x9.5 1

7 TQ13516 Grooved Parallel key Both Ends

Round 4x4x12 1

8 TB08883 Bearing Set Screw Ass’y 1set

9 TB08918 Wheel Guard Ass’y 1set

10 (TQ02357) Label Warning for Wheel Guard 1

11 TQ13049 Driving Flange 1

12 TQ00775 Outer Flange 1

13 TP09932 Disk Lock Bolt 1

14 TP04061 Spring Pin 3x6 2

15 TQ13033 Cylinder 1

16 TB08707 Blade Ass’y(4pcs.) 1set

17 TP10130 Parallel key Both Ends

Round 3x3x10 1

18 TQ13032 Rotor 1

19 TQ13030 EndPlate B 1

20 TP10133 Ball Bearing 609ZZ 1

21 TQ12726 Pinion 1

22 TQ12739 Raised Countersunk Head Screw

4x12 1

23 TQ12647 Toothed Washer CW-4 1

24 TQ12729 Exhaust Cover 1

25 TQ13038 Filter Support 40 1

26 TQ13039 Exhaust Filter 40 1

27 TQ13036 Spacer 4.3x8x2.8 1

28 TQ13037 Exhaust Plate 1

29 TQ12730 Packing Cover 1

30 TQ12724 Plug 40 1

31 TB08702 Housing SUB Ass’y 1set

32 (TQ12774) Label Warning CE Marking 1

No. PartsNo. Description Qty

33 (TQ13074) Plug 7.2 1

34 TQ12542 Lock Pin 1

35 TQ12537 Pin Guide 1

36 TQ12544 Conical Spring 0.6x7.2x8.8x8 1

37 TQ12543 Lock Button 1

38 TQ13029 EndPlate A 1

39 TQ12782 Ball Bearing 699ZZ 1

40 TB08676 Governor Ass’y 1set

41 (TQ12813) Base 1

42 (CP03282) Ball 7/32 3

43 (TQ12067) Sleeve 1

44 (TQ12090) Needle Roller 2.5x13.8 1

45 (TQ13035) Spring 1.4x15.5x16.3 1

46 (TQ12068) Stopper 1

47 TQ12777 Adapter 1

48 TQ12778 Lock Ring 1

49 TQ12780 O-ring JASO-1033 1

50 TB08704 Valve Body Ass’y 1set

51 (TQ12776) Label Model 1

52 TB08669 Lever Ass’y 1set

53 (TP13893) Spring Pin 3x22AW 1

54 TP03473 Internal Retaining Ring C-14 1

55 TP11992 O-ring KS-9 1

56 TP04394 Adjust Valve 1

57 TB05591 Throttle Valve Ass’y 1set

58 TP01658 Filter 1

59 CP25821 O-ring JASO-1020 1

60 TQ12671 Bushing M23xRc3/8 1

Accessories

No. PartsNo. Description Qty

TP00170 Hex.Socket Screw Key 6 1

TQ12673 Instruction Manual 1

TQ02350 Bushing R3/8xNPT3/8 1

13

14. EXPLODED DIAGRAM : MLG-50

WARNING

This diagram is for your reference only. Do not attempt to service or repair the Tool.

Do not take the Tool apart. Contact an authorized Nitto dealer for all service and repair of the Tool.

Improper service and repair can cause accidents and service injuries.

Never attempt to modify the Tool.

Never attempt service or repair the Tool yourself.

The part numbers with ( ) are included in the Ass’y parts written above them.

1

2

3

4

5

6

7

8

9

10

11

12

14

15

16

19

18

17

20

31

30

(22)

32

33

34

35

36

37

37

38

39

29

24

25

23

26

27

(28)

51

50

(21)

40

(43)

(42)

(44)

(45)

41

(46)

(47)

(49)

48

(54)

53

52

55

56

57

58

61

59

13

60

No. PartsNo. Parts Name Qty

1 TQ12088 Needle Bearing BK1012 1

2 TP18356 External Retaining Ring C-14 1

3 TQ14290 Gear 1

4 TP04138 Ball Bearing 6204ZZ 1

5 TQ14289 Spindle 1

6 TP09933 Parallel Key Both Ends Round 4X4X12 1

7 TB12073 Bearing Set Screw Ass'y 1set

8 TQ04123 Driving Flange 1

9 TQ04124 Outer Flange 1

10 TQ04139 Wahser 6.3x21x4.5 1

11 TP14688 Hex. Socket Button Head Screw 6x15 1

12 TQ12330 Raised Countersunk Head Screw 4x20 1

13 TQ12647 Toothed Washer CW-4 1

14 TQ12076 Exhaust Cover 1

15 TQ12570 Filter Support 1

16 TQ12541 Silencer Plate 1

17 TQ12540 Exhaust Filter 1

18 TQ12109 Spacer 5x6x11.8 1

19 TQ12559 Packing Cover 1

20 TB09676 Housing Sub Ass'y 1set

21 (TQ12663) Label Warning CE Marking 1

22 (TQ14301) Label Model 1

23 TQ12542 Lock Pin 1

24 TQ12537 Pin Guide 1

25 TQ12544 Conical Spring 0.6x7.2x8.8x8 1

26 TQ12543 Lock Button 1

30 TQ12571 Plug 1

31 TQ14288 Pinion 1

32 TQ12087 Ball Bearing 638ZZ 1

33 TQ12064 EndPlate B 1

34 TP10130 Parallel Key Both Ends Round 3x3x10 1

35 TQ12061 Rotor 1

36 TB08555 Blade Ass'y 1set

37 TP04061 SpringPin 3x6 AW 2

No. PartsNo. Parts Name Qty

38 TQ12062 Cylinder 1

39 TQ12063 EndPlate A 1

40 TP06242 Ball Bearing 629ZZ 1

41 TB08258 Governor Ass'y 1set

42 (TQ12066) Base 1

43 (TP01566) Ball φ63

44 (TQ12067) Sleeve 1

45 (TQ12090) Needle Roller 2.5x13.8 1

46 (TQ12069) Spring 1.4x15.5x15.5 1

47 (TQ12068) Stopper 1

48 TB09678 Valve Holder Ass’y 1set

49 (TQ14292) Label Specification 1

50 TP17452 Lock Ring 1

51 TP17445 O-ring S-35.5 1

52 TQ12662 Valve Body 1

53 TB08669 Lever Ass'y 1set

54 (TP13893) SpringPin 3x30AW 1

55 TP10448 Internal Retaining Ring C-24 1

56 TQ12668 Adjust Valve 1

57 TP10714 O-ring S-22 1

58 TB09001 Valve Stem Ass'y 1set

59 TP01658 Filter 1

60 CP25821 O-ring JASO-1020 1

61 TQ12671 Bushing M23xRc3/8 1

Accessories

No. PartsNo. Parts Name Qty

27 TB09681 Wheel guard Ass'y 1set

28 (TQ04121) Label Warning Wheel guard 1

29 TB09680 Side Handle Ass'y 1set

TP00170 Hex. Socket Screw Key 6 1

TP01939 Hex. Socket Screw Key 4 1

TQ04125 Pin Face Wrench 1

TQ02350 Bushing R3/8xNPT3/8 1

TQ12673 Instruction Manual 1

14

15. EXPLODED DIAGRAM : MLG-70

WARNING

This diagram is for your reference only. Do not attempt to service or repair the Tool.

Do not take the Tool apart. Contact an authorized Nitto dealer for all service and repair of the Tool.

Improper service and repair can cause accidents and service injuries.

Never attempt to modify the Tool.

Never attempt service or repair the Tool yourself.

1

10

12

13

14

17

16

15

18

28

27

29

30

31

32

33

34

34

35

36

26

21 22

20

23

24

(25)

48

47

(19)

2

3

59

4

5

6

7

37

(40)

(39)

(41)

(42)

38

(43)

(44)

(46)

45

(51)

50

49

52

53

54

55

58

56

8

9

11

57

The part numbers with ( ) are included in the Ass’y parts written above them.

No. PartsNo. Description Qty

1 TQ12088 Needle Bearing BK1012 1

2 TQ12546 Spindle 1

3 TP09933 Parallel Key Both Ends Round

4X4X12 1

59 TQ13516 Grooved Parallel Key Both Ends

Round 4X4X12 1

4 TQ12547 Gear 1

5 TP04138 Ball Bearing 6204ZZ 1

6 TB08263 Bearing Set Screw Ass'y 1set

7 TQ00772 Driving Flange 1

8 TQ00771 Outer Flange 1

9 TP11688 Disk Lock Bolt 1

10 TQ12330 Raised Countersunk Head Screw

4X20 1

11 TQ12647 Toothed Washer CW-4 1

12 TQ12076 Exhaust Cover 1

13 TQ12570 Filter Support 1

14 TQ12541 Silencer Plate 1

15 TQ12540 Exhaust Filter 1

16 TQ12109 Spacer 5X6X11.8 1

17 TQ12559 Packing Cover 1

18 TB08793 Housing SUB Ass'y 1set

19 (TQ12663) Label Warning CE Marking 1

20 TQ12542 Lock Pin 1

21 TQ12537 Pin Guide 1

22 TQ12544 Conical Spring 0.6X7.2X8.8X8 1

23 TQ12543 Lock Button 1

27 TQ12571 Plug 1

28 TQ12070 Pinion 1

29 TQ12087 Ball Bearing 638ZZ 1

30 TQ12064 EndPlate B 1

31 TP10130 Parallel Key Both Ends Round

3X3X10 1

32 TQ12061 Rotor 1

33 TB08555 Blade Ass'y 1set

No. PartsNo. Description Qty

34 TP04061 SpringPin 3X 6 AW 2

35 TQ12062 Cylinder 1

36 TQ12063 EndPlate A 1

37 TP06242 Ball Bearing 629ZZ 1

38 TB08258 Governor Ass'y 1set

39 (TQ12066) Base 1

40 (TP01566) Ball 63

41 (TQ12067) Sleeve 1

42 (TQ12090) Needle Roller 2.5X13.8 1

43 (TQ12069) Spring 1.4X15.5X15.5 1

44 (TQ12068) Stopper 1

45 TB08668 Valve Holder Ass’y 1set

46 (TQ12750) Label Model 1

47 TP17452 Lock Ring 1

48 TP17445 O-ring S-35.5 1

49 TQ12662 Valve Body 1

50 TB08669 Lever Ass'y 1set

51 (TP13893) SpringPin 3X30AW 1

52 TP10448 Internal Retaining Ring C-24 1

53 TQ12668 Adjust Valve 1

54 TP10714 O-ring S-22 1

55 TA96331 Valve Stem Ass'y 1set

56 TP01658 Filter 1

57 CP25821 O-ring JASO-1020 1

58 TQ12671 Bushing M23XRc3/8 1

Accessories

No. PartsNo. Description Qty

24 TB08757 Wheel guard Ass'y 1set

25 (TQ12640) Label Warning Wheel guard 1

26 TB08265 Handle Ass'y 1set

TP00170 Hex. Socket Screw Key 6 1

TP11723 Hex. Socket Screw Key 10 1

TQ02350 Bushing R3/8XNPT3/8 1

TQ12673 Instruction Manual 1

Printed in KOREA TQ12673-6

2YHUVHDV$IILOLDWHV2IILFHV

1,772.2+.,86$,1&

&KDQFHOORU'ULYH5RVHOOH,/86$

7HO )D[

1,772.2+.,(8523(&2/7'

8QLW7KH(PSLUH&HQWUH,PSHULDO:D\

:DWIRUG+HUWV:'768.

7HO )D[

1,772.2+.,'(876&+/$1'*0%+

/HUFKHQVWU'6WHLQHQEURQQ*HUPDQ\

7HO )D[

1,772.2+.,&2/7'6,1*$325(%5$1&+

8%,&5(6&(17

8%,7(&+3$5./2%%<'6,1*$325(

7HO )D[

1,772.2+.,&2/7'

%$1*.2.5(35(6(17$7,9(2)),&(

0$%XVLQHVV&HQWHU4+RXVH&RQYHQW%OGJ

WK)ORRU8QLW$&RQYHQW5G6LORP%DQJUDN

%DQJNRN7KDLODQG

7HO )D[

1,772.2+.,$8675$/,$37</7'

%UDQGO6W%ULVEDQH7HFKQRORJ\3DUN

(LJKW0LOH3ODLQV4/'$XVWUDOLD

7HO )D[

1,772.2+.,6+$1*+$,&2/7'

5RRPVXLWH&2ULHQW,QWHUQDWLRQDO3OD]D

12/RX6KDQ*XDQ5RDG6KDQJKDL&+,1$

7HO )D[

1,772.2+.,&2/7'

6+(1=+(15(35(6(17$7,9(2)),&(

&6KHQ]KHQ,&&7RZHU)XKXDVDQOX)XWLDQ'LVWULFW

6KHQ]KHQ*XDQJGRQJ&KLQD

7HO )D[

This manual suits for next models

5

Table of contents

Other Nitto Grinder manuals

Popular Grinder manuals by other brands

Flex

Flex L 8-11 125 operating instructions

OPTIMUM Maschinen

OPTIMUM Maschinen OPTIgrind GBS 75 operating manual

EINHELL

EINHELL TC-WD 150 operating instructions

DeWalt

DeWalt DW756 instruction manual

Parkside

Parkside PWSA 20-Li C3 Translation of the original instructions

Makita

Makita DGA411 instruction manual