NKE GYROPILOT 2 User manual

Zi de Kerandré – Rue Gutemberg – 56700 – HENNEBONT – FRANCE

www.nke-marine-electronics.com

+33 297 365 685

GYROPILOT 2 computer

product reference : 90-60-130

INSTALLATION GUIDE

REV 2

- 2 - Gyropilot_2_um_EN_7_30

SOMMAIRE

1 PRESENTATION ............................................................................................................ 3

2 INSTALLING THE HYDRAULIC UNIT ........................................................................... 5

2.1 PREPARING THE RUDDER ARM......................................................................................... 5

2.2 INSTALLATION OF THE HYDRAULIC LINEAR DRIVE ................................................................ 6

2.3 INSTALLATION OF THE HYDRAULIC PUMP ........................................................................... 8

2.4 INSTALLATION OF THE RUDDER ANGLE SENSOR ................................................................. 8

3 INSTALLATION AND CONNECTING THE COMPUTER ............................................. 10

3.1 PACKING LIST ............................................................................................................... 10

3.2 LIST OF ACCESSORIES .................................................................................................. 10

3.3 INSTALLING AND LOCATION OF THE COMPUTER GYROPILOT 2 ............................................ 10

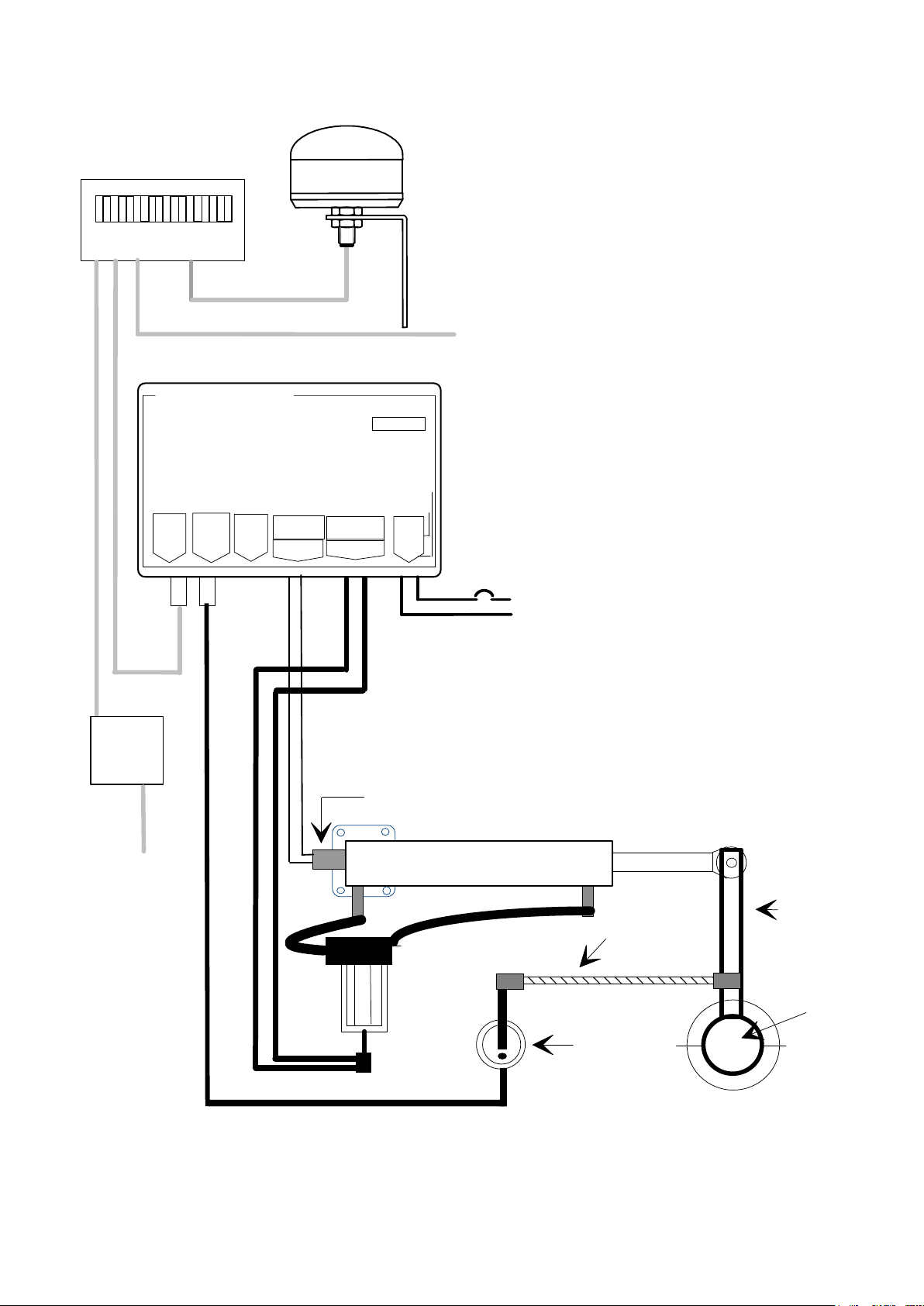

3.4 ELECTRIC DIAGRAM OF GYROPILOT 2 RVP COMPUTER (REVERSIBLE PUMP) ...................... 11

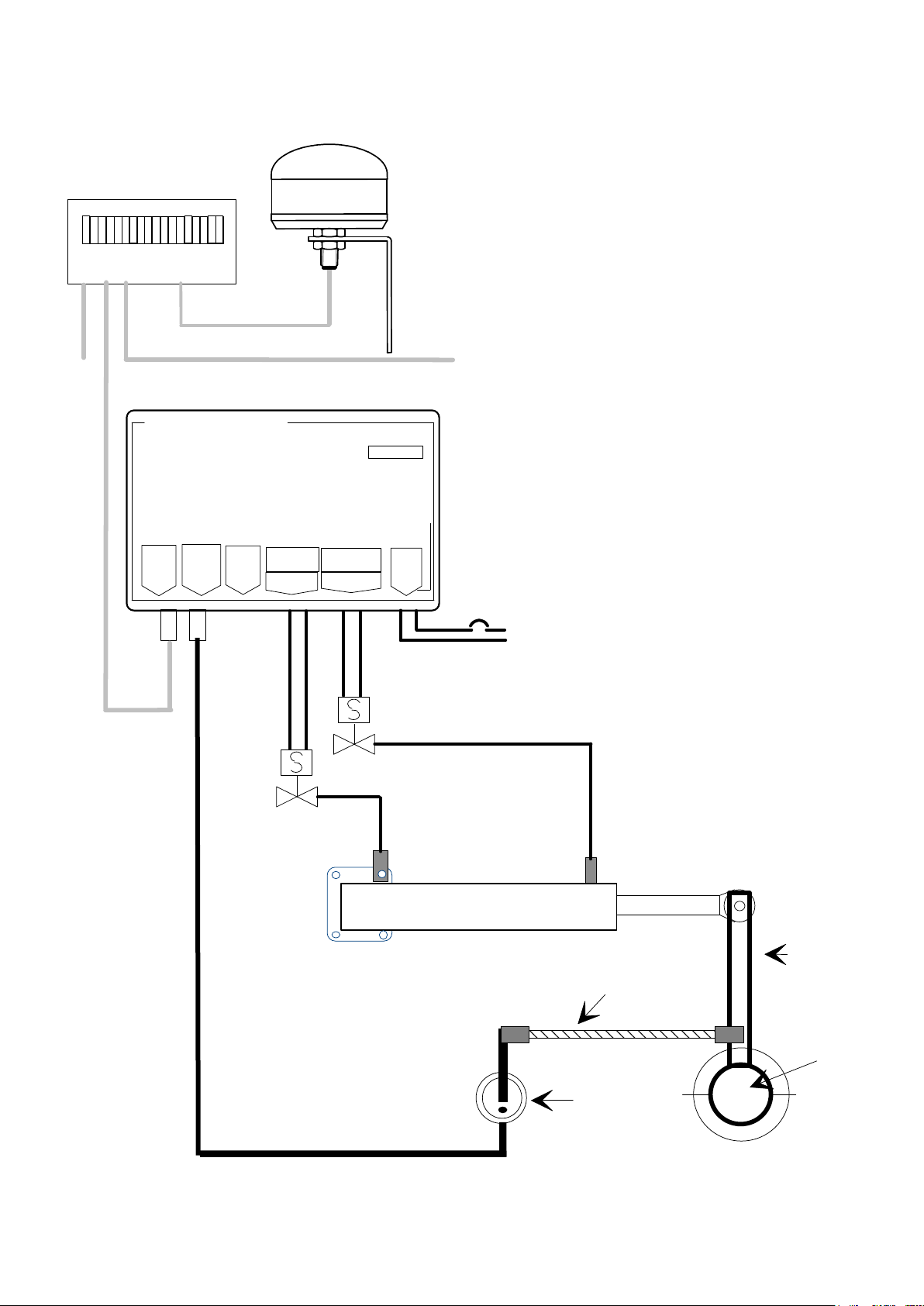

3.5 ELECTRIC DIAGRAM GYROPILOT 2 CRP COMPUTER ........................................................ 13

3.6 CONNECTING THE POWER SUPPLY OF THE LINEAR DRIVE MOTOR ....................................... 15

3.7 CONNECTING THE COMPUTER TO TOPLINE BUS ............................................................... 16

3.8 TECHNICAL SPECIFICATION ............................................................................................ 17

3.9 SOFTWARE COMPUTER VERSION .................................................................................... 17

3.10 DIAGNOSTIC FOR 1ST LEVEL TROUBLES SHOOTING. ....................................................... 17

4 INITIALISATION OF THE COMPUTER ........................................................................ 18

4.1 INITIALISATION .............................................................................................................. 18

4.2 FIRST START-UP OF THE PILOT ....................................................................................... 19

- 3 - Gyropilot_2_um_EN_7_30

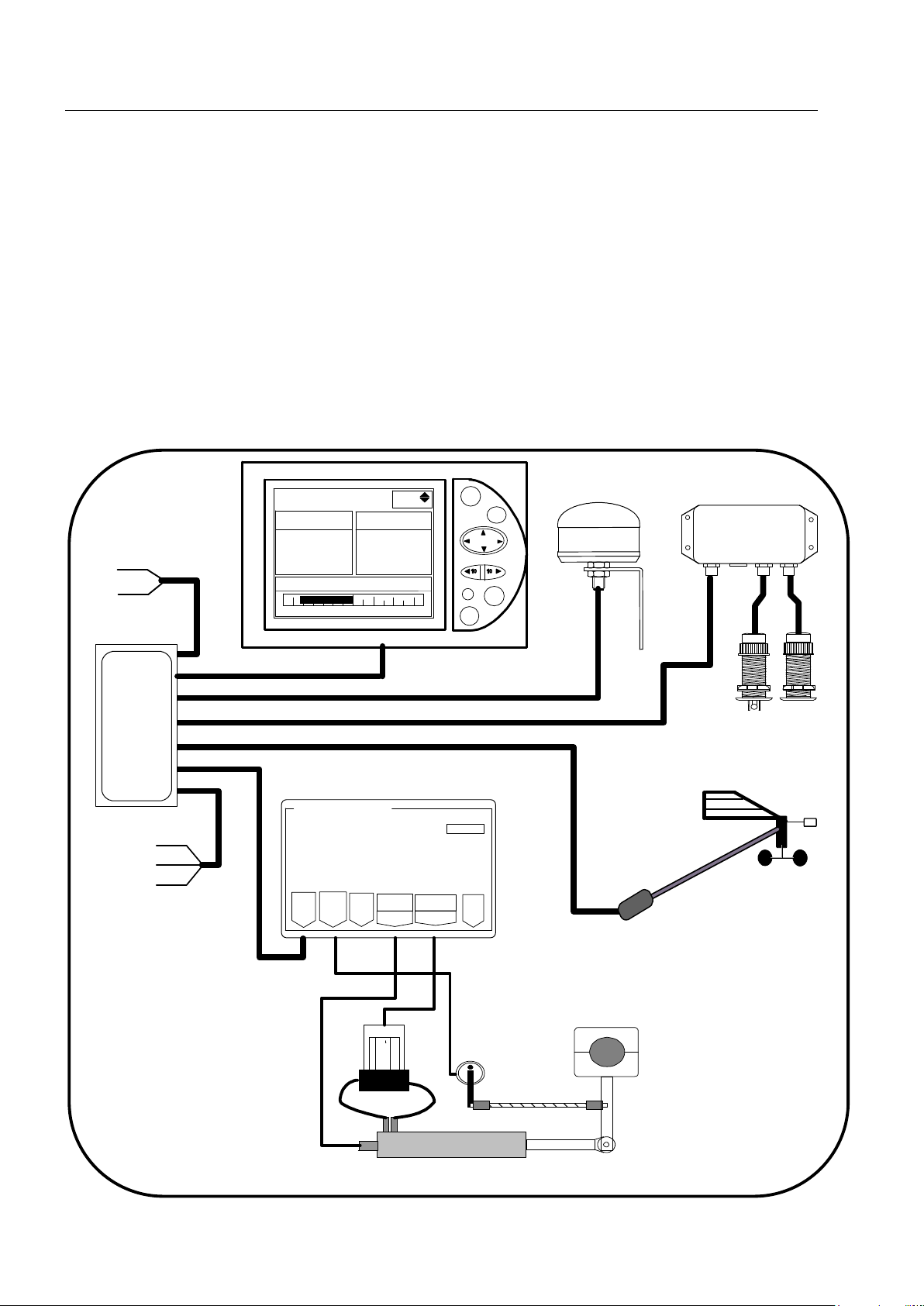

1 PRESENTATION

This installation guide gives you all information :

- To install the computer Gyropilot 2

- To install rudder angle sensor

- To install de the hydraulic unit

- To get the optimal performances from your pilot and your boat.

See the installation guide for fluxgate compass and multifonction Gyrographic.

Installation architecture

The presence of the equipment in the following diagram is for information only, and does

not represent the equipment of your installation.

nke Gyrop

i

lot 2

CRP

RVP

RVP

Calculateur Gyro2

Bus

Angle

Barre Tiller

Embrayage Alim.

Pompe

réversible

TOPLINE câble

20-61-001

GND

DATA black

12VDC white

Figure 1

loch depth interface

90-60-450

loch

speedomètre

depth

Connecting box

90-60-417

NMEA -

NMEA +

Input NMEA

11

Auto

Stop

Page

Ent

True wind mode G5

Reference True wind

Rudder angle

0

-10 10

-30° -30°

Gyropilote Graphic

nke

M

nke

Helm spindle

Rudder angle

hydaulic ram

Masthead unit

- 4 - Gyropilot_2_um_EN_7_30

- 5 - Gyropilot_2_um_EN_7_30

35° 35°

Rudder Arm

Rudder Shaft

2 INSTALLING THE HYDRAULIC UNIT

Read this guide entirely before starting the installation .

Read the installation manual the hydraulic linear drive manufacture.

2.1 Preparing the rudder arm

If it is not possible to install the drive unit directly to the steering quadrant, then you will

have to buy and install a rudder arm for your rudder shaft. The rudder arm can be mounted

on the rudder shaft in any direction.

Make sure that the ruder arm can freely move 35° in both directions and that there is

enough room available to mount the drive unit and rudder angle sensor as per the following

sections.

Check with your boat manufacturer for special instructions on mounting autopilots to your

rudder shaft or your quadrant

Drill a 16mm hole to mount the hydraulic linear drive axis:

- 240mm from ruder axis for pack type 60

Drill a 14mm hole to mount the hydraulic linear drive axis:

- 190mm from ruder axis pack type 40

- 170mm from ruder axis pack type 32

- 150mm from ruder axis pack type 27

Drill a 12mm hole to mount the hydraulic linear drive axis:

- 129mm from ruder axis pack type mini

- 6 - Gyropilot_2_um_EN_7_30

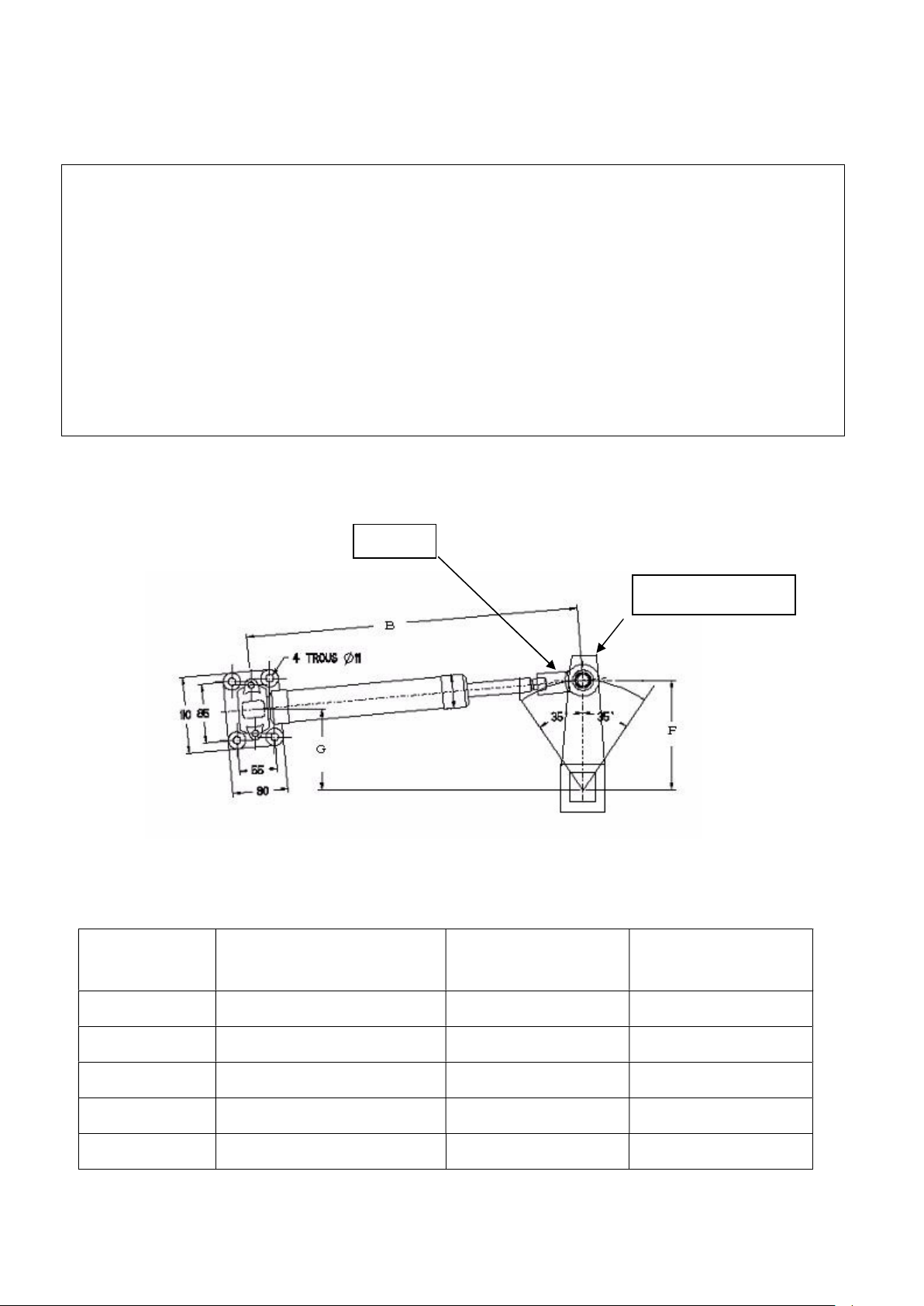

2.2 Installation of the hydraulic linear drive

2.2.1 Linear drive for inboard mounting

You will find with the hydraulic linear drive, the manufacturer mounting instructions.

Dimensions for installation

Pack type B

the rod half the way out F G

60 727mm 240mm 218mm

40 627mm 190mm 172,5mm

32 533mm 170mm 160mm

27 472mm 150mm 136,5mm

Mini 395mm 129mm 117mm

WARNING:

The force developed by a hydrauli

c linear drive is very strong and could result in serious

damage if impropally installed.

The linear drive and the hydraulic pump must be positioned on an horizontal plan.

Make sure that the linear drive support is positioned in the way that the

rudder arm or rudder

sector is in the same horizontal plan as the linear drive axis.

The mounting

of the linear must be very rigid and you should not hesitate to strengthen it with

a stainless steel plate strongly attached to the boat.

The rod of the cylinder is very fragile, and must not receive shocks, which could cause the rip

of the lip seal and therefore an oil leak.

Rudder arm

Rod tip

- 7 - Gyropilot_2_um_EN_7_30

2.2.2 Hydraulic linear drive type 40 for outboard mounting

You will find with the hydraulic linear drive, the manufacturer mounting instructions.

Dimensions for installation hydraulic linear drive type 40 outboard

2.2.3 Installation procedure

- Put the rudder to the axis

- Unscrew half the way the tip at the end of the drive rod, and pull the rod half the way out

such as the length between the axis of the linear support and the thrust axis is equal to

the rod length

- Place the linear drive at 90° of the rudder arm

- Fixed it with 4 stainless steel screws and nuts.

- Grease the thrust axis of the linear drive and fix it on the rudder arm or rudder sector

with the supplied nylstop nut.

- Adjust the rod tip on the same axis than the thrust axis and block it in position with the

counter-nut.

- Insert the thrust axis in the rod tip and block it with a lynch pin.

WARNING:

Check that the mechanical rudder stops are in use. If the l

inear drive is used as a rudder

stop, it could be irremediably damaged.

- 8 - Gyropilot_2_um_EN_7_30

2.3 Installation of the hydraulic pump

Select a location where it is easy to access to the pump for maintaining : oil adjust, speed

setting.

Fix the pump with 4 screw and nuts 6mm, on an horizontal plan.

WARNING:

Don’t forget before start up , remove the shipping cap on the top of the oil tank

and replace it

by the evented cap supplied with the hydraulic unit.

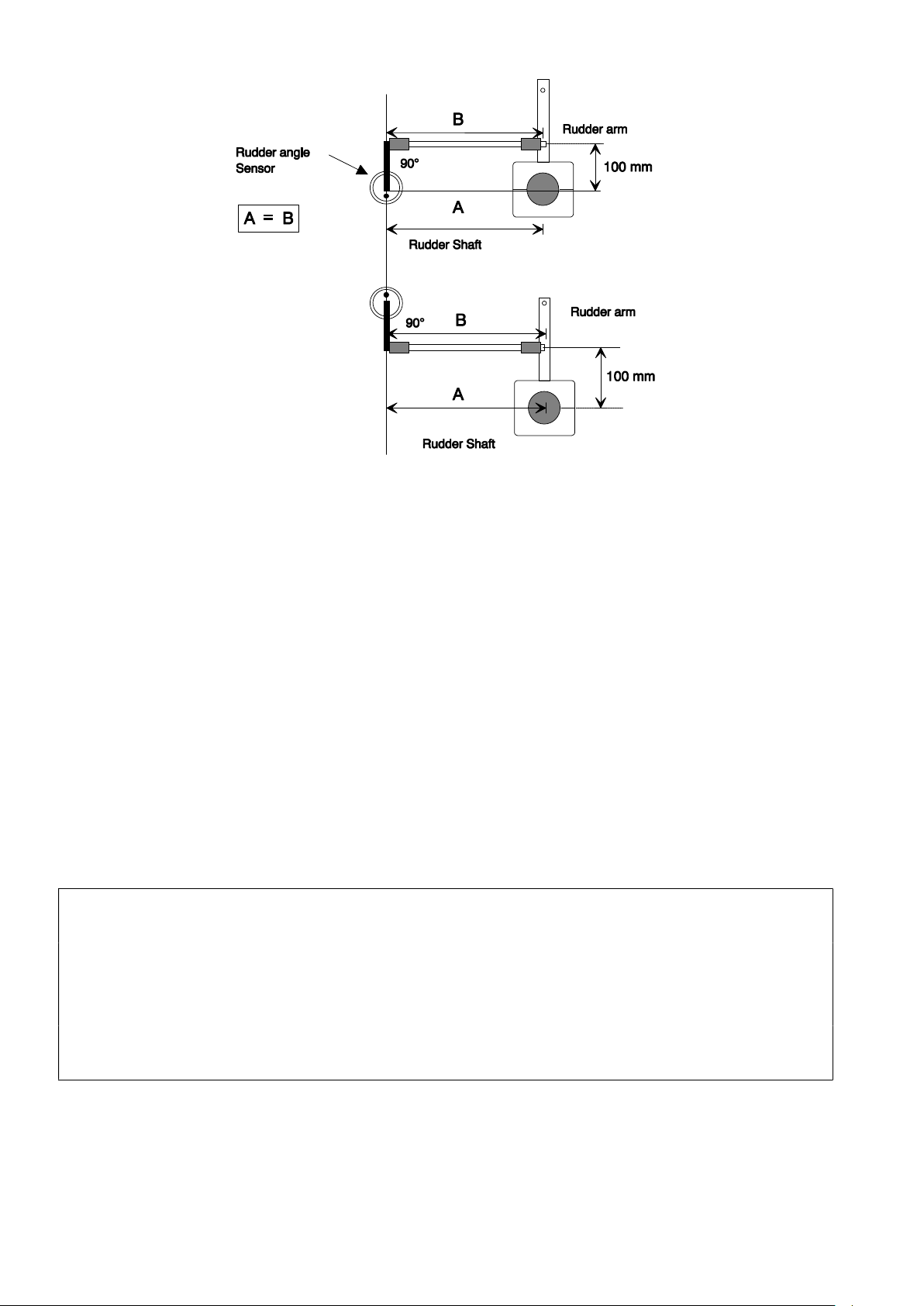

2.4 Installation of the rudder angle sensor

2.4.1 Precautions

- The sensor arm must be able to move ± 90° UNOBSTRUCTED.

- When the rudder is centred, the sensor arm must also be centred (in relation to the axis

screw head-see below).

- Distance “A” must be equal to “B”.

- The sensor connector must be 90° to the rudder arm when the rudder is centred.

- It must be installed in a safe/dry location and away from interfering equipment (radio

receivers, compressors, speakers, generators, etc.)

- The mounting location must be rigid and with the sensor arm and the rudder arm in

the same horizontal plan.

Correct mounting Not allowed

- 9 - Gyropilot_2_um_EN_7_30

2.4.2 Installation procedure

1. Present the threaded rod in front of the rudder shaft, measure the maximum distance

where you can place the sensor, in function of the rod length. The sensor arm will have

to be able to rotate by 70° in both ways.

2. Measure precisely the distance A

3. Carefully centre the sensor so that the straight line going by the axis of the sensor arm

and the blocking nut is parallel to the rudder arm.

4. Drill a 7mm hole and mount the threaded connector arm to the rudder arm and the

sensor arm.

5. Then, cut the threaded rod such as value L = A-22mm

6. Mount the tips on the threaded rod, and block them with the counter nuts.

7. Before mounting the rod and tips on the connector arm, test manually your installation :

maintain the tips just above each connector, and move the rudder from Port to

starboard. If the parallelism is good, you can mount the tips on the connector arms.

WARNING :

When the rudder is centred, the rudder arm of the angle sensor must also be centred and

parallel to the rudder arm.

The threaded rod must always be parallel to the linear drive axis. If not, this could seriously

damage the sensor.

The A lenght of the threaded rod must be less than 360mm.

- 10 - Gyropilot_2_um_EN_7_30

3 INSTALLATION AND CONNECTING THE COMPUTER

3.1 Packing list

- One computer Gyropilote 2, with its connecting cables.

- One installation guide.

- One TOPLINE bus cable.

3.2 List of accessories

- Standard terminal box TOPLINE bus : 90-60-121

- Terminal box TOPLINE bus with NMEA input : 90-60-417

3.3 Installing and location of the computer Gyropilot 2

Precautions

The gyrometer sensor, essential to have good performances with the pilot, is integrated in

the computer Gyropilot 2. As this sensor is very sensible, the computer must be :

- Mounted on a vertical wall,

- It is screw with 4 screw 4mm and the cable outlet are to the bottom.

- The location must be dry, above 50°C and not subjected to excessive vibrations

ATTENTION :

- During fixing, tighten the nuts moderately. An excessive tightening can cause a break

of the case.

- Do not use silicon glue to mount the computer.

- 11 - Gyropilot_2_um_EN_7_30

3.4 Electric diagram of Gyropilot 2 RVP computer (reversible pump)

nke Gyrop

i

lot 2

CRP

RVP

RVP

Hydraulic linear drive

Calculateur Gyro2

Bus

Rudder

reference

Tiller Clutch Power

supply

Reversible

pump

clutch

REVERSIBLE

PUMP

Rudder angle

sensor

Rudder arm

Rudder shaft

threaded rod

Brown

BLUE

white

Topline

BUS

++

+

+

+

-

-

--

--

-

+

+

noir

Tresse

noir

²Blanc

²Blanc

Tresse

²Blanc

Tresse

Tresse

²Blanc

Tresse

Vert

²Blanc

²Jaune

NMEA

noir

noir

Bus

power

supply

12 Vdc

to BUS TOPLINE

fuse

or circuit breaker

+

-

Linear drive

power supply

nke

Red

Noir

12V/12V

converter

- 12 - Gyropilot_2_um_EN_7_30

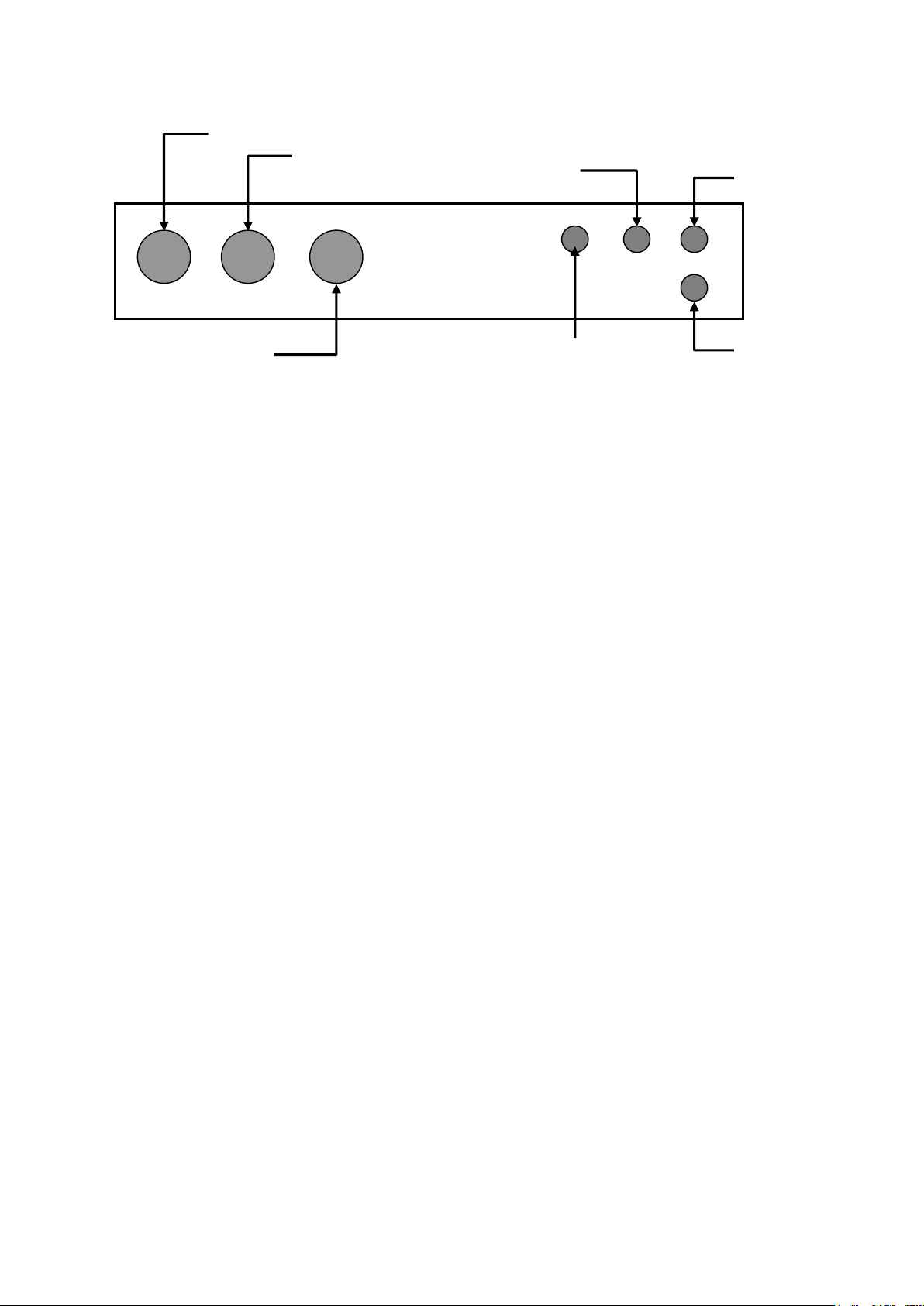

GYROPILOT 2 RVP computer : bottom side

TOPLINE BUS

Two white wire : clutch coil

Tiller

Rudder angle sensor

Blue wire : ground

Hydraulic pump Black wire: ground

Hydraulic power

supply

Red wire : +

Hydraulic power

supply

Brown wire : +

Hydraulic pump

Two white wires

- 13 - Gyropilot_2_um_EN_7_30

3.5 Electric diagram Gyropilot 2 CRP computer

Left solenoide

nke Gyrop

i

lot 2

CRP

RVP

CRP

Linear drive unit

Calculateur Gyro2

Bus

Rudder

reference

Tiller

Clutch Supply

Reversible

Pump

Rudder angle

sensor

Rudder arm

Rudder

Shatf

Threaded rod

Topline

BUS

cable

++

+

+

+

-

-

--

--

-

+

+

noir

Tresse

noir

²Blanc

²Blanc

Tresse

²Blanc

Tresse

Tresse

²Blanc

Tresse

Vert

²Blanc

²Jaune

NMEA

noir

noir

Bus

power

Supply

12 Volts

Right solenoide

TOPLINE bus

Linear drive

power supply

Circuit breaker

or fuse

+

-

nke

Red

Black

- 14 - Gyropilot_2_um_EN_7_30

3.5.1 GYROPILOT 2 CRP computer : bottom side

The GYROPILOT 2 CRP computer is designed to drive the solenoids of an hydraulic

system ; This hydraulic system is generally mounted on big boat.

Topline bus

Two white wires

Right solenoide

Tiller

Rudder angle sensor

Two white wires :

Left solenoide

Black wire : ground

Power supply

Red wire : +

Power supply

- 15 - Gyropilot_2_um_EN_7_30

3.6 Connecting the power supply of the linear drive motor

ATTENTION:

The Gyropilot 2

computer is designed to supply the linear power supply with 12VDC or

24VDC, but the TOPLINE bus must always be supplied with 12VDC.

The supply power wires, from the computer and linear drive to the power batt

ery, must be

as short as possible.

It is necessary to protect the linear drive power supply, using a fuse or a circuit breaker on

the red wire : 30A for a 12VDC supply and 16A for a 24VDC supply.

Recommended wire section to supply the power battery to the linear drive motor.

Length from battery to the linear drive

motor, via the Gyropilot 2 computer Recommended section

3 m 2,5 mm²

5 m 4 mm²

7 m 6 mm²

10 m 10 mm²

A too low section cause heating of cable and decrease the performances of the Gyropilot.

As the electric power of the solenoid are low, it is not necessary to connect the power

supply with higher electric wires diameter.

WARNING:

To avoid drop voltage on the TOPLINE BUS, it is strongly recommended to use two Batteries :

one for the linear drive unit power and another one for the TOPLINE BUS and the instrument. If

it is not possible on your boat, use a DC/DC 12V converter to separate the

TOPLINE BUS

From the linear drive unit power.

WARNING:

After a longtime ( some months ) without drive unit activity

Suggestion : To connect the clutch directly on your battery, because at the first time after

this long time the clutch will request a big current to start and the internal fuse of the

autopilot computer will down ! To repair that, we must send back your computer in factory.

- 16 - Gyropilot_2_um_EN_7_30

3.7 Connecting the computer to Topline bus

1. Make the computer bus cable run towards the TOPLINE terminal box of your

installation.

2. Connect the bus cable inside the terminal box :

If you reduce the length of the bus cable, strip and galvanise the wires before connecting

them inside the terminal box.

BLANC

GND

NOIR

BLANC

GND

NOIR

12V

GND

NMEA-

NMEA+

NMEA-

NMEA+

init

12Vdc

Connection box

90-60-417

-

GND braid

DATA black

12VDC white

Figure 3 : Connection to the TOPLINE bus

NMEA INPUT

+

BLANC

GND

NOIR

11

Auto

Stop

Page

Ent

mode vent reel G5

Consigne ang vent rl

Angle de barre

0

-10 10

-30° -30°

Gyropilote Graphic

nke

M

nke Gyrop

i

lot 2

CRP

RVP

RVP

Calculateur Gyro2

Bus

Angle

Barre Tiller

Embrayage Alim.

Pompe

réversible

nke

FLUXGATE COMPASS

12V/12V

Converter

- 17 - Gyropilot_2_um_EN_7_30

3.8 Technical specification

- Supply : 10 à 16VDC

- Consumption : 50mA, without the hydraulic linear unit.

- IP protection : IP67

- Weight : 1kg, with cable

- Dimensions : width = 210mm ; height = 134mm ; thickness = 42mm

- Operating temperature : -10°C à +50°C

- Temperature of storage : -20°C à +60°C

3.9 Software computer version

The software version is indicated on the label of the product.

3.10 Diagnostic for 1st level troubles shooting.

This chapter can help you rapidly resolve minor problems which do not require the

intervention of a specialist. Before contacting technical support, please check the

troubleshooting table below.

Problem Possible causes and solutions

The Topline installation does not detect the Gyropilot Graphic The bus cable is not or is badly connected to the terminal box : check the

plugging and the connection inside the terminal box. Check the state of

the cables : they must not show any sign of wear or cut.

The Gyropilot Graphic displays the message « master

absent »

Initialise the Gyropilot Graphic : see installation chapter.

The Gyropilot Graphic displays the message « bus error .

The data cable (black) is in short-circuit »

Check that the black data wire is properly connected inside the terminal

box : see installation chapter.

The Gyropilot Graphic display three dashes «- - -» in place of

the data of a channel. Check the sensor of this channel, check the connection cable : it may be

damaged or disconnected.

The Gyropilot Graphic displays the message « bus error :

conflict problem »

It may be that there are two master displays (at address 1) on your

installation : check the addresses, if that is the case, reinitialise one of

the displays.

The Gyropilot Graphic does not display the NMEA data : those

from the GPS for example. Has the NMEA link been initialised ? see NMEA initialisation chapter

The NMEA link is not or is badly connected to the terminal box : check

the connection of the Gyropilot Graphic and that of the NMEA

transmitter (GPS). see installation chapter.

The Gyropilot Graphic displays the message « low battery » Check the voltage of your battery with a voltmeter : the operating voltage

must be above 10VDC. Check that the battery maintains the load.

The Gyropilot Graphic indicates « Error EPROM».

Reinitialise your Gyropilot Graphic. If the error message persists, please

contact your distributor.

If you do not manage to solve the problem, please contact your distributor.

- 18 - Gyropilot_2_um_EN_7_30

4 INITIALISATION OF THE COMPUTER

This chapter describes the initialisation of the Gyropilot 2 computer and the Gyropilot

Graphic. See also the Gyropilot Graphic user manual.

4.1 Initialisation

After installing the Gyropilot, you must initialise the whole of your pilot system. This is

required in order to perform the training of the Gyropilot computer: position the rudder at

the centre, then into limit stop on starboard side and finally into limit stop on port side, so

that the computer stores these positions of the rudder. These three rudder positions are

essential for the good operation of the cylinder of the pilot.

Follow the menu « Pilot Initialisation » of the Gyropilot Graphic which will guide you

along the procedure.

Procedure

Using the Page key, select the Main menu page,

then using the browser, select Configuration then Pilot initialisation,

press the Ent key,

the following message is displayed « This procedure will erase current settings.

Press the Ent key to start. Press the Page key to exit », press the Ent key,

the Gyropilot Graphic will guide you through the positioning of the rudder : follow the

indications :

After performing an auto test, your pilot is initialised,

Exit this menu by pressing the Page key.

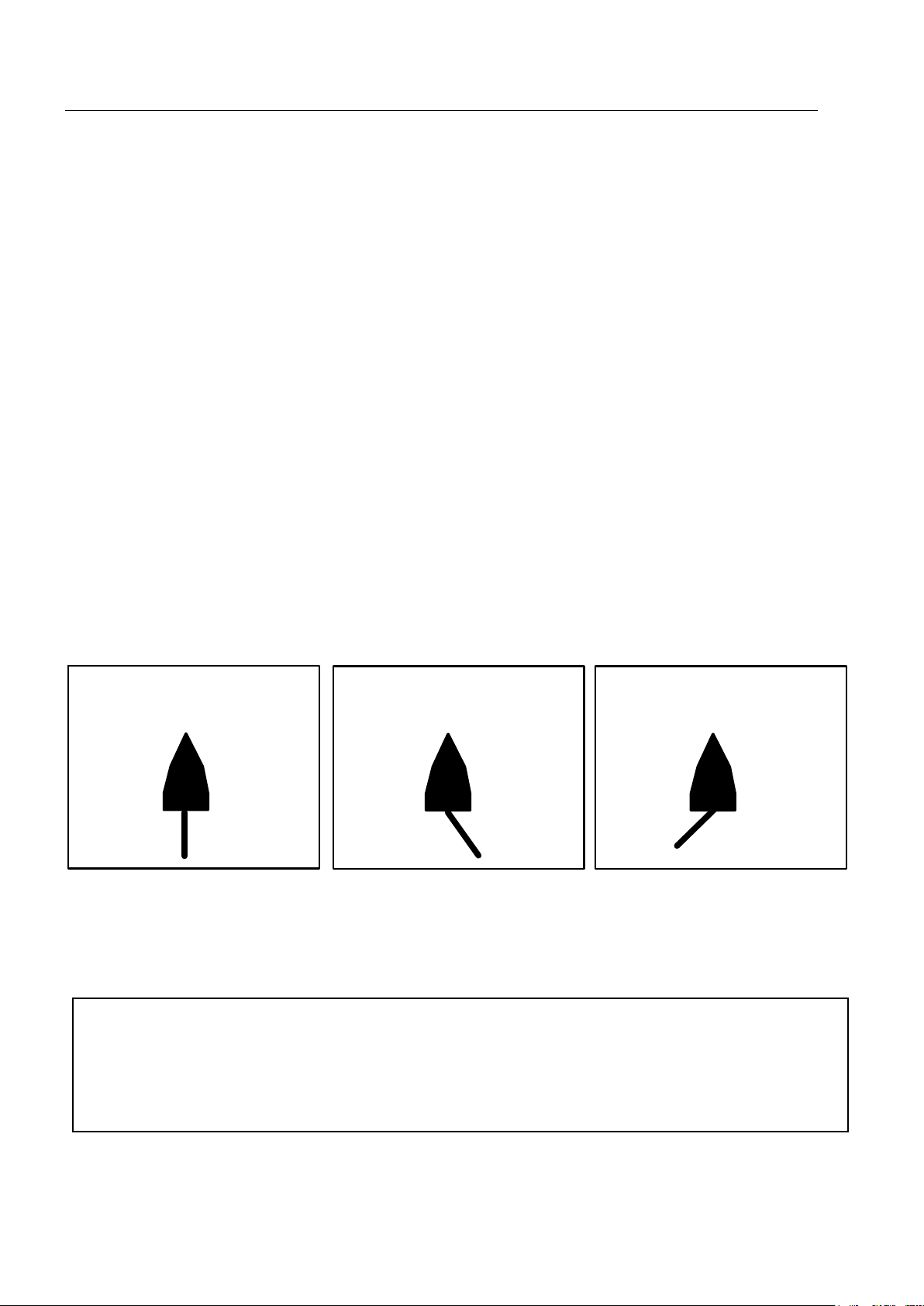

Position the helm perfectly

in the centre then press

the Ent Key

Position the helm into

limit stop on starboard

side then press the Ent Key

Position the helm into limit

stop on port side then

press the Ent Key

WARNING :

Inadequate initialisation of the pilot can lead to premature wear of the parts, poor heading

maintenance by the pilot and excessive electrical consumption.

If you are unsure about your setting, perform the initialisation once again.

- 19 - Gyropilot_2_um_EN_7_30

4.2 First start-up of the pilot

See the Gyropilot Graphic user manual.

Note that powering up or powering down your installation is done using the auxiliary switch

of the electric switchboard of your boat. Your installation must comprise two separate 12V

power supplies : one for power to the hydraulic pump and to the computer and the other for

the Gyropilot Graphic, the TOPLINE bus and the sensors. If it is not possible to have 2

batteries pack you must set up a converter 12V/12V.

WARNING : It is imperative that you power the autopilot breaker before the Topline

breaker. This allows the instruments system to recognise the Gyropilot

- 20 - Gyropilot_2_um_EN_7_30

NOTES

________________________________________________________________________________________________

________________________________________________________________________________________________

________________________________________________________________________________________________

________________________________________________________________________________________________

________________________________________________________________________________________________

________________________________________________________________________________________________

________________________________________________________________________________________________

________________________________________________________________________________________________

________________________________________________________________________________________________

________________________________________________________________________________________________

________________________________________________________________________________________________

_______________________________________________________

Table of contents