Nohken GW100NR User manual

TS02-100022

INSTRUCTION MANUAL

FOR

GUIDED PULSE LEVEL MEASUREMENT

MODEL: GW100

Revised 2020-10-28

- ADD 1 -

Read this manual carefully for safe usage.

・This manual applies to general purpose equipment. For equipment intended for

use in potentially explosive atmospheres, see applicable manuals.

・This manual contains important information on handling, inspection and

operation of the equipment indicated on the cover page. Before handling the

equipment, read this manual carefully.

・Instructions in documents submitted by Nohken or its representative have

higher priority than those in this manual.

・Keep this manual within easy access.

・Depending on environment, the equipment may not satisfy specifications

shown in this manual. Check the application conditions carefully beforehand.

・Please contact our sales office for any questions or comments about the

equipment or this manual. Sales offices are shown on the back of the manual.

Safety Symbols:

WARNING Means a potentially hazardous situation which,

if necessary precautions are not observed, can result

in death, serious injury and/or considerable material

damage.

CAUTION Means a hazardous situation which, if necessary

precautions are not observed, can result in minor or

moderate injury or damage to the device.

Means prohibited actions.

Means mandatory actions.

- ADD 2 -

WARNING

This equipment is NOT intended for use in potentially hazardous

atmospheres. Never use it where flammable gas or vapor may be

present. Failure to observe this may result in ignition of flammable

gas or vapor, causing disaster.

Do not alter or disassemble the equipment, unless you have been

instructed to do so by Nohken or its representative.

Failure to observe this may result in:

- malfunction of or damage to the equipment or connected devices;

- ignition;

- electric shock or user injury.

Turn off the equipment before wiring or inspection. Otherwise

leakage or short circuit may cause ignition or electric shock.

After wiring is complete, always check for its correctness. Wrong

wiring may cause:

- damage to or malfunction of the equipment or connected devices;

- ignition;

- electric shock or user injury.

Turn off the equipment immediately in case smoke, unusual smells

or sounds are noticed. Do not supply power until problems are

solved.

CAUTION

Handle the equipment with care. Do not drop, throw, or give

a strong shock to avoid damage.

Observe operation conditions specified in the manual. Use outside

the specified conditions may result in malfunction of or damage to

the equipment or connected devices, ignition, user injury, or

electric shock.

Perform operation tests before actual application to ensure

performance. Install back-up instruments based on different

technologies if failure of this equipment is expected to result in

a serious incident.

- ADD 3 -

CAUTION

Check carefully for chemical compatibility of materials of

construction before installation.

Use the flange, thread or somewhere close to the process

connection to handle the equipment. Do not use the housing to

avoid dropping the equipment, and resultant damage to the

equipment or user injury.

Equipment 50cm or longer:

Lay the equipment when not in use. Otherwise it may fall and

damage itself or things around it, and cause user injury.

Always ground the equipment. (Grounding resistance: 100Ωmax.)

Without grounding, electric shock may occur in case excessive

voltage is applied to the housing.

When connecting to inductive or lamp loads:

Ensure the maximum voltage/current ratings will not be exceeded

to avoid damage to the relay contacts.

Use lightening arrestors or surge absorbers to prevent:

- malfunction, damage, or ignition of the equipment and connected

instruments;

- electric shock or injury.

- ADD 4 -

INTRODUCTION

A) This manual applies to standard models. Please note that information in

this manual may not be applied to customized versions.

B) We are willing to help customers select a suitable model or provide

information about chemical compatibility of materials used, but the

customer is responsible for the decisions made.

C) We always welcome suggestions and comments about this manual.

Please contact our sales office when you have questions or comments.

D) Component replacement:

The equipment design is regularly reviewed and improved. The same

components therefore may not be available when replacement is required.

In such cases, different components or products may be supplied. Please

contact our sales office for detail.

E) The contents of this manual are subject to change without prior notice as

a result of improvement of the equipment.

WARRANTY & DISCLAIMER

A) Nohken warrants the equipment against defect in design or material, and

workmanship for a period of one (1) year from the date of original

shipment from Nohken’s factory.

B) Nohken will not assume liability for loss nor damage resulting from the

use of the equipment.

C) Nohken will not assume liability for damage resulting from:

C-a) not observing instructions in this manual;

C-b) installation, wiring, operation, maintenance, inspection, or storing in

a manner not outlined in this manual;

C-c) unauthorized alterations and repairs;

C-d) the use of or replacement with components not provided by Nohken;

C-e) devices or instrument other than those manufactured by Nohken;

C-f) the use not described in Chapter 1 Purpose of Use of the manual;

C-g) force majeure including, but not limited to, fire, earthquake, tsunami,

lightning strike, riot, commotion, war, armed conflict or terrorist

attack, radioactive pollution, act of God, governmental decisions or

actions, and compliance with laws and regulations.

THE PROVISIONS OF THIS SECTION DO NO LIMIT YOUR LEGAL RIGHTS.

Table of Contents

1.PURPOSE OF USE

····································· 1

2.DESCRIPTION

····································· 1

2.1 Product Overview ····································· 1

2.2 Principle of Operation ····································· 1

3.SPECIFICATIONS

····································· 2

3.1 Parts Name and Function ····································· 2

3.2 Model Numbering ····································· 3

3.3 Specifications ····································· 4

3.4 Outline Drawing ····································· 5

3.5 Probe length and Components ····································· 9

3.6 Optional Components ····································· 10

4.HANDLING NOTES

····································· 11

5.INSTALLATION

····································· 12

5.1 Tools for Mounting ····································· 12

5.2 Tools for Probe Trimming ····································· 13

5.3 Unpacking ····································· 14

5.4 Assembling Probe ····································· 15

5.4.1 Rod probe sensors (GW100□R□□) ···································· 15

5.4.2 Sensors with tubing with threaded connection(GW100NP□□) ················ 17

5.4.3 Sensors with tubing with gasket(GW100SP□□)······························ 19

5.5 Cutting Probe ····································· 20

5.5.1 Rod probe (GW100□R□□) ····································· 20

5.5.2 Wire probe (GW100□W□□) ····································· 21

5.6 Mounting Sensor ····································· 23

5.6.1 Location ····································· 23

5.6.2 Mounting ····································· 26

6.WIRING

····································· 27

6.1 Before Wiring ····································· 27

6.2 Wiring ····································· 27

6.3 Cable Inlet ····································· 29

6.4 Placing Cover ····································· 29

7.OPERATION

····································· 30

7.1 Before Operation ····································· 30

7.1.1 Key name and function ····································· 30

7.1.2 Modes and operation flow ····································· 31

7.1.3 Startup behavior ····································· 32

7.2 Commissioning ····································· 33

7.3 Quick Setting ····································· 33

7.3.1 Procedures ····································· 34

7.3.2 Canceling Quick Setting ····································· 37

7.4 Parameter Reference ····································· 38

7.4.1 Program mode parameter ····································· 38

7.4.2 Test mode parameter ····································· 43

7.5 Reference Drawing ····································· 44

7.6 Program Mode ····································· 45

7.6.1 Switching to Program Mode ····································· 45

7.6.2 Updating data ····································· 46

7.6.3 Canceling entry ····································· 47

7.6.4 Blanking ····································· 48

7.6.5 Fail-safe ····································· 50

7.6.6 Sensitivity ····································· 53

7.6.7 False echo suppression with material ····································· 55

7.6.8 False echo suppression without material ·································· 57

7.6.9 Reset ····································· 59

7.7 Test Mode ····································· 61

7.7.1 Switching to Test Mode ····································· 61

7.7.2 Exiting Test Mode ····································· 62

7.7.3 Simulation (mm, %) ····································· 63

7.7.4 Simulation (mA) ····································· 65

7.7.5 LCD test ····································· 67

8.MAINTENANCE AND INSPECTION

························· 68

8.1 Maintenance Procedure ····································· 68

8.2 When to Replace Components ····································· 68

9.STORING

····································· 69

9.1 Conditions ····································· 69

10.TROUBLESHOOTING

····································· 70

10.1 Error Code ····································· 70

10.2 Troubleshooting ····································· 71

11.APPENDIX

····································· 76

11.1 Glossary ····································· 76

11.2 Parameter List ····································· 77

- 1 -

1. PURPOSE OF USE

Guided Pulse Level Measurement GW is a sensor designed to continuously measure liquid level, and

provide output for alarms or to control pumps. Do not use the product for any other purpose.

2. DESCRIPTION

2.1 Product Overview

GW comprises of an electronics in a housing, process connection (threaded connection*or flange*)

and probe*. The probe is inserted into the tank and used to measure the distance to the material

level.

The probe assembly has no moving parts, so the material buildup and resultant adverse affection

to measurement are minimized. The user can cut off the end of the rod or wire type probe to a desired

length. The sensor is easy to program without needing a tester or other device to configure the

zero and span points.

2.2 Principle of Operation

The characteristic impedance of the probe changes when material surface reaches the probe.

The sensor electronics transmits high frequency signals that travel down on the probe. The signals

are reflected on the material surface, where the characteristic impedance changes, and then received

by the sensor electronics. The sensor electronics measures the time taken from transmission to

reception of the signals, and calculates the distance from the reference point to the material

surface. The distance is then converted to analog output of 4 to 20mA.

Fig. 2-1

* See

11.1 Glossary

.

- 2 -

3. SPECIFICATIONS

3.1 Parts Name and Function

GW100NR□□

Rod type

Threaded (G3/4)

Rod probe

GW100NW□□

Wire type

Threaded (G3/4)

Wire probe

GW100NP□□

Tubed type

Threaded (G1)

Tubed rod probe

GW100SP□□

Sanitary type

ISO 2.0 or equivalent

Tubed rod probe

① Cover

② Housing : protects the electronics.

③ Reference point : Point referenced to when deciding the measurement range. Location is model

dependent.

④ Probe : Component in rod or wire that is inserted in the tank and detects liquid

surface.

⑤ Lower blanking : Area close to the probe end where measurement is not possible or accuracy

low.

⑥ Probe length : Distance from the reference point to the probe end.

⑦ Upper blanking : Area close to the process connection where measurement is not possible or

accuracy low.

⑧ Cable inlet

⑨ Earth plate : Metal plate to stabilize operation. Required for non-metallic mounting

connection such as plastic vessel applications.

- 3 -

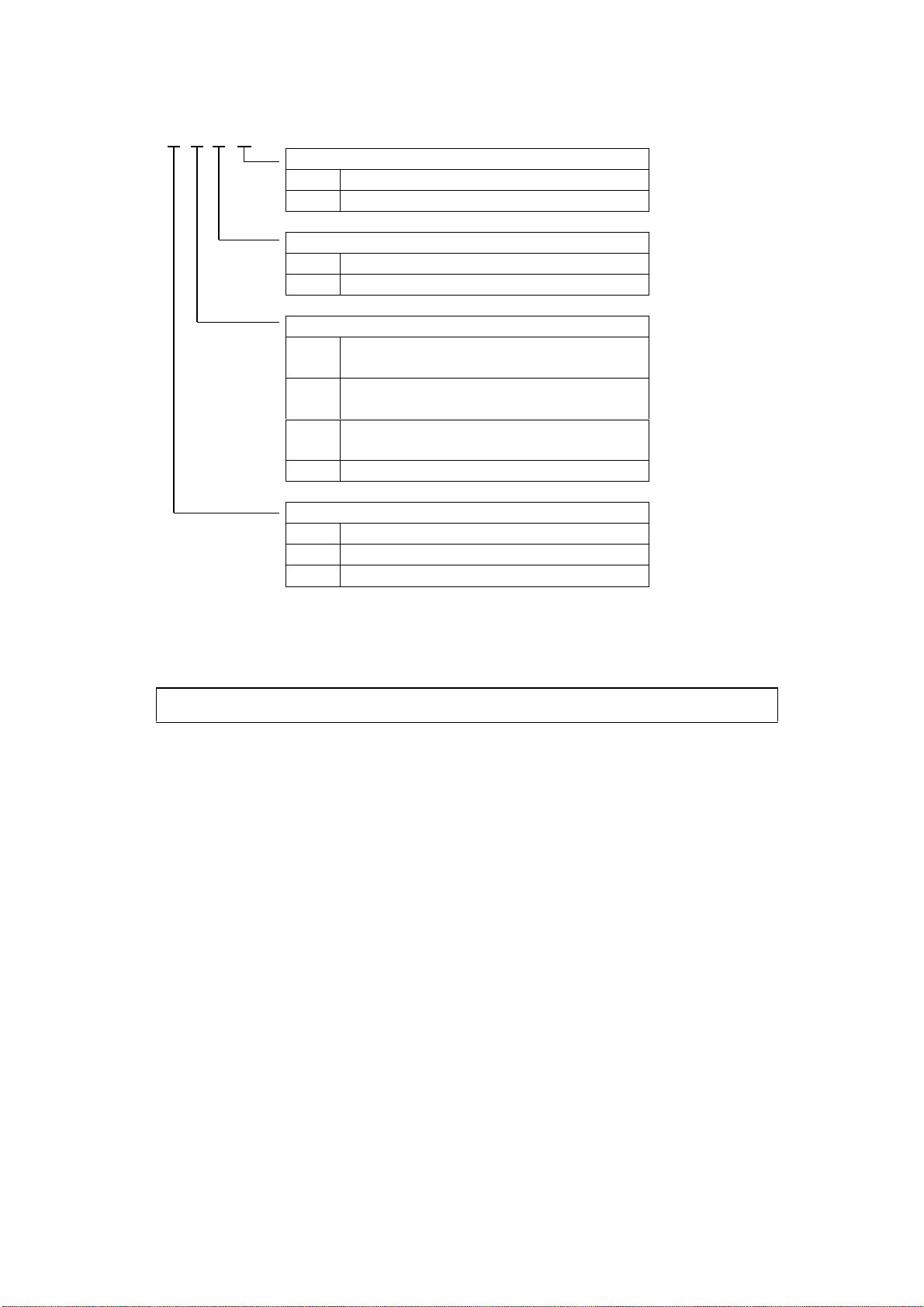

3.2 Model Numbering

GW100 □ □ □ □

Configuration

0*1 Without probe

1 With probe

Temperature

A Standard (100℃ max.)

T High temperature (150℃ max.)

Probe and material

R*2 Rod

316SS, PEEK, FKM

W*2 Wire

316SS, PEEK, FKM

PTubed rod

PFA, PTFE (316SS, PEEK, FKM)*3

Z Custom

Process connection

N Threaded

S Sanitary

Z Other connections

*1 Available only for Probe and material option “R”(rod).

*2 Not available for process connection option “S”(sanitary). Select “Z”here instead.

*3 Not wetted.

Rod and tubed rod probes are NOT factory assembled.

- 4 -

3.3 Specifications

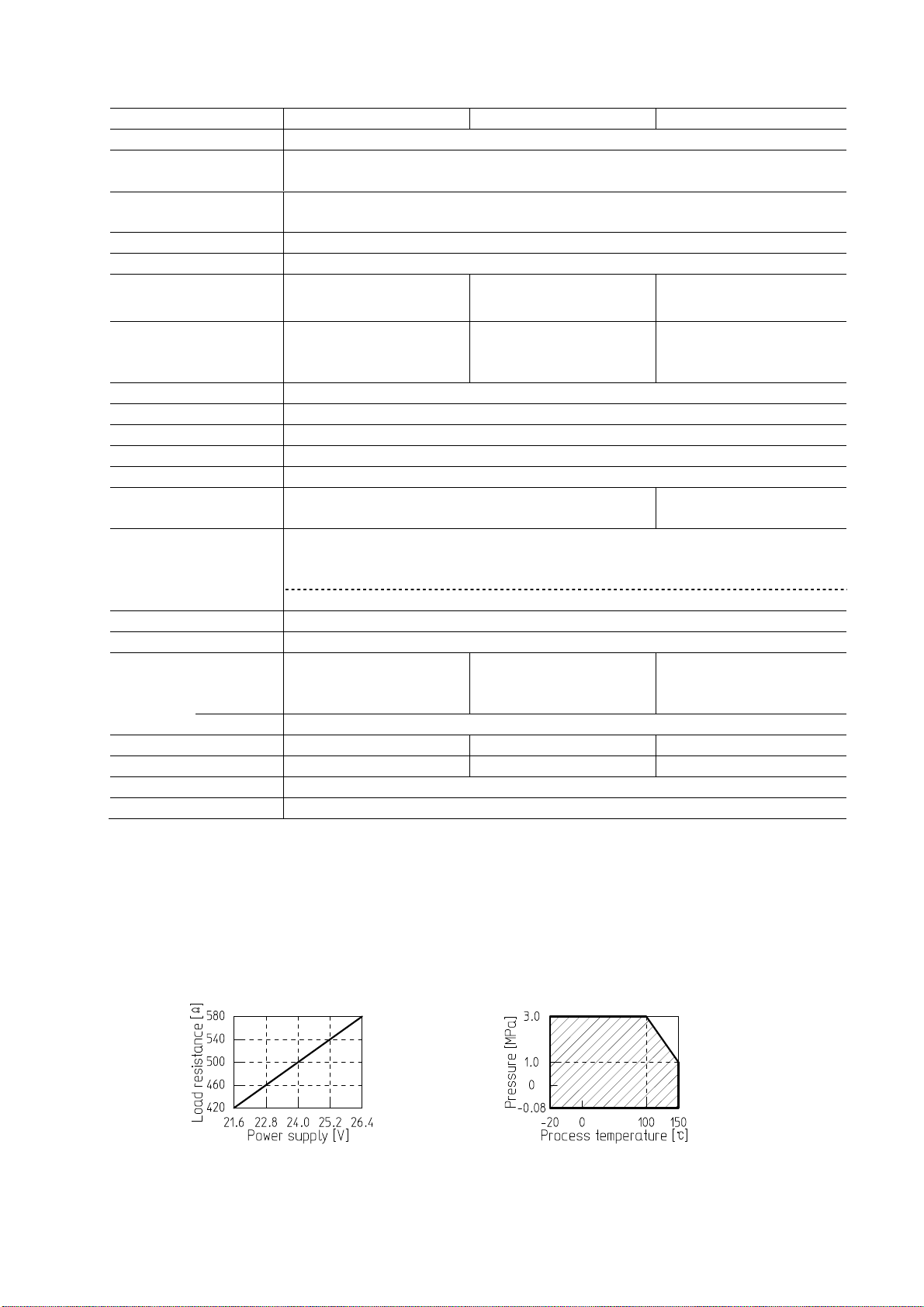

Model GW100□R□□ GW100□W□□ GW100□P□□

Measured material Liquids

Accuracy*1, *2 up to 2000mm: ±10mm

remainder of range: ±0.5% of span

Temperature

characteristics ±0.02% of span/℃

Dielectric constant*εr≧ 1.8

Probe length*3 300 to 4000mm

Upper blanking*3

with water (εr= 80)*4 25mm min. 80mm min. 25mm min.

Lower blanking*3

with water (εr= 80) *4 10mm min. 165mm min.

(2% x Probe length +50)

mm min. or 60mm min.,

whichever is greater

Wiring 3 wire *5

Power supply 24V DC ±10%

Power consumption Approx. 2.0W

Output signal Analog output, 1 point, 4 to 20mA DC

Load resistance 500Ω max. at 24V DC (Fig.3-1)

Pressure (static) -0.08 to +3.0MPa

See figure 3-2 for high temperature version. 0 to +200kPa

Working temperature - Process

Standard version: -20 to +100℃ (no freezing)

High temperature version: -20 to +150℃ (no freezing)

- Ambient: -20 to +60℃ (no condensation)

Relative humidity 85% max.

Protection class Probe: IP68 / Housing: IP65

Material - process

316SS, PEEK, FKM 316SS, PEEK, FKM

PFA, PTFE

(not wetted - 316SS,

PEEK, FKM)

- housing Cast aluminum (ADC12), acrylic coated

Tensile load 4kN 4kN -

Lateral load 1.5Nm - 1.5Nm

Cable inlet G 3/4

Cable Shielded cable (recommended: CVV-S, 3x1.25mm2)

*1 Reference conditions

- Environmental: +25℃, 60%RH

- Application: metal tank (I.D. 84.1mm), 1200mm range, water (εr= approx. 80)

*2 ±15mm from reference point to 150mm

*3 See

3.4 Outline Drawing

.

*4 The lower the dielectric constant of the material, the longer the blanking will be.

- With Kerosene (εr= 1.8) upper blanking 200mm min., lower blanking 200mm min.

*5 See

6. Wiring

.

Fig.3-1: Load resistance Fig.3-2: Withstand pressure

(static, excluding process connection)

* See

11.1 GLOSSARY

.

- 5 -

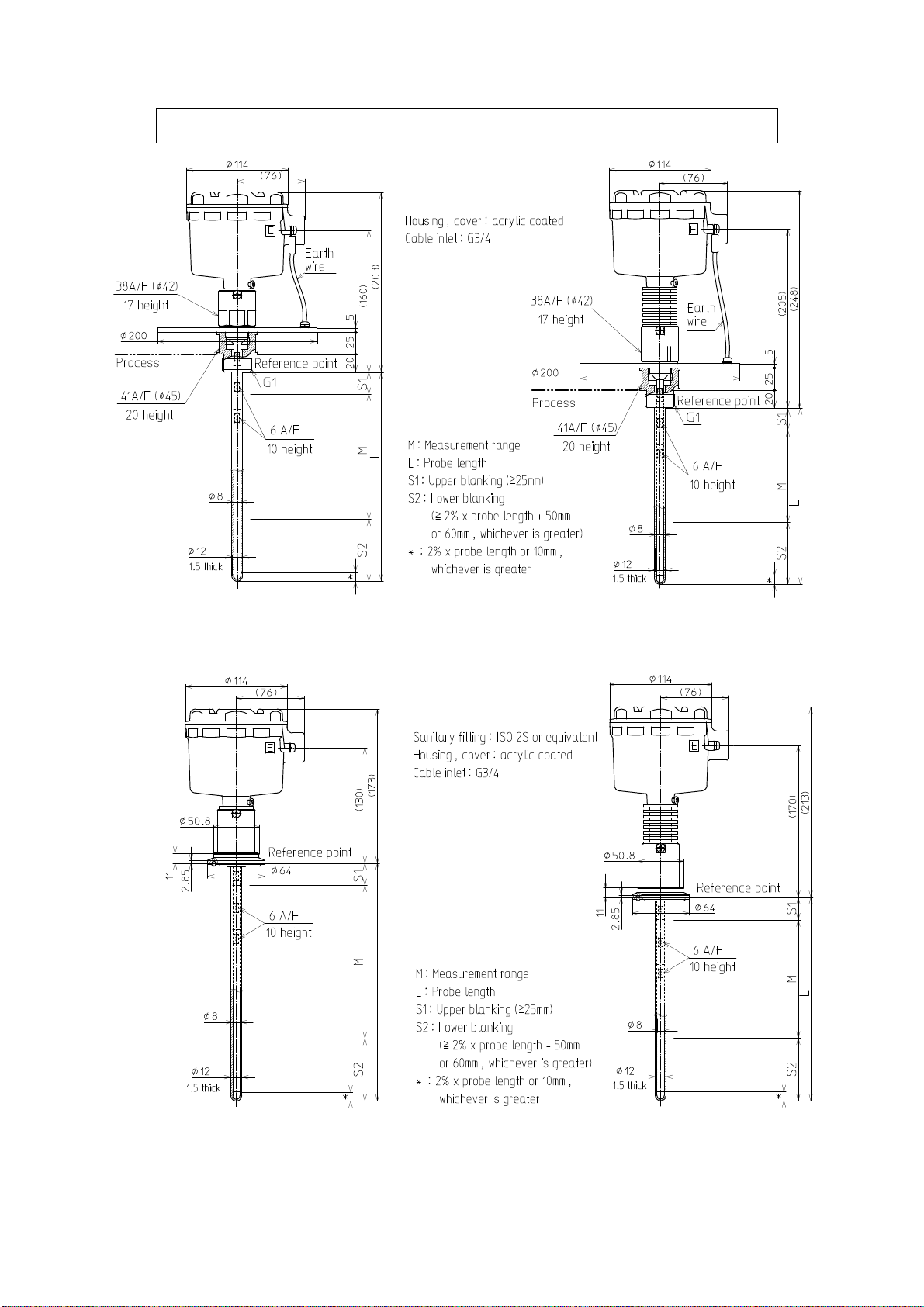

3.4 Outline Drawing

Rod and tubed rod probes are NOT factory assembled.

Fig.3-3: GW100NRA1 Fig.3-4: GW100NRT1

Fig.3-5: GW100NWA1 Fig.3-6: GW100NWT1

- 6 -

Fig.3-7: GW100NRA0 Fig.3-8: GW100NRT0

Fig.3-9: Component E Fig.3-10: Component L1M

- 7 -

<For non-metallic tank applications>

Tubing, gasket, earth plate, and probe are not factory assembled.

Fig.3-11: GW100NRA1 with Earth plate A Fig.3-12: GW100NRA1 with Earth plate B

Fig.3-13: Earth plate A (optional) Fig.3-14: Earth plate B (optional)

- 8 -

Tubing, gasket, earth plate, and probe are not factory assembled.

Fig.3-15: GW100NPA1 Fig.3-16: GW100NPT1

Fig.3-17: GW100SPA1 Fig.3-18: GW100SPT1

- 9 -

3.5 Probe length and Components

GW100NR□□ (threaded, rod probe)

Probe length (L) in mm Quantity End rod in mm

Component E Component L1M

300 to 1110 0 1 L - 80

1111 to 2090 1 1 L - 1060

2091 to 3070 2 1 L - 2040

3071 to 4000 3 1 L - 3020

GW100NP□□*(threaded, rod probe)

Probe length (L) in mm Quantity End rod in mm

Component E Component L1M

300 to 500 0 1 L - 53

501 to 1095 0 1 L x 0.98 - 43

1096 to 2095 1 1 L x 0.98 –1023

2096 to 3095 2 1 L x 0.98 –2003

3096 to 4000 3 1 L x 0.98 - 2983

* Earth plate thickness 5mm, gasket thickness 2mm

GW100SP□□ (sanitary, tubed rod probe)

Probe length (L) in mm Quantity End rod in mm

Component E Component L1M

300 to 500 0 1 L - 85

501 to 1128 0 1 L x 0.98 - 75

1129 to 2128 1 1 L x 0.98 –1055

2129 to 3128 2 1 L x 0.98 –2035

3129 to 4000 3 1 L x 0.98 - 3015

- 10 -

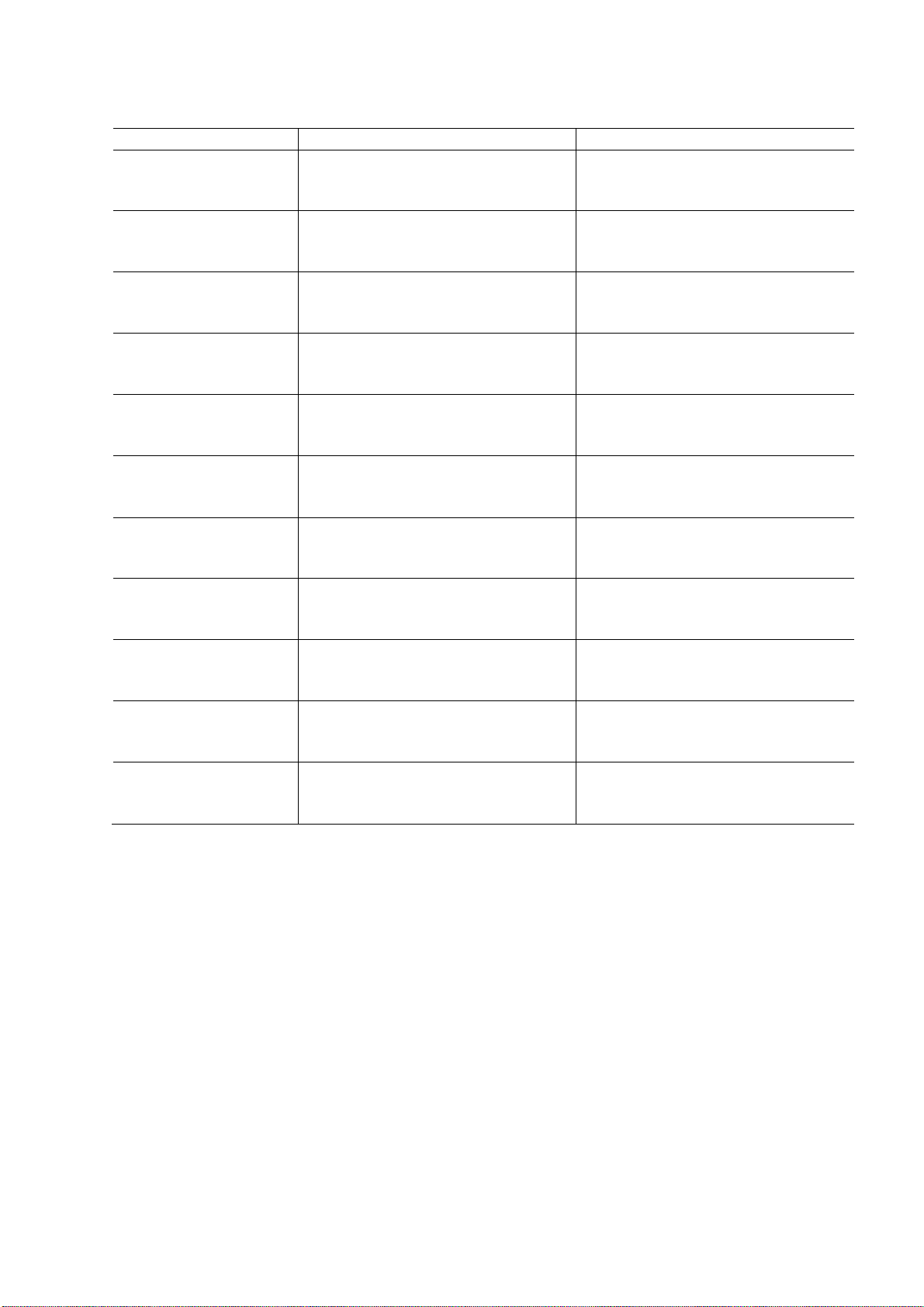

3.6 Optional Components

Item Description Remarks

Component E Extension rod (930mm, 316SS) x 1

Connection rod (50mm, 316SS) x 1

Screw (M4 x L5, 316LSS) x 2

980mm extension kit for rod versions

(GW100NR□□).

Component L1M End rod (1030mm, 316SS) x 1 Extends the probe length of rod

versions (GW100NR□□) to 1110mm.

Component L2M Component E x 1

Component L1M x 1

Extends the probe length of rod

versions (GW100NR□□) to 2090mm.

Component L3M Component E x 2

Component L1M x 1

Extends the probe length of rod

versions (GW100NR□□) to 3070mm.

Component L4M Component E x 3

Component L1M x 1

Extends the probe length of rod

versions (GW100NR□□) to 4050mm.

Gasket for G3/4 thread NBR gasket (Valqua, No.6500) x 1

(φ42mm, φ27mm, 2mm thick)

Standard accessory to GW100NR□□,

GW100NW□□, GW100NP□□ versions.

Gasket for G1 thread PTFE gasket (Valqua, No.7020) x 1

(φ49mm, φ34.5mm, 2mm thick)

Standard accessory to GW100NP□□

versions.

Earth plate A G3/4 threaded earth plate x 1

(φ200, 2mm thick, 304SS)

Comes with a gasket for G3/4 thread.

Earth plate B Earth plate for flange x 1

(φ200, 6mm thick, 304SS)

Specify the flange size at the time

of order.

Threaded tubing PFA tubing with G1 thread

ed

connection in PTFE x 1

Standard accessory to GW100NP□□

versions. Specify probe length at

the time of order.

Tubing with gasket PFA tubing with a PTFE

gasket fitted

to ISO 2.0S connections x 1

Standard accessory to GW100SP□□

versions. Specify probe length at

the time of order.

* Probe will be cut to the specified length at factory if requested.

- 11 -

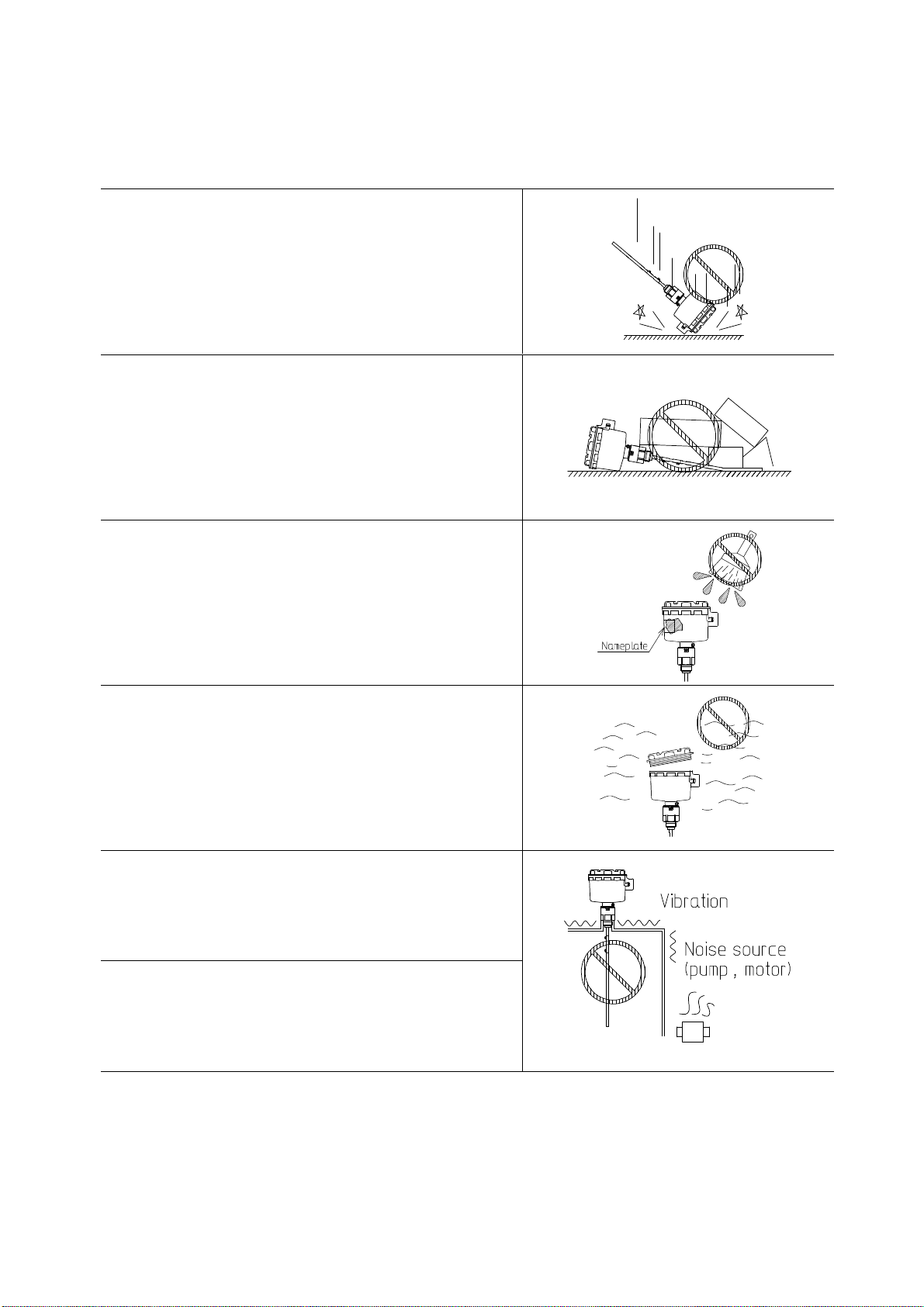

4. HANDLING NOTES

Observe instructions below when handling the sensor, or faulty operation or user injury may result.

Do not drop, throw, drag, or give a strong shock to the

sensor to avoid damage.

Do not place anything o

n the sensor to avoid deformation

or damage.

The nameplate contains maintenance and other important

information. Keep it legible when painting the sensor.

Avoid corrosive atmosphere (NH3, SO2, Cl2).

Such atmosphere may penetrate the housing and dam

age

internal components.

Avoid or protect against vibration.

Avoid strong magnetic fields such as proximity to a

large motor. Magnetic field may cause faulty operation.

- 12 -

5. INSTALLATION

WARNING

This product is not intended for use in hazardous areas*. Never use it

in areas where flammable or explosive gases or vapors may be present.

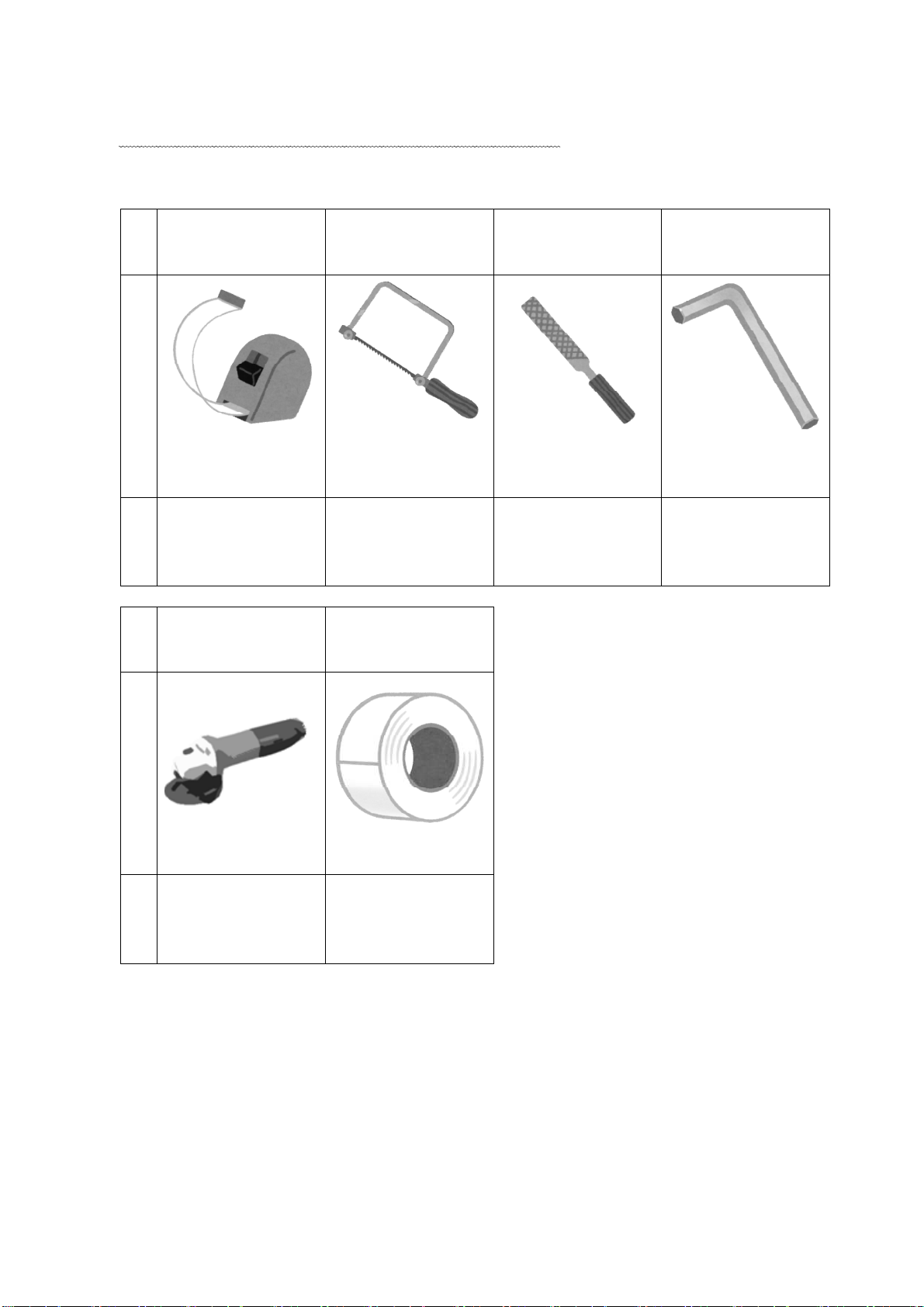

5.1 Tools for Mounting

Rod probes are not factory assembled. Assemble the probe before installation. Table 5-1 shows the

tools to be used for each model.

Table 5-1: Tools for mounting

Model

GW100□R□□

(rod)

GW100□P□1

(tubed, sanitary)

GW100□R□□

(rod)

GW100□P□1

(tubed, sanitary)

GW100N□□□

(threaded,

G3/4 or G1)

GW100NP□1

(threaded, G1)

Tool

Phillips screwdriver

x 1

Spanner (6mm A/F) x 2 Spanner (38mm A/F)

x 1

Spanner (41mm A/F)

x 2

Used on

Lock screws Rod Threaded connection Threaded tubing

Other tools than those mentioned above are necessary for flange fasteners, or the sanitary clamp.

Use suitable tools for your sensors.

* See

11.1 GLOSSARY

.

- 13 -

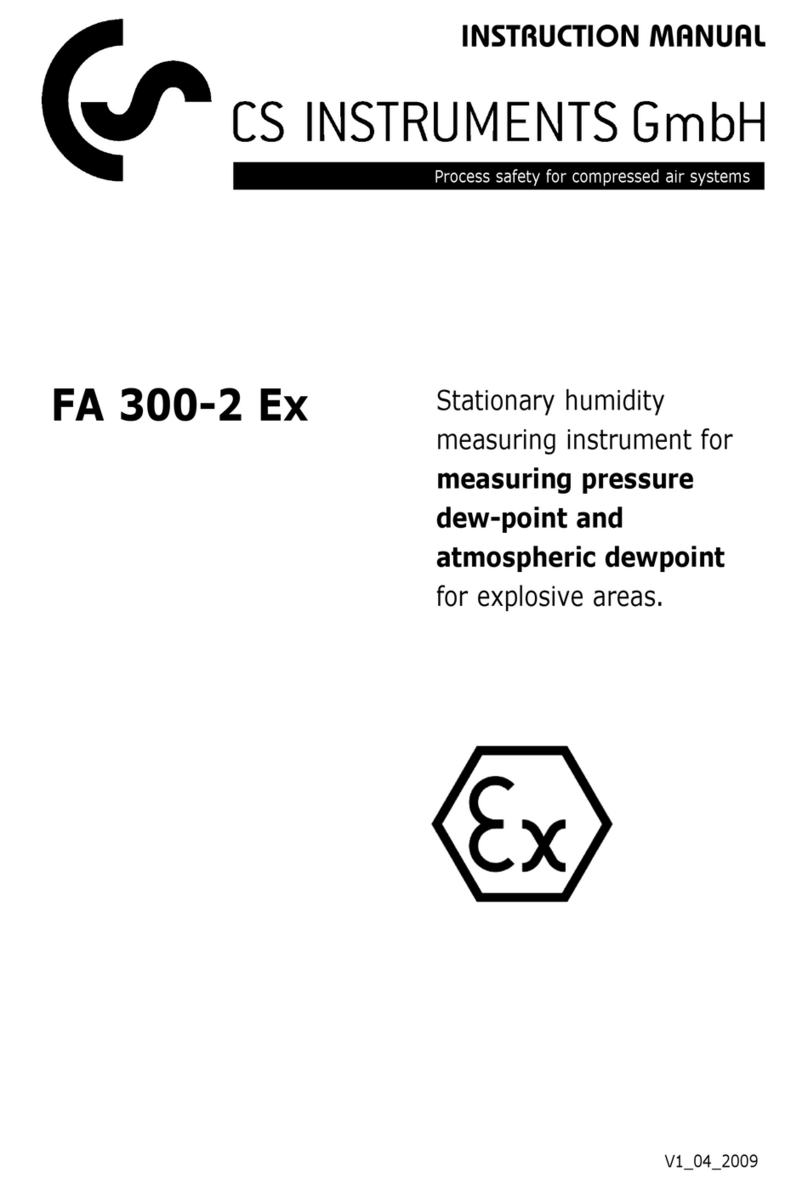

5.2 Tools for Probe Trimming

Rod or wire probes can be cut on site to a desired length. Table 5-2 shows the tools necessary

to cut the probe. See

5.5 Cutting Probe

on page 20 for how to cut the probe.

Table 5-2: Tools for cutting the probe

Model

All GW100□R□□

(rod)

GW100□R□□

(rod)

GW100□W□□

(wire)

Tool

Tape measure

x 1

Saw or grinder

x 1

Metal file or

sandpaper

Wrench (3mm A/F)

x 1

Used to

M

easure the probe

length.

Cut the rod. Remove burrs. T

ighten or loosen

weight screws.

Model

GW100□W□□

(wire)

GW100□W□□

(wire)

Tool

Grinder x 1 Plastic tape

Used to

Cut off the wire. Bind cut wire tip.

This manual suits for next models

3

Table of contents

Popular Measuring Instrument manuals by other brands

CS Instruments

CS Instruments FA 300-2 Ex instruction manual

HBM

HBM ME250 S6 operating manual

Spectrasensors

Spectrasensors SS2100 Hardware installation and maintenance manual

Apera Instruments

Apera Instruments PH60 instruction manual

Halma

Halma ALICAT SCIENTIFIC M operating manual

GW Instek

GW Instek GOM-804 user manual