Noirot Intils HTi70 User manual

Made in

France

Manual ref.: 1898458

Edition no23.34

Installation and User manual

HTi70

High temperature, ultra modulating

Heat pump

HTi70 11 single-phase

Ref. 155020

HTi70 11 three-phase

Ref. 155060

HTi70 14 single-phase

Ref. 155030

HTi70 14 three-phase

Ref. 155070

The information contained in this document is non-contractual. The manufacturer reserves the right to modify any technical specifications and equipment of any appliances without prior notice

- MANUAL HTi70 11 14 KW HEAT PUMPS -

2

- MANUAL HTi70 11 14 KW HEAT PUMPS -3

TABLE OF CONTENTS

1SAFETY ............................................................. 4

2 PLEASE READ IMMEDIATLY ........................... 5

2.1 - Conservation of documents ............................................................5

2.2 - Symbols used........................................................................................5

2.3 - Abbreviations and acronyms...........................................................5

2.4 - Rating plate............................................................................................6

3 DELIVERY AND STORAGE............................. 7

3.1 - Delivery terms and conditions........................................................7

3.2 - Storage and transport........................................................................7

3.2.1 - General information ................................................................................................ 7

3.2.2 - Transporting with a forklift ..................................................................................7

3.2.3 - Transporting manually............................................................................................7

4 INTRODUCTION............................................. 8

4.1 - Operation................................................................................................8

4.2 - Accessories (included) .......................................................................8

4.3 - Accessories available to order.........................................................8

5 INSTALLATION................................................ 9

5.1 - Standard conguration .....................................................................9

5.2 - Placement.............................................................................................10

5.2.1 - Noise levels...............................................................................................................10

5.2.2 - Safe area.....................................................................................................................10

5.2.2.1 - Ground security area ............................................................................10

5.2.2.2 - Security area in front of a wall...........................................................11

5.2.3 - Accepted installation sites ..................................................................................11

5.2.4 - Prohibited installation sites ................................................................................11

5.3 - Setting up.............................................................................................12

5.4 - Condensate evacuation...................................................................12

5.5 - Hydraulic installation........................................................................13

5.5.1 - Hydraulic connections on the installation ....................................................13

5.5.2 - Hydraulic connection between Heat pump and pilot..............................14

5.5.2.1 - Hydraulic connections on the HTi 11 &14kW ..............................14

5.5.3 - Heat pump water inlet lter (supplied)..........................................................15

5.6 - Connecting to the power supply.................................................15

5.6.1 - General recommendations.................................................................................15

5.6.2 - Accessing the connection terminals ...............................................................16

5.6.3 - Recommendations for connecting the system to the power supply..16

5.6.4 - Connection to the power supply......................................................................16

5.6.4.1 - Single-phase connection ....................................................................16

5.6.4.2 - Three-phase connection .....................................................................17

5.6.5 - Communication bus cable between the heat pump and the pilot......18

6 MAINTENANCE AND TROUBLESHOOTING19

6.1 - General information .........................................................................19

6.2 - Maintenance on the hydraulic circuit.................................................19

6.3 - Maintenance of the Heat pump...................................................19

6.4 - Maintenance of the electrical components..........................................19

6.5 - Consulting the meters .....................................................................19

6.6 - Sensor data curve charts.................................................................20

6.6.1 - Waterinlet and outlet

Air intake sensor

Sensors installed on compressors 1 and 2 ..................................................................................20

6.7 - Modication.........................................................................................20

6.8 - Decommissioning..............................................................................20

6.8.1- Interim Decommissioning of Product..............................................................20

6.8.2- Final decommissioning of the product ...........................................................20

6.9 - Recycling and Disposal....................................................................20

6.9.1- Disposal of refrigerant ...........................................................................................20

7 LIST OF SPARE PARTS.................................. 22

8 WARRANTY ................................................... 24

8.1 - Warranty coverage ............................................................................24

8.2 - Limitations of warranty....................................................................24

8.2.1 - General information ..............................................................................................24

8.2.2 - Cases (not limited to) for exclusion from warranty ....................................24

8.2.2.1 - Heating circuit water ............................................................................24

8.2.2.2 - Handling....................................................................................................24

8.2.2.3 - Installation site........................................................................................24

8.2.2.4 - Electrical connections ..........................................................................24

8.2.2.5 - Hydraulic connections .........................................................................24

8.2.2.6 - Accessories...............................................................................................24

8.2.2.7 -Maintenance.............................................................................................24

APPENDIX .......................................................... 25

A1 - Technical specications....................................................................25

A1.1 - General characteristics..........................................................................................25

A1.2 - Performances............................................................................................................25

A2 - EU declaration .....................................................................................26

A3 - Frost protection ..................................................................................26

A4 - Treatment of the water in the heating circuit..........................26

A4.1 - Preparing the hydraulic circuit (rinsing) .........................................................26

A4.2 - Filling water..............................................................................................................26

A4.3 - Treatment of the heating circuit........................................................................26

A5 - Dimensions...........................................................................................27

A6 - Product technical information sheet ..........................................28

A6.1 - HTi70 11 kW single-phase Heat pump..............................................................28

A6.2 - HTi70 11 kW three-phase Heat pump ...............................................................29

A6.3 - HTi70 14 kW single-phase Heat pump..............................................................30

A6.4 - HTi70 14 kW three-phase Heat pump ...............................................................31

A7 - Internal wiring diagram ...................................................................32

A7.1 - HTi70 11 & 14 kW single-phase Heat pump....................................................32

A7.2 - HTi70 11 & 14 kW three-phase Heat pump .....................................................33

NOTES / MAINTENANCE ................................... 34

- MANUAL HTi70 11 14 KW HEAT PUMPS -

4

1-SAFETY

Danger resulting from improper qualications

• Any work carried out by an unqualied person

can result in damage to the installation or in

physical injury.

• Do not perform maintenance on this appliance

unless you are a qualied professional.

• If the appliance is malfunctioning or not

working, cut the electricicty supply to the

electrical components and seek advice from a

qualied professional.

Danger resulting from improper use

This appliance should not be used by anyone

(including children under the age of 8 years

old)with reduced physical, sensory or mental

capabilities, or by anyone with insufficient

experience or knowledge of the appliance; unless

they are being supervised by someone who is

responsible for their safety and in possession of

the operating instructions of the appliance, or if

they have been instructed in the proper use and

in the risks of operating the appliance.

Children must not play with the appliance.

Cleaning and maintenance of the appliance

must not be undertaken by children without

supervision.

Applicable areas of use

The appliance is intended for use an appliance

for the production of domestic hot water: it must

be connected to a heating installation, and while

complying with the instructions, connected to

the drinking water network.

The intended use of the appliance includes the

following points:

•Following the instructions for operating,

installing and maintaining this appliance and

all of its components.

• Ensuring the compliance of the appliance to all

inspection and maintenance conditions which

are listed in this manual.

Danger of death by electrocution

• Touching live electrical wires can cause severe

bodily injury, and lead to death by electrocution.

All installation and maintenance work must be

carried out with the appliance switched o and

by a qualied professional. Before carrying out

any work on the appliance:

-Cut-o the electricity supply.

- Ensure that there is no possibility of the power

supply becoming active again.

-Wait at least 5 minutes for the capacitors to

lose their charge.

• Do not get water on any of the control or

electrical components. Always disconnect the

appliance from the electricity supply before

carrying out work on any of the electrical

components.

Danger of death if the pressure relief valves

are missing or defective

A defective pressure relief valve may prove

dangerous and could lead to burns or other

injuries by, for example, the pipes bursting.

The information presented in this document does

not contain all of the schematic diagrams needed

for a professional installation of the pressure relief

valves.

• Install the necessary pressure relief valves on

the circuit.

• Inform the user concerning the function and

the placement of the pressure relief valves.

• Respect all applicable national and international

regulations, standards and decrees.

Risk of material damage

The heat pump can only work when lled with

water. Never switch on the appliance if it is not

completely lled with water and purged of air.

Rules and regulations (decrees, standards,

laws)

Once the appliance is installed and switched

on, all decrees, directives, technical rules, safety

measures and standards, must be respected in

their current version in eect.

The electrical supply must conform to all

applicable regulations in the country of

installation, as well as the NFC 15-100 standard.

• Amethod ofdisconnection ensuring acomplete

cut-o must be installed in the xed piping to

conform to installation regulations (do not use

a movable outlet).

•Protect the appliance with a 2-pole circuit

breaker with a minimum contact opening of

3mm and must be grounded.

• The devices for electrical cut-o must remain

accessible.

• Water may drain from the discharge pipe of

the pressure limiting device. This pipe should

be kept open to open air.

• The pressure relief valve is mounted on the

condenser. Ensure that the drainage is properly

oriented to prevent water from leaking onto the

electrical components.

Maintenance - Troubleshooting

Maintenance and cleaning of the pilot must be

carried out at least once a year by a qualied

professional.

- MANUAL HTi70 11 14 KW HEAT PUMPS -5

•The appliance should be cleaned carefully

so as not to damage its electronics from the

outside. The use of a high pressure cleaner is

PROHIBITED.

• Any intervention on the refrigeration circuit

must be made by a qualified person who

holds a Category 1 certicate of tness.

Refrigerant R290, contained in the heat pump

circuit, does not pose an environmental hazard

but is ammable.

→Refrigerant R290 is odorless.

→Do not damage the refrigeration circuit

tubes,

→Do not handle ame or other ammable

sources inside the device,

→In the event of a leakage of the refrigerant,

unplug the plug, ventilate the room and

contact the customer service,

→Do not pierce or burn the appliance: the

recovery of the uid is mandatory in case

of intervention on the refrigeration circuit.

REFRIGERANT CIRCUIT

2 -PLEASE READ

IMMEDIATLY

This technical installation manual forms part of the appliance which

it refers to. In order for the warranty to be valid, the instructions must

be read prior to using the appliance.

The safety advice and instructions provided in this manual must be

strictly respected.

Our society is not liable for any damages caused from not following

the instructions provided, or improper handling, installation or use.

This technical installation manual can be modied without prior

notice.

This manual must be safeguarded and passed on to successive users

for future reference.

It will be considered as evidence in case of litigation.

2.1 - Conservation of documents

DHW.......Domestic Hot Water

DCW .......Domestic Cold Water

T°..............Temperature

HP............Heat pump

2.3 - Abbreviations and acronyms

Type and refrigerant charge.

PS : Max high service pressure

Indicates warnings and important recommendations.

2.2 - Symbols used

Contains regulated substances, do not throw in the

garbage. If disposing, please respect all regulations

pertaining to the recovery of electric and electronic

equipment.

Heat power output produced.

Pnom : nominal

Max current protection (A)

Caution : contains a ammable refrigerant uid.

Please make sure to respect the installation and

handling precautions.

Consult the installation manual before any intervention

on the product, before handling, installation, use , and

maintenance.

- MANUAL HTi70 11 14 KW HEAT PUMPS -

6

2.4 - Rating plate

1898305

Ser.n° : 155020-232300000

Hermétiquement scellé / Hermetically sealed

Made In France

Réf :

155020

HTi 11 mono

70

Pompe à chaleur

AUER

Rue de la République

80210 Feuquières en Vimeu

*Selon EN14511 / According to EN14511

1898305

*Selon EN14511 / According to EN14511

R290 (groupe 1) : 0,900kg

PS : 3,1MPa (31 bar)

Ts min : -20°C

Ts max : +40°C

230V mono ~ 50/60Hz

Imax : 30A - Pmax : - kW

Pnom* : 8,95kW

COP* : 4,85 (A7W35)

IPX4

P : 0,3MPa

(3 bar)

PED cat. 1

136 kg

Manufacturer’s identity

Appliance identity

Serial number of the appliance

Appliance type

Certication agency

intuis reference

of the appliance

Rating plate reference

appliance weight

CE marking

Appliance electric data

PED’s category

According to 2014/68/EU

Protection rating

Reference of

the appliance

Year of

manufacture

2023

Week of

manufacture

Appliance

number in the

series

155020 - 23 23 00000

Serial number of the appliance

Maximum hydraulic system

pressure

P : 0,3MPa

(3 bar)

Pnom* : 8,95kW

COP* : 4,85 (A7W35)

Nomimal performances

According to EN 14511

Description :

Refrigerant type/quantity

R290 (groupe 1) : 0,900kg

PS : 3,1MPa (31 bar)

Ts min : -20°C

Ts max : +40°C

H

L

Outside temperature limits

operating

Maximal pressure of the refrigerant

circuit

- MANUAL HTi70 11 14 KW HEAT PUMPS -7

3.2 - Storage and transport

Admissible storage and transport temperatures of the appliance are

between -20°C and +60°C.

The appliance must be stored in a room that does not contain

sources of ignition that are continuously operating (for example,

bare res, gas appliance or electric radiator in operation).

3.2.1 - General information

The appliances must be stored and transported packaged and

on their wooden pallets, in a vertical position, and completely

empty of water.

3.2.2 - Transporting with a forklift

When transporting with a forklift truck, the Heat Pump must be on

its wooden pallet.

When moving the Heat Pump do not lower or raise the unit suddenly

as the Heat Pump can easily lose it equilibrium. The Heat Pump should

be suitably secured to prevent it from tipping.

3 - DELIVERY AND STORAGE

3.1 - Delivery terms and conditions

In general, the material is transported at the recipient’s own risk.

It is important to verify that all of the elements have been received

and that no damage has been sustained during transport upon

receipt of the appliance and before beginning the installation

procedures.

1. Heat pump

2. Hydraulic connection kit

(inside the heat pump)

3. Hydraulic pilot

3.2.3 - Transporting manually

The Heat pump can be transported manually.

The Heat pump must always be transported in a horizontal position,

including during installation.

Do not handlethe unit by its hydraulic connections.

It’s possible to transport the appliance with straps (not supplied)

The appliance can be moved using straps (not provided) through

the four slots at the base. If necessary, carry paratransit equipment

to avoid any risk of incident.

Do not incline more than 30°

Maintain a protective covering on the nned

heat exchanger during handling.

* Straps not supplied.

Installation procedures must be carried out by a qualied professional,

so as to prevent any risks of bodily harm and/or material damage.

- MANUAL HTi70 11 14 KW HEAT PUMPS -

8

4 - INTRODUCTION

1. Compressor

2. Pressure reducer

3. Evaporator

4. Condenser

5. Ventilator

6. Heating inlet / outlet

7. Condensates drainage

Note:

The Heat Pump is exclusively designed for heating purposes.

It cannot be used for cooling.

The manufacturer cannot be held responsible for any other usage

of the appliance.

4.1 - Operation

The Heat pump is a closed and pressurised system in which the

refrigerant serves as the medium for transferring energy.

A safety pressure switch is used on the refrigeration circuit, it is

located on the high pressure part of the circuit at the output of the

compressors. It is a dry contact that when the pressure becomes

too high (>31 bar) opens. Once opened, it cuts the power to the

compressors, independently of the electronics and thus protects

all circuit components.

The evaporator dis a cooling exchanger which draws calories from

the air. The humidity in the air condenses on contact with the cold

surface, and forms condensation which must be drained regularly

during operation of the Heat pump (evacuation in h).

The condenser eis a plated heat exchanger which allows to transfer

the heat towards the heating water of the installation g.

The operating range of the Heat pump ranges from an air

temperature of -20°C to 40°C.

It is FORBIDDEN:

•tooperate the Heatpumpusing airintake

containing solvents or explosive materials.

• to use air intake containing grease, dust, or

aerosol particles.

• to connect vented exhaust hoods to the

appliance.

Use of the appliances are FORBIDDEN if

the installation is not lled with water.

External defrost kit (Réf. 754101)

to keep the external condensate evacuation duct from

freezing.

4.3 - Accessories available to order

2-core sheathed cable (Ref. 753102)

linking the Heat Pump and the Pilot (lg 20m)

20m length for connection instead of the

10m length delivered as standard.

Adjustable raiser kit for heat pump (Ref. 754600)

allows raise of the heat pump and catch up with ground levels.

4.2 - Accessories (included)

The components described below are delivered with the Heat

Pump:

2-core sheathed cable linking the

Heat Pump and the Pilot (lg 10m)

HTi70 11 & 14 Hydraulic Fitting (Ref. 751019)

(included a 1’’lter valve, a safety valve assembly 1’’1/4, 2 vannes

d’isolement 1"1/4, 1 purgeur manuel, a hydraulic connection

[reduction F3/4 M1’’ + nipple MM 1’’])

HTi70 accessory kit

Set of four mounting feet.

- MANUAL HTi70 11 14 KW HEAT PUMPS -9

5.1 - Standard conguration

5 - INSTALLATION

• The Heat pump must be installed outside exclusively.

• Avoid any obstruction of the airow of the ventilator.

Ensure that there is nothing blocking the exchanger’s air circulation. Ensure that the Heat pump is placed so that

it is sheltered from dominant winds.

It is prohibited to install the Heat pump:

• In a non-ventilated room.

• Near sources of excessive heat, combustible

materials, or near ventilation points of adjacent

buildings.

• Near a kitchen or workshop exhaust ducts; this

can result in a mixture of oil and air settling onto

the heat exchanger ns which could hamper its

performance.

• In an area with ammable gaz, acidic substances,

or alkalines which could cause irreversible

damage to the copper-aluminium heat

exchanger.

PROHIBITED INSTALLATION

• Avoid installing the Heat pump in a

location subject to noise reverberation such

as near windows or near the corners of buildings.

• As the condensates draining trough slopes

downward, the Heat pump must be installed on a

level base.

• The Heat pump must be easily accessible so as to

facilitate access for inspections and maintenance.

IMPORTANT INSTALLATION RULES

Pilot

HTi70

heat pump

2 electrical supplies

230V single phase

hydraulic

connection

communication

cable

2-core sheathed

- MANUAL HTi70 11 14 KW HEAT PUMPS -

10

5.2 - Placement

The Heat Pump is designed to be installed outdoors exclusively, while respecting a minimum of free space around the appliance in an area free

from excessive levels of dust. It should never be placed in an enclosed space.

The Heat Pump is designed to operate in rainy weather conditions, although it can be installed under a well-ventilated shelter (Withan opening

large enough to allow sucient air ow for intake and exhaust).

Regarding the fan, the free space from any obstacles must be at least 2m.

≥ 50cm

≥ 1m

≥ 1m

≥ 50cm ≥ 50cm

≥ 2m

Placed on the

ground or on a

terrace

(empty area) Placed against a wall

+3dB (A) Placed in a yard

+9dB (A)

Placed in a corner

+6dB (A)

5.2.1 - Noise levels

The Heat Pump is equipped with a large diameter fan so as to allow for an appropriate air ow rate. This ow rate can rise up to 9.000 m3/h. The

fan speed is adjustable to limit the noise level.

Depending on the installation conditions, the noise levels may be dierent, in particular if the walls closest to the Heat Pump cause a reverberation

and amplication of noise.

The diagrams below show dierent installation examples for dierent placements.

5.2.2 - Safe area

The heat pump contains a ammable refrigerant. In case of leak, the refrigerant could accumulate near the ground (higher density than air). or

spread through openings in the building. In order to limit the risk of a toxic, suocating, explosive or dangerous atmosphere, a safety perimeter

must be established around the machine.This perimeter must not include a window, door, or any openings towards the interior of the building.

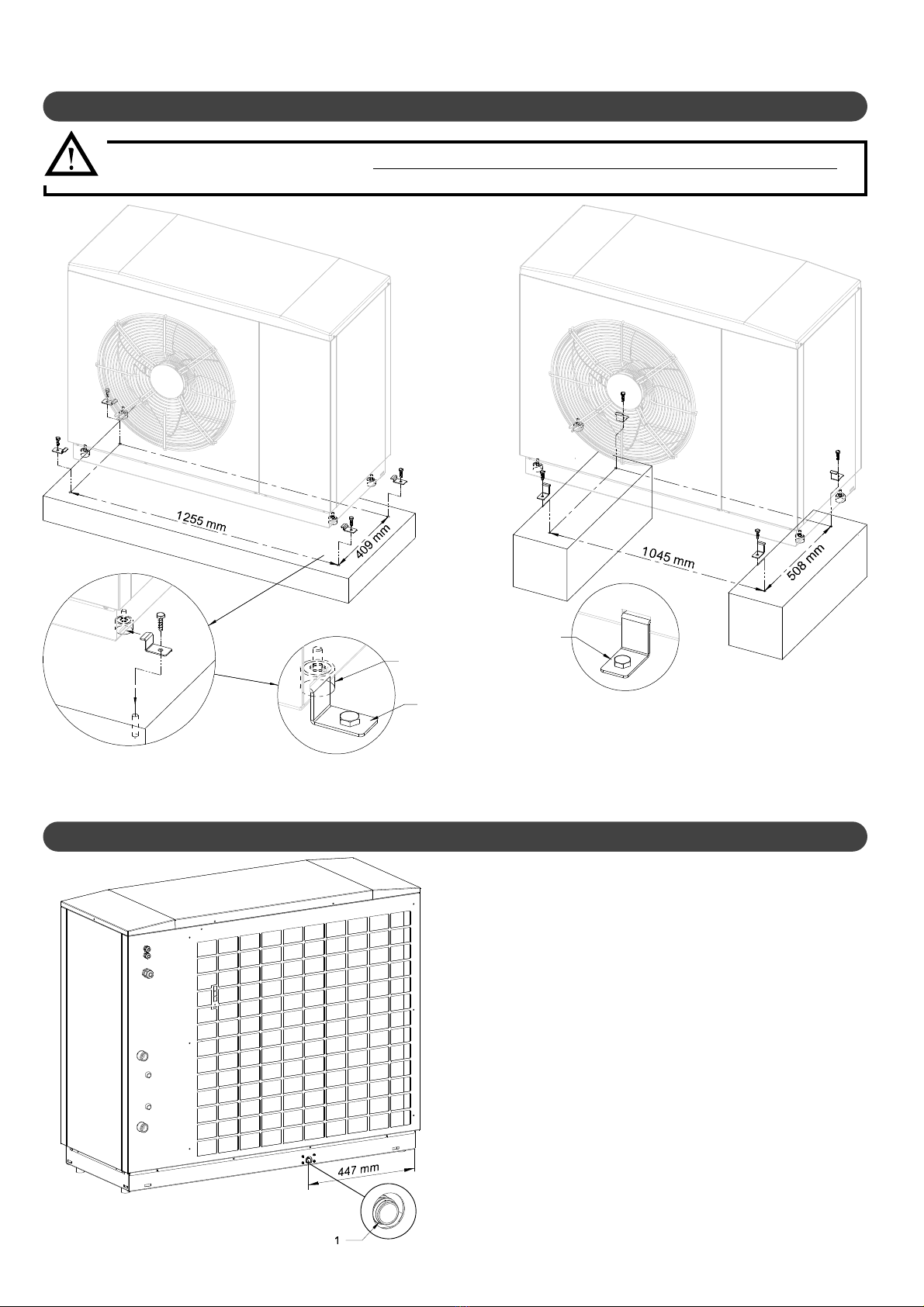

5.2.2.1 - Ground security area

Observe this area if the heat pump is in free eld.

A

A

A

A

- MANUAL HTi70 11 14 KW HEAT PUMPS -11

5.2.2.2 - Security area in front of a wall

This area must be respected if the heat pump is against a wall and close to the opening of a building.

Distances from the security perimeter (mm)

HTi70 11kW HTi70 14kW

A 1000 1000

B 1300 1300

C 1600 1600

D 500 500

D

A

C

B

AA

C

B

AA

5.2.4 - Prohibited installation sites

Underneath a

window

Neighbouring

home

5.2.3 - Accepted installation sites

Oset from all

windows

The noise prevention screen must be made of insulated materials.

Neighbouring

home

Neighbouring

home

Neighbouring

home

- MANUAL HTi70 11 14 KW HEAT PUMPS -

12

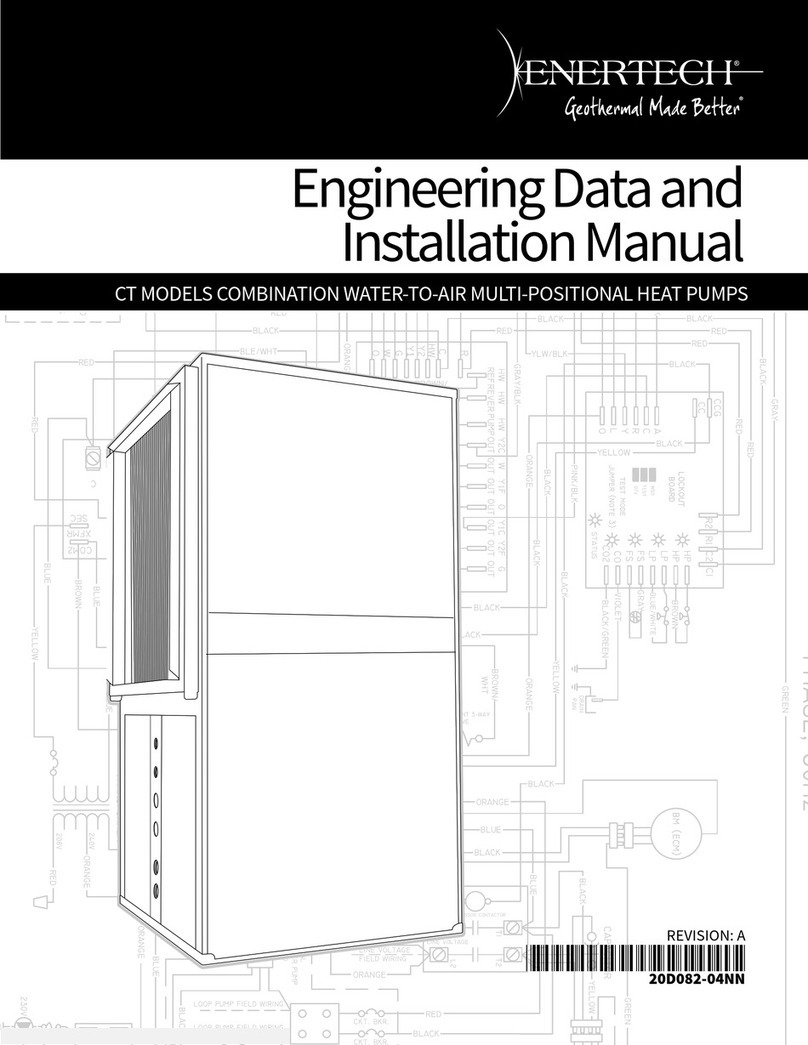

5.4 - Condensate evacuation

When the appliance is operating in frost protection mode, the

condensed water must be drained o. In order for the condensates

to drain properly, the drainage trough and hole 1must be clean and

free of all debris (leaves, grass, etc...).

During cold weather, ice may form on the evaporator.The heat pump

has an automatic defrosting system to eliminate this phenomenon.

Do not use tools to remove the glass as this could damage the

evaporator.

The condensates can be connected to the drain with the optional

external defrost kit (Ref. 754101). It’s made up of a reinforced PVC

pipe and a heating cord allowing drainage in freezing weather.

It’s also possible to let the condensates ow freely at the back of

the heat pump. In this case, it’s necessary to provide in the ground

a device allowing a drainage of water in depth.

5.3 - Setting up

The Heat pump must be installed on a hard and stable base, which is suciently raised from ground level to

avoid risks of damage in case of ooding or snow.

- Put the heat pump in his 4 attachment tabs (b)

- If needed, attach the heat pump to the oor using these 4 xing lugs (c). (ref. 754601) screws not supplied.

b

c

c

- MANUAL HTi70 11 14 KW HEAT PUMPS -13

5.5.1 - Hydraulic connections on the installation

5.5 - Hydraulic installation

In order to ensure that uids can circulate properly, it is advisable to check that the sizing of piping in the circuit is appropriate between the

Heat Pump and the Pilot.

All piping should be thermally insulated,

especially the connecting pipes from the Pilot

to the Heat Pump.

The Heat Pump is equipped with a hydraulic

pressure relief valve set at 2.5 bars. A service

pressure below this value should be maintained.

- MANUAL HTi70 11 14 KW HEAT PUMPS -

14

5.5.2 - Hydraulic connection between Heat pump and pilot

A sucient ow rate should be ensured so that the range of temperature between the outlet and inlet of the Heat Pump does not exceed 5°C

when the Heat Pump is operating at full power (take a temperature measure when the HTi Heat Pump is in heating mode and the system is

fully functioning):

The hydraulic connection section between the Heat Pump and the Pilot must be sucient.

Using the tables provided in the hydraulic pilot installation manual, determine the minimum inner diameter of the connection of piping needed

depending on the distance* which separates the Heat Pump and the Pilot.

Make sure that all sections of piping are equipped with functional

and accessible air valves.

Thehydraulickitmust be installed using exible pipingon thewater

inlet and outlet points of the Heat pump in order to prevent any

vibrations from being transmitted to the heating system.

Heat pump model 11kW 14kW

Minimum nominal ow rate 1600L/h 2000L/h

Maximum pressure 2.5 bar 2.5 bar

Hydraulic connection 1’’ 1’’

5.5.2.1 - Hydraulic connections on the HTi 11 &14kW

The hydraulic connection kit (Ref. 751019) supplied with the heat pump must be installed. See instructions supplied with the kit.

Départ PAC

Retour PAC

Départ PAC

Retour PAC

Départ PAC

Retour PAC

Départ PAC

Retour PAC

HP starting HP starting

HP starting HP starting

HP feedback

HP feedback HP feedback

HP feedback

- MANUAL HTi70 11 14 KW HEAT PUMPS -15

5.5.3 - Heat pump water inlet lter (supplied)

A 1’’ valve with a built-in 500μm lter must be installed on the water

inlet piping on the Heat pump:

• Respect the direction of ow on the lter (arrow on the

valve).

Clean the lter several times as soon as

the Heat pump circulator pump has been

activated (make sure to switch o the Heat pump

circulator pump before cleaning).

Please refer to the pilot’s user manual for any

additional recommendations concerning

hydraulic connnection.

• Clean the lter at least once per year.

5.6 - Connecting to the power supply

The rules and regulations in the country of

installation MUST be respected (standard

C15-100).

• The electrical lines for general power supply to the

circuits must be made in compliance with your

country’s current rules and regulations (standard

C15-100).

• Standard C15-100 determines the cable section to

be used based on acceptable currents.

• Standard C15-100 determines the cable section to

be used based on the following elements:

- Nature of the conductor:

. type of insulation, number of strands, etc...

- Installation mode:

. inuence of conductor and cable groups

. ambient temperature

. tightly or non-tightly installed

. length of cables, etc...

Ensure that the power supply is sucient to supply both the Heat

pump and the electrical back-up if necessary, taking into account

any other domestic usage of electricity.

Connection to the power supply for each appliance must be done

by a qualied professional with the mains power switched o.

5.6.1 - General recommendations

• During transport, the electrical connections

may be subject to accidental loosening.

• To eliminate any risk of abnormal heating, it is

necessary to ensure the placement of the faston

type electrical connections are secure and tighten

the screw connections.

See§ «Spare parts - electrical boxes»

Each appliance is delivered from the factory completely pre-wired.

However, it is necessary to connect the following elements to the

relevant terminals:

• The electrical supply of the Heat pump’s power supply

circuit.

• The 2-core sheathed connecting cable (10m length

supplied) between the Heat pump and the Pilot.

Under no circumstances will the manufacturer be held liable for

any problems which may arise due to improper installation and/or

choice of power supply cable.

Connecting terminals

The terminal strips are spring-loaded «Cage

Clamps».

For Handling, use the following :

- for 2.5mm² or 4mm² control terminals, use a

3.5 x 0.5mm at-head screwdriver.

- for 6mm² power terminal, use a 5.5 x 0.8mm

at-head screwdriver.

1: Insert the screwdriver into the rectangular

window located on top of the terminal block.

2: Insert the wire ito the «Cage Clamp» when the

ap is open.

3: Remove the screwdriver.

Nota : The wires must be stripped to the following lengths :

- for the 2.5mm² control terminals between 8 and 10mm.

- for the 4mm² control terminals between 10 and 12mm.

- fort the 6mm² power therminal between 13 and 15mm.

- MANUAL HTi70 11 14 KW HEAT PUMPS -

16

5.6.3 - Recommendations for connecting the

system to the power supply

Check:

• The power consumption

• Number and thickness of the power supply

cables

• Fuse or circuit breaker ratings

The power supply must come from an electrical protection and

sectioning device which complies with all current rules and

regulation in eect in the country of use.

This CE-approved unit complies with all the essential requirements

of the following directives:

- Low voltage n°2006/95/CE

- Electromagnetic compatibility n° 2004/108/CE

5.6.4 - Connection to the power supply

The HTi70 Heat pump is CE-marked. It is compliant with French

standard NF C15-100 as well as European standards EN 61000-3-3

and EN 61000-3-11, among others.

The power supply cable should be sized carefully according to the

following factors:

- Maximum current required

- Distance between the HTi70 Heat pump and the power

supply

- Overall protection

- The neutral operating system

Make sure to strip the cable before placing it into the

terminals, and make sure that the copper is in good

condition.

A method of disconnection must always be installed in compliance

with the installation rules.

If the power supply cable is damaged, it must be replaced by a

qualied professional to avoid any risk of danger.

5.6.2 - Accessing the connection terminals

1 : Remove the 2 screws

2 : Slide the panel downwards

3 : Pull the panel forwards

1 : Remove the two screws

2 : Slide upwards and pull forwards

5.6.4.1 - Single-phase connection

Ensure that the installation is equipped with a properly sized and

connected grounding cable.

Ensure that the voltage and frequency of the general power supply

ts requirements.

The acceptable variation in voltage is:

230 V +/- 10% 50Hz for single-phase models

400 V +/- 10% 50Hz for three-phase models

See Appendix A1 for components adapted to the heat

pump.

- MANUAL HTi70 11 14 KW HEAT PUMPS -17

5.6.4.2 - Three-phase connection

• A phase controller relayHTi70 three-pase 11kW and 14kW heat pump.

In order to prevent a phase fault or bad sequence -which could cause compressor damage- a phase controller relay is installed. It prohibits the

power supply to the heat pump if phases are reversed.

Proper Wiring

Amber

and green

lights on

Incorrect wiring

Green light

only on

If the order of the phases is reversed or if a phase is missing, the relay cuts the power supply to the electronic board. A «BUS Err» defect appears.

On the phase controller relay, this is indicated by the absence of the orange light on the top and the green light on the bottom. To correct this

fault situation, two phases must be reversed on the power terminal block general power cable.

When the hydraulic driver is powered on, a «BUS fault» is displayed. Reverse two phases on the heat pump three-phase power cable. Power

back on and check the voltage on each phase.

In case of incorrect wiring :

Attention, never work under tension

- MANUAL HTi70 11 14 KW HEAT PUMPS -

18

5.6.5 - Communication bus cable between the heat pump and the pilot

- MANUAL HTi70 11 14 KW HEAT PUMPS -19

6 - MAINTENANCE AND

TROUBLESHOOTING

•In order to ensure the best performance

results from your HTi70 Heat pump it

should be subject to regular maintenance.

•An annual maintenance check is recommended

to be carried out by a qualied professional on

the hydraulic heating circuit.

•All work carried out on the refrigerant circuit

must be done by a qualied professional with a

category 1 certicate of aptitude.

•Always switch the appliance off before opening it.

6.1 - General information

After the appliance has been operating for a few days, it is advised

to check that the water circuit is properly sealed.

Note: In case of maintenance work or decommissioning of an

appliance, please respect all environmental protection

instructions concerning recovery, recycling, and disposal

of consumables and components.

6.2 - Maintenance on the hydraulic circuit

Inspection of the water circuit consists of removing sludge, checking

the lters, and stopping up any leaks that may have appeared. Clean

or replace clogged or dirty lters.

From time to time check that the condensates are draining properly.

The HTi70 Heat pump contains R290 refrigerant fluid. It is not

subject to regulations concerning greenhouse gasses, and does

not necessitate mandatory annual maintenance by a qualified

professional.

However, it is still recommended to carry out periodic (at least once

per year) cleaning of the evaporator ns if it is obstructed by dust or

leaves: this should be done using a vacuum cleaner or by spraying

with water.

Never clean the nned heat exchanger

with high-pressure cleaning equipment

as it could damage the ns.

6.3 - Maintenance of the Heat pump

• Always disconnect the appliance from

the power supply before accessing the

electrical terminals.

• Do not get water on any of the electrical

components.

6.4 - Maintenance of the electrical

components

• Check on both the HTi70 Heat pump and the HTi70 Pilot that the

electrical supply cables are properly connected to the terminals.

• Check the electrical connections for oxidization or overheated

sections.

• Check the tightness of the cables on the compressor starters.

• Clean any dust from the electrical box and check the connections.

• Check that the ground cable is properly connected.

In case of repair work on the HTi70 Heat pump, the refrigerant

circuit, or the electrical box, it is important to follow the following

instructions:

Any work on the refrigerant circuit must be undertaken by a qualied

professional with a category 1 certicate of aptitude. 1. It is forbidden

to release gas from the refrigerant circuit into the atmosphere, and

it is obligatory to recover the refrigerant before undertaking any

work on the circuit.

The HTi70 Heat pump uses R290 refrigerant uid. Given the ammable

nature of this uid, any work on the refrigerant circuit must be carried

out using suitable equipment which complies with the current rules

and regulations in eect.

When handling the uid (recovery, draining, or relling), the appliance

must be disconnected from the power supply. Do not smoke. Do not

generate any ame (lighter, blowtorch) while handing the uid. If

work is necessary on the refrigerant circuit using a ame (blowtorch),

the refrigerant circuit must be emptied and replaced with nitrogen.

Consulation of the meters can be done from the hydrualic pilot’s

display screen (refer to the Pilot’s user maual).

6.5 - Consulting the meters

Keep in mind that there may be some

refrigerant uid remaining in certain

parts of the circuit after it has been emptied and

replaced with nitrogen. (Creation of a ame is

possible).

- MANUAL HTi70 11 14 KW HEAT PUMPS -

20

0

50

100

150

200

250

300

350

-40 -30 -20 -10 0 10 20 °C

k:

6.6 - Sensor data curve charts

6.6.1 - Waterinlet and outlet

Air intake sensor

Sensors installed on compressors 1 and 2

0,2

0,3

0,4

0,5

0,6

0,7

0,8

0,9

1,0

90 100 110 120 130 140 °C

k:

Temp.

(°C)

Sensor

value

(KOhms)

Temp.

(°C)

Sensor

value

(KOhms)

Temp.

(°C)

Sensor

value

(KOhms)

Temp.

(°C)

Sensor

value

(KOhms)

-40 351.078 10 20.017 60 2.472 110 0.504

-35 251.277 15 15.768 65 2.068 115 0.439

-30 182.451 20 12.513 70 1.739 120 0.384

-25 133.827 25 10.000 75 1.469 125 0.336

-20 99.221 30 8.045 80 1.246 130 0.296

-15 74.316 35 6.514 85 1.061 135 0.261

-10 56.202 40 5.306 90 0.908 140 0.231

-5 42.894 45 4.348 95 0.779 145 0.204

0 33.024 50 3.583 100 0.672

5 25.607 55 2.968 105 0.581

0

1

2

3

4

5

6

7

8

9

10

11

12

20 30 40 50 60 70 80 90 °C

k:

6.7 - Modication

Any modication of the device is prohibited. Any replacement of

components must be done by a professional with original parts

from the manufacturer.

6.8 - Decommissioning

In the event of a prolonged absence with a power cut to the housing

and product, ask a qualied professional to drain the product or

protect it from freezing.

6.8.1- Interim Decommissioning of Product

6.8.2- Final decommissioning of the product

Turn o the product to a specialized installer.

6.9 - Recycling and Disposal

Entrust the disposal of the packaging to the installer who installed

the product.

The above symbol requires:

- Do not dispose of the product with the household waste.

- Dispose of the product at a collection point for used electrical

and electronic equipment.

The product contains refrigerant R290 (propane).

- Routinely dispose of refrigerant to qualied personnel.

-Follow the general safety conditions.

6.9.1- Disposal of refrigerant

This manual suits for next models

6

Table of contents

Popular Heat Pump manuals by other brands

Watts

Watts HS-200 PT installation instructions

emmeti

emmeti ECO HOT WATER EQ 1123 Use and installation manual

Gree

Gree FLEXX Series Service manual

Northern Heatpump

Northern Heatpump RT-SE* Installation & operating instructions

Smith

Smith WWHB Series Technical manual

Enertech

Enertech CT024 Engineering data and installation manual