Nordyne R-410A User manual

Installation Instructions

Split System Indoor Coils

!

CAUTION:

ReadtheInstallationInstructionssup-

plied with furnace/air handler and ob-

serveallsafetyrequirementsoutlined

ininstructionsand/orfurnace/airhan-

dler markings before proceeding with

installationofthe coil

These instructions are primarily intended to

assist qualified individuals experienced in the

properinstallationofthisappliance. Somelocal

andnationalcodesrequirelicensedinstallation/

service personnel for this type of equipment.

Read all instructions carefully before starting

the installation.

2

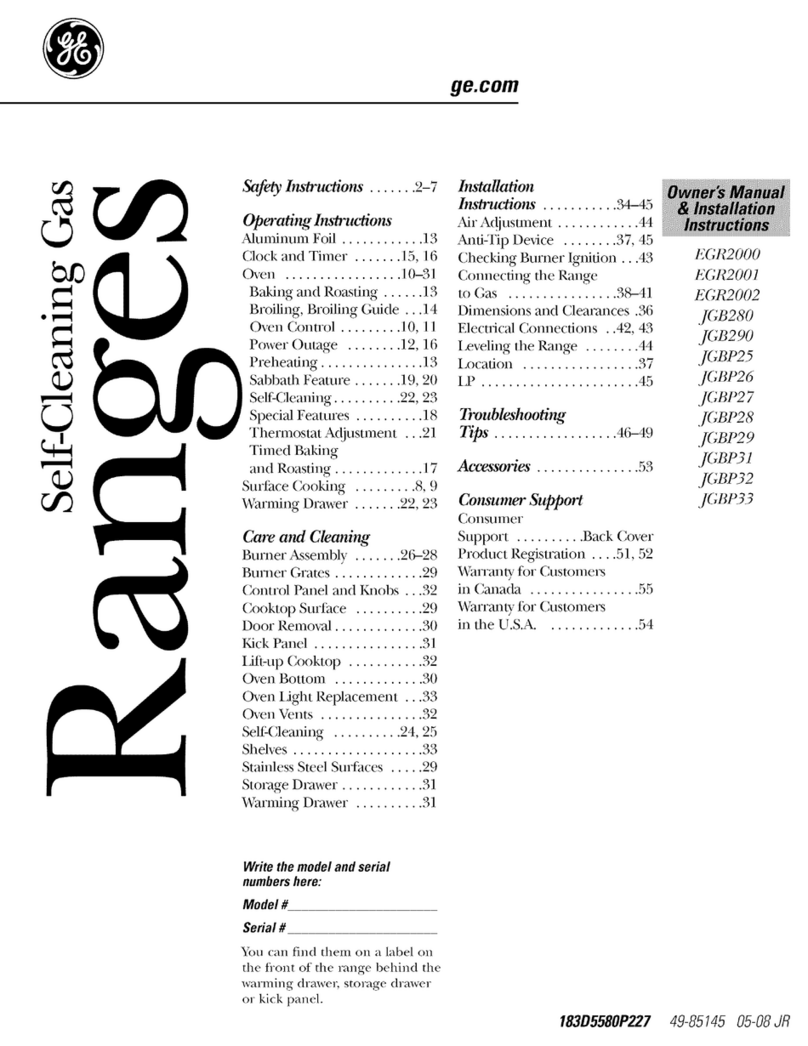

TableofContents

1. General Information ............................................................................................................. 3

2. Coil Specifications ............................................................................................................... 4

3. Coil Installation..................................................................................................................... 5

• Upflow Furnace

• Downflow Furnace

• Horizontal Furnace

• Horizontal Ready Coils for Horizontal Left Installation

• Horizontal Ready Coils for Horizontal Right Installation

4. Refrigerant Line Connections............................................................................................ 6

5. Completing the Installation ................................................................................................ 7

• Condensate Drain

• Air Filters

• Close-off Plates and Panels

• Refrigerant Charging

6. Maintenance and Service .................................................................................................... 8

3

1. GENERALINFORMATION

Standard cased coils are designed for upflow/

downflowapplicationsorhorizontalapplications

when used in conjunction with our horizontal

drain pan kit (See page 5). Accessory kits are

not required for factory ready horizontal coils.

Coils are equipped with braze type refrigerant

connections for easy installation.

Read the installation manual supplied with the

outdoor unit for refrigerant line connection pro-

cedure, required line sizes, and other informa-

tion pertaining to the system installation.

1. Make certain that the air delivery of the

furnace/air handler is adequate to handle

thestaticpressuredropofthecoil,filter,and

duct work.

2. Check the orifice size of the coil’s expan-

siondeviceandconfirmthatitissuitablefor

application with the intended outdoor unit.

NOTE: Some C4 series coils (R-410A re-

frigerant) employ a thermostatic expansion

valve (TXV) as the metering device (See

page 4).

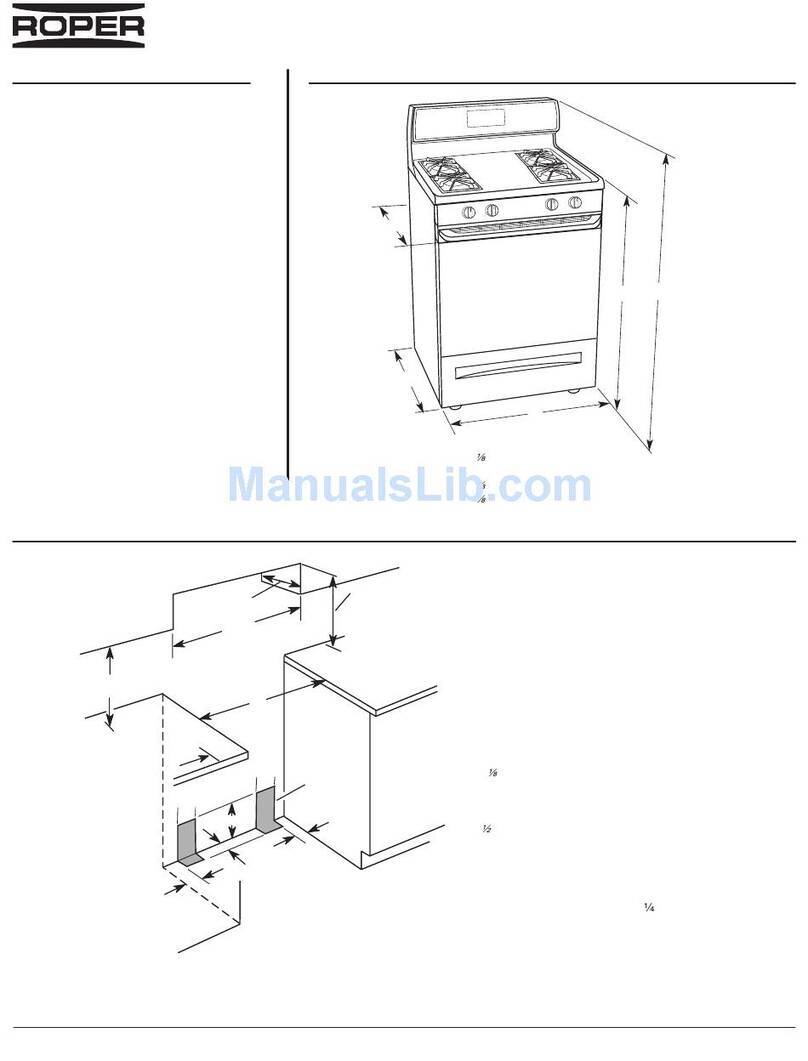

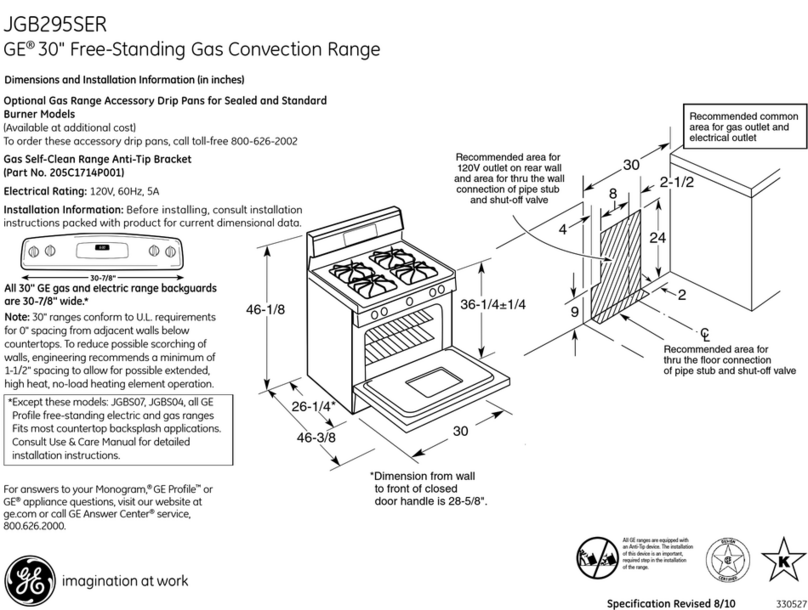

H

20

3

/

4

"

B

16

5

/

8

"

W

A3/4"

13

3/8"

155/8"

19 3/4"

Figure 1.

3. Where precise forming of the refrigerant

lines is required, a copper tubing bender

designed for the size lines used is recom-

mended. Avoid sharp bends and contact of

the refrigerant lines with metal surfaces.

4. Refrigerant lines should be wrapped with

pressure sensitive neoprene or other suit-

able material where they pass through the

raw edges of holes.

5. Coil must be level for proper condensate

drainage.

NOTE: Optional cooling/heating equipment

must be properly sized and installed in accor-

dance with the furnace manufacturer’s specifi-

cationsandapproved recommendations. “Heat-

ing only” furnace air circulators may have to be

replaced with multi-speed “Heating/Cooling”

blowers to upgrade the air delivery (CFM) when

an add-on coil is installed. Refer to Coil Speci-

fications for recommended CFM and allow for

pressure drop across the coil and filters.

4

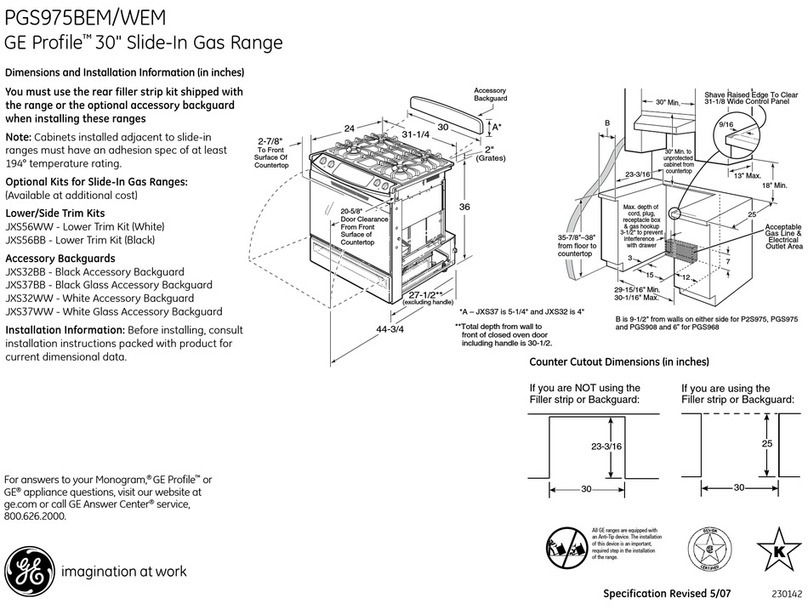

2.COIL SPECIFICATIONS

(1) Refer to sales specification sheets for Listed/

Certified combinations of equipment and re-

quired accessories.

(2) Refer to the current ARI Directory for certified

ratings of split systems.

(3) Orificesizeisfor10SEERsystems.Additional

orifices may be supplied with the coil.

(4) Allows application of larger coil cases to

smaller furnace cabinet.

(5) This coil is for 4 ton 12 SEER match.

(6) An X in the model description designates

factory installed TXV.

Coil Model

(1)

C3BA-

024C-A

C3BH-

024C-A

C3BA-

030C-A

C3BH-

030C-A

C3BA-

036C-A

C3BH-

036C-A

C3BA-

043C-A

C3BA-

030C-B

C3BA-

036C-B

C3BH-

036C-B

C3BA-

042C-B

C3BH-

042C-B

C3BA-

048C-B

C3BH-

048C-B

(5)

C3BA-

050C-B

C3BA-

048C-C

C3BA-

060C-C

C3BH-

060C-C

Nominal Capacity BTUH

(2)

24,000 24,000 30,000 30,000 36,000 36,000 43,000 30,000 36,000 36,000 42,000 42,000 48,000 48,000 48,000 48,000 60,000 60,000

Nominal Airflow 900 900 1100 1100 1200 1200 1400 1100 1350 1350 1500 1500 1500 1500 1500 1500 1800 1800

Installed Orifice Size

(3)

0.060 0.060 0.063 0.063 0.067 0.067 0.080 0.063 0.067 0.067 0.075 0.075 0.080 0.080 0.080 0.080 0.093 0.093

Width (in.) W 14 1/4 14 1/4 14 1/4 14 1/4 14 1/4 14 1/4 14 1/4 19 3/4 19 3/4 19 3/4 19 3/4 19 3/4 19 3/4 19 3/4 19 3/4 22 1/2 22 1/2 22 1/2

Height (in.) H 20 20 20 26 20 26 26 20 20 26 20 26 20 26 26 20 26 26

Top F 12 7/8 12 7/8 12 7/8 12 7/8 12 7/8 12 7/8 12 7/8 18 3/8 18 3/8 18 3/8 18 3/8 18 3/8 18 3/8 18 3/8 18 3/8 21 1/8 21 1/8 21 1/8

Connections (in.) Liquid Line 3/8 3/8 3/8 3/8 3/8 3/8 3/8 3/8 3/8 3/8 3/8 3/8 3/8 3/8 3/8 3/8 3/8 3/8

Suction Line 3/4 3/4 3/4 3/4 3/4 3/4 3/4 3/4 3/4 3/4 3/4 3/4 3/4 3/4 7/8 3/4 7/8 7/8

Horizontal Drain Kit 914633 - 917492 - 917492 - 914634 917492 917492 - 917492 - 917492 - 914634 914633 914634 -

Coil Case Adapter

(4)

- - - - - - - 913963 913963 913963 913963 913963 913963 913963 913963 913964 913964 913964

R - 22 Units

Coil Model

(1) (6) C4BA-X24C

-

B

C4BH-X24C

-

B

C4BA-X36C

-

B

C4BH-X36C

-

B

C4BA-X48C

-

C

C4BH-X48C

-

C

C4BA-X60C

-

C

C4BH-X60C

-

C

Nominal Capacity BTUH (2) 24,000 24,000 36,000 36,000 48,000 48,000 60,000 60,000

Nominal Airflow 900 900 1350 1350 1500 1500 1800 1800

Metering Device TXV TXV TXV TXV TXV TXV TXV TXV

Width (in.) W 19 3/4 19 3/4 19 3/4 19 3/4 22 1/2 22 1/2 22 1/2 22 1/2

Height (in.) H 20 26 26 26 29 29 29 29

Top F 18 3/8 18 3/8 18 3/8 18 3/8 21 1/8 21 1/8 21 1/8 21 1/8

Connections (in.)

Liquid Line 3/8 3/8 3/8 3/8 3/8 3/8 3/8 3/8

Suction Line 3/4 3/4 7/8 7/8 7/8 7/8 7/8 7/8

Horizontal Drain Kit 917492 - 914634 - 917188 - 917188 -

Coil Case Adapter (4) 913963 913963 913963 913963 913964 913964 913964 913964

R - 410A Units

5

3.COILINSTALLATION

!

WARNING:

Electricfurnacesmaybeconnectedto

more than one supply circuit.

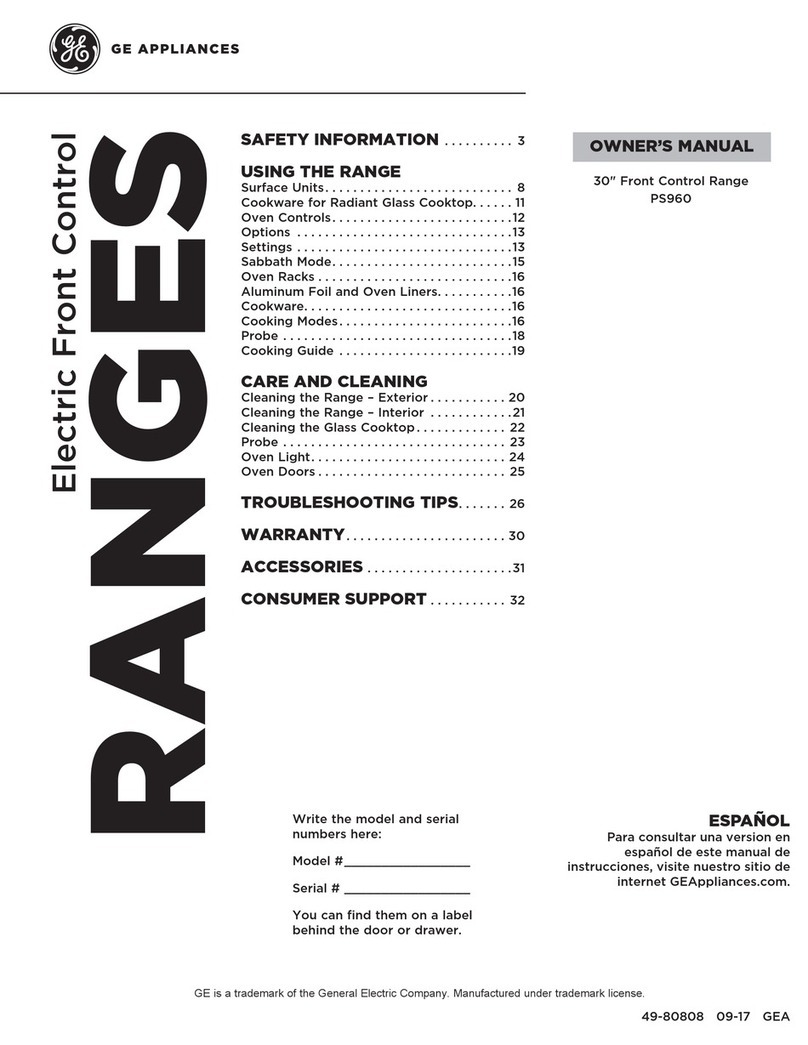

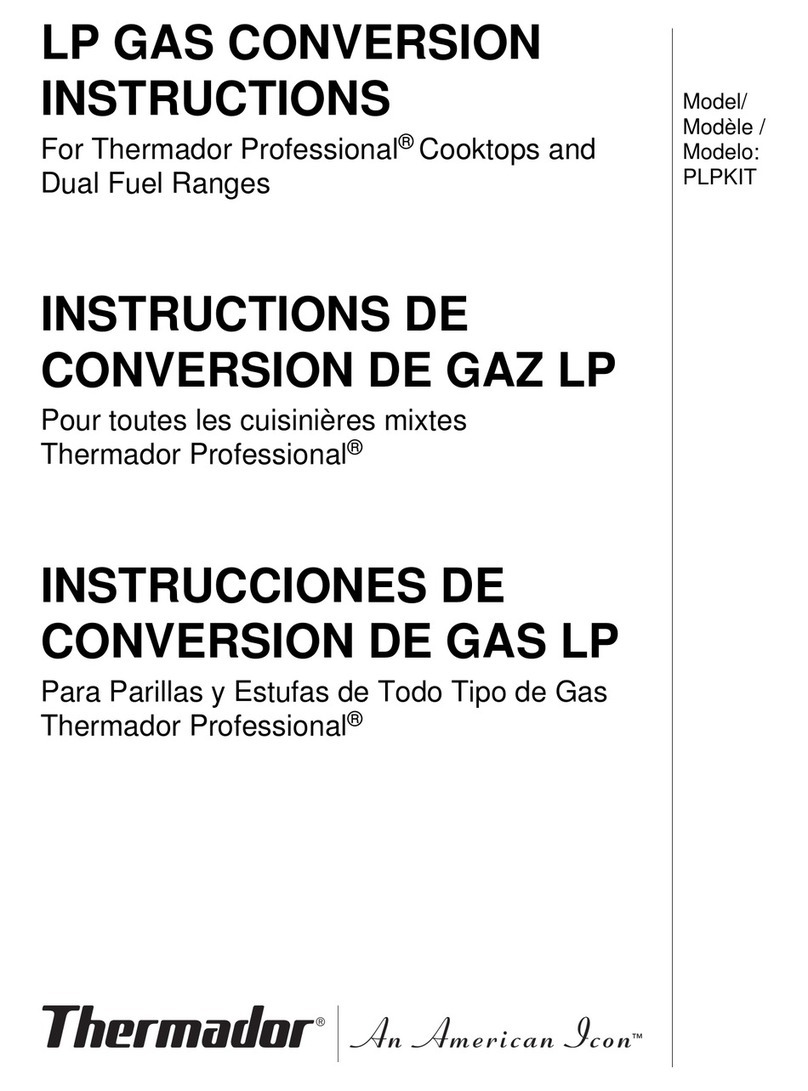

Upflow Furnace —

1. Disconnect all electrical power to the fur-

nace.

2. If needed, use one of the coil case adapter

kits to match the coil to the furnace air

dischargeopening. Referto the CoilSpeci-

fications Section for proper kit numbers.

3. Install the coil and level it as needed to

ensure proper condensate drainage. (See

Figure 2)

4. Seal the enclosure as required to minimize

air leakage.

5. Connect the refrigerant lines as outlined in

the Refrigerant Lines section.

Downflow — These coils may be installed in

downflow applications. Installation of the coils

in these applications only require that the fur-

nace and coil cabinets are securely mounted

together before setting in place. Fossil fuel

applications require coil to be placed in the

supply air stream only.

Horizontal — Standard coils may also be

installedinhorizontalapplications. Installationof

the standard coils in these applications only

require that the furnace and coil cabinets are

securelymountedtogetherand thatahorizontal

drainpankit be installed.Referto the Specifica-

tions Section for proper kit numbers.

To Configure Horizontal Ready Coils for

Horizontal LEFT Installations:

1) Remove the coil access door.

2) IMPORTANT:Removetheplugfromoneof

the threaded holes in the horizontal drain

pan. Completely remove the webbing lo-

catedinthethreadedholesofthehorizontal

drain pan. If webbing is not removed, the

drain will not function properly and ceiling

damage may occur.

3) Insert a plug(from the horizontaldrainpan)

into the open and unused drain hole in the

drain pan at the bottom of the unit to block

bypass air.

4) Removethecorrespondingdrainlineknock-

out from the coil access door to allow

access to the horizontal drain.

5) Replace the door.

NOTE: Installdrainpan extension (supplied)on

C3BH060 models.

To Configure Horizontal Ready Coils for

Horizontal RIGHT Installations:

1) Remove the coil access door. Unscrew the

line-set tube close-off plate from the front

left cabinet rail.

2) Slidethecoilanddrainpanassemblyoutof

the unit.

3) IMPORTANT: Remove the plug from one

ofthethreadedholesinthehorizontaldrain

pan. Completely remove the webbing lo-

catedinthethreadedholesofthedrainpan.

If webbing is not removed, the drain will not

function properly and ceiling damage may

occur.

4) Remove the sheet metal hairpin covers (if

supplied) from the back of the coil and

discard.

5) Place the horizontal drain pan on the oppo-

site side of the coil. On units with 2 sets of

knockouts, remove the other set of knock-

outs in the coil spacing plates and insert

support rod.

6) Insert a plug(from the horizontaldrainpan)

into the open and unused drain hole in the

drain pan at the bottom of the unit to block

bypass air.

7) Slide the coil and the horizontal drain pan

assembly back into the unit. Reattach the

tube close off plate.

Figure 2. Upflow Furnace Application

6

8) Removethecorrespondingdrainlineknock-

out from the coil access door to allow

access to the horizontal drain.

9) Replace the door.

Note: All condensate pans have primary

and secondary drain connections to meet

FHA requirements. If the application is lo-

cated in or above a living space where

damage may result from condensate over-

flow, a separate 3/4 inch drain must be

provided from the secondary drain connec-

tion and a secondary drain pan must be

installed under the entire unit. Run second-

ary drain lines to a place where they are

noticeable if used.

4. REFRIGERANT LINE

CONNECTIONS

NOTE – Move to instruction step #7 when

installing a C4 series (R-410A refrigerant) coil

with factory installed TXV valve.

NOTE – Before proceeding with the connection

of refrigerant lines, confirm that the orifice size

meets the requirements outlined in the outdoor

unitinstallationmanual.Factory-installedorifice

sizes are listed in the Specifications section. If

theorificesizeisincorrect,itshouldbereplaced,

following the steps below:

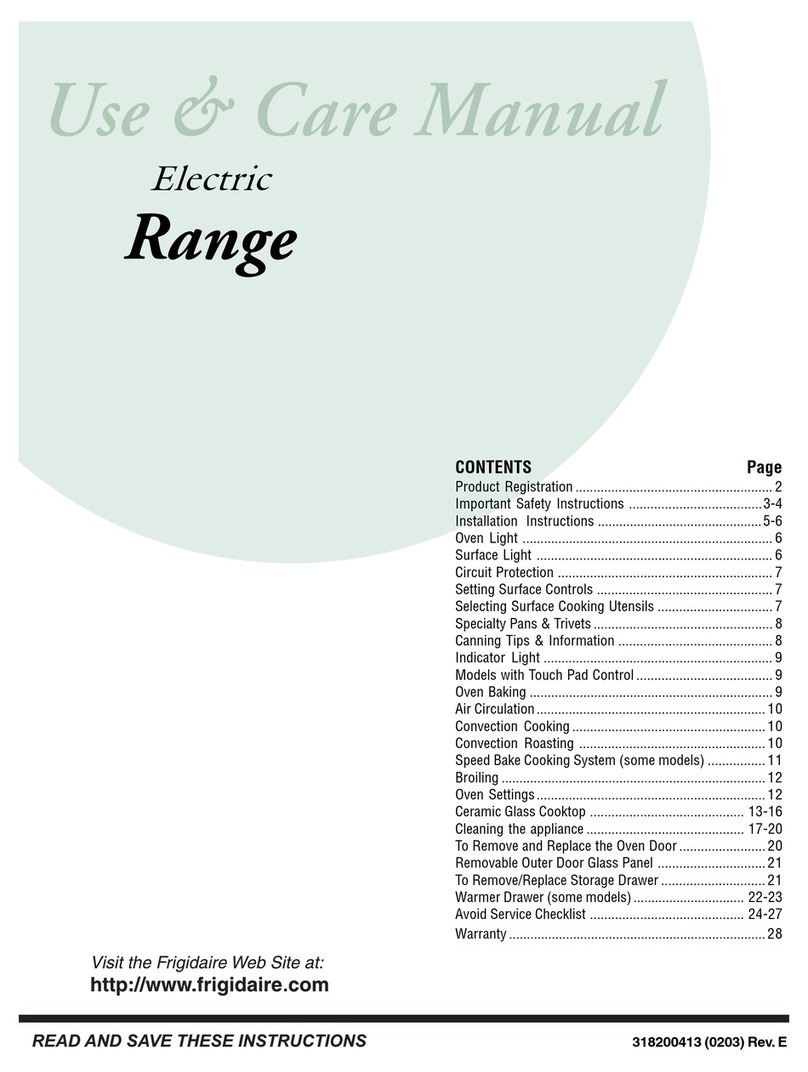

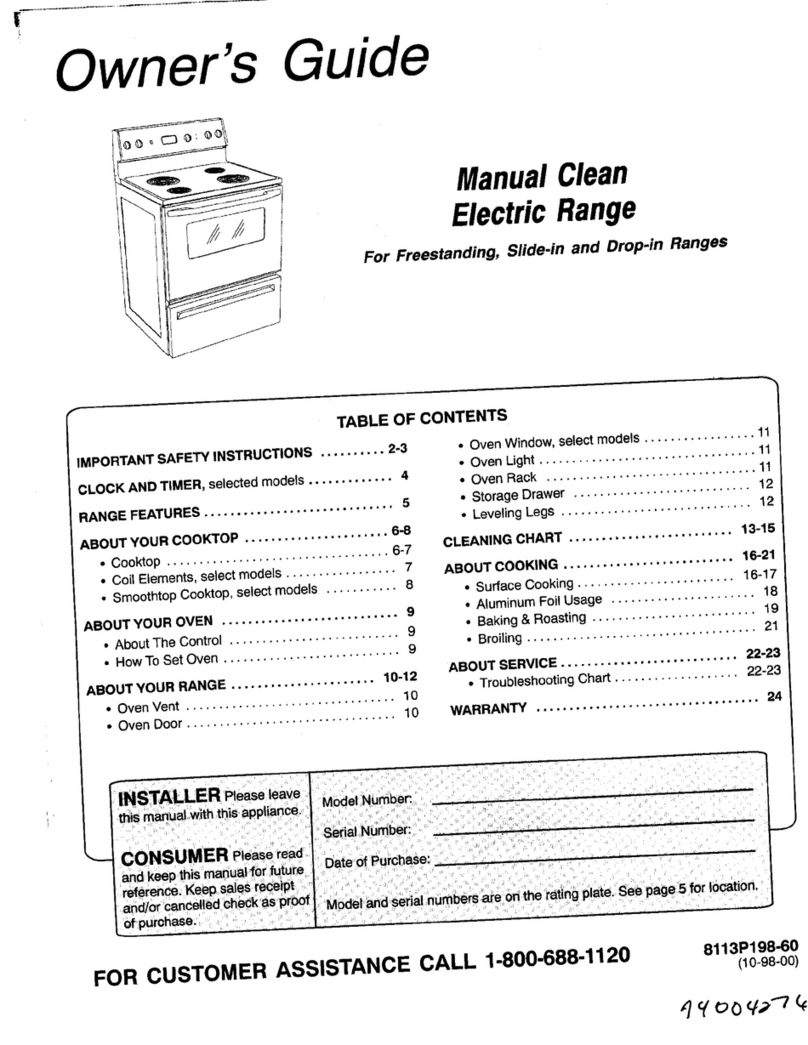

1. Loosen the orifice/distributor body halves

by applying two wrenches and squeezing

themtogether,asshowninFigure3,toturn

the assembly nut counter-clockwise.

2. Continue to unscrew the assembly nut to

separateitfromthedistributorbodyportion.

3. Insert a light-gauge wire hook between the

distributor body and the orifice to lift the

orifice out of the body. (See Figure 4)

Remove the orifice being careful not to

scratch either part.

4. Checktheactualsizeoftheneworifice(the

size is stamped on the side of the orifice).

Do not use pin gauges to measure the

orifice diameter.

Figure 4. Removal of Orifice

Figure 3. Wrenches on Distributor Body

and Assembly Nut

7

5. Insert the new orifice in the distributor body

rounded end down as shown in Figure 5.

6. After installing the orifice in the distributor

body, realign the assembly nut to the dis-

tributorbody. Mark alinealong both bodies

after hand tightening and then tighten an

additional 1/4 turn. Caution: Do not over-

tighten! The misalignment of the two lines

will show how much the nut is tightened. If

atorque wrenchis used, tightento 10-12 ft.

lbs. or 14-16 Nm.

Line Connections:

7. Remove the protective caps from the coil

andrefrigerantlinesetandalsoremovethe

hole grommets and tube close-off insula-

tion from around the tubes.

8. Cut the line set tubing to the proper length.

Be sure that the tubing has been sized in

accordance with the outdoor unit specifica-

tions.

9. Inspect both refrigerant lines. The ends of

the lines must be round, clean, and free of

any burrs.

10. Insert the line set tubes into the coil tube

stubs until they bottom out.

11. Braze the individual connections with dry

nitrogen flowing through the joints to elimi-

nate internal oxidation and scaling.

NOTE: On C4 (R-410A refrigerant) models

which use a TXV, it is recommended to

Figure 5. Orifice Insertion in Distributor Body

wrap a wet rag around the sensing bulb

located on the suction line while brazing.

12. Check the assembly for leaks with dry

nitrogen.

13. On horizontal applications of C4 (R-410A

refrigerant) models with TXV valve, re-

positionthesensingbulbonthesuctionline

so it is in the 10 o'clock to 2 o'clock position

on the suction tube.

14. Replace the tube close-off insulation.

5. COMPLETING THE

INSTALLATION

Condensate Drain:

!

CAUTION:

The indoor coil must be checked to

ensurealevelinstallation.Failuretodo

somayresultinimpropercondensate

disposal, causing structural damage,

premature equipment failure, or pos-

siblepersonal injury.

1. The coil condensate pan is furnished with

3/4" NPSC drain connections. Use a PVC

or similar material fitting to attach the drain

line to the pan. The fitting should be hand

tightenedonly. Overtighteningmaycrack

the drain pan and cause a condensate

leak.

INSTALLER: PLEASE LEAVE THESE

INSTALLATION INSTRUCTIONS WITH

THE HOMEOWNER

708360B(Replaces708360A)

Specifications and illustrations subject to change

without notice and without incurring obligations.

Printed in U.S.A. (11/04)

O'Fallon,MO

¢708360¬¤

708360B

2. Connect the drain line and run to a suitable

drainavoiding sharpbends and pinchingof

theline. Installacondensatetrapandprime

with water.

3. During the system checkout, inspect the

drain line and connections to verify proper

condensate disposal.

Air Filter — Air filters are not provided as an

integralpartofthiscoil,however,afiltermustbe

installed upstream of the coil and inspected

frequently. When the filter becomes clogged

with dust or lint, it should be replaced (dispos-

abletype)orcleaned(washabletype). Thefilter

should be inspected and replaced or cleaned at

leasttwice during theyear,generally at thestart

of each heating and cooling season.

Close-Off Plates and Panels — Install the

necessary air close-off plates around the refrig-

erant lines and drain line where required. Rein-

stallallinnerandouterpanelsofthecoilcaseand

furnace that were previously removed to install

the indoor coil.

Refrigerant Charging — These cased indoor

coils are not factory charged with refrigerant.

It will be necessary to evacuate the indoor coil

and line set prior to charging. Refer to the

outdoor unit installation manual for detailed

charges and instructions.

6. MAINTENANCEANDSERVICE

!

WARNING:

Ensure that all electrical power to the

furnaceandoutdoor(condensing)unit

is off before performing any mainte-

nance or service on the system.

To ensure optimum performance and to mini-

mize possible equipment failure, the following

periodic maintenance should be performed on

this equipment:

1. The air filter installed with the system should

be checked and cleaned or replaced twice per

year.

2. Check the coil, drain pan, and condensate

drain line for cleanliness at the start of each

heating and cooling season. Clean as needed.

!

CAUTION:

Do not operate the system without

having a suitable filter in place in the

returnairductsystem.Alwaysreplace

the filter with the same size and type.

Other manuals for R-410A

9

This manual suits for next models

1

Table of contents