NORPOLE NPRAC6KEWMZ1 User manual

1

READ THIS MANUAL CAREFULLY BEFORE USING YOUR WINDOW AIR

CONDITIONER AND KEEP IT FOR FUTURE REFERENCE.

Model NPRAC6KEWMZ1 / NPRAC8KEWMZ1 / NPRAC10KEWMZ1 / NPRAC12KEWMZ1

Window Air Conditioner

6000 / 8000 / 10000 / 12000 BTU

User’s Manual

2

PRODUCT REGISTRATION

Thank you for purchasing a Norpole® product. The rst step to protect your new product is to complete the product

registration on our website: www.mcappliance.com/register. The benets of registering your product include the following:

1. Registering your product will allow us to contact you regarding a safety notication or product update.

2. Registering your product will allow for more efcient warranty service processing when warranty service is

required.

3. Registering your product could act as your proof of purchase in the event of insurance loss.

Once again, thank you for purchasing our product.

3

CONTENTS

PRODUCT REGISTRATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

IMPORTANT SAFETY INSTRUCTIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

SPECIFICATIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

INSTALLATION INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

OPERATION INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

CARE AND MAINTENANCE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

LIMITED WARRANTY. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

4

IMPORTANT SAFETY INSTRUCTIONS

EXPLANATION OF SYMBOLS

WARNING: Hazards or unsafe practices which COULD result in severe personal injury or death.

CAUTION: Hazards or unsafe practices which COULD result in minor personal injury or property damage.

IMPORTANT SAFETY INSTRUCTIONS

1. Read all instructions before using the appliance.

2. For household use only. DO NOT use for other than the intended purpose.

3. WARNING: To prevent injuries or property damage, the following instructions must be followed.

4. This appliance should not be operated, cleaned or maintained by anyone that is not able to follow

proper safety procedures or does not have experience with this type of equipment, unless under

close supervision.

5. WARNING: DO NOT use in an area where it may be exposed to combustible gases or liquids, as

6. CAUTION: Installation must be performed according to the installation instructions and ALWAYS

7. Ventilate the room if unit is used near a stove or furnace.

8. DO NOT operate in a wet environment, such as a bathroom or laundry room.

9. DO NOT stand, sit, or place anything on top of the unit.

10. DO NOT let children operate or play on or around the air conditioner. Children should be supervised

around the unit at all times.

11. CAUTION: The power cord is equipped with a 3-prong grounding plug to protect against

shock hazards. ALWAYS plug cord into a dedicated, properly installed and grounded 3-prong wall

this unit.

12. DO NOT modify or cut the power cord, or use any other cord or plug. If the cord or plug is damaged,

13. DO NOT run cord under carpeting, throw rugs, runners, or similar coverings. DO NOT route cord

under furniture, appliances, or any heavy object. Place the cord where it will not be tripped over, way

from any sources of heat.

14. DO NOT start or stop the unit by turning the power on or off.

15. DO NOT insert or pull out the plug, or operate the unit with wet hands.

16. DO NOT remove the plug by pulling the cord.

17. ALWAYS turn off and unplug the unit when not in use.

18. DO NOT obstruct the unit to ensure proper function and safety.

19.

20. CAUTION: ALWAYS turn off and unplug the unit prior to cleaning or maintenance.

5

21. Contact customer service or an authorized service technician for repair or maintenance of this unit.

DO NOT try to take apart or repair the unit by yourself.

22. Turn off and unplug the unit if strange sounds, smells, or smoke come from it.

23. DO NOT open or remove any of the panels of the unit while it is operating or plugged in.

24.

25.

26.

parts of the unit while changing or cleaning.

27. DO NOT disassemble or modify the unit in any way.

28. DO NOT drink water condensation from the unit.

29. Periodically check the installation bracket for damage or wear due to exposure. A damaged bracket

could result in the unit falling from the window.

READ AND FOLLOW THIS

SAFETY INFORMATION CAREFULLY

SAVE THESE INSTRUCTIONS

6

WARNING (FOR USING R290/R32 REFRIGERANT ONLY)

• Do not use means to accelerate the defrosting process or to clean, other than those recommended

by the manufacturer.

• The appliance shall be stored in a room without continuously operating ignition sources (for example:

heater) close to the appliance. The appliance shall be stored in a room without continuously

electric heater).

• Do not pierce or burn.

• Be aware that the refrigerants may not contain an odor.

• Compliance with national gas regulations shall be observed.

• Keep ventilation openings clear of obstruction.

• The appliance shall be stored so as to prevent mechanical damage from occurring.

• A warning that the appliance shall be stored in a well-ventilated area where the room size

• Any person who is involved with working on or breaking into a refrigerant circuit should hold a current

, which authorizes their competence

• Servicing shall only be performed as recommended by the equipment manufacturer.

• Maintenance and repair requiring the assistance of other skilled personnel shall be carried out under

• DO NOT modify the length of the power cord or use an extension cord to power the unit.

•

or electrical shock.

• Please follow the instruction carefully to handle, install, clear or service the air conditioner to avoid

any damage or hazard. Flammable Refrigerant R32 is used within air conditioner. When maintaining

or disposing the air conditioner, the refrigerant (R32 or R290) shall be properly recovered and not

discharged into the air.

• conditioner to avoid

maintain the air conditioner to prevent mechanical damage from occurring.

• Flammable refrigerant R32 is used in air conditioner. Please follow the instruction carefully to avoid

any hazard.

CAUTION

IMPORTANT NOTE

Read this manual carefully before installing or operating

Make sure to save this manual for future reference.

your new air conditioning unit.

7

Explanation of symbols displayed on the unit (For the unit adopts R32/R290 Refrigerant only):

WARNING

CAUTION This symbol shows that the operation manual should be read carefully.

CAUTION This symbol shows that a service personnel should be handling this equipment with

reference to the installation manual.

CAUTION This symbol shows that information is available such as the operating manual or installation

manual.

WARNINGS (for using R290/R32 refrigerant only)

1.

See transport regulations.

2. Marking of equipment using signs

See local regulations.

3.

See national regulations.

4. Storage of equipment/appliances

The storage of equipment should be in accordance with the manufacturer’s instructions.

5. Storage of packed (unsold) equipment

Storage package protection should be constructed such that mechanical damage to the equipment

inside the package will not cause a leak of the refrigerant charge.

The maximum number of pieces of equipment permitted to be stored together will be determined by

local regulations.

6. Information on servicing

a)

safety checks are necessary to ensure that the risk of ignition is minimized. For repair to the

refrigerating system, the following precautions shall be complied with prior to conducting work

on the system.

b) Work procedure: Work shall be undertaken under a controlled procedure so as to minimize the

c) General work area: All maintenance staff and others working in the local area shall be

The area around the workspace shall be sectioned off. Ensure that the conditions within the

d) Checking for presence of refrigerant: The area shall be checked with an appropriate refrigerant

atmospheres. Ensure that the leak detection equipment being used is suitable for use with

e)

8

f) No ignition sources: No person carrying out work in relation to a refrigeration system which

All

possibly be released to the surrounding space. Prior to work taking place, the area around the

No Smoking signs shall be displayed.

g) Ventilated area: Ensure that the area is in the open or that it is adequately ventilated before

breaking into the system or conducting any hot work. A degree of ventilation shall continue

during the period that the work is carried out. The ventilation should safely disperse any

released refrigerant and preferably expel it externally into the atmosphere.

h) Checks to the refrigeration equipment: Where electrical components are being changed, they

maintenance and service guidelines shall be followed. If in doubt consult the manufacturer’s

technical department for assistance. The following checks shall be applied to installations using

• The charge size is in accordance with the room size within which the refrigerant

containing parts are installed;

• The ventilation machinery and outlets are operating adequately and are not obstructed;

• If an indirect refrigerating circuit is being used, the secondary circuit shall be checked for

the presence of refrigerant;

• Marking to the equipment continues to be visible and legible. Markings and signs that are

illegible shall be corrected;

• Refrigeration pipe or components are installed in a position where they are unlikely to be

exposed to any substance which may corrode refrigerant containing components, unless

the components are constructed of materials which are inherently resistant to being

corroded or are suitably protected against being so corroded.

i) Checks to electrical devices: Repair and maintenance to electrical components shall

include initial safety checks and component inspection procedures. If a fault exists that

could compromise safety, then no electrical supply shall be connected to the circuit until it

is satisfactorily dealt with. If the fault cannot be corrected immediately but it is necessary to

continue operation, an adequate temporary solution shall be used. This shall be reported to the

owner of the equipment so all parties are advised. Initial safety checks shall include:

• That capacitors are discharged: this shall be done in a safe manner to avoid possibility of

sparking;

• That there no live electrical components and wiring are exposed while charging,

recovering or purging the system;

• That there is continuity of grounding.

7. Repairs to sealed components

a) During repairs to sealed components, all electrical supplies shall be disconnected from the

equipment being worked upon prior to any removal of sealed covers, etc. If it is absolutely

necessary to have an electrical supply to equipment during servicing, then a permanently

operating form of leak detection shall be located at the most critical point to warn of a

potentially hazardous situation.

9

b) Particular attention shall be paid to the following to ensure that by working on electrical

components, the casing is not altered in such a way that the level of protection is affected.

This shall include damage to cables, excessive number of connections, terminals not made to

• Ensure that apparatus is mounted securely.

• Ensure that seals or sealing materials have not degraded such that they no longer serve

NOTE: The use of silicon sealant may inhibit the effectiveness of some types of leak detection

equipment. Intrinsically safe components do not have to be isolated prior to working on them.

8. Repair to intrinsically safe components

Do not apply any permanent inductive or capacitance loads to the circuit without ensuring that this

will not exceed the permissible voltage and current permitted for the equipment in use.

Intrinsically safe components are the only types that can be worked on while live in the presence of a

ignition of refrigerant in the atmosphere from a leak.

9. Cabling

Check that cabling will not be subject to wear, corrosion, excessive pressure, vibration, sharp edges

or any other adverse environmental effects. The check shall also take into account the effects of

aging or continual vibration from sources such as compressors or fans.

10.

Under no circumstances shall potential sources of ignition be used in the searching for or detection

11. Leak detection methods

sensitivity may not be adequate, or may need re-calibration. (Detection equipment shall be

calibrated in a refrigerant-free area.) Ensure that the detector is not a potential source of ignition

and is suitable for the refrigerant used. Leak detection equipment shall be set at a percentage of

the LFL of the refrigerant and shall be calibrated to the refrigerant employed and the appropriate

most refrigerants but the use of detergents containing chlorine shall be avoided as the chlorine may

shall be removed/ extinguished. If a leakage of refrigerant is found which requires brazing, all of the

refrigerant shall be recovered from the system, or isolated (by means of shut off valves) in a part

of the system remote from the leak. Oxygen free nitrogen (OFN) shall then be purged through the

system both before and during the brazing process.

12. Removal and evacuation

When breaking into the refrigerant circuit to make repairs or for any other purpose conventional

is a consideration. Opening of the refrigeration systems shall not be done by brazing. The following

procedure shall be adhered to:

• Remove refrigerant;

10

• Purge the circuit with inert gas;

• Evacuate;

• Purge again with inert gas;

• Open the circuit by cutting or brazing.

The refrigerant charge shall be recovered into the correct recovery cylinders. The system shall

times. Compressed air or oxygen shall not be used for this task.

is used, the system shall be vented down to atmospheric pressure to enable work to take place. This

operation is absolutely vital if brazing operations on the pipe-work are to take place.

Ensure that the outlet for the vacuum pump is not close to any ignition sources and there is

ventilation available.

13. Charging procedures

In addition to conventional charging procedures, the following requirements shall be followed.

• Ensure that contamination of different refrigerants does not occur when using charging

equipment. Hoses or lines shall be as short as possible to minimize the amount of refrigerant

contained in them.

• Cylinders shall be kept upright.

• Ensure that the refrigeration system is earthed prior to charging the system with refrigerant.

• Label the system when charging is complete (if not already).

•

• Prior to recharging the system it shall be pressure tested with OFN. The system shall be leak

tested on completion of charging but prior to commissioning. A follow up leak test shall be

carried out prior to leaving the site.

14. Decommissioning

Before carrying out this procedure, it is essential that the technician is completely familiar with the

equipment and all its detail. It is recommended good practice that all refrigerants are recovered

safely. Prior to the task being carried out, an oil and refrigerant sample shall be taken in case

analysis is required prior to re-use of reclaimed refrigerant. It is essential that electrical power is

available before the task is commenced.

a) Become familiar with the equipment and its operation.

b) Isolate system electrically.

c) Before attempting the procedure ensure that: Mechanical handling equipment is available, if

required, for handling refrigerant cylinders; All personal protective equipment is available and

being used correctly; The recovery process is supervised at all times by a competent person;

Recovery equipment and cylinders conform to the appropriate standards.

d) Pump down refrigerant system, if possible.

e) If a vacuum is not possible, make a manifold so that refrigerant can be removed from various

parts of the system.

f) Make sure that cylinder is situated on the scales before recovery takes place.

11

g) Start the recovery machine and operate in accordance with manufacturer’s instructions.

h)

i) Do not exceed the maximum working pressure of the cylinder, even temporarily.

j)

cylinders and the equipment are removed from site promptly and all isolation valves on the

equipment are closed off.

k) Recovered refrigerant shall not be charged into another refrigeration system unless it has been

cleaned and checked.

15. Labelling

Equipment shall be labelled stating that it has been de-commissioned and emptied of refrigerant. The

label shall be dated and signed. Ensure that there are labels on the equipment stating the equipment

16. Recovery

When removing refrigerant from a system, either for servicing or decommissioning, it is

recommended good practice that all refrigerants are removed safely.

When transferring refrigerant into cylinders, ensure that only appropriate refrigerant recovery

cylinders are employed. Ensure that the correct number of cylinders for holding the total system

charge is available. All cylinders to be used are designated for the recovered refrigerant and

labelled for that refrigerant (i.e. special cylinders for the recovery of refrigerant). Cylinders shall

be complete with pressure relief valve and associated shut-off valves in good working order.

Empty recovery cylinders are evacuated and, if possible, cooled before recovery occurs.

The recovery equipment shall be in good working order with a set of instructions concerning

In addition, a set of calibrated weighing scales shall be available and in good working order.

Hoses shall be complete with leak-free disconnect couplings and in good condition. Before

using the recovery machine, check that it is in satisfactory working order, has been properly

maintained and that any associated electrical components are sealed to prevent ignition in the

event of a refrigerant release. Consult manufacturer if in doubt.

The recovered refrigerant shall be returned to the refrigerant supplier in the correct recovery

cylinder, and the relevant Waste Transfer Note arranged. Do not mix refrigerants in recovery

units and especially not in cylinders. If compressors or compressor oils are to be removed,

refrigerant does not remain within the lubricant. The evacuation process shall be carried out

prior to returning the compressor to the suppliers. Only electric heating to the compressor

body shall be employed to accelerate this process. When oil is drained from a system, it shall

be carried out safely.

12

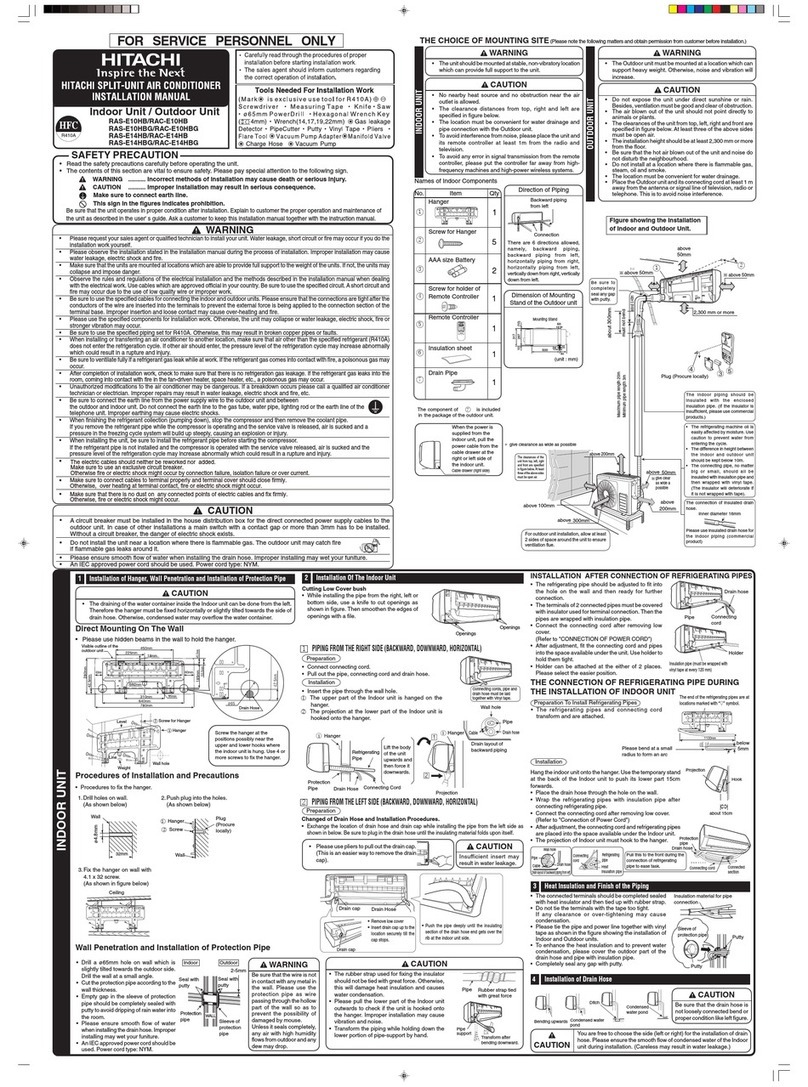

SPECIFICATIONS

Model

Dimensions

(W x D x H) 18.5” x 15.7” x 13.4” 18.5” x 15.7” x 13.4” 19.0” x 21.5” x 14.6” 19.0” x 21.5” x 14.6”

Weight 41.9 lbs. 46.9 lbs. lbs.

BTU 6,000 8,000 10,000 12,000

Voltage 115V / 60Hz 115V / 60Hz 115V / 60Hz 115V / 60Hz

Watts 535 667 1000

4. 5.9 A

Refrigerant Type R32 R32 R32 R32

Moisture

Removal (L/h) 0.7 1.0 1.1 1.2

12.1 12.0 12.0 12.0

Outdoor Temperature 64-109°F (18-43°C)

Indoor Temperature 62-90°F (17-32°C)

H

W

D

Figure 1

OPERATING TEMPERATURE RANGE

CurrentRated

CEER

66A

925

8.03 A

57.3 lbs.

9.72A

67.7

NPRAC6KEWMZ1 NPRAC8KEWMZ1 NPRAC10KEWMZ1 NPRAC12KEWMZ1

Your air conditioner is designed to install in standard

double hung windows with openings of 23 to 36”

(584mm to 914mm) wide and at least 13”(330mm)

high for 5,000 -6,000 btu units,14” (356mm)high for

6,000 -8,000 btu units, and 15-1/2” (394mm)high for

10,000 – 12,000 btu units.

Model

H

6000~8000Btu/h

10000~12000Btu/h

14 (356mm)

15-1/2 (394mm)

5000~6000Btu/h

13 (330mm)

H

13

INSTALLATION INSTRUCTIONS

BEFORE YOU BEGIN

IMPORTANT: Save these instructions for local inspectors use.

IMPORTANT: Observe all governing codes and ordinances.

NOTE TO CONSUMER: Keep these instructions for future reference.

NOTE TO INSTALLER: Be sure to leave these instructions with the Consumer.

• Read these instructions completely and carefully.

• Completion Time: Approximately 1 hour

• Skill Level: Installation of this appliance requires basic mechanical skills. We recommend that two

people install this product.

• Proper installation is the responsibility of the installer. Product failure due to improper installation

is not covered under the Warranty. You MUST use all supplied parts and use proper installation

procedures as described in these instructions when installing this air conditioner.

WINDOW REQUIREMENTS

Figure 3

CAUTION: DO NOT, underany circumstances, cut

or remove the third (ground)prong from the power cord.

CAUTION: DO NOT change the plug on the power

cord of the air conditioner.

CAUTION: Aluminum house wiring may present

CAUTION: When handling unit, be careful to avoid

front and rear coils.

REQUIRED TOOLS (NOT INCLUDED)

Phillips Head Screwdriver

Bubble Level Flathead Screwdriver

Pencil

Tape

Measure

Scissors or knife

OPTIONAL TOOLS (not included)

14

PREPARE THE WINDOW

-8,000 btu units, and 15-1/2” (394mm) high for 10,000 – 12,000 btu units. Side louvers and the rear of the

The rear of the

unit must be outdoors, not inside a building or garage.

Figure 4

Mounting Hardware

Top Rail Hardware

a

g h i

bde f

a. 3/4” or 1/2” Screws (7)

b. Frame Lock (2)

(For Wooden windows)

NOTE: Weather stripping is only for Energy star models.

PREPARE THE AIR CONDITIONER

Figure 5

Figure 7Figure 6

1. Remove the air conditioner from the

2. Remove top rail (h) and R1 hardware (i)

from the packaging material as shown in

Figure 5. (R1 hardware is only included

for Energy star models.)

3. Align the holes in the top rail (h) with

those in the top of the unit as shown in

Figure 6.

4. Secure the top rail (g) to the unit with

the 3/8 Screws (g) as shown in Figure 7.

NOTE: For safety reasons, all four(4)

screws MUST be securely fastened.

NOTE: The top rail hardware and Figure

5, Figure 6 and Figure 7 are not applicable to

the units with more than 10000Btu/h. Before

installing unit, the top rail must be assembled

on the unit (For <10000Btu/h models only).

Packaging

Top Rail

R1 Hardware

(<10000 BTU/h

models only)

R1 Hardware

(≥10000 BTU/h

models only)

NOTE: Save the carton and these Installation Instructions for future reference. The carton is the best

way to store unit during winter, or when not in use.

c

d.

c.

Sash Lock (1)

e. Window Sash Seal

Foam (1)

f. 10” x 3/4” x 1-1/2”

Weather Stripping (5)

g. 3/8” Screws (4)

h. Top Rail (1)

i. R1 Hardware (2)

Lock Frame (2)

(For Vinyl-Clad windows)

15

Figure 8

Figure 10 Figure 11

INSTALL THE ACCORDIAN PANELS

NOTE: Top rail and Sliding Panels at each side are offset to provide the proper pitch to the

rear of (5/16 ). This is necessary for proper condensed water utilization and drainage. If you

are not using the Side Panels for any reason, this pitch to the rear must be maintained.

1.

center beyond the ends of the top and bottom frame to free the open end. See Figure 8.

2. Slide the free end “I” section of the panel into the cabinet as shown in Figure 9. Slide the panel all

the way down. Be sure to leave enough space to slip the top and bottom of the frame into the rails on

the cabinet.

“I” section

Top Rail

Top Rail Top Right

Bottom Rail Bottom Rail

Top Left

Figure 9

3. Once the panel has been installed on the side of the cabinet, make sure it sits securely inside the

frame channel by making slight adjustments. Slide the top and bottom ends of the frame into the top

and bottom rails of the cabinet as seen in Figure 10.

4. Slide the panel all the way in to the top and bottom rails on the unit and repeat for the other side. See

Figure 11.

SECURE THE ACCORDION PANELS

Figure 12

1.

conditioner, and carefully

place the unit into the window

opening so the bottom of the air

conditioner frame is against the

window sill (Figure 12). Carefully

close the window behind the top

rail of the unit. It is recommended

to have two people install the air

conditioner.

Wooden Windows

H

Measure from the cabinet edge

INSIDE OUTSIDE

H: About 3/4” to 1”

(for 5 to 8K)

H: About 1” to 1-3/8”

(for 10 to 12K)

H: About 3/4” to 1”

(for 5 to 8K)

H: About 1” to 1-3/8”

(for 10 to 12K)

Vinyl-Clad Windows

INSIDE

OUTSIDE

Measure from the cabinet edge

H

A: For wooden windows:

Drive 1/ 2" (12.7 mm) locking screws

through the frame lock and into the sill

(Fig.15A).

NOTE: To prevent window sill from splitting,

drill 1/8" (3mm) pilot holes before driving

screws. Drive 1/2" (12.7mm) locking screws

through frame holes into window sash

(Fig.15B).

B: For Vinyl-Clad windows:

Drive 1/2" (12.7 mm) locking screws

through the frame lock and into the window

sashl (Fig.15B).

NOTE: Before driving the screws, use a

drill to drill 5 holes through the holes in the

frame lock and frame extensions into the

windows sash as shown (Fig. 15B).

Figure 14

Wooden windows

Vinyl-Clad windows

Figure 15A

Figure 15B

16

INSTALL SUPPORT BRACKET

Figure 13

Window

Frame

1. Place the frame lock (b) between the

frame extensions and the window sill

(See Figure 14). Drive 3/4” (19mm)or 1/2”

(12.7mm) locking screws (a) through the

frame lock and into the sill.

NOTE: To prevent window sill from

splitting, drill 1 / 8” (3mm) pilot holes

before driving screws.

2.

NOTE: Check that the air

conditioner is tilted back about

3° to 4° down towards the

outside (Figure 12). After proper

installation, if condensation does

hole during normal use, correct

the angle of the slope.

2. Extend the side panels out against

the window frame (Figure 13).

3. To secure lower sash in place, attach right

angle sash lock (c) with 3/4” (19mm) or

1/2” (12.7mm) (a) screw as shown (See

Figure 16).

4. Cut the Window Sash Seal foam (d) and

insert it in the space between the upper

and lower sashes (See Figure 17).

Figure 16 Figure 17

Foam Seal

17

Figure 18

INSTALL R1 HARDWARE (ONLY APPLICABLE TO ENERGY STAR MODELS)

In orderto minimize airleaks and ensure optimal insulation, it is necessary to install the included R1

hardware (h) to the side curtain. Followthe instructions below.

1. After the unit is installed to the window, measure the inner width of the side curtain as shown in

Figure 18.

2. Mark a line on the provided R1 insulation panel (h)according to a length 1/8 (3mm) less than the

measured width in step 1, then cut the R1 insulation panel along the line with a knife or scissors.

(See Figure 19.)

3. Slide the R1 insulation panel(h) into the side curtain, the side with pattern should facing the indoor

side. (See Figure 20.)

4. Repeat for the other side.

Figure 19 Figure 20

Use knife

or scissors

Measure the inner width

of the side curtain

INSTALL WEATHER STRIPPING

(ONLY APPLICABLE TO ENERGY STAR

MODELS)

In order to minimize air leaks between the air

conditioner and the window opening, trim the

weather stripping (e) to the proper length, peel

off the protective backing and plug any gaps if

needed (See Figure 21).

Figure 21

18

IF AC IS BLOCKED BY STORM

WINDOW

If a storm window prevents the air conditioner

cannot be removed, use a board with a

width of at least 1-1/2” and a thickness that

allows clearance for the installation of the unit

(Figure 22) . Be sure the drain holes or slots

for the storm window frame are not caulked

or painted shut. Rain water or condensation

must be allowed to drain out.

REMOVING AC FROM WINDOW

Turn the unit off and disconnect power cord. Remove sash seal from between windows, and unscrew

safety sash lock. Remove all screws installed through frame and frame lock. Remove the R1 Panel and

, raise sash and carefully remove. Be

carefully not to spill any remaining water while lifting unit from window. Store parts with air conditioner. It is

recommended to have two people to remove the air conditioner from the window.

Figure 22

Sash

1-1/2” (38 mm)

minimum Board thickness

as required, for

proper pitch to

rear, along entire

sill. Fasten with

nails or screws.

Storm window

frame or other

obstruction

19

Figure 23

OPERATING INSTRUCTIONS

OPERATION OF CURRENT DEVICE

The power supply cord contains a current device that senses damage to the power cord. To test your

power supply cord do the following:

1. Plug in the Air Conditioner.

2. The power supply cord will have TWO buttons on the plug head. Press the TEST button, you will

notice a click as the RESET button pops out.

3. Press the RESET button, again you will notice a click as the button engages.

4. The power supply cord is now supplying electricity to the unit. (On some products this it also

indicated by a light on the plug head.)

NOTE: DO NOT use this device to turn the unit on or off.

NOTE: ALWAYS make sure the RESET button is pushed in for correct operation.

NOTE: The power supply must be replaced if it fails reset when either the TEST button is pushed, or it

cannot be reset. A new one can be obtained from the product manufacturer.

NOTE: If power supply cord is damaged, it cannot be repaired. It MUST be replaced by one obtained

from the product manufacturer.

Before you begin, thoroughly familiarize yourself with the control panel as shown below and all its

functions then follow the symbol for the functions you desire. The unit can be controlled by the unit control

alone or with the remote.

NOTE: All illustrations in this manual are for explanation purpose only. Your air conditioner may be

slightly different.

CONTROL PANEL

TO TURN UNIT ON OR OFF

Press the (ON/OFF) button to turn the unit on or off.

NOTE: The unit will automatically initiate the Energy Saver

function under Cool, Dry, Auto modes (only when set to Auto-

Cooling and Auto-Fan).

TO CHANGE TEMPERATURE SETTING

Press / (UP/DOWN) button to change temperature setting.

NOTE: Press or hold either UP ( ) or DOWN ( )

button until the desired temperature is seen on the display. This

temperature will be automatically maintained anywhere between

62°F (17°C) and 86°F (30°C). If you want the display to read the

actual room temperature, see To Operate on Fan Only section.

TO ADJUST FAN SPEEDS

Press (FAN) button to select the Fan Speed in four steps-Auto,

Low, Med or High. Each time the button is pressed, the fan speed

mode changes. On Dry mode, the fan speed is controlled at Low

automatically.

Low

Auto

Med

High

TEMP/TIMER

Auto

Cool

Dry

Fan

Fan

Mode

On

Off

Sleep

Timer

Check

Filter

Energy

Saver

20

SLEEP FEATURE

Press (Sleep) button to initiate the sleep mode. The selected temperature will increase by 2°F/1 or 2°C

30 minutes after the mode is selected, then another 2°F/ 1 or 2°C after an additional 30 minutes. This new

temperature will be maintained for 6 hours and then return to the original temperature setting. The Sleep

mode program can be cancelled at any time during operation by pressing the Sleep button again.

TO SELECT THE OPERATING MODE

To choose operating mode, press (Mode) button. Each time you press the button, the selected mode

will cycle through Auto, Cool, Dry and Fan. The indicator light will be illuminated and remain on once

the mode is selected. The unit will automatically initiate the Energy Saver function under Cool, Dry, Auto

modes (only when set to Auto-Cooling and Auto-Fan).

1. AUTO MODE: When you set the air conditioner to AUTO mode, it will automatically select cooling

or fan only operation depending on what temperature you have selected and the room temperature.

The air conditioner will control room temperature automatically based on the temperature point set

by you. When set on AUTO, the fan speed cannot be adjusted and will run as needed based on the

room temperature.

2. COOL MODE: When the unit is set on Cool Mode it will run the fan and compressor to reach and

maintain the set temperature.

3.

space is enclosed, and the condenser is operational, there will be some degree of cooling.

4. FAN ONLY MODE: Use this function to circulate air without cooling it. ALWAYS be sure to open the

.) Use

the fan button to set the desired fan speed. During set to Fan Only, the display will show the actual

room temperature, not the set temperature, and the temperature setting cannot be adjusted.

OTHER FUNCTIONS

• ENERGY SAVER: Press (Energy Saver) button to set this function. This function is available in

COOL, DRY, AUTO (AUTO-COOLING and AUTO-FAN only) modes. The fan will continue to run for

3 minutes after the compressor shuts off. The fan then cycles on for 2 minutes at 10 minute intervals

until the room temperature is above the set temperature, at which time the compressor turns back on

and cooling starts again.

• (Timer) button. The TIMER ON indicator light will

illuminate to indicate the Auto Start program is initiated and the display will show the time currently

set for the air conditioner to automatically start.

When the time of TIMER ON is displayed press the Timer button again and the TIMER OFF indicator

light will illuminate to indicate the Auto Stop program is initiated. Press or hold the UP or DOWN

button to change the Auto time by 0.5 hour increments, up to 10 hours, then at 1 hour increments up

to 24 hours.

The selected time will show on the display for 5 seconds, and the system will automatically revert

back to display the previous temperature setting or room temperature when the unit is on. If the unit

is off, there is no display. The control will count down the time remaining until start.

Turning the unit ON or OFF at any time or setting the timer to 0.0 will cancel the Auto Start/Stop

timed program.

NOTE: The timer will count down the time displayed, and does not operate based on the actual

time of day. Setting the Timer On to 4 and Timer Off to 8 means the air conditioner will turn on 4

hours from the time the auto-start function is initiated, and turn off after another 4 hours.

This manual suits for next models

3

Table of contents

Languages:

Other NORPOLE Air Conditioner manuals