Norris FI 700 User manual

Rev No. 3 23/03/2023

Norris Upright Dishwasher

FI 700/750

Operation Manual

Page 1 of 19

Contents

1INTRODUCTION ...........................................................................................................2

2INSTALLATION.............................................................................................................3

2.1 Requirements ........................................................................................................3

2.2 Positioning & Connecting.......................................................................................4

2.3 Screen and Dial .....................................................................................................5

2.4 Water Levels..........................................................................................................5

2.5 Priming Boiler ........................................................................................................5

2.6 Priming New Rinse and Detergent Lines ...............................................................5

3OPERATION .................................................................................................................6

3.1 General Operation and Safety Instructions ............................................................6

3.2 Start of Day Operation ...........................................................................................7

3.3 General Operation .................................................................................................8

3.4 End of Day Drain and Shutdown............................................................................9

4MAINTENANCE ..........................................................................................................10

4.1 Daily Cleaning .....................................................................................................10

4.2 Weekly Cleaning..................................................................................................10

4.3 Servicing and Descaling ......................................................................................10

4.3.1 Machine Servicing..................................................................................................... 10

4.3.2 Descaling................................................................................................................... 10

5MACHINE INFORMATION ..........................................................................................11

5.1 Screen Display ....................................................................................................11

5.2 Detergent & Rinse Aid .........................................................................................11

5.3 Minimum Operating Temperatures ......................................................................11

6TROUBLESHOOTING & ERROR MESSAGES...........................................................12

6.1 Troubleshooting...................................................................................................12

7SAFETY ......................................................................................................................13

7.1 Intended Use .......................................................................................................13

7.2 Non-Intended Use................................................................................................13

7.3 Handling Chemicals.............................................................................................13

8DISPOSAL ..................................................................................................................14

9ENVIRONMENTAL......................................................................................................14

10 WARRANTY TERMS AND CONDITIONS ...................................................................15

At the time of printing, this document is accurate and complete. In order to offer a reliable product with a long service life

and advanced technology, the manufacturer reserves the right to modify the electrical, technical, and aesthetic features of

this appliance and replace any of its parts without notice, as deemed necessary.

Page 2 of 19

1 INTRODUCTION

Thank you for choosing a Norris Dishwasher. Since 1954 Norris has been manufacturing & supplying the

hospitality industry with our range of commercial glass and dishwashers.

In true Australian tradition, our innovative founder Vince Norris designed and produced the first

Australian commercial glass washer in his garage. We are an Australian-owned company and to this day

our products are still proudly Australian-made.

We have grown from humble beginnings into our current headquarters and manufacturing plant located

in Caves Beach, NSW.

Norris believes that “We would like to leave the world a better place than when we found it”, a

philosophy that requires constant innovation and keeps sustainability at the forefront of our business

practices.

This means we are focussed not only on what we make – high performance warewashing machines built

with high quality materials – but how we make it.

In 2014, with over 300 solar panels installed on the factory roof, rainwater tanks, cardboard and waste

metal recycling initiatives, Norris became a Silver Partner in the NSW Office of Environment & Heritage

Sustainability Advantage Program.

Our team at Caves Beach NSW is committed to keep innovating! Every step we take is intended to give

you confidence and peace of mind that choosing a Norris machine supports a better future for Australian

manufacturing - and for the planet.

Due to continued product development, some details in this manual may vary to the appliance. This

manual is correct at the time of printing and every effort is made to ensure that all information in this

manual is current and correct.

Information contained in this manual is intended as a guide to the safe use and long life of the appliance

and should be kept handy for future reference.

For more information about this appliance, or for spare parts and/or warranty,

please contact our Norris Customer Service team:

Phone: +61 2 4971 4500

Free call: +61 1800 803 569

www.norris.com.au

Page 3 of 19

2 INSTALLATION

2.1 Requirements

Authorised Technician

defined as:

Qualified Electrician

or Disconnect/

Reconnect Technician

Have the machine installed by an authorised technician in accordance

with the locally applicable regulations (water, wastewater, electrics).

Note: incorrect installation may void warranty

A Safe Location The dishwashing machine must not be installed in a potentially explosive

atmosphere or in areas subject to frost or extreme heat.

Cold Water Tap

Cold water tap (½” BSP male) located adjacent to the machine to allow

the water supply to be isolated if maintenance is required.

Water pressure requirements are: 10 L/min at 200-400 kPa max. Higher

water pressure can cause damage to the machine which may void

warranties, please contact Norris for more information.

Drain Connection

Point

Drain connection point within 1 metre of the machine. The hot water

discharge rate is approximately 16 L/min at up to 65ᵒc.

Detergent & Rinse Aid

connection

External dosing pump system is supplied with the machine. Refer to

dosing pump installation instructions.

3 Phase Power Supply A 20 Amp per phase, 3 phase power supply located within 1 metre of the

machine and within easy reach, but not behind the machine.

Page 4 of 19

2.2 Positioning & Connecting

Step

Action

Warning: Risk of electric shock. Failure to connect properly to the power supply can cause mortal

danger from electric shock. (Have the machine connected to the power supply by an authorised

technician according to the local and national codes. For Australia: in accordance with

AS/NZS3500.1)

1

Position and Level Your Machine

a)

Fit adjustable feet to the underside of the machine.

b)

Position the machine and adjust the feet so that the machine is level. Note: Ensure that

the machine IS LEVEL. If the machine is not level, it may cause issues with the level sensors

within the machine, which can lead to the machine flooding.

2

Connect Water

a)

Purge the site’s incoming water supply to be free from foreign matter prior to connecting.

Place a bucket under the tap before connecting hoses and turn it on to flush any foreign

matter from the water line.

Note: Failure to do this could result in foreign matter becoming lodged in the solenoid

valve causing it to leak. This will not be covered by warranty.

b)

Connect the braided hose to the cold water tap then connect the other end to the

solenoid. Firmly hand tighten (See illustrations below)

Note: Do not over-tighten connections.

c)

Turn the tap on and check for leaks (adjust accordingly)

3

Pipes and Leads

a)

Connect the drain hose to the drain spigot and lightly apply clamp.

b)

Connect the power lead from the machine to the power supply. (Check correct amperage).

4

Detergent and Rinse Aid

a)

Detergent and Rinse Aid dispensers can be connected to the machine. Refer to supplied

Instructions on external dosing system.

We recommend using the Zexa range of Machine Wash and Rinse Aid products. These

products are formulated for optimising your machines performance and protecting inner

components. Using these products also provides eligibility for our extended warranty – see

page 15 for details.

5

Exhaust Hood or Canopy (if required)

a)

As an option: The FI750 can have a steam condenser hood unit attached

Note: Some Councils require an exhaust hood or canopy for dishwashers. Check with your

local authority regarding your installation.

6

Basket Runner

a)

The Basket Runner is removable for ease of cleaning.

Page 5 of 19

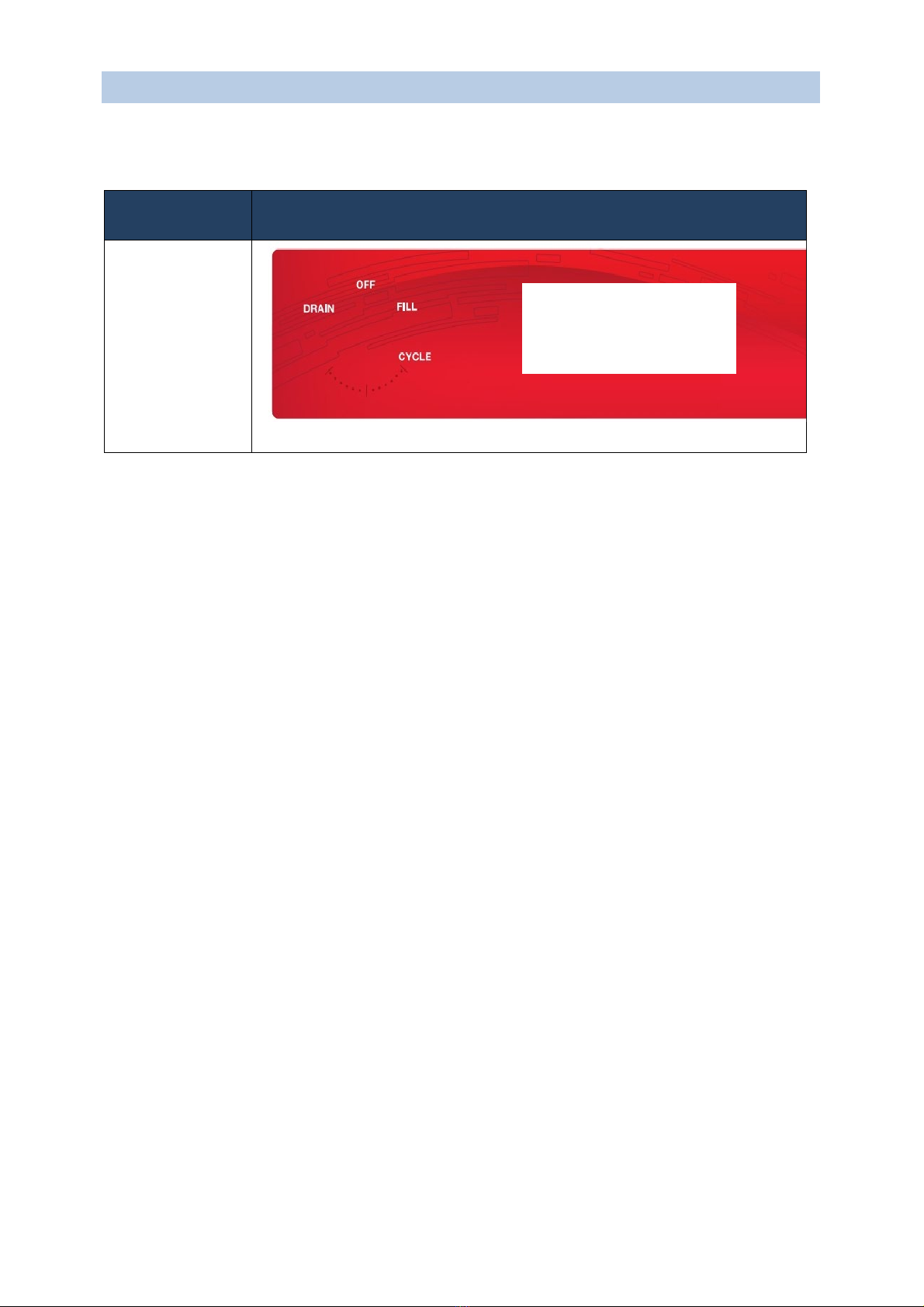

2.3 Screen and Dial

2.4 Water Levels

This machine is set up with a water pressure switch from the factory. The pressure switch controls the

water levels in the machine and protects the wash element in the case of no water in the tank.

2.5 Priming Boiler

This machine automatically primes the boiler before the rinse elements are energised.

For repairs or loss of water, there is a manual priming switch. Contact Norris for further technical

instructions.

2.6 Priming New Rinse and Detergent Lines

Norris recommends that you prime the chemical lines before you run the machine for the first time or

are connecting new chemical containers in order to remove all air from the lines.

For dosing instructions, refer to manufacturers chemical label instructions.

Selector Dial Use the Selector Dial for:

OFF, FILL, CYCLE and DRAIN options (Cycle selections are pre-set to 90 seconds)

Temperature

Display

The digital display shows the status of the rinse temperature.

82.5

Page 6 of 19

3 OPERATION

3.1 General Operation and Safety Instructions

•Carefully read through the safety and operating notes contained in these instructions. Norris

will not accept any liability and all warranty claims will be rendered null and void if the safety

notes are not observed.

•Have the machine connected by authorised technicians in accordance with the locally

applicable regulations (water, wastewater, electrics).

•Have the machine worked on and serviced by authorised technicians.

•The dishwashing machine must not be installed in a potentially explosive atmosphere or in

areas subject to frost or extreme heat.

•Load sharp, pointed utensils so that they cannot injure anyone.

•Keep children away from the dishwashing machine. The inside of the machine holds a solution

of detergent in hot water at about 60 °C – 82.5 °C.

•Train the operating personnel in how to use the machine and inform them of the information

in the safety notes. Repeat the training at regular intervals in order to prevent accidents.

•Do not use sharp objects to operate the controls of the machine.

•Do not open the machine hood whilst in operation. There is a risk that the hot washing

solution could be sprayed out.

•In case of danger and/or defects, switch off the machine immediately. Switch off the local

mains separator (main switch). Only then is the machine without power.

Page 7 of 19

3.2 Start of Day Operation

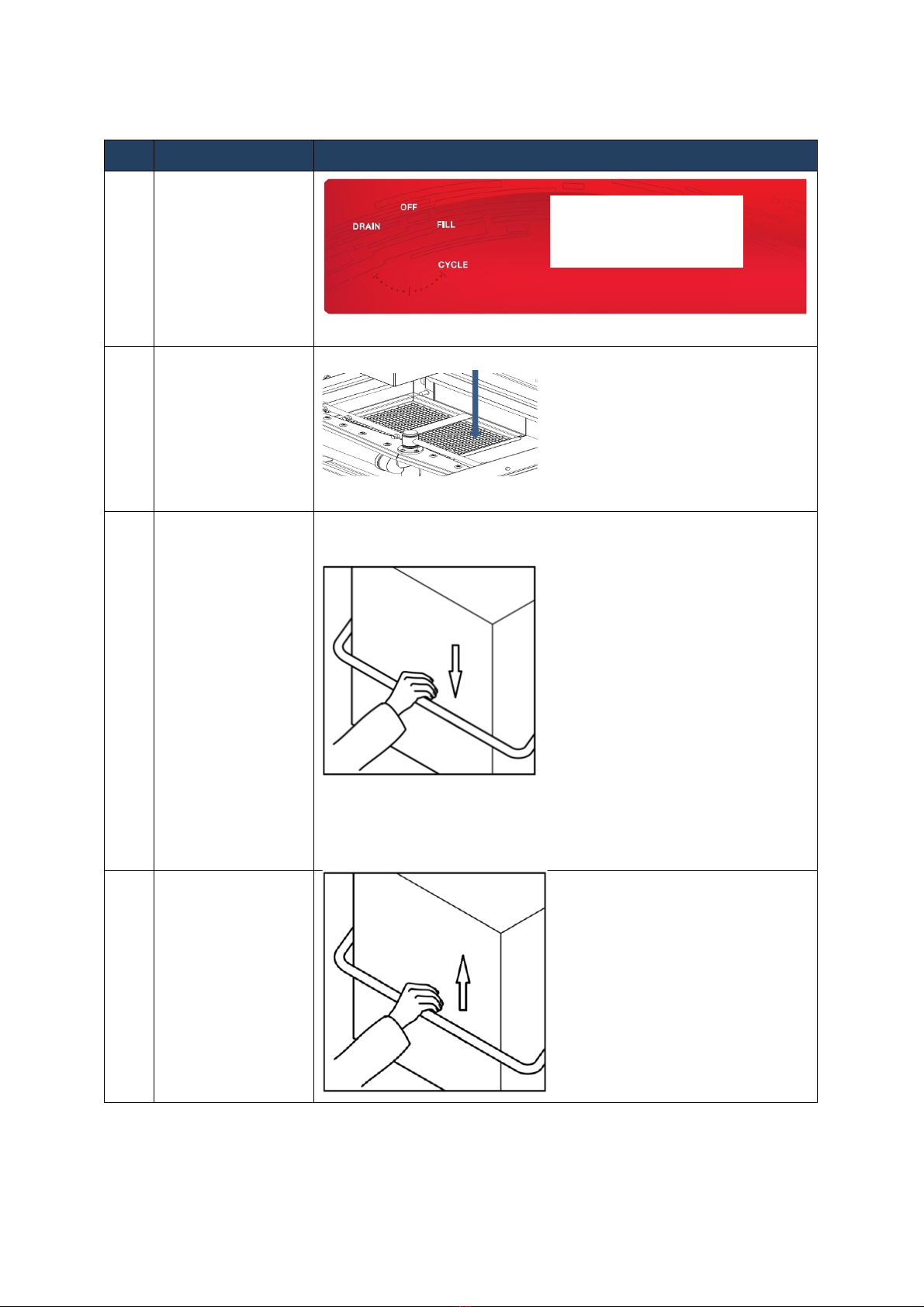

Step Action Illustration

1

Open the Hood

Remove Rack Slide

2

Replace Filter

Covers & Scrap

Trays

Replace Rack Slide

3

Close the Hood and

turn Selector Dial to

FILL

The machine will fill

the wash chamber

with water.

Note: Closing the

hood starts the

operation

4

Once water stops

filling –

machine is

ready for operation.

Hood can be left

open or closed.

Page 8 of 19

3.3 General Operation

Step Action Illustration

1

Open the hood

and insert rack

Turn the Selector Dial to

CYCLE

2

To start the cycle:

Close the Hood.

The cycle will always start

once the hood is fully

closed.

The machine will

automatically complete its

rinse cycle once correct

temperature has been

reached

3

Once the cycle has

completed allow 3 - 5

seconds for excess water to

drain away before opening

the hood.

Best practice is to leave

hood open when not in use

Note: During general operation please ensure to regularly clean scrap tray and remove excess

debris

82.5

Page 9 of 19

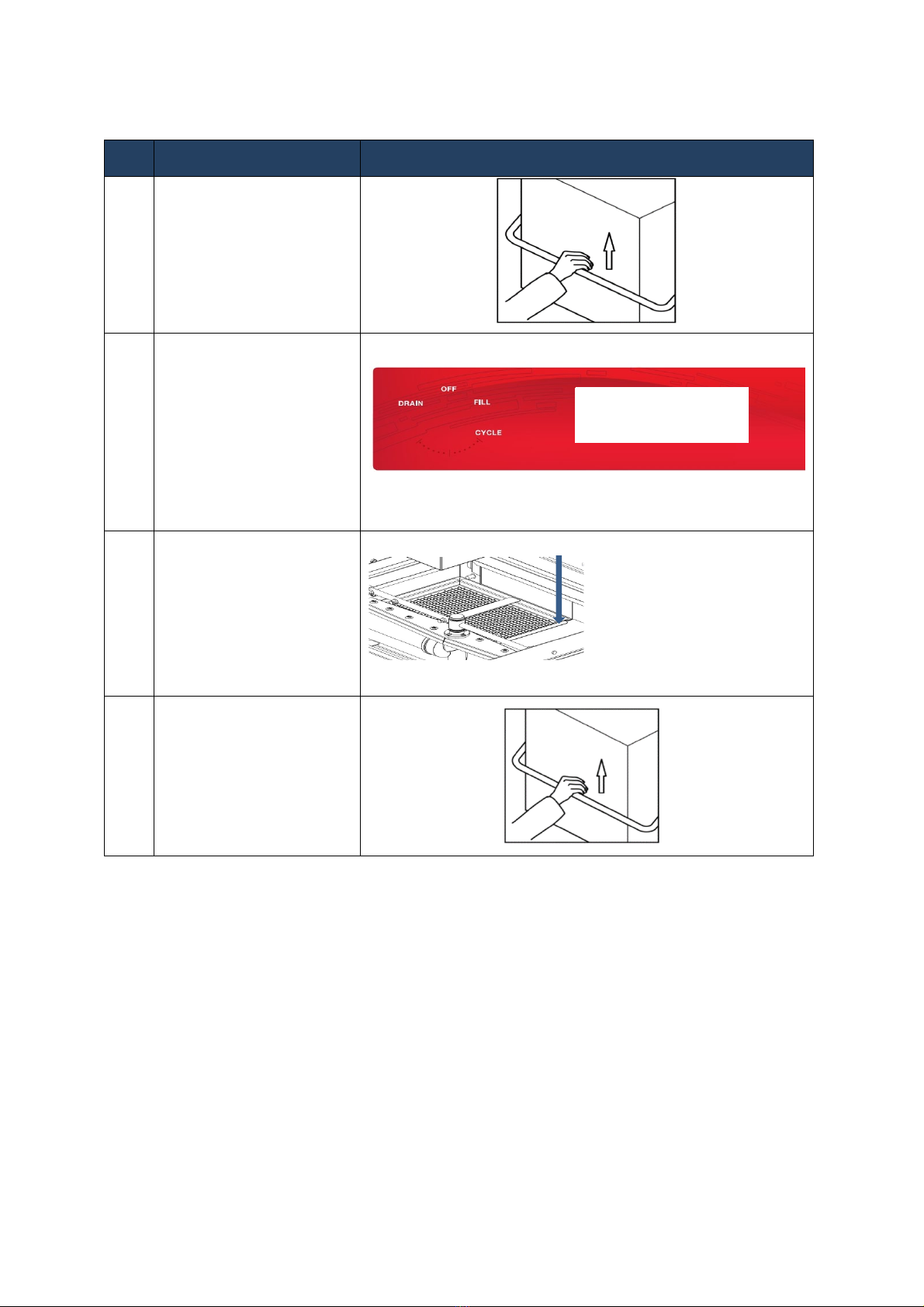

3.4 End of Day Drain and Shutdown

Step Action Notes

1

Open the Hood and

remove excess debris.

Turn the Selector Dial to

Drain

2

When all the water is

drained away and wash

tank is empty, turn the

Selector Dial to OFF

Machine must be turned

OFF. Continuous running

of drain pump without

water can lead to pump

failure

2

Remove the Rack Slide,

Scrap Trays and any

excess debris. Filter covers

can also be removed

Wipe out excess water

(Caution elements may hot

to touch)

4 Allow to air dry overnight

by leaving the Hood Open

82.5

Page 10 of 19

4 MAINTENANCE

Norris recommends carrying out appropriate daily and weekly maintenance on the machine to keep it

in working order.

•Wear protective clothing and protective gloves before touching any parts which are covered

with a detergent solution (filters, wash fields etc.).

•Do not spray the machine or the immediate vicinity (walls, floors etc.) with a water hose,

steam cleaner or pressure washer. Do not allow water to be sprayed in and around the

machine as this may result in machine failure.

•Do not use any scouring powder or abrasive cleaning agents.

4.1 Daily Cleaning

•Remove excess debris from scrap tray regularly during operation.

•Clean the outside of the machine using a suitable stainless-steel cleaner and a soft cloth. We

recommend Zexa stainless steel cleaner.

•While performing daily cleaning, make sure that no foreign objects which may rust have been

left in the interior of the machine. Rust particles may originate from non-stainless-steel dishes,

cleaning aids, damaged wire racks or water pipes with no corrosion protection.

4.2 Weekly Cleaning

•Use a brush or a cloth - NOT a Pressure Washer - for cleaning the interior of the machine.

•Remove the Wash Arms and rinse them thoroughly to remove any soil that may have been

stuck inside them. Failure to clean these areas regularly may result in premature wear on wash

spindles and bearings.

4.3 Servicing and Descaling

Norris recommends using your local Norris-Approved authorised service technicians for machine

servicing and descaling. For information on service agents www.norris.com.au or contact: Norris

Customer Service Team 0n PH: +61 1800 803 569

Warranty will be voided if using unqualified technicians.

4.3.1 Machine Servicing

Norris recommends having your machine serviced at least once a year by an authorised Norris-

Approved service technician. This service should also include having components that are subject to

wear or ageing (bearings and dosing tubes) checked and replaced as necessary.

4.3.2 Descaling

Regular descaling of the machine wash tank should occur relative to water quality and machine use.

Descaling should be performed by a Norris-Approved service technician, in accordance with the

descaling solution instructions. We suggest a minimum of every 3 months.

If the machine is operated with very hard water and without the appropriate water treatment, limescale

can build up in the boiler, in the interior of the machine and in all lines which carry water. A build-up of

limescale deposits can present a hygiene risk and the limescale can cause the heating elements to fail.

Page 11 of 19

5 MACHINE INFORMATION

5.1 Screen Display

5.2 Detergent & Rinse Aid

This Norris Dishwasher model has external detergent and rinse aid pumps and these are set in

accordance with pump instructions.

A commercial liquid, non-foaming dishwashing detergent must be used in accordance with the

chemical manufacturer’s recommendations.

We recommend using Zexa Machine Wash and Rinse Aid which when used will extend machine

warranty. Refer to Warranty Terms and Conditions for more information.

5.3 Minimum Operating Temperatures

Norris Dishwashers are designed to operate at minimum rinse temperatures, as required by

health regulations.

This dishwasher is factory set to complete its operation only when the rinse water is 82 °C and above.

Until the correct temperature is reached the dishwasher will not finish its wash cycle.

The 3 phase is designed to run on cold water and improves reliability and saves energy.

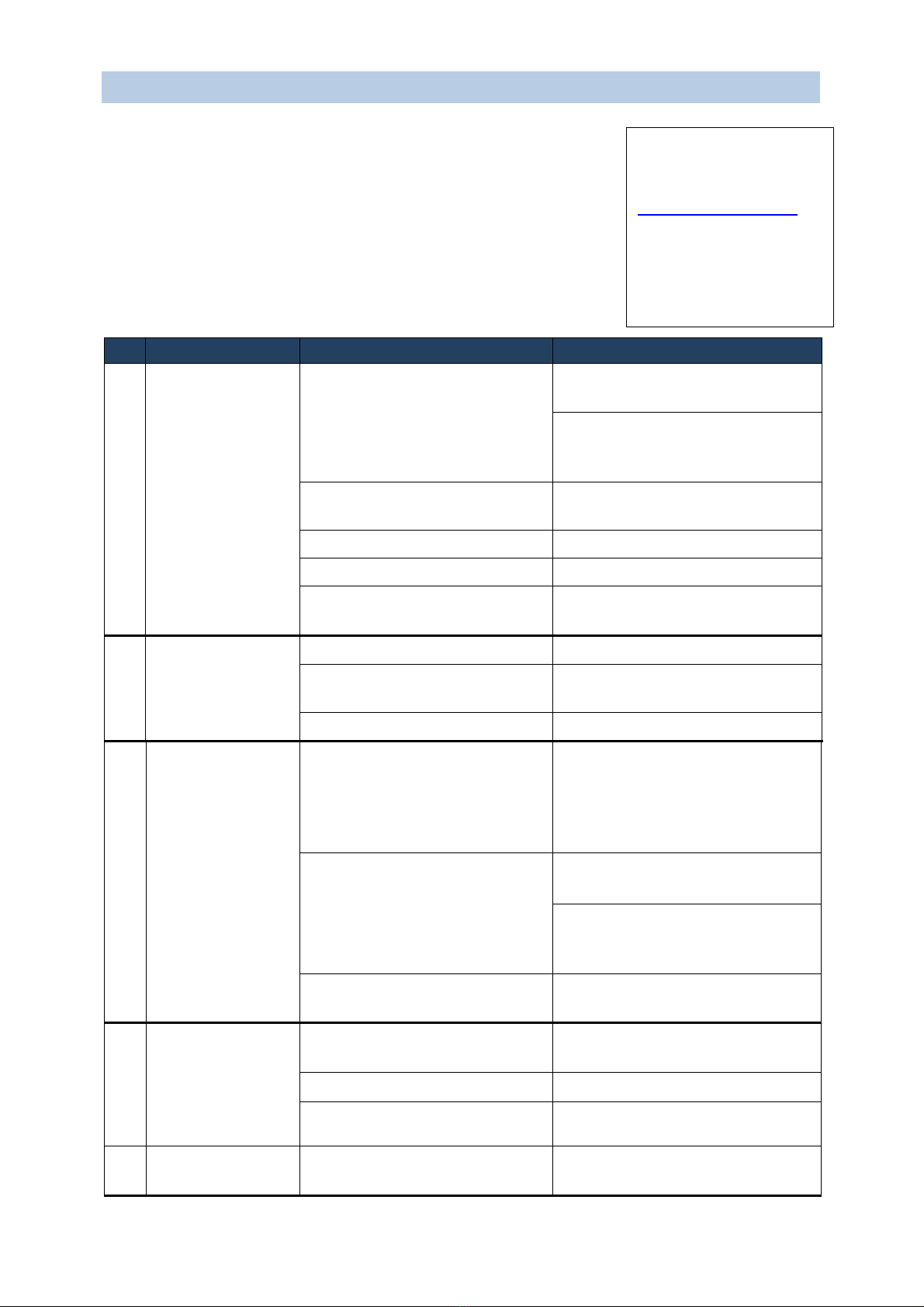

Description Screen Display

The Screen Display

will show the

Current Rinse

Tank Temperature

in ° C.

82.5

Page 12 of 19

6 TROUBLESHOOTING & ERROR MESSAGES

6.1 Troubleshooting

Please ensure the following are checked if the machine has a fault:

•Machine is level

•Water is ON / Power is ON

•Pipework and Drains are clear

•Hood is closed

No Issue Possible Cause Possible Solution

1

Dishes are not

clean when

washed

Too little or no detergent

Check the Detergent supply is not

empty

Check the tubes (outside the

machine) to ensure nothing is

obstructing or impeding the flow

Dishes not loaded correctly Ensure dishes are not stacked on

top of each other

Blocked Wash Jets Remove the Wash Arms and clean

Temperature is too low Allow wash water to heat up

Faulty Dosing Pump or Technical

Error Contact Norris

2 Dishes are still

soapy after rinsing

Too much detergent Reduce amount of detergent used

Incorrect detergent has been

used

Ensure the use of non-foaming

detergent

Blocked Rinse Jets Remove the Rinse Arms and clean

3

Dishes are not dry

Note: plastics and

Tupperware will

need to be air

dried or wiped

with a clean towel

This machine does not have a

drying feature. As a result of the

wash and rinse process, heat is

transferred into the item that is

being washed.

Some items conduct heat better

than others. Rinse aid is designed to

assist in the drying function

Too little or no rinse-aid

Check the rinse-aid supply is not

empty

Check the tubes (outside the

machine) to ensure nothing is

obstructing or impeding the flow

Faulty Dosing Pump or Technical

Error Contact Norris

4 Not Filling with

Water or Rinsing

No Water Ensure the Water is turned ON and

hood is closed

Blockage in the Rinse Jets Remove the Rinse Arms and clean

Hood switch faulty Contact Norris

5 Water not draining Filters are blocked or foreign

material has entered the pump Contact Norris

Customer Service Team:

Email the following

information to

1. Business Name

2. Machine Serial no

3. Contact details

4. Machine error or fault

Page 13 of 19

7 SAFETY

7.1 Intended Use

•The dishwashing machine is to be used exclusively for washing dishes, i.e., plates, cups,

cutlery, and trays or for washing glasses in catering, hospitality or similar industries.

•This machine does not have a drying feature. As a result of the wash and rinse process, heat is

transferred into the items that are being washed. Some items conduct heat better than

others. Rinse aid is designed to assist in the drying function.

•Always wash using washing racks suitable for the dishes. Never wash without a washing rack,

as this can cause irreparable damage to the machine.

•The dishwashing machines are technical pieces of equipment for commercial use and are not

intended for domestic applications.

7.2 Non-Intended Use

•This device is not designed for use by persons (including children) who have a restricted

physical, sensory or mental capacity, or persons who lack experience and knowledge of how to

use this device.

•Any such persons must first be instructed by a supervisory person with responsibility for their

safety or be supervised whilst operating the machine.

•Do not use the dishwashing machine for washing electrically heated cooking implements or

items made of wood.

•Do not wash plastic items unless they are heat-resistant and will not be damaged by the

detergent solution.

•Norris Industries will not accept liability for any damage caused by failure to use the

dishwashing machine in accordance with the intended use.

7.3 Handling Chemicals

•Most warewashing chemicals are highly corrosive. When using chemicals, adhere to the safety

notes and recommended dosages printed on the packaging.

•Wear protective clothing, protective gloves, and protective goggles when handling chemicals.

•Only use products that are suitable for commercial dishwashing machines. Such products are

marked accordingly. We recommend using products developed by Zexa chemicals. These

products are specially designed for Norris Glasswashers & Dishwashers and can be purchased

from www.zexa.com.au

•Do not mix different detergent products as this could result in crystallisation and consequently

cause irreparable damage to the detergent dosing device.

•Do not use any foaming products, e.g., hand soap, soft soap, or manual wash-up cleaner.

These products must not enter the dishwashing machine.

•Please note any residue from manual detergents used during the pre-wash process can

interfere with the performance of the machine

Page 14 of 19

8 DISPOSAL

There are no materials found in our machines that require special disposal procedures. All Norris

Machines are made from high-quality stainless steel and recyclable plastics.

Please contact your local council or tip for the best place to dispose of your machine.

A Norris machine is designed to last a long time. Before disposal, we strongly recommend you consider

refurbishment. Contact Norris for further assistance.

9 ENVIRONMENTAL

Norris prides itself on developing sustainable and efficient products

•If power consumption is a consideration, please close the hood if the machine is not in use for

an extended period of time

•Make sure the drains flow into a suitable sewer.

•Do not exceed the recommended dose of detergent.

•Where suitable, use an environmentally friendly machine wash. Zexa provides a range of non-

hazardous, non-caustic machine wash products safe for grey water and septic tanks

Page 15 of 19

10 WARRANTY TERMS AND CONDITIONS

All Norris, Australian Manufactured Glass and Dishwashers come with a two (2) year parts & labour

warranty as set out below. This warranty is given by Norris Industries Pty Ltd, hereinafter referred to

as Norris, ABN 69 002 351 840, of 28 Strathmore Road, Caves Beach, NSW, Australia, the

manufacturer of Norris brand Glasswashers and Dishwashers (the appliance) and shall only apply to

appliances installed in premises within the Commonwealth of Australia.

1. Subject to the exclusions set out in section 2 below, Norris warrants that the component

parts of the appliance are free from defects in material and workmanship for the following

periods:

1.1. The warranty period for the cabinet is five (5) years from the date of original purchase;

1.2. The warranty period for all parts and labour, whether internal or external, is two (2) years

from the date of original purchase.

1.3. If a defect in workmanship or materials occurs within the warranty period, Norris will repair

the defect using a Norris authorised technician, subject to the exclusions below.

2. Service under warranty will not apply where:

2.1. The purchaser or installer has not complied with the conditions or directions contained

within the operating and installation instructions supplied with the appliance;

2.2. There is a failure of the purchaser/operator to reasonably maintain the appliance

according to instructions supplied; for example; scale build up inside machine,

elements and solenoids.

2.3. There is general wear and tear of wash and rinse arm bearings;

2.4. There is general wear and tear of the detergent and or rinse aid dispenser squeeze tubes;

2.5. There is a failure in any way of the “S” or “P” trap;

2.6. There is a failure of the drain hose;

2.7. There is a failure of the drain tube ‘O’ ring; if applies

2.9. There is malicious damage or damage caused by careless and improper use;

2.10. There is a malfunction caused by dirty or poor-quality water or water pressures outside the

recommended range;

2.11. There is damage caused to the appliance in delivery from the dealer to the customer;

2.12. There is damage caused by the customer’s installer at the time of installation;

2.13. There is consequential damage caused to premises or fittings through a component part

failure;

2.14. There is damage caused by vermin, insects, or other pests;

2.15. The customer has used replacement parts not supplied by Norris or labour not being that of

an authorised Norris technician;

2.16. An authorised Norris technician attends to the appliance and no fault is found; or

2.17. There is damage caused by the installation or attachment to the appliance of external

apparatus not supplied to the customer by Norris and will be charged at Norris technician's

normal rates.

Note 1: The adjustment of any detergent and or rinse aid dispensers, whether native to the machine

or by another chemical supplier, is not covered under warranty.

Note 2: The detergent and rinse aid dispenser squeeze tubes are consumable and as such should be

replaced at six (6) monthly intervals. The squeeze tubes and the service to replace the squeeze tubes

are not covered under warranty.

Page 16 of 19

3. Warranty service is carried out on-site during business hours.

This warranty does not cover distance in excess of a 1 hour travel by road of the machine

location, additional travelling time, or any after-hour charges or costs unless previously

agreed to by Norris. For any warranty service call, Norris may require the customer to

provide details of and to authorise the use of, the customer’s credit card to cover any

excess charges under this item, and relevant service, labour, or parts charges. If the

warranty service call proves to be due to one of the exclusions set out in clause 2; relevant

service, labour, and parts charges will be at the customer’s expense. If Norris deems it

necessary to return the appliance or a component part of the appliance to its factory for

repairs the customer will pay the freight in both directions unless otherwise agreed to by

Norris.

4. Use of replacement parts not supplied by Norris or the use of labour not being that of an

authorised Norris technician shall relieve Norris of all future liability and responsibility.

5. (a) This warranty is the only warranty applicable to the appliance and subject to any

warranties that cannot be excluded at law is expressly in lieu of all other expressed or

implied warranties including any implied warranty of merchantability or fitness for a

particular purpose and any other on the part of Norris.

(b) The remedy contained in this warranty is the sole remedy for any defect found to exist in

the appliance and subject to clause 6, all other remedies, losses and damages are excluded,

including any liability for incidental or consequential damages.

6. If the Trade Practices Act 2012 or any other legislation implies a condition or warranty in

respect of any appliance or any labour services provided, and Norris’s liability for breach of

that condition or warranty may not be excluded but may be limited, clause 5(b) does not

apply to that liability and instead Norris’s liability for such breach is limited to, in the case of

the supply of goods, Norris replacing the goods or supplying equivalent goods or repairing

the goods, or in the case of a supply of services, Norris supplying the services again or

paying the cost of having the services supplied again.

7. Persons requiring service and seeking to rely on this warranty must contact and deal with

Norris (Free call +61 1800 803 569) who will appoint an approved Norris service technician.

8. All partsreplaced under the provisions of this warranty shall become the property of Norris

and shall be released by the customer to the authorised Norris technician for return to

Norris.

9. The rights or obligations under this warranty must not be assigned, transferred, or licenced

by the original purchaser of the appliance, and is not transferable to any subsequent owner

of the appliance.

10.This warranty is only applicable to the Norris Australian Manufactured Machines.

Our products come with guarantees that cannot be excluded under the Australian Consumer Law.

You are entitled to a replacement or refund for a major failure and compensation for any other

reasonably foreseeable loss or damage. You are also entitled to have the goods repaired or replaced

if the goods fail to be of acceptable quality and the failure does not amount to a major failure. For

any further information please call Norris.

Customer Service Team:

Email the following

information to

1. Business Name

2. Machine Serial no

3. Contact details

4. Machine error or fault

Page 17 of 19

SERVICE NOTES:

Page 18 of 19

SERVICE NOTES:

Page 19 of 19

www.norris.com.au

This manual suits for next models

1

Table of contents

Popular Dishwasher manuals by other brands

NEFF

NEFF Dishwasher Instructions for use

Kenmore

Kenmore 665.1 603 Use & care guide

Siemens

Siemens SN85TX00CE Quick reference guide

Electrolux

Electrolux EIDW1805KS Use and care guide

GE

GE GLDT696D00SS installation instructions

Champion

Champion M1.5 Series Installation, Operation, Cleaning and Maintenance Manual