O6108 08/01

5. Storing fuel:

a. Keep dirt, scale, water and other foreign

matter out of fuel.

b. Avoid storing fuel for long periods of time.

c. Fill the fuel tank at the end of each day's

operation. This will reduce condensation.

SP7-9. FUEL FILTERS

1. Your engine or generator set should have a

primary fuel filter installed. We recommend the

Racor brand of fuel filter - water separators.

a. Check the primary fuel filter daily as recom-

mended by the filter manufacturer. Empty

the collection bowl as necessary.

b. Change the element every 250 hours or when

necessary.

c. If the bowl fills with water, change the pri-

mary and secondary element immediately.

2. Change secondary fuel filter every 750 hours.

a. Remove the filter cartridge by turning it

counterclockwise with a filter wrench. Fill

the new cartridge with fuel and install it

after applying engine oil to gasket surface.

Screw on until the gasket surface comes into

contact with sealing surface of filter base.

Then, tighten it two-thirds of a turn by hand.

BLEEDING THE FUEL SYSTEM

CAUTION: Escaping diesel fuel under pres-

sure can penetrate the skin, causing serious

personal injury. Before disconnecting lines

be sure to relieve all pressure. Before apply-

ing pressure to the system be sure all con-

nections are tight and the lines, pipes and

hoses are not damaged. Fuel escaping from

a very small hole can be almost invisible. Use

a piece of cardboard or wood, rather than

the hands, to search for suspected leaks. If

injured by escaping fuel, see a doctor at once.

Serious infection or reaction can develop if

proper medical treatment is not administered

immediately.

1. Whenever the fuel system has been opened for

service, (lines disconnected, filter changed, etc.)

it should be bled.

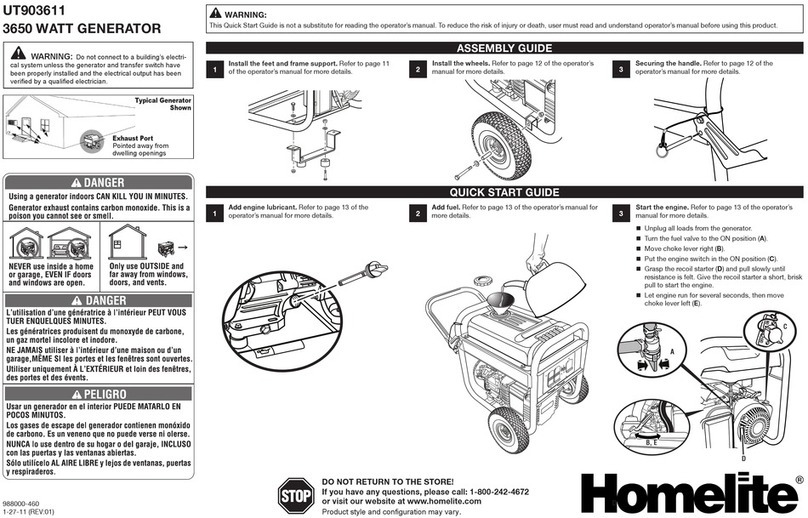

2. To bleed the fuel system, loosen the vent plug

in the top of the fuel filter housing. Unscrew the

16

hand primer knurled knob on the injection pump

and loosen until it can be pulled up by hand (see

Fig. 12,6).

Operate the hand primer up and down until most

of the air bubbles are expelled and clear fuel

escapes the vent plug. Push hand primer down and

tighten. Tighten the vent plug.

3. If the engine will not start, it may be necessary

to loosen the fuel pipes at the injectors. With the

throttle on full, crank the engine over with the

starter until fuel without air flows from the loose

fuel pipe connections. Tighten the connections.

SP10. INJECTORS

1. Fuel injectors should be checked by a Lugger-

Northern Lights dealer or qualified fuel injection

shop after every 750 hours.

2. Injector Removal:

a. Thoroughly clean the area around injection

pump and injectors, including all pipe and line

connections. Use compressed air if available.

b. Remove fuel line connecting nuts from injec-

tion pump and injectors. Remove fuel line

clamps below the intake manifold.

c. Put fuel lines aside. It is not necessary to

remove the pipes entirely.

d. Remove the return lines from the injectors.

e. Remove hold down bolts, holders and injec-

tors.

3. Clean Injector Bore:

Injector seat in cylinder head can be cleaned by

wrapping a clean, lint-free rag around the tapered

end of a wooden rod and wiping the bore and seat.

Hardened carbon can be removed from the seat by

using a tapered wire brush to break carbon free.

Then clean the bore with rag and rod.

4. Have injectors tested and rebuilt if necessary. Or,

take them to a Lugger-Northern Lights dealer and

use them as core exchange for rebuilt injectors.

5. Injector Installation:

a. Insert injector into bore. Install holders and

torque to 29-36 foot lbs. (4-5 kgm).

b. Install injector fuel return line. Torque banjo

bolts to 8-11 foot lbs. (1.0-1.5 kgm).

c. Install injector lines. Torque fuel line nuts to

14.5-18footlbs.(2-2.5kgm).Onthepumpside,

torque nuts 18-25 foot lb. (2.5-3.5 kgm).

d. Bleed the fuel system, start the engine

and check the system for leaks using a piece of

cardboard.

Servicing