Northwest Machine Works CP65 User manual

CP65

DIAMOND CORE DRILL

OPERATOR/SERVICE MANUAL

2318 Grand Park Drive Grand Junction, CO 81505

Phone: 970-242-1356 Fax: 970-241-1825

sales@northwestmachine.com

Contents

Description –

CP65 Diamond Drill

CP65 Air Rod Puller 2

CP65 Air Rod Puller Specifications 2

Care and Operation 2-3

Lubrication

Recommended Grease

Operation

Gear Changes

Speeds

Maintenance 3-4

Motor

Drill

Rod Puller

Water Circulation

Suggestions for Drilling 5-6

with the CP65

Setting Up

Drilling

Drill Rod Recommendation

Blast Hole and Grout Hole Drilling

Parts Drawings

Recommended Spare Parts 16

Illustrations

CP65 Diamond Core Drill

CP65 Diamond Drill with Blasthole Coupling 1

CP65 Grout Pipe Assembly 1

CP65 Motor – Exploded View 4

CP65 Diamond Core and Blast Hole Drill

(Parts Drawing) 7-8

Standard Equipment 9

Special Equipment 10

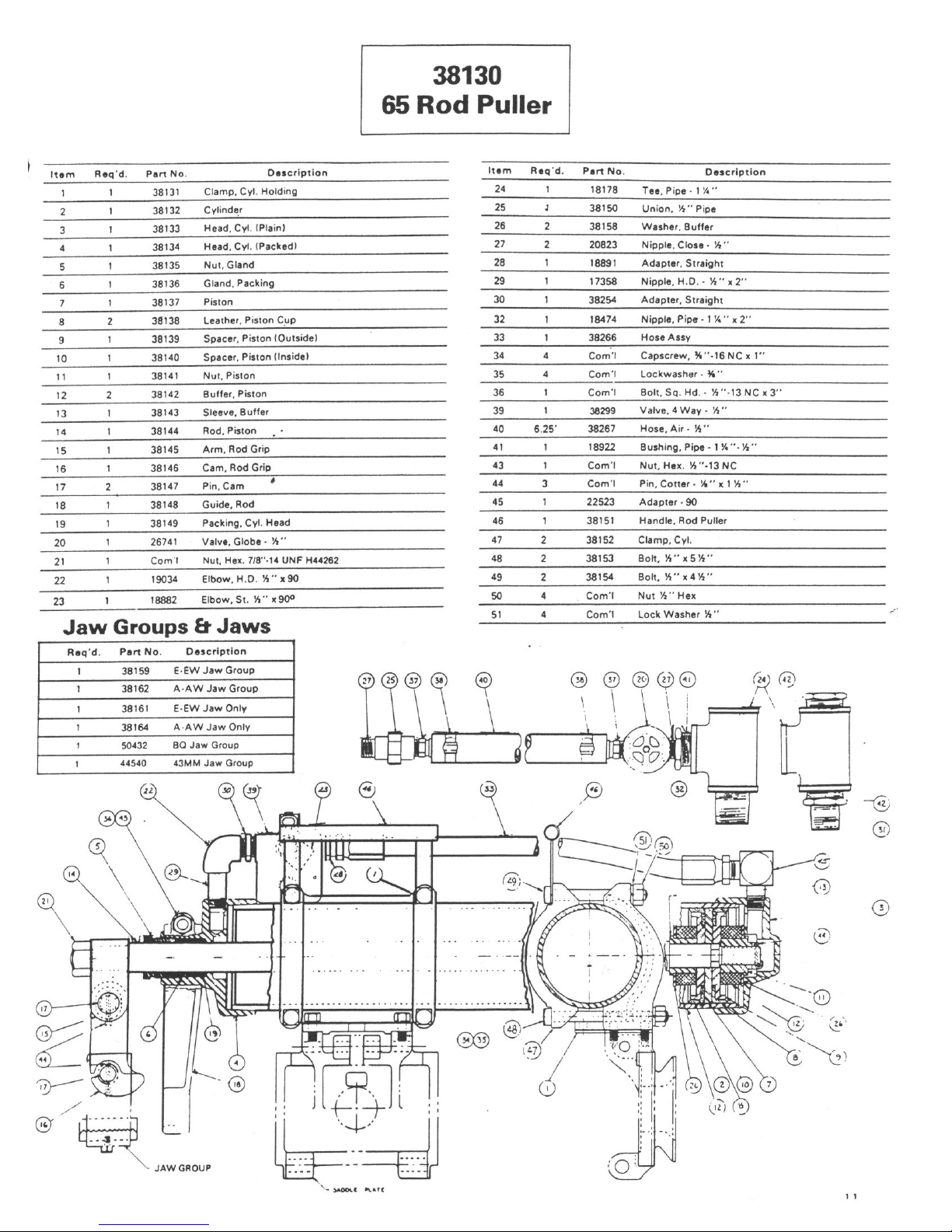

CP65 Air Rod Puller (Parts Drawing)

11

CP65 Double Screw Column and Arm

Assembly (Parts Drawing) 12

3 in. Grout Pipe Clamp Assembly 13

1-1/2 in. & 2 in. Grout Pipe Clamp

Assembly 13

CP65 Diamond Drill

The CP65 is a fully enclosed, dust proof, oil tight unit in a

sturdy, rugged steel housing. Ball bearings, used

throughout the drill, and an efficient spur gear drive

running grease, reduce friction losses to a minimum.

A standard rock drill saddle is used to mouth the drill on a

column, arm or crossbar from which it can work in any

position. The complete drill with built-in screw feed

swivel head is 42-1/2 inches long, weighs 200 pounds and

handles with the facility of a drifter.

Principal Features

CP65 Diamond Drill

with Blast Hole Coupling and

High Speed Water Swivel

Coring

1. Capacity – 600 feet with EW rods and EX fittings.

2. Self aligning, two position rod puller is available when

required for deeper drilling.

3. Delicacy of bit control gives low bit cost and high core

recovery.

4. Wide selection of feeds and speed available to cover special

drilling conditions.

Non- Coring

1. The reversible air motor greatly speeds blast hole drilling

by allowing rapid unscrewing of rod joints, after breaking

joint with a wrench, and allowing for rapidly moving the

chuck or blast hole coupling into drilling position.

2. High bit speeds available where drilling conditions admit

their use.

3. Adequate torque to maintain higher bit speeds results in

increased footage.

4. A heavy feed screw, blast hole coupling and high- speed

water swivel available for use when drilling with two foot

rods in front of machine.

Motor

The CP65 motor is a reversible, six blade, 20 HP air motor

which packs plenty of extra power for the most severe operating

conditions. This motor has its highest torque at “stall”, so it will

start heavy loads and run smoothly at any speed. Air

consumption is low, the CP65 motor actually delivering more

horsepower on the same amount of air as motors of lesser

horsepower rating, which means that the use of a compressor for

maximum capacity is not mandatory. The average ait

consumption of the motor is approximately 250 CFM, and

maximum consumption about 400 CFM.

This unusually trouble free motor runs without vibration and has

very few wearing parts.

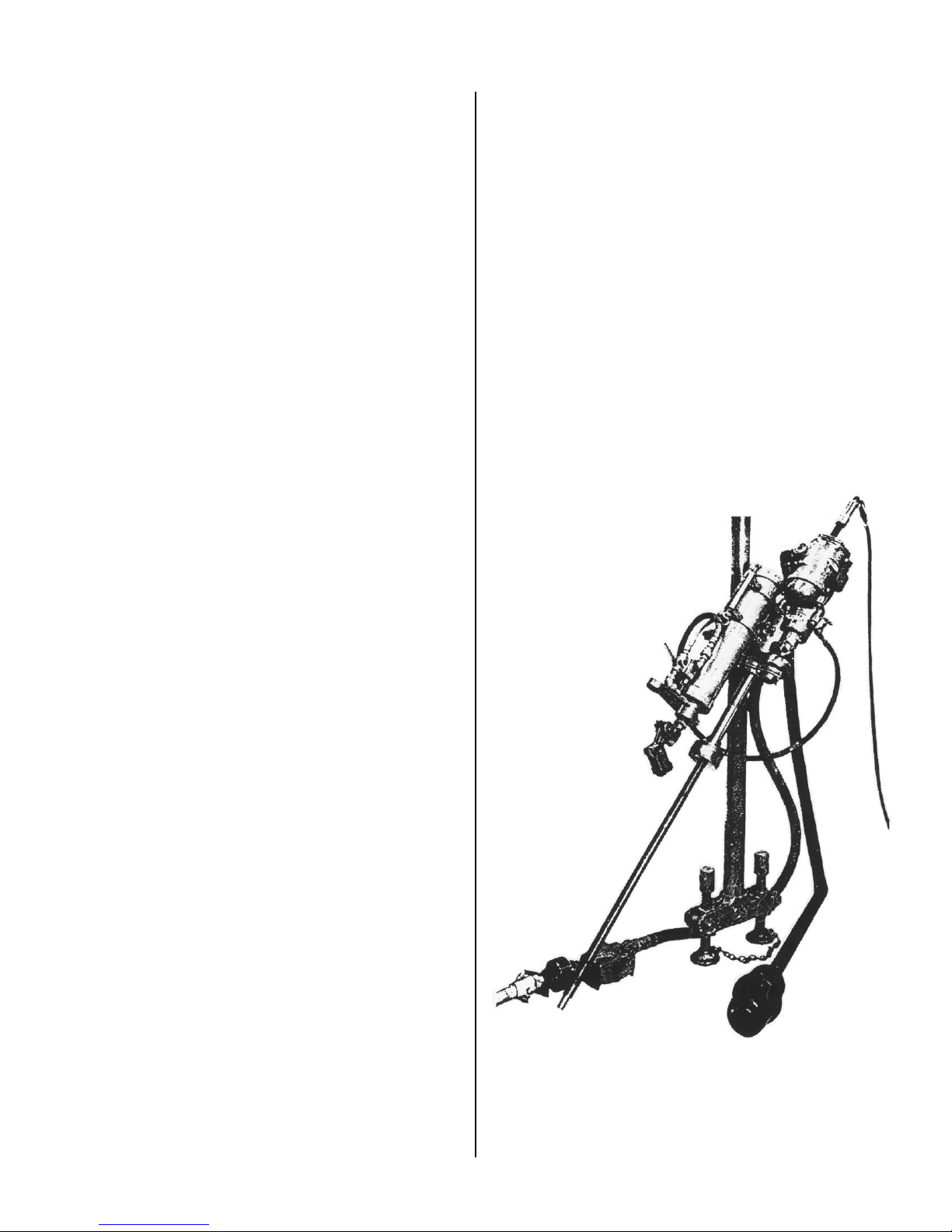

CP65 Grout Pipe Clamp Assembly with CP65 Diamond Drill

Assembly includes column pipe, saddle clamp, safety collar and

bushing. For use on 1-1/2” or 2” grout pipe.

(Special: may be bored for 3” pipe if needed)

Rated Capacity

The CP65 has a rated capacity of 600 feet with EW rods and EX

core barrel.

General

The CP65 is designed for coring work where a light fast drilling

machine is required. It is also ideal as a blast hole or grout hole

drill because of its compact design, powerful motor, and

reversible features.

Swivel Head

A swivel head with four sets of feed gears is built into the drill

to maintain absolute alignment. Any feed gear may be thrown

into action without stopping the drill. Ball bearings take the

thrust of drilling and the weight of drill rods. Length of feed is

24 in., bit rotation speeds are available as listed in the table of

specifications.

“Safety” Chuck

The chuck is accurately machined to assure perfect alignment.

The jaws are held by two large, Allen set screws with

countersunk heads in chuck body to make it impossible for them

to catch the operator’s clothing while rotating. Successive pairs

of holes in the chuck body may be used as threads become worn

which lengthens the effective life of the chuck.

Blast Hole Coupling

Where it is desired to use 24 in. rods in front of machine, use the

heavy Feed Screw and (EW) Blast Hole Coupling with the High

Speed Water Swivel screwed directly to the back of the feed

screw.

Principal Features, continued

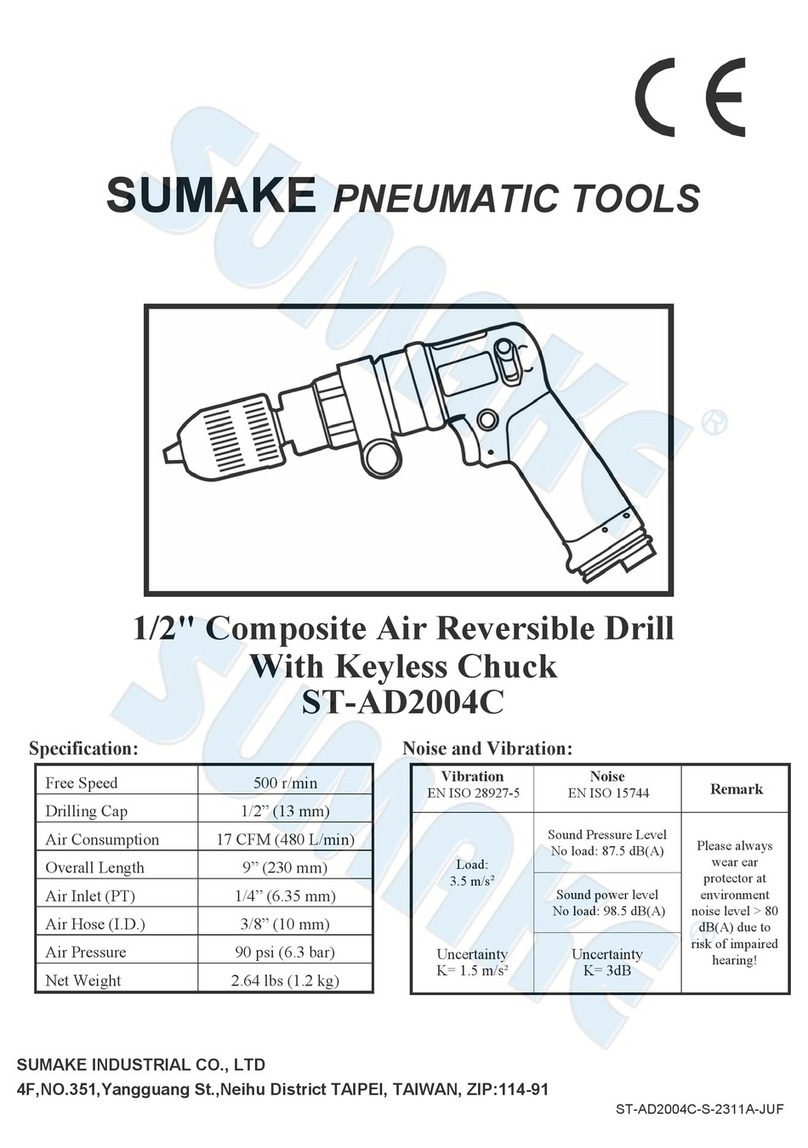

Table of Specifications

CP65 Diamond Drill

Rated Capacity (Feet)

EW-EX

600

AW-AX

500

BW-BX

350

NW-NX

300

Rotary Motor – HP

20 (reversible)

Dimensions (Inches)

Width

15-1/2

Height

12

Length

42-1/2

Net Weight (Lbs.)

Drill with Chuck

200

Drill with Blast Hole Coupling

195

Drill with Rod Puller

290

Bit Rotating Speeds

Standard

0-1500

Optional

0-1000

Optional

0-3000

“Built In” Screw Feed

Length of Feed

24 in.

I.D. of Coring Feed Screw (Inches)*

1-1/2 in.

Feed Gears (4) Revolutions/

Inch Advance

Standard

100, 200,

300, 500

Optional

50, 75, 800,

1100

Special

0, 101, 170

*See page 10 for heavy walled, non-coring blast hole feed screw.

CP65 Rod Puller

The CP65 Rod Puller with a 4-1/2 in. diameter piston and

21 in. of travel has been designed to match the short

overall length of the CP65. Its capacity is from 400 ft. of

EW rods up, depending on the inclination of the drill hole.

Its use is recommended for holes over 60 ft. in depth. Rod

Puller may also be used on AW Rod.

Rod Pullers have a short mounting bracket which bolts to

the drill saddle plate in either of two positions. In the

lower position, this allows for mounting the cylinder

assembly farther back, past the motor when space is at a

minimum. This also eliminates the necessity of removing

the saddle plate from the drill when mounting or removing

the Rod Puller.

Rod Puller Specifications

Capacity – EW Rods, Vertical

400 ft.

Length of Stroke

21 in.

Length Overall, Extended

54-1/2 in.

Cylinder I.D.

4-1/2 in.

Weight (Pounds)

100

Care and Operation

Capacity of the CP65 is 600 feet of EW rod with EX fittings.

The feed screw easily accommodates the EX core barrel for

starting holes. Rods may be pulled by hand to a depth of 60 ft.;

for any depth over this the Rod Puller is recommended since

considerable time is saved which can be used on actual drilling.

Lubrication

The motor is lubricated by a Line Oiler with a short air inlet

hose, which is supplied as standard equipment with each

machine. The Line Oiler must be adjusted according to local

conditions such as the temperature and the grade of oil being

used. With oiler properly adjusted, one filling should be enough

for four hours normal operation.. Use SAE #10 to #30,

depending on temperature and local conditions. Be sure the

motor is getting oil at all times.

For the drill itself, use a lithium base, high viscosity grease as

recommended below. Once each eight hours, inject grease into

the eight grease fittings on the drill, two of which are located on

the housing front cover, four on the housing and two on the rear

cover. Special attention should be given to the upper fitting on

the rear cover. The feed screw is greased by a small hole in the

drive sleeve and cleaned and oiled by the auxiliary exhaust.

The piston rod of the Rod Puller should be oiled occasionally.

No other oiling is necessary as the Line Oiler lubricates the disc

type valve and the two piston cup leathers.

Remove two chuck set screws from chuck occasionally, clean

them and coat with light oil to make adjustment quicker and

easier.

Recommended Grease

A lithium-based grease having high temperature stability

for a wide temperature range is required in the swivel head

of the CP65. The following greases, or their equivalents,

meet the requirements for this application.

Standard Oil Co. of Indiana, Stanolith No. 57

Union Oil Co. of California, Unoba EP No. 1

Shell Oil Keystone Lubricating Co., 84H Medium or Light

Sinclair Oil Co., Litholene

Texas Co., Multi-Fak No. 2

Swan Finch Oil Co., 70-169S

Fisk Bros., Lubriplate No. 630AA

Dow Corning, No. DC-44

Operation

For efficient operation of the CP65 Diamond Core and Blast

Hole Drill, at least 80 psi OPERATING pressure should be

maintained at the drill. Use 1-1/4 in. hose up to 25 feet and 1-

1/2 in. hose for longer lengths.

Blow our air hose before attaching to inlet. Remove and clean

air screen at frequent intervals, being careful not to damage or

distort screen and allow grit or scale to get into motor.

If the motor freezes from excess moisture in the air line, remove

hose from the drill and blow out hose until the line is clear. If

this does not remove water, the use of an air receiver is

recommended. After blowing out line, inspect and clean air

screen, since quantities of water moving through the line

generally carry scale and grit which may plug screen and

seriously impede air flow.

CAUTION: Do not over speed motor on light loads.

This may cause the blades to burn and delaminate.

Gear Changes

There are four feed gear changes on the CP65, the rating figure

representing the number of revolutions of the bit per inch of

advance. The Specification Table lists feeds available, the drill

being supplied with 100, 200, 300 and 500 feed gears unles

otherwise specified.

The drill is assembled with fast feeds toward the front and

slower feeds toward the rear. These may be reversed at

operator’s discretion, since it makes no difference in actual

operation. Gears are engaged by turning the shifter handle until

the longer part of the handle is midway between the letters “N”

stamped on the housing or as far as it will go in either direction.

As assembled, turn the shifter handle CLOCKWISE for a fast

feed or COUNTER-CLOCKWISE for a slow feed. Three

neutral positions, one between each feed, are marked by the

letter “N” on the housing. To return feed screw when run out,

close throttle, move shifter lever to NEUTRAL position, hold

down feed nut stop pin and open throttle slowly. When chuck or

coupling is about one inch from front of housing cover, release

stop pin and close throttle. To re-engage gears, move shifter

handle toward gear to be used, open throttle slightly and the

feed gear key should slip into position. If the gear key does not

immediately slip into slot in gear, do not attempt to force it, but

hold shifter handle against gear until correct position is reached

and key slips into place.

CAUTION: Be careful not to jam chuck against front

housing when returning the feed screw.

If jamming occurs, CLOSE THROTTLE VALVE, leave shifter

handle in NEUTRAL position, hold down feed nut stop pin and

turn chuck or feed screw backward to loosen it.

With shifter handle in neutral, feed screw may be returned

rapidly (taking care not to jam chuck against housing) or may be

run forward into position just as rapidly by reversing motor. If

desired, the screw may be run completely out of the feed nut.

Feed screw may be run normally a full 24” without difficulty.

A full 26” run is obtained without running feed screw down into

feed nut by using the Blasthole Feed Screw and EW Blasthole

Coupling with High Speed Water Swivel attached directly to the

feed screw.

Speeds

As normally assembled, unless another speed range has been

specified, the motor pinion and drive gear set for the CP65 gives

a nominal spindle speed of 1500 RPM with a gear reduction of

two to one. This gives the drill enough torque for holes up to

600 feet deep and plenty of speed for coring.

Other gear combinations are available for the most difficult

conditions, such as deeper NX holes where the 1000 RPM gear

set will give extremely high torque, or for blasthole drilling

where the 3000 RPM set will give a high rotating speed for

drilling up to 24 in. a minute.

Speed of rotation is not to be confused with feed, which is a

definite ratio of revolutions per inch of feed screw advance. For

example, when drilling in the 200 feed gear, the feed screw will

be advancing one inch for every 200 revolutions of the screw.

High rotational speeds will drill faster, but the ratio of

revolutions of the screw to each inch the screw advances

remains constant.

Maintenance

Motor

The motor consists of a cylinder in which a rotor is mounted

eccentrically, six slots in the rotor hold six laminated, phenolic

blades which move in and out against the cylinder wall as the

rotor revolves. These blades and the rotor are the only rotating

parts. Ball bearings, end plates, rotor housing liner and blades

are the only wearing parts. It is recommended that an extra set

be kept on hand. Adequate lubrication is important in

maintaining rotor blades, as running a relatively short time

without lubrication will cause them to wear rapidly and

unevenly, burn or delaminate.

The rotor blades may be removed and the wearing faces dressed

down with sandpaper or a file in case of uneven wear. Care must

be taken to keep the wearing faces square with the sides.

To remove or change blades, remove eight Cap Screws holding

the Rotor Housing Cover to the Rotor Housing and remove

cover. Remove the Rotor Locking Nut and, with two Allen

wrenches tighten the Set Screws to jack the End Plate out of the

housing. The rotor blades may then be removed for inspection

or replacement. Before replacing end plate, retract Set Screws to

avoid interference during assembly.

To remove the Rotor Housing Liner or to change Ball Bearings,

the motor must be removed from drill and, after the Rotor

Housing Cover has been removed, the assembly of rotor, liner

and end plates may be pushed out the rear end of the motor

housing for inspection or replacement.

Maintenance, continued

J-1455 MOTOR

Exploded view showing method of jacking rear end

plate out of motor housing for changing rotor blades

Drill

To disassemble, first move shifter level to neutral, hold down

feed nut stop pin, reverse motor and run screw out of feed nut.

The drill may now be disconnected from the air line and the

motor removed from the drill. Next remove Drive Gear Screw

and remove drive shaft drive gear from Rear Housing Cover,

and remove rear housing cover from Housing. Next, remove

Shifter Sleeve Detent Spring Plug and Detent Spring and

remove Front Housing Cover.

After removing Castle Nut from end of Drive Shaft, drive shaft

with feed gears and feed nut assembly may be pulled out

together. Remove Drive Sleeve.

Do not disassemble drive shaft or feed nut assembly unless

replacement of parts is required. If feed nut is disassembled,

remove Lock Nuts with two spanners, LEFT HAND THREAD!

To reassemble, if feed nut has been disassembled, first drive

Key into slot in nut and place feed gears on feed nut with the

gears in sequence from the lowest to the highest or the reverse,

according to operator’s preference. Place Ball Bearing on gears

and tighten Lock Nuts in place, using two spanners. LEFT

HAND THREAD! After tightening nuts, stake in at least four

places with center punch.

If drive shaft has been disassembled, first place Steel Ball and

Spring in Shifter Rod and tighten Plug in end of rod. Insert rod

in drive shaft and drive Feed Gear Key into rod under steel ball.

Pack feed gears with recommended grease and place on drive

shaft to mate with those on the feed nut. Remember that the two

assemblies are put together from opposite ends and that the

sequence of assembly must be the reverse of that used on the

feed nut in order to pair feed gears on final assembly.

Next, place Thrust Washer and Ball Bearing on drive shaft.

Place one Washer and Shifter Collar in Shifter Sleeve, invert

sleeve, place second Washer on shifter collar and screw Shifter

Collar Nut on shifter collar. Place Pin Retainer on drive shaft,

insert Shifter Pin through hole in shifter rod and place

assembled shifter sleeve on drive shaft, entering pin in slot in

shifter collar nut. Place Pin Retainer in groove in shifter collar

nut.

Before reassembling drill, remove the shifter handle assembly

and the drive Shaft Front Bearing. If two Ball Bearings located

in the drive sleeve chamber of the housing require replacement,

drive the first down tightly against should in housing, add

Spacer and drive second bearing against spacer.

During assembly all parts should be coated liberally with

recommended grease.

Mesh gears of drive shaft and feed nut assemblies and insert in

housing together. Hold Drive Shaft Gear in housing and

assemble with drive shaft using Key. Place Ball Bearing in

housing and tighten Castle Nut on drive shaft against Drive

Shaft Washer. Place Drive Sleeve assembled with one Call

Bearing in housing. Fasten Front Housing Cover assembled with

Grease Seal on housing.

Rotate drive shaft until shifter handle assembly may be inserted

in housing, rotate shifter handle as far as it will go

CLOCKWISE to engage shifter key with last feed gear, remove

assembly and place in its proper position, with handle to left of

‘N’ toward chuck end of housing.

Fasten Rear Housing Cover assembled with Grease Seal and

Roller Bearing to housing, place drive shaft drive gear and two

Keys on drive shaft and tighten Drive Gear Screw into drive

shaft against Washer.

Assemble motor with swivel head, attach air line, thread drive

screw into feed nut, depress stop pin and, with motor on forward

rotation, open throttle and run screw into nut. DO NOT jam

chuck against front housing cover.

Rod Puller

To replace worn piston cup leathers, unscrew back cylinder

head and pull out piston and piston rod.

Water Circulation

Good drilling practice requires a dependable water supply used

at the lowest pressure conducive to good sludge removal, which

results in saving of the pump, power and diamond bits. Local

conditions will dictate the correct pressure and volume required,

for instance, sticky ground will require high pressure and deep

drilling, because of leaky rod joints and the necessity to keep

sludge in suspension for long periods of time will require larger

volumes of water. Large holes drilled with small rods will need

a large volume of water to maintain normal circulation velocity.

Suggestions for Core Drilling

With the CP65

Setting Up

When installing drill on column, column are, or cross bar, be

sure setup is rigid. Misalignment resulting from loose column or

arm may break rods or feed screw. The use of a double screw

column instead of the single screw type is recommended for this

reason. Column should be set up about 42 inches back from

where the hole is to be collared to allow for the full run of the

feed screw and the stroke of the rod puller.

If sludge samples are to be taken, as is done where core

recovery is poor, it is advisable to use a piece of casing in the

collar of the hole. In this case, the column should be set back

sufficiently so that there is still approximately 42 inches

between the column and the end of the casing.

When drilling down holes, where there is danger of muck or

other foreign material falling into the hole, it is advisable to use

casing in the collar of the hole as a safety precaution. In drilling

up holes more than 30 degrees above horizontal, the hole should

be started with a casing bit so that a stuffing box may be used to

prevent water and muck from pouring out of the hole and onto

the drill and operator.

When starting holes in fractured or faulty ground where there is

danger of small pieces of rock caving into the hole, case

sufficiently long to bottom in solid ground should be inserted.

If this is not done, the small pieces of rock, especially if hard,

may materially increase the diamond bit cost per foot of hole

drilled by becoming wedged between the diamonds in the bit

and breaking them when pulling out of the hole. The same holds

true when going to the bottom of the hole, as the pieces may be

forced to the bottom and it will be necessary to run over them

with the probability that some of the diamonds will be broken.

Even if the sharpness of the bit is not materially impaired, each

of the diamonds in the bit represents a portion of its value, and a

correspondingly lower footage and salvage may be had.

Drilling

Diamond bits required for core drilling are the casing bit, double

tube reaming shell and bevel wall coring bit.

In starting to drill (where casing will be used) a five foot rod is

put through the chuck and feed screw, the starting barrel is

tightened to the rod in front of the chuck and the water swivel is

screwed on the back end of the five foot rod. Next, tighten the

casing bit in place, using care not to contact the diamonds with

the wrench.

Move up to rock face and inspect to make sure it is square with

the bit. If it is not, pick or moil the surface until it is square. The

chick screws may now be tightened and adjusted to center the

rod in the chuck. If the ground is soft, the hole mat be started

immediately by holding the starting barrel against the face by

hand. If the ground is hard, a ‘vee’ should be cut in the edge of a

plank or lagging and the plank secured under the starting barrel.

Then, holding the starting barrel down into the ‘vee’ with

another plank or lagging, turn on the water, place drill in lowest

feed gear and open the throttle slowly.

Always start the drill slowly and collar the hole carefully. More

damage may be done to the bit in collaring the hole than in the

next 20 feet of drilling. When a portion of the bit is in the rock,

remove the plank and open the throttle.

Casing should be run into the solid rock far enough so that when

the diamond casing bit is removed and the hole cased,

approximately four inches of casing is outside the collar. The

starting barrel is simply a short piece of casing with a rod-to-

casing bushing and on which a diamond set casing bit may be

used.

If casing is to be fun deeper, longer pieces may be added as

required. After hold is cased to solid bottom, hole should be

washed out, using cross chipping bit on the end of rods to chop

out any small pieces of core that may be left in the hole. This

will ensure a clean hole for the start.

If the casing is only into the rock a couple feet, it will be

necessary to put the double tube core barrel through the feed

screw after removing the Feed Screw Bushing. LEFT HAND

THREAD!

The inner tube of the core barrel is quite thin in section and is

designed to receive the core cut by the bit. Water coming from

the rod into the back end connection of the core barrel flows

between the inner and outer tubes toward the bit. Most of this

water passes out around the bit to keep it cool and carry away

the sludge. A small amount of the water passes back up the

inner tube to float pieces of core back away from the bit and to

keep them from wedging in the tube or bit and causing the bit to

choke or block prematurely and grind up the core; this feature is

the reason that double tube core barrels are usually

recommended instead of single tube barrels. After passing

through the inner tube, the water runs out two small holes in the

side of the back end connection of the core barrel. When starting

a hole with part of the core barrel outside the collar of the hole,

remove bit and push cork, rubber plug or wad of paper to the

back of the core barrel to keep water from spraying on the drill

and operator while drilling. After core barrel is well into hole,

remove the plug the next time the core barrel is emptied.

When the hole has been drilling to approximately five feet, the

core barrel and rods should be kept greased. Different ground

conditions call for different greases, but usually a cup or fibre

grease of No. 3 government specification is suitable. After

greasing, it will be necessary to cut burlap into six or eight inch

squares and use it to grip the rods when pulling them.

The practice of greasing is necessary to cut friction and

vibration to a minimum. Vibration is very hard on diamond bits,

at times shattering the diamonds if allowed to continue for any

length of time. When vibration occurs it may not show on the

surface, but it slows down the drill at once; the best practice is

to shut off the motor completely, and then reopen the throttle

valve slowly, changing speeds until a spot is found where

vibration is not so intense.

When the feed screw has been run down its full length, shut off

the circulating water BEFORE loosening chuck screws. If this is

not done, the water pressure may push the rods and core barrel

off the bottom of the hole and allow some of the core to drop

out of the bit. When drilling with a short string of rods, always

hold them down with a wrench while running the feed screw

back to prevent the string being raised and the core lost if the

chuck jaws should catch on the rods while returning.

If pieces of core should drop out of the bit and lie sideways in

the hole, damage to the diamond bit will result in running over

them.

When the feed screw has been returned, tighten the chuck

screws, turn on the water and wait for it to start running out of

the hole before drilling is resumed.

In normal ground the machine will run smoothly while drilling,

but as soon as the bit is blocked or the core barrel gets full the

motor will act erratically, alternately slowing down, speeding

up, or even stopping momentarily and shutting off the water

when core breaks tightly.

When this happens, core barrel must be pulled and emptied. As

soon as the core barrel is out of the hole, remove the bit and

reaming shell, then remove the back end connection and empty

the inner tube. If some of the core sticks in the inner tube, tap

tube lightly with the flat of a wooden paddle, taking are not to

bend or dent tube.

It is a good plan to have a trough made up that is long enough to

take the core as it is emptied from the tube so that it does not get

mixed up with cores pulled previously. It is important also that

the core be marked as to depth every time the barrel is emptied,

using wooden blocks in boxes made up for preserving the core.

Normally, very little trouble will be encountered in diamond

drilling. Make sure before starting the drill that water circulation

is established. If water shuts off while drilling, stop immediately

until the cause is found. If the bit is blocked or mudded, at

which time the bit will slow down or stop, rods must be pulled

and the core barrel emptied and cleaned. If it is found that rods

turn easily and water is still circulating after chuck screws have

been loosened and still no water shows at the collar, it is

probable that the bit has run into a seam or small cavity which is

taking up the water and drilling may be safely resumed. Since a

new face is then being cut, start drilling for an inch or so. If drill

operates smoothly, it is safe to open the throttle again.

Generally the drill should be run in the fastest feed gear possible

as long as it operates smoothly and without too much effort.

With a sharp bit, after the hole is collared, the drill may be run

in the 100 feed gear. When the motor begins to labor or slow

down, because of a dull bit or harder ground, gear should be

shifted to a slower rate of feed.

Diamond bits should not be run too far for economic reasons. In

very hard ground, bits should be changed as soon as the motor

labors too hard in slowest feed gear. In abrasive formations, or

where the bits have run to the point where metal is worn away

from the diamonds and there is danger of their being torn out,

the bit should be taken out of service because loose stones may

break up the entire bit.

Drill Rod Recommendations

It should be recognized that size of chuck, chuck jaws and drill

rod do not necessarily govern the size of hole what is to be

drilled. For example, the largest size NW casing may be drilled

into the rock using EW drill rod. The EW rod is run through the

chuck jaws and an EW to NW rod-to-casing sub is used to

connect to the NW casing or starting barrel equipped with a

diamond casing bit.

The foregoing is not recommended as a desirable combination

but frequently it is necessary to improvise in order to expedite

the work. Obviously it is impractical to have every desirable

piece of equipment on all jobs, many of which are isolated from

sources of supply.

With the exception of short holes in easy drilling conditions, do

not use EW rods for drilling AX or larger holes EXCEPT

THROUGH FEED SCREW AND CHUCK!

AW rods have the necessary strength for drilling to any depth up

to 3500 feet; however, when drilling with AW rods and BX or

NX core barrels, be sure to insert one or two rods of

complementary size (BW or NW) immediately behind the core

barrel; otherwise, serious rod vibration or wobble may develop.

Blast Hole and Grout Hole Drilling

When drilling blast or grout holes, where recovery of core is

unnecessary, the use of a short, hard metal protected blast hole

barrel, is recommended. The use of a diamond set reaming shell

is dispensed with and the bit screwed directly into the barrel.

The advantage of using these barrels lies in their greater wearing

qualities as compared to the ordinary core barrel.

Where space is at a premium in blast hole drilling, the use of

two foot rods ahead of the drill is recommended. This is the

most rapid method of drilling with the CP65. Using the water

swivel screwed directly to the back end of the blast hole feed

screw, and with blast hole coupling in the front end, drilling is

simply a matter of adding rods instead of chucking and

changing water swivel in the ordinary manner. The reversible

feature of the CP65 motor is a time-saver in this type of drilling

since the rods, after the joint has been broken, may be

unscrewed and screwed up using the motor.

When drilling in soft ground, it is recommended that the spindle

and gear which gives a spindle speed of 3000 RPM be used. In

harder ground the 1500 RPM set may be used to advantage, but

the highest practical spindle speed is recommended to cut

drilling time to the minimum.

The Grout Pipe Clamp setup is indispensable for grout hole

drilling as the drill is always in alignment when moving on and

off grout pipes.

Table of contents

Popular Drill manuals by other brands

Drill Master

Drill Master 67025 Operating insructions

Ferm

Ferm CDM1134 Original instructions

Black & Decker

Black & Decker KD1001 TYPE 2 manual

Lissmac

Lissmac CDR 251 operating manual

DeWalt

DeWalt XR LI-ION DCD980 instruction manual

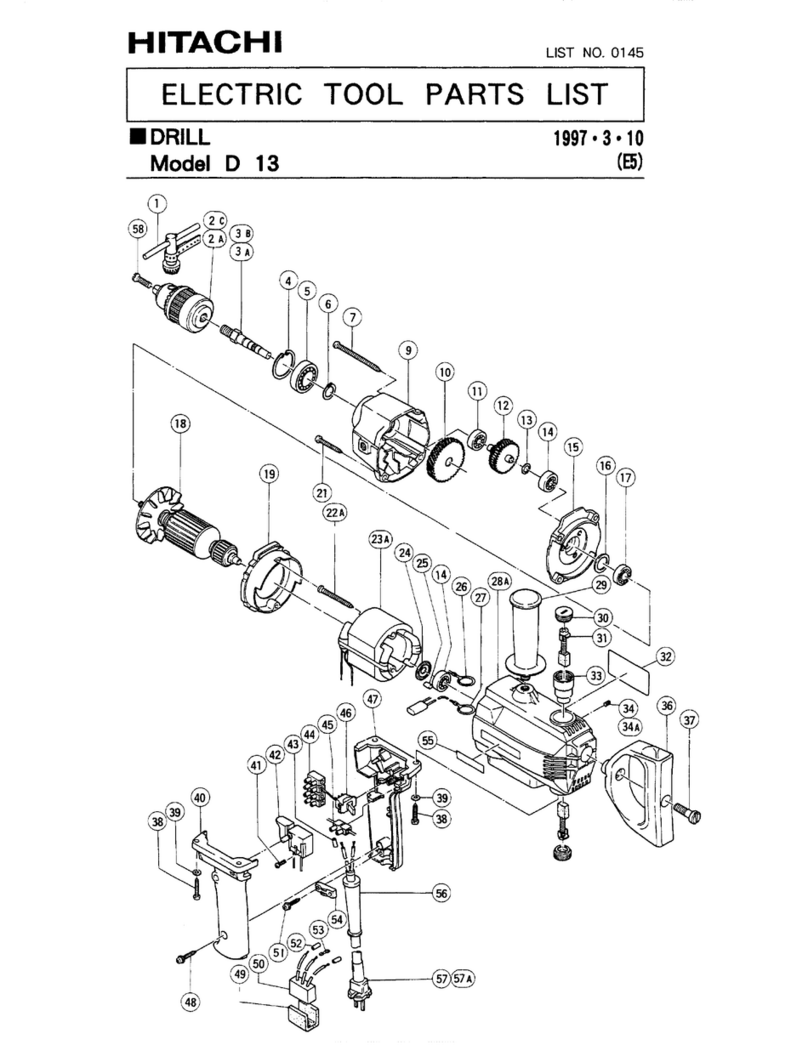

Hitachi

Hitachi 6.2Amp - D13 1/2" Electric Drill Rev. D-Handle... parts list

Stanley

Stanley SK58 Service manual

Black & Decker

Black & Decker DR350FD instruction manual

Narex

Narex CSV 13-2 Original operating manual

MK Diamond Products

MK Diamond Products MK-Manta III owner's manual

EINHELL

EINHELL TE-ID 1050 CE Original operating instructions

Stomer Professional

Stomer Professional SPD-851x2 user manual