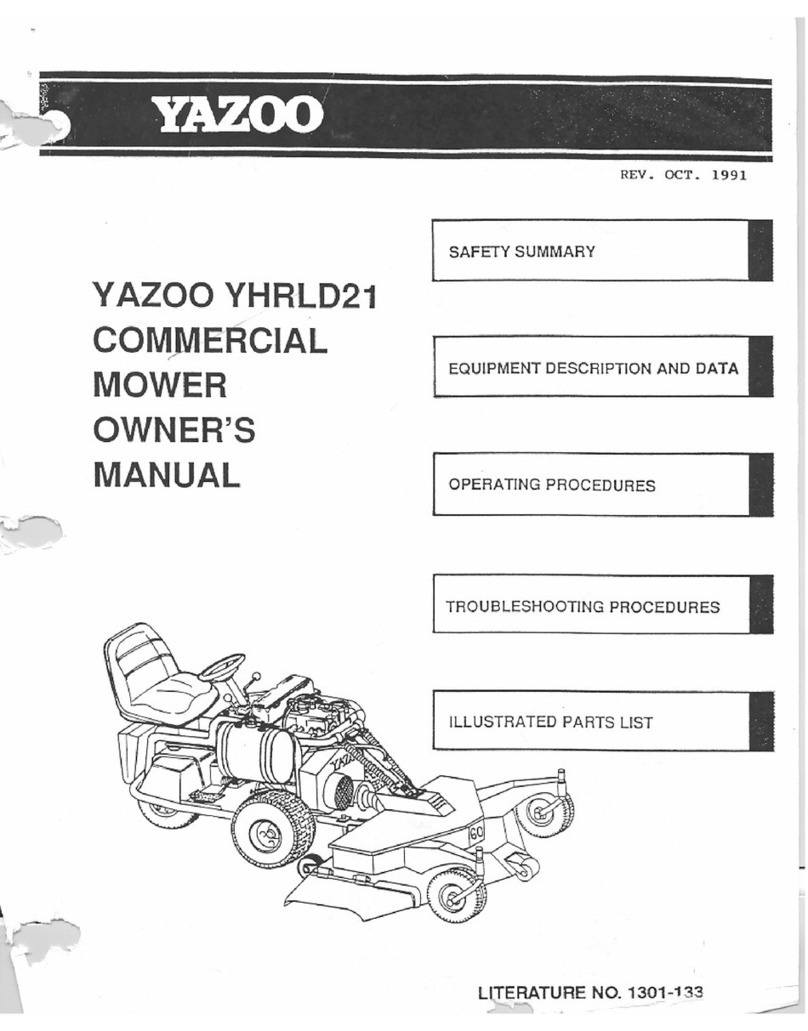

NOVACAT 225 ED User manual

/PERATOR@SMANUAL

GB

Ihre / Your / Votre • Masch.Nr. • Fgst.Ident.Nr.

).3425#4)/.3&/202/$5#4$%,)6%290AGE

4RANSLATIONOFTHEORIGINAL/PERATING-ANUAL

Ihre / Your / Votre • Masch.Nr. • Fgst.Ident.Nr.

.R

• Disc mower

99 377.GB.80I.0

NOVACAT 225 ED

(Type PSM 377 : + . . 01001)

NOVACAT 265 ED

(Type PSM 378 : + . . 01001)

ALLG./BA SEITE 2 / 0000-GB

Important information concerning Product

Liability.

According to the laws governing product liability, the manufacturer and dealer are obliged to hand the

operating manual to the customer at the time of sale, and to instruct them in the recommended operating,

safety, and maintenance regulations. Conrmation is necessary to prove that the machine and operating

manual have been handed over accordingly.

For this purpose,

- document A is to be signed and sent to Pöttinger,

- document B remains with the dealer supplying the machine,

- and the customer receives document C.

In accordance with the laws of product liability, every farmer is an entrepreneur.

According to the laws of product liability, property damage is damage caused by a machine and not to

it. An excess of Euro 500 is provided for such a liabilioty.

In accordance with the laws of product liability, entrepreneurial property damages are excluded from

the liability.

Attention! Should the customer resell the machine at a later date, the operating manual must be given

to the new owner who must then be instructed in the recommended regulations referred to herein.

GB Dear Farmer

You have just made an excellent choice. Naturally we are very happy

and wish to congratulate you for having chosen Pöttinger. As your

agricultural partner, we offer you quality and efciency combined with

reliable servicing.

In order to assess the spare-parts demand for our agricultural machines

and to take these demands into consideration when developing new

machines, we would ask you to provide us with some details.

Furthermore, we will also be able to inform you of new developments.

Dokument D

GB-0600 Dokum D Anbaugeräte - 3 -

ALOIS PÖTTINGER Maschinenfabrik GmbH

A-4710 Grieskirchen

Tel. (07248) 600 -0

Telefax (07248) 600-511

GEBR. PÖTTINGER GMBH

D-86899 Landsberg/Lech, Spöttinger-Straße 24

Telefon (0 81 91) 92 99-111 / 112

Telefax (0 81 91) 92 99-188

GEBR. PÖTTINGER GMBH

Servicezentrum

D-86899 Landsberg/Lech, Spöttinger-Straße 24

Telefon (0 81 91) 92 99-130 / 231

Telefax (0 81 91) 59 656

Machine checked according to delivery note. All attached parts removed. All safety equipment, drive shaft and operating

devices at hand.

Operation and maintenance of machine and/or implement according to operating instructions explained to the customer.

Tyres checked re. correct pressure.

Wheel nuts checked re. tightness.

Drive shaft cut to correct lenght.

Correct power-take-off speed indicated.

Fitting to tractor carried out: to three-point linkage

Trial run carried out and no defects found.

Functions explained during trial run.

Pivoting in transporting and operating position explained.

Information given re. optional extras.

Absolute need to read the operating manual indicated.

Please check. X

According to the product liability please check the above mentioned items.

INSTRUCTIONS FOR

PRODUCT DELIVERY

GB

In order to prove that the machine and the operating manual have been properly delivered, a confirmation is necessary.

For this purpose please do the following:

- sign the document A and send it to the company Pöttinger

(in case of Landsberg equipment: to the company Landsberg)

- document B stays with the specialist factory delivering the machine.

- document C stays with the customer.

GB

0800_GB-INHALT_377 - 4 -

WARNING SIGNS

CE sign .............................................................................................. 5

Meaning of warning signs ................................................................. 5

ATTACHING TO TRACTOR

Attaching implement to tractor.......................................................... 6

Adjusting lower links.......................................................................... 7

Important recommendation!.............................................................. 7

Fitting drive shaft .............................................................................. 7

Parking in the open ........................................................................... 7

TRANSPORT- AND WORKING POSITION

Conversion from working to transport position................................. 8

Conversion from transport to working position................................. 8

Transport position - 1 ....................................................................... 9

Transport position - 2 ....................................................................... 9

Transport position - 3 ..................................................................... 10

Transport position - 4 ..................................................................... 10

Reducing the Total Height .............................................................. 10

DISMOUNT AND PARKING

Dismount implement from tractor ................................................... 11

Parking the implement .................................................................... 12

Support Stand ................................................................................. 12

Take care when turning on slopes!.................................................. 13

STARTING WORK

Important points before starting work............................................. 14

Safety hints...................................................................................... 14

Operation......................................................................................... 15

Adjustment ...................................................................................... 15

CONDITIONER

Mowing with the conditioner........................................................... 16

Correct belt tension......................................................................... 16

Position of the rotor prongs............................................................. 16

Dismounting and mounting the conditioner.................................... 17

Mowing without Conditioner ........................................................... 19

Optional extra.................................................................................. 19

Settings ........................................................................................... 21

Cleaning and maintenance.............................................................. 21

SET THE POSITIONS OF THE GUIDING PLATES

"Extra dry" system........................................................................... 22

Dismount guide plate ...................................................................... 23

Mount guide plate ........................................................................... 23

SWATH DISCS

Swath Discs..................................................................................... 24

Flat cone conveyor (Optional extra) ................................................ 24

COLLISION SAFETY DEVICE

Collision safety device..................................................................... 25

How the hydraulic collision safety device functions ....................... 25

Function of collision safety device .................................................. 25

MAINTENANCE

Safety point ..................................................................................... 26

General maintenance hints.............................................................. 26

Cleaning of machine parts .............................................................. 26

Parking in the ope ........................................................................... 26

Winter storage ................................................................................. 26

Drive shafts...................................................................................... 26

Hydraulic unit .................................................................................. 26

Cutter bar oil level check ............................................................... 27

Changing oil - Angular gear............................................................. 28

Installing cutter blades ................................................................... 28

Changing oil - Cutter bar................................................................. 28

Check initial spring tension. ............................................................ 29

Alter spring tension ......................................................................... 29

Tabel: ............................................................................................... 30

Checking wear on mowing blade holders....................................... 31

Holder for a quick change of cutter blades..................................... 32

Checking the mowing blade suspension ........................................ 32

Changing the Cutter Blades (up to 2003 model)............................. 32

Changing the Cutter Blades (from 2004 model).............................. 33

Storing the lever .............................................................................. 33

TECHNICAL DATA

Technical data ................................................................................. 34

Optional equipment:........................................................................ 34

Necessary connections ................................................................... 34

The dened use of the mower unit.................................................. 35

Position of Vehicle Identication Plate ............................................ 35

SUPPLEMENT

Driveshaft ........................................................................................ 39

Lubrication chart ............................................................................. 41

Lubricants........................................................................................ 43

Attachment variations...................................................................... 45

Repairs on the cutter bar................................................................. 46

Combination of tractor and mounted implement............................ 47

- 5 -

9700_GB-Warnbilder_361

GB

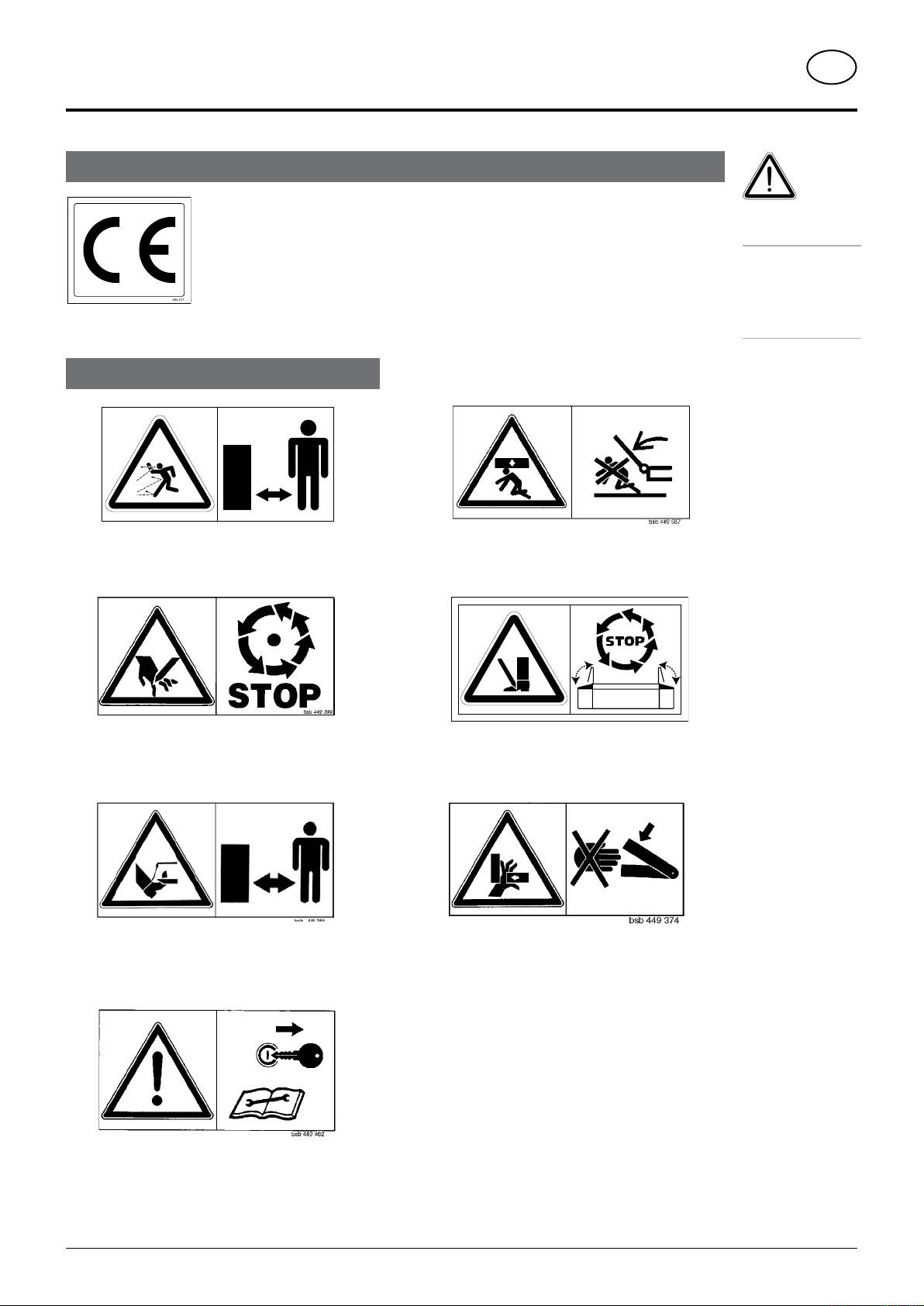

Warning signs

Stay clear of swinging area of implements

Close both side protective coverings before engaging

p.t.o..

Never reach into the crushing danger area as long as

parts may move.

CE sign

The CE sign, which is affixed by the manufacturer, indicates outwardly that this machine

conforms to the engineering guideline regulations and the other relevant EU guidelines.

EU Declaration of Conformity (see supplement)

By signing the EU Declaration of Conformity, the manufacturer declares that the machine being

brought into service complies with all relevant safety and health requirements.

Meaning of warning signs

Danger - flying objects; keep safe distance from the

machine as long as the engine is running.

Wait until all machine components have stopped

completely before touching them.

Stay clear of mower knife area as long as tractor engine

is running with PTO connected.

Shut off engine and remove key before performing

maintenance or repair work.

Recommendations

for work safety

All points referring

to satety in this

manual are

indicated by this

sign.

bsb 447 410

495.167

(348) ANBAU 0000-GB

GB

- 6 -

attaching tO tractOr

Attaching implement to tractor

Safety hints:

see supplement-A1 points 7.), 8a. - 8h.)

- Attach mower so that the edge of the tractor-side drum is just outside the right-hand

tractor tyre!

- See also chapter "Side-located attachment", supplement-D

- Adjust lower link bolt (1) on frame accordingly.

- Bring frame into horizontal position by adjusting linkage arm spindle (15).

- By turning upper link spindle (16) the cutting height is adjusted .

(348) ANBAU 0000-GB

attaching tO tractOr GB

- 7 -

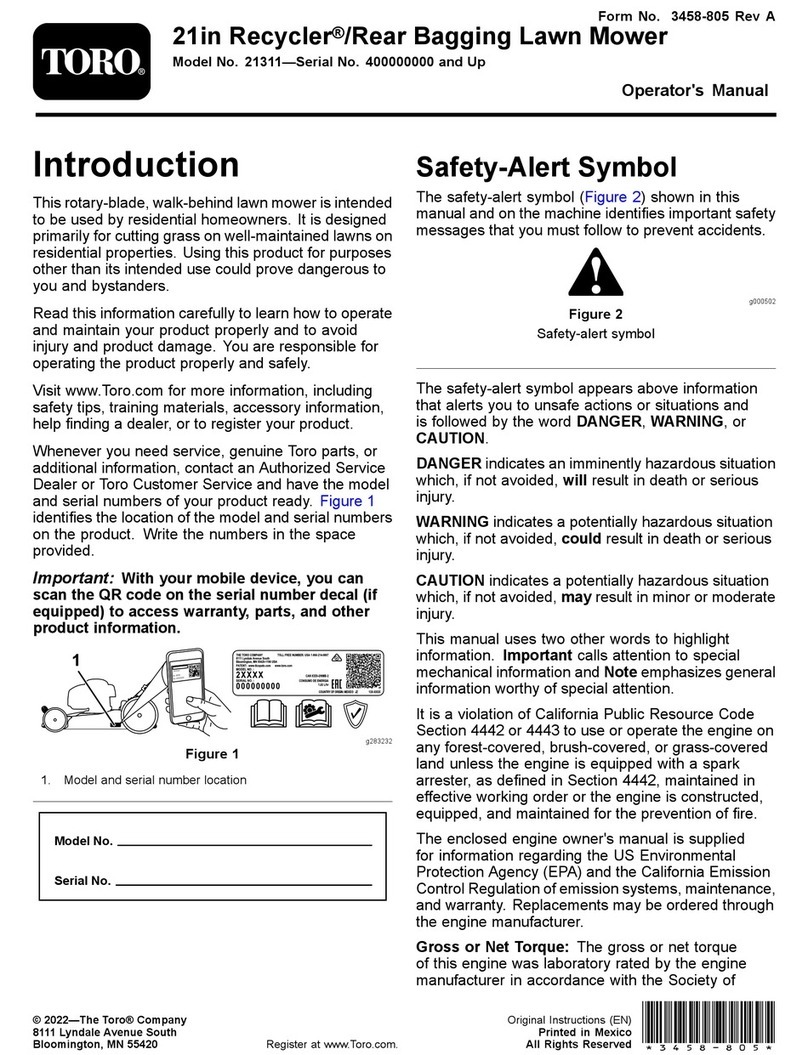

Adjusting lower links

• The drive shaft (GW) position should be approximately horizontal

when mowing.

- Set the tractor's lifting gear accordingly (H1)

- Set the tractor hydraulics (ST) using the bit stop.

This height allows optimal evenness when working on uneven ground

and need not be changed for swinging cutter bar up.

- Connect hydraulic snap coupling for swivel cylinder.

Important recommendation!

A transfer, which is located near the gear, advises which p.t.o. speed

your mower unit is equipped for.

Standard: Gear for power take-off 1000 rpm.

Optional exra: Gear for power take-off 500 rpm.

Order number: spare part book

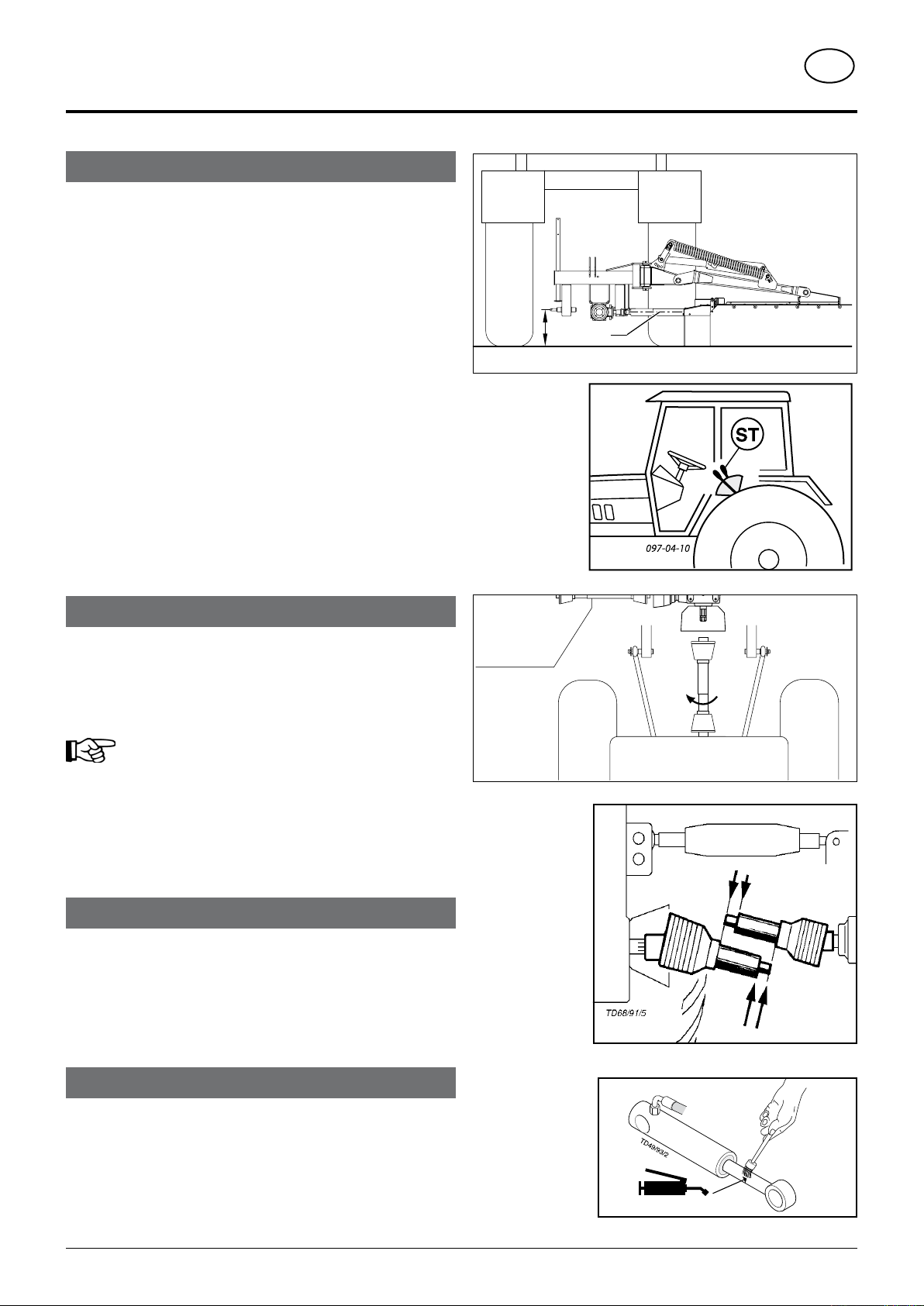

Fitting drive shaft

- Before operating for the first time, drive shaft is to be checked and

adapted if necessary. See alse chapter "Drive Shaft" in supplement

B.

Parking in the open

When parking for longer periods in the open, clean plunger rods and

then coat with grease.

H1 GW

TD 4-00-1

1000 rpm

540 rpm

TD 18/96/2

Standard (540 rpm)

Standard (540 rpm)

FETT

(348) TRANSPORTSTELLUNG 0400-GB

GB

- 8 -

Attention!

Take care with transport positions 1, 2, 3.

Before swivelling the cutter bar up, turn

off the drive and wait for the mower discs

to come to a complete standstill.

NOTE:

The implement has been so designed that the mower

unit is positioned as close as possible to the tractor.

This has important advantages for both mowing and

transporting operations.

• The implements´s centre of gravity lies close to the

tractor and through this

- less supporting structure load

- less load alleviation of the steering axle when

transporting

- better cutter bar ground adaption when mowing

• Themowerbarcanbeswivelledinto3differentpositions

for transportation.

Safety Precaution!

see supplement-

A1 points 7.), 8c.

- 8h.)

Changing from

working position

to transport

position is only

to be carried out

on even, firm

ground.

Never let mowing

mechanism run

with the mower

raised.

Swinging cutter bar down

- Make sure that

swivelareaisfree

and that nobody

is standing in the

danger area.

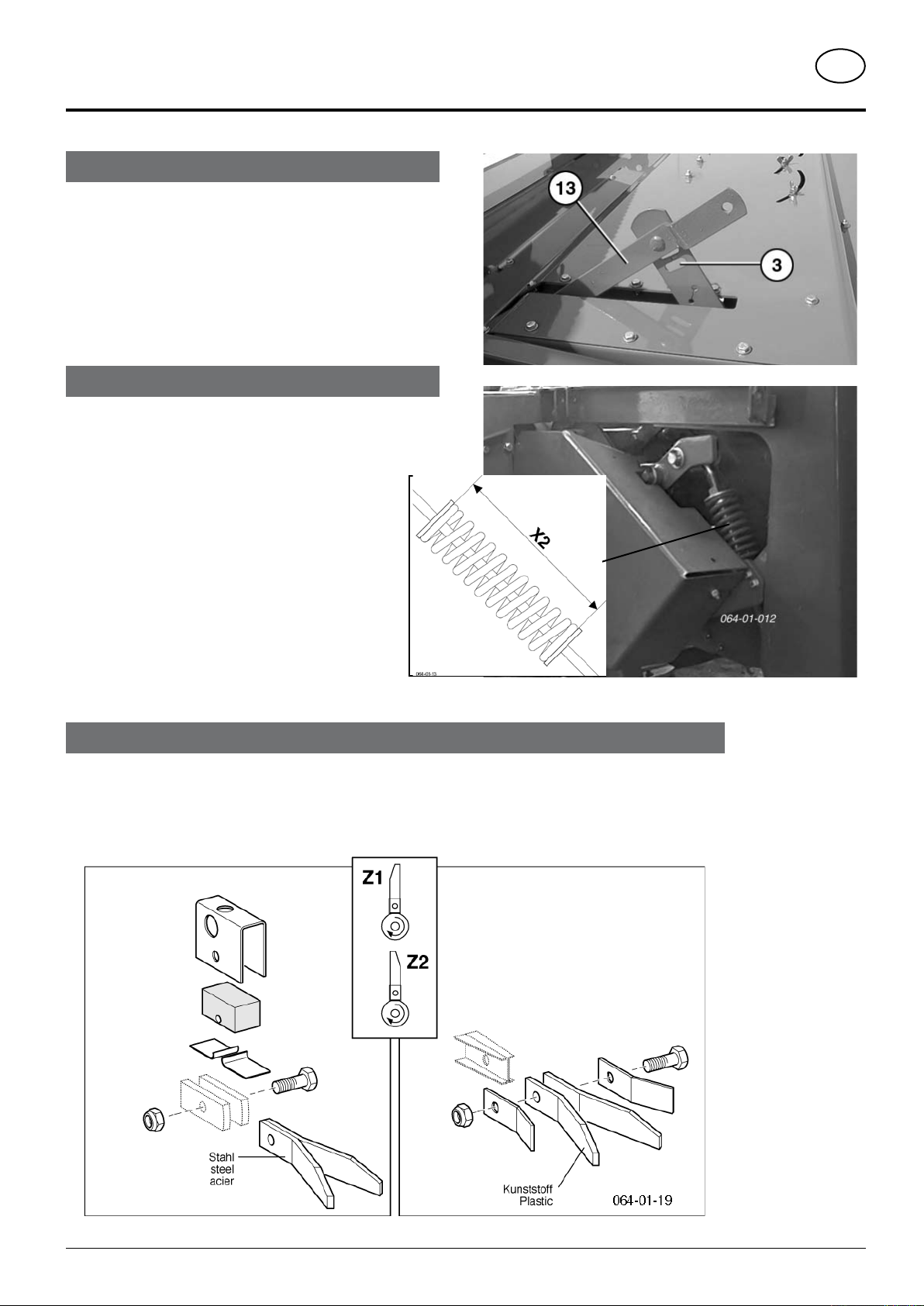

Conversion from working to transport position

Conversion from transport to working position

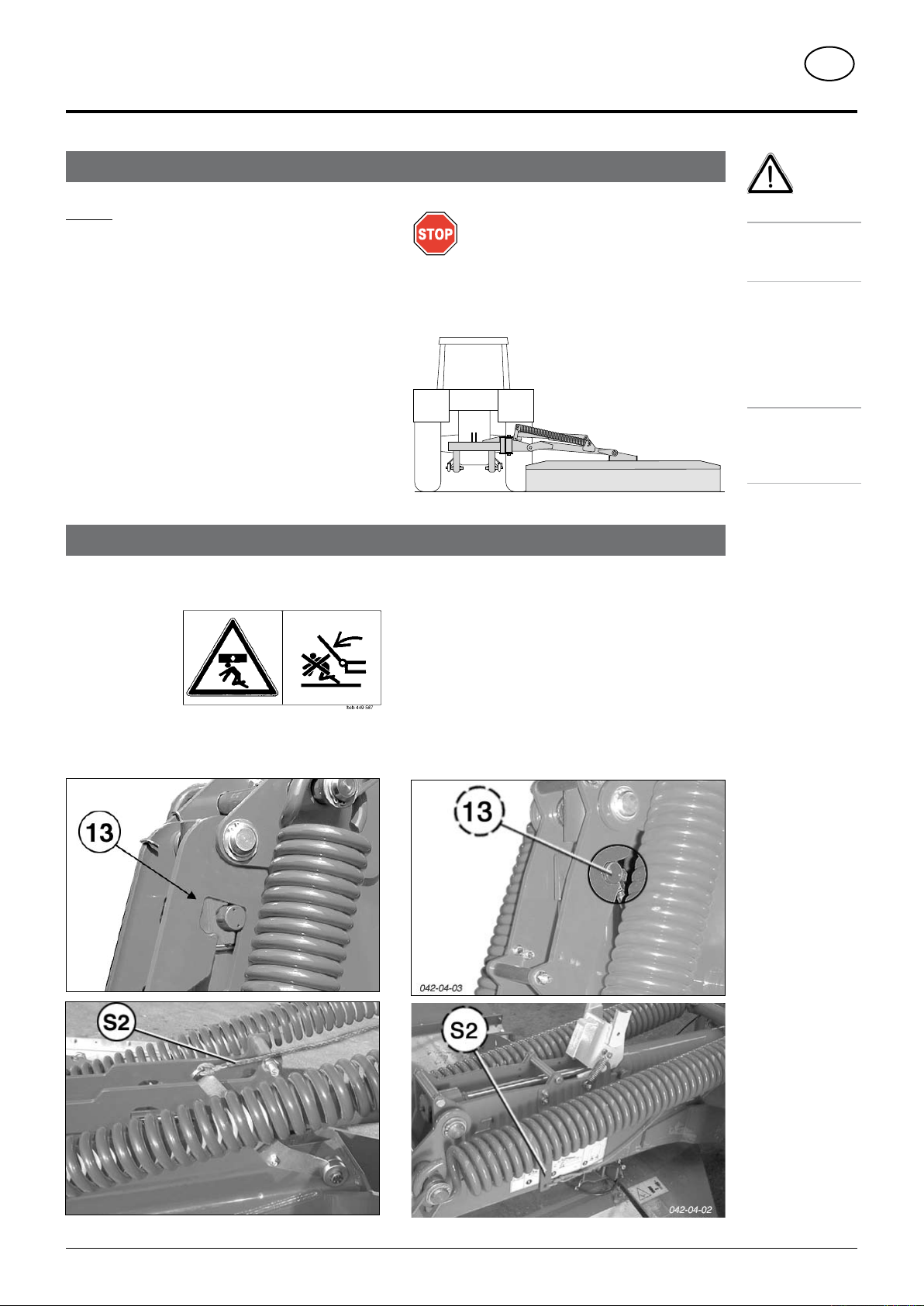

- Gently raise cutter bar with swivel cylinder so that hook

(13) can be released.

- Release hook (13) by pulling on the rope (S2).

- Lower cutter bar hydraulically.

Up to 2003 model From 2004 model

48/00/20

transpOrt- and WOrking pOsitiOn

(348) TRANSPORTSTELLUNG 0400-GB

GB

- 9 -

transpOrt- and WOrking pOsitiOn

Transport position - 2

Mower bar swivelled back.

Cutter bar o the rear and swivelled up until it stops

(approx. 20°)

Note: Only short trips at low speed may be carried

out in this position

Variant 1:

Without hydraulic slewing mechanism

- Lower cutter bar to ground.

- Release bolt (40) by pulling

on the rope (S1) and move

forwards with the tractor.

In doing so, the cutter bar

swivels back so far until

the bolt (40) is locked into

position.

- Raise the implement using

the tractor's lifting gear.

Variant 2:

With hydraulic slewing mechanism

An additional double-action hydraulic connection is

necessary on the tractor.

Ahydraulicunitis installed instead of a mechanicalslewing

unit (with bolts 40). See chapter “Collision Safety”.

- Raise cutter baractuate

single-action control valve (ST)

- Swivel cutter bar to the rearactuate

double-action control valve (ST)

Transport position - 1

Mower bar only swivelled up at the side.

- Pull on rope (S2) and simultaneously actuate servo-

valve (ST).

- Gradually move cutter bar into vertical position and

release rope (S2).

- Secure cutter bar with hook (13).

- Servo-valve (ST) to O

position

Tips for transportation:

Do not move the servo-valve (ST) to the ”float” position.

The hook (13) will become very worn.

- Before driving on roads always check correct

locking!

- Connect lighting and raise implement for transport.

- Before leaving the tractor lower cutter bar to ground!

Ensure a sufficient gap (X1) !

Incombination with larger tractor types, it couldhappen

that there is insufficient gap

to the mud guard or tyre

(X1) which could then cause

a cxollision with the cutter

bar.

If this is the case, this

transport position must not

be used.

It is possible to try to move

the cutter bar further to the

right.

- Insert lower linkage bolts

accordingly (see instructions in the supplement to

this manual)

- However the total sidth must not exeed a

maximum

Attention!

Important

instructions

in the chapter

entitled ”Parking

the implement”

02/00/05

02/00/04

X1

02/00/08

max. 3 m

(348) TRANSPORTSTELLUNG 0400-GB

GB

- 10 -

transpOrt- and WOrking pOsitiOn

Transport position - 3

Cutter bar to the rear and swivelled up (approx.

90°).

1. Swivel mower bar back as described in "Transport

Position - 2".

2. Move mower bar into vertical position as described in

"Transport Position - 1".

- Secure cutter bar with hook (13).

3. Before driving on roads always check correct

locking!

- Connect lighting and raise implement for transport.

- Before leaving the tractor lower cutter bar to ground!

Transport position - 4

Cutter bar laterally swivelled up (approx. 20°)

- this position upwards is limited by a stop buffer.

• only for turning manoeuvres in the field.

• do not use on roads or public thoroughfares!

Reducing the Total Height

Before converting to transport position

• The external guard plate (10) can be swivelled in to

reduce the total height (- 30 cm) when in the transport

position.

Note:

For safety reasons

the mower

disks must be

at a complete

standstill before

swivelling the

guard plate.

02/00/06

TD48/00/21

30cm

10

02/00/07

0400_GB-Abbauen_348

GB

- 11 -

Dismount implement from tractor

Attention!

• Always

park implement

steadfast

• Use

support stand -

otherwise danger

of tipping

• Danger of injury

from crushing

and shearing

sections in

the area of the

support stand

• Follow the

instructions on

the following

page also.

Instructions

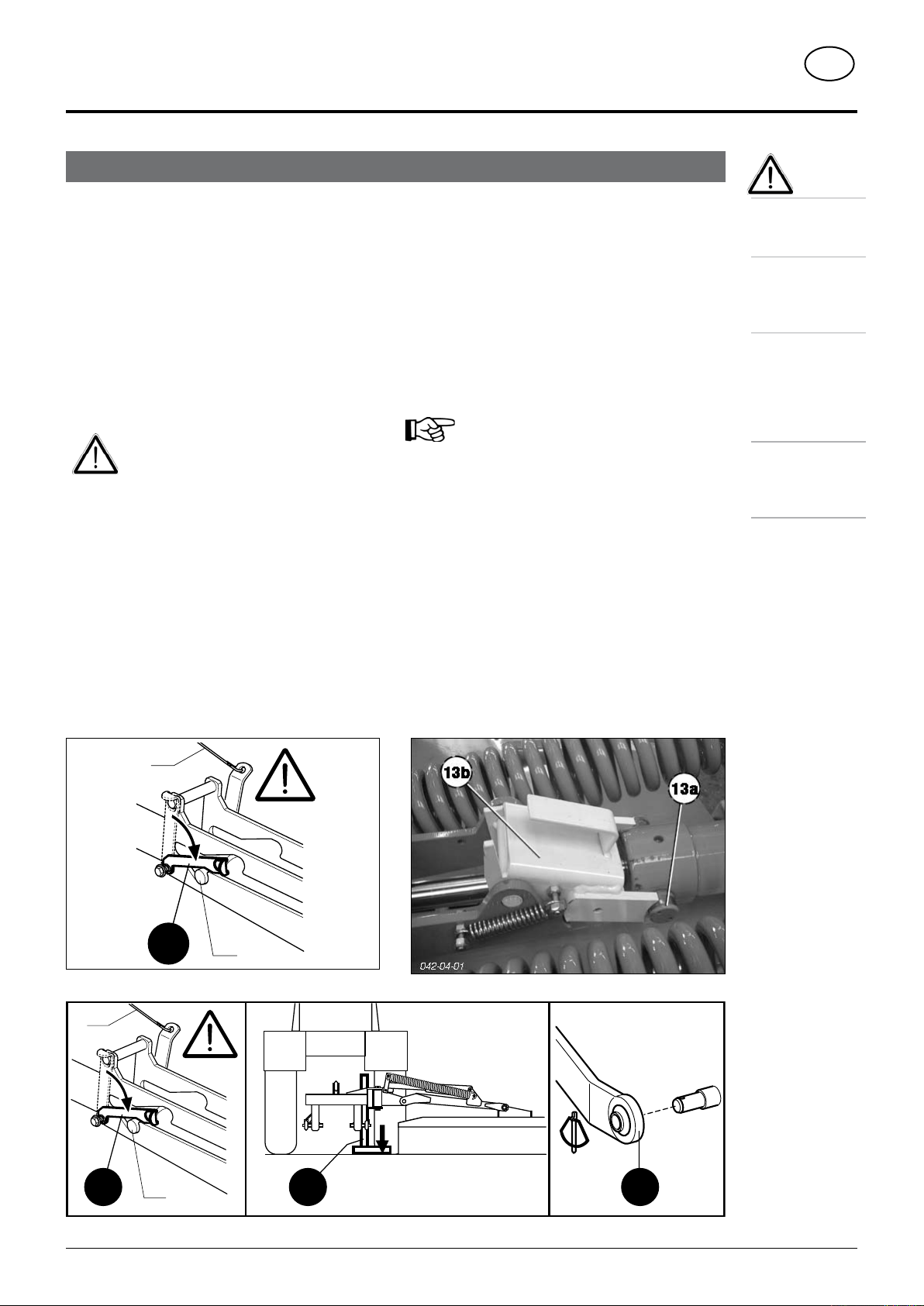

The lever 13b is a safety device. It should not be

changed in its form and functions.

Theleverissoconstructed thatitwillnotspringoutfrom

the bolt position (13b, 13a) during hydraulically slewing

of the mowing bar. The lever is thus only damaged

(deformed) but remains in the bolt position.

Thishas been arranged by the manufacturer – forsafety

reasons.

• Do not operate the hydraulic cylinder to

slewacrossthemowing bar whenthe lever

is in the bolt position

• Exchangedamagedleversimmediatelyfor

new ones.

Important!

Keep to the order of operation

1. Shift servo to floating position so that no residual air

pressure remains in hydraulic lines.

2. Let bolt (13a) rest in the hook.

- Pull the rope (S2)

- Lower mounting frame with lifting gear until the bolt

(13a) rests in the hook.

3. Move the lever (13b) to the locking position

Doing this secures the bolt (13a) in the hook

This safeguard is important!

Otherwise the danger exists that the

mounting frame of the cutter bar could

swivelupinjerksandjoltswhenuncoupling

the lower link

4. Bring support stand (14) into support position and

secure with linch pin

5. Lower lifting gear far enough so that implement stands

on support stand on the ground

6. Dismount implement from tractor (15)

- Uncouple drive shaft.

- Uncouple hydraulic lines.

- Remove rope from tractor cabin.

Up to 2003 model From 2004 model

15

14

495-733a

S2

13a

13b

15

14

495-733a

S2

13a

13b

dismOunt and parking

0400_GB-Abbauen_348

GB

- 12 -

dismOunt and parking

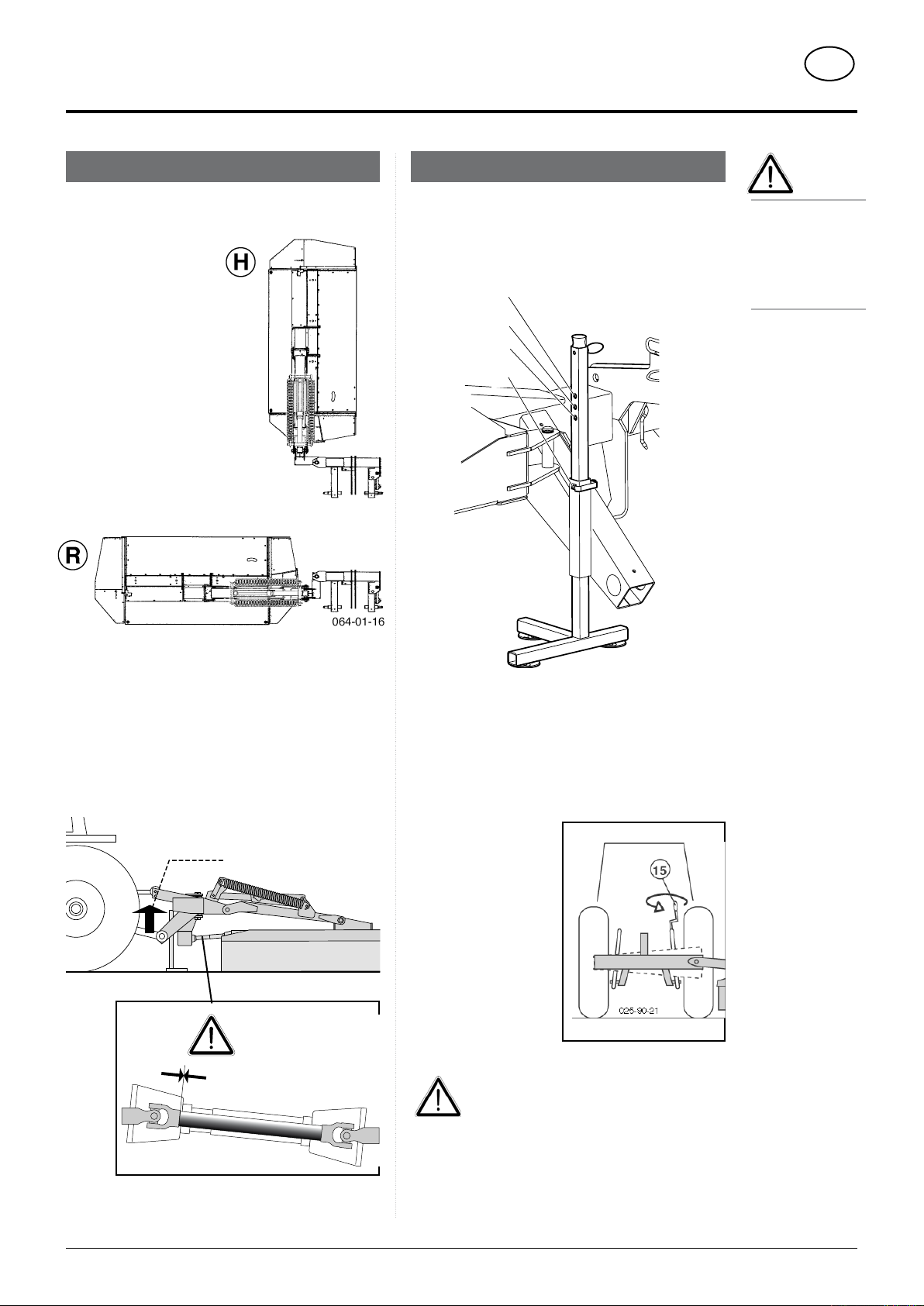

Support Stand

The support stand can be pinned in 4 positions

Positions 1, 2, 3: when parking the implement

Position 4: For transport and operating positions

Parking the implement on the support stand

Any position (1, 2, 3) can be chosen which enables

lifting gear to be uncoupled without problems.

Nevertheless, should a problem arise when

uncoupling the lifting gear

- park the implement on

flat, firm ground

- turn the lower link

adjusting spindle (15)

far enough so that

the lower link can be

pulled from the bolt.

Caution!

Crushing and shearing sections in the lifting

gear area.

Parking the implement

The implement can be parked in two positions (R and

H).

• Donotsetthehydraulic

controlvalveto floating

position if the support

stand is raised.

Attention! (STOP)

The support stand should not be raised too high

- if the implement is parked in ”H” position and the

hydraulic control valve is set to floating position.

The drive shaft could thus be damaged as it is telescoped

on to the bar (0mm).

Beware!

Before

uncoupling

the lower link,

always secure

the bolt 13a with

the lever 13b.

1

2

3

4

48-00-24

064-01-014

STOP

0 mm

064-01-015

(358) 9500-GB HANGFAHRT - 13 -

WOrking On sLOpEs GB

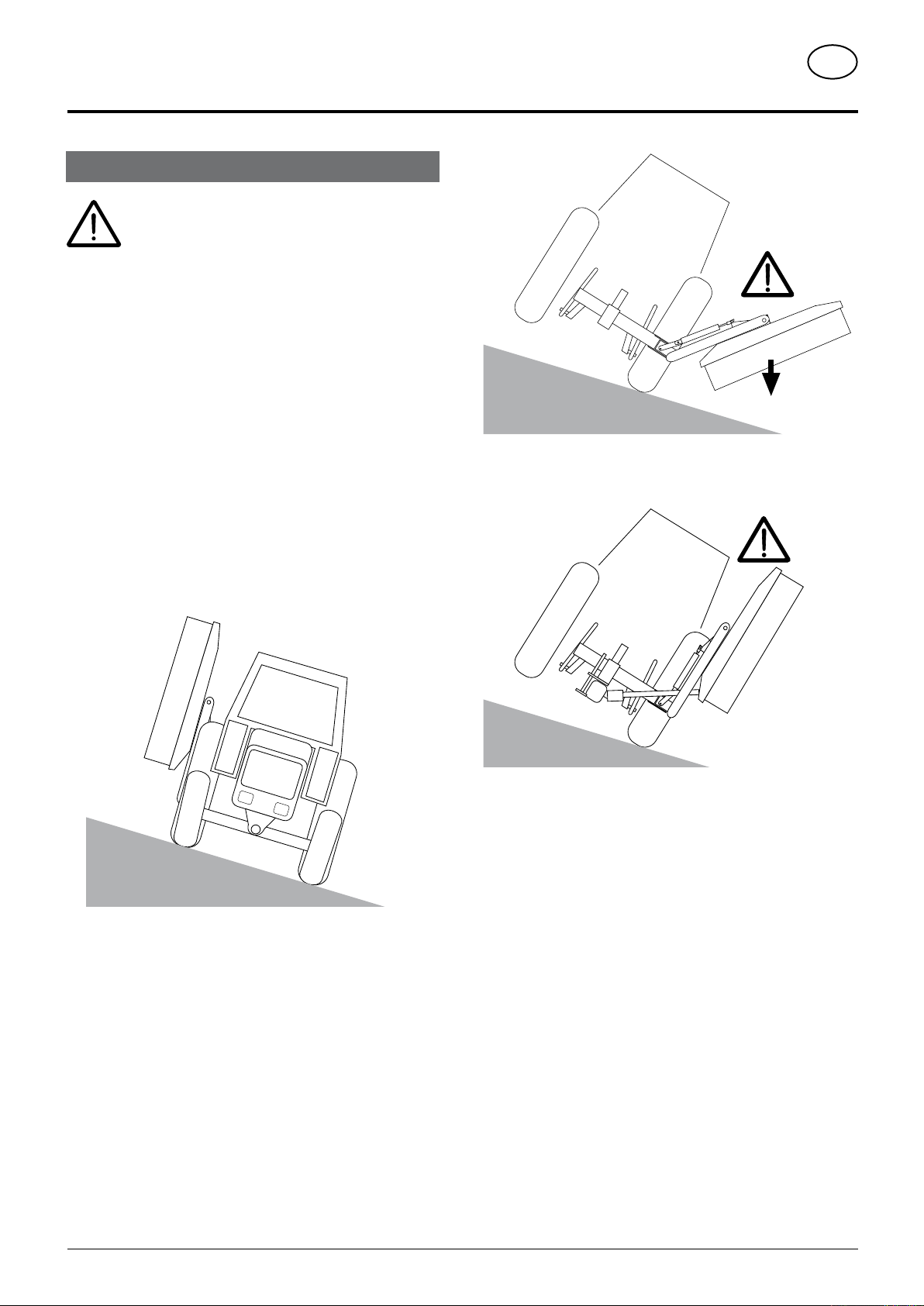

Take care when turning on slopes!

Thetractor'stravelling characteristicsare influenced

by the weight (G) of the mower unit. This can lead to

dangerous situations, especially on slopes.

Danger of tipping occurs

- when the mower unit is facing downhill and in a raised position,

- when travelling in a left-hand curve with the mower unit raised,

- whentravelling in a left-handcurve in the transportposition(mower

unit completely raised).

Safety advice

• Reduce speed in left-hand curves accordingly.

• Travel so that the raised mower unit is facing uphill.

• It is better to travel in reverse on a slope than to carry out a risky

turning manoeuvre.

TD15/95/3

G

TD15/95/2

TD15/95/4

(379) 0100-GB INBETRIEBN - 14 -

GB

starting WOrk

Important points before starting work

Safety hints:

see supplement-A1 points 1. - 7.)

After the first hours of operation

• Retighten all knife screw fittings.

Safety hints

1. Check

- Check the condition of knives and the knife holder.

- Check cutting drums for damage (see also chapter

"Maintenance").

2. Switch-on the machine only in working position and do

not exceed the prescribed power take-off speed (for

example max. 540 rpm).

A transfer, which is located near the gear, advises which p.t.o.

speed your mower unit is equipped for.

• Turn thep.t.o.ononlywhen allsafetydevices(coverings,protective

aprons, casings, etc.) are in proper condition and attached to the

implement in the correct protective positions.

3. Pay attention to correct p.t.o. direction of

rotation!

4. Damage protection!

• Thesurfacetobemowedmustbefreeofobstructions

or foreign objects. Such objects (e.g. large stones,

pieces of wood, boundary stones, etc.) can damage

the mower unit.

In the event of a collision

• Stop immediately and switch off the drive.

• Carefully check the implement for damage. The mowing discs

and their drive shaft must be checked in particulare.

• Have the implement checked also by a specialist workshop if

necessary.

After any contact with foreign objects

• Check the condition of knives and the knife holder (see chapter

"Maintenance and service").

• Retighten all knife screw fittings.

4. Stay clear while engine is running.

- Keep people out of the danger zone - foreign bodies which can

be ejected by the mower could injure them.

Special care is

necessary on

or near stony

ground.

5. Wear hearing protection

The noise level in the workplace can deviate from the

measured value (see Technical Data) partly because

of the differing cabin types of various tractors.

• If a noise level of 85 dB (A) is reached or exceeded, the farmer must

have suitable hearing protection in readiness (UVV 1.1 §2).

• If a noise level of 90 dB (A) is reached or exceeded, the hearing

protection must be worn (UVV 1.1 § 16).

01-00-10

4a

540 Upm 100 0 U pm

bsb 447 410

TD8/95/6

(379) 0100-GB INBETRIEBN - 15 -

GB

starting WOrk

Operation

1. Adjust cutting height by turning upper link spindle

(inclination of the cutting discs max. 5°).

2. To mow, gradually supply power to the p.t.o. before

entering the crop and bring the mowing discs up to full

revs.

Smoothly increase the p.t.o. speed, in order to avoid noises in

the free-wheel conditioned by the system.

- Adjust travel speed to terrain and crop.

Adjustment

- Adjust tractor hydraulics in a way that the machine can adapt to

uneven ground.

- Put hydraulic control device (ST) into "free gear" (floating

position or "lower")

- Thedriveshaft(GW)positionshouldbeapproximatelyhorizontal

when mowing.

- Frame horizontal.

- Fix hydraulic lower links in a way that the machine cannot swing

out sideways.

H1 GW

TD 4-00-1

- 16 -

0500-GB AUFBEREITER_348

GB

cOnditiOnEr

Mowing with the conditioner

The conditioning effect can be modified:

- with lever (13), which adjusts the gap between adjustable plate

and rotor. The conditioning effect is most intense with the lever

at the bottom of its travel (Pos. 3).

However the crop should not be chopped.

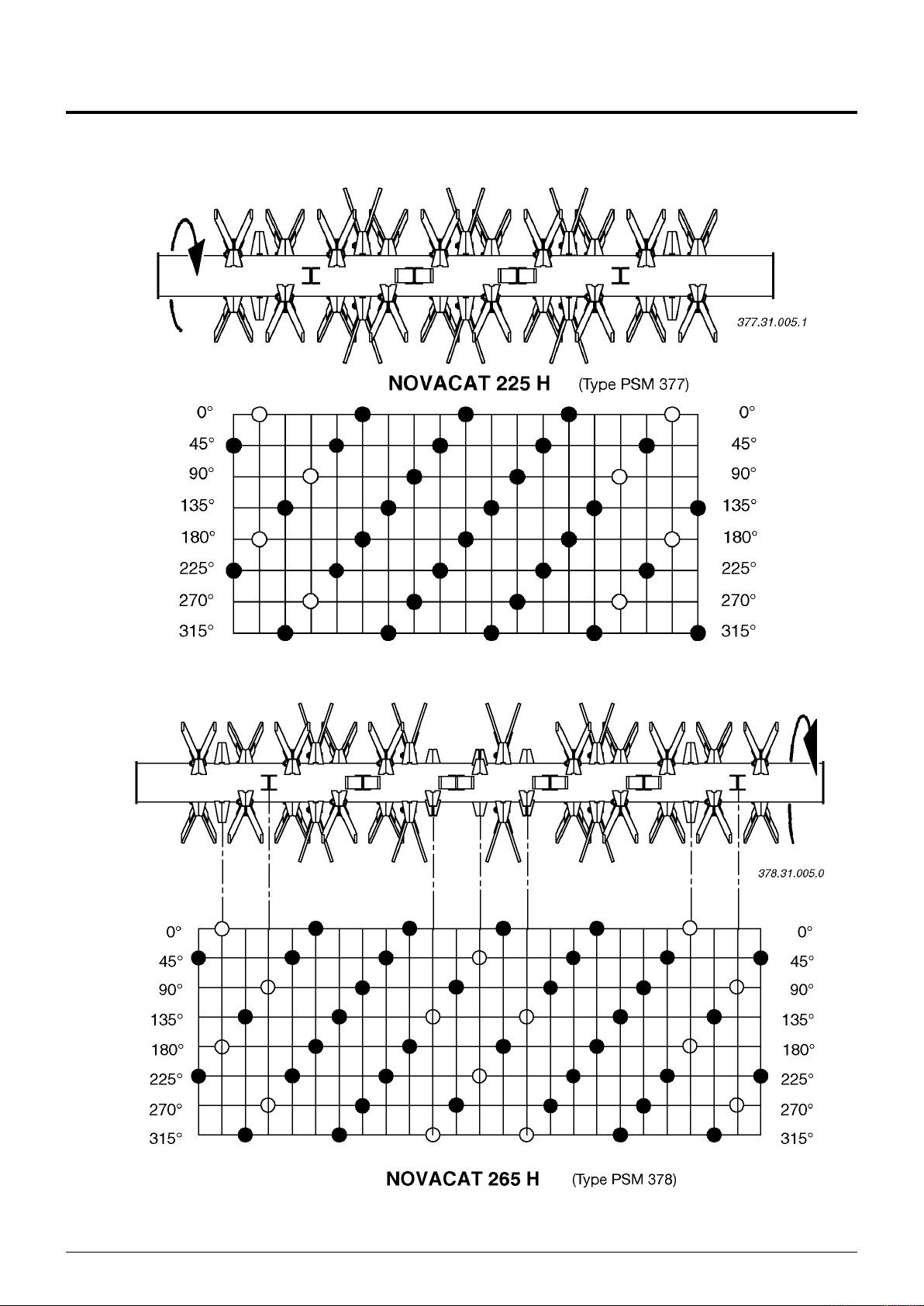

Correct belt tension

Check X2 size

NOVACAT 225: X2 = 164 mm

NOVACAT 265: X2 = 164 mm

NOVACAT 305: X2 = 164 mm

EUROCAT 275: X2 = 178 mm

Position of the rotor prongs

Pos. Z1: position of the rotor prongs for normal operating conditions

Pos. Z2: for difficult operating conditions if for example the chuck wraps around the rotor

The rotor prongs turn 180° (pos.Z2). This prong position removes the problem in most cases. The preparation effect is

thereby somewhat reduced.

- 17 -

0500-GB AUFBEREITER_348

GB

cOnditiOnEr

3. Remove belts

- Release the tension using lever (3) beforehand

4. Fit transport wheels (4)

- left and right

- secure with linch pin

Dismounting and mounting the

conditioner

Reduce spring tension before dismounting

the conditioner

Pin bolt (18) in the relative position (a, b, c)

- see chapter "MAINTENANCE"

Otherwise the danger exists that the

mountingframeofthecutterbarcouldswivel

up in jerks and jolts when uncoupling the

1. Loosen locking mechanism (1) and swing

protection (2) up.

2. Remove the belt protection (2) and withdraw

the drive shaft (GW) from the gear.

- 18 -

0500-GB AUFBEREITER_348

GB

cOnditiOnEr

5. Release left and right locks

• Spring loaded positioning bolt up to 2004

model

Remove linch pin (V1) and release bolts

• Pos. A = released

• Pos. B = Locked

• Screwed in from 2004 model

Remove screw (S)

(Spring loaded positioning bolt = optional)

6. Always park conditioner steadfast.

7. Mount the guard (5)

This guard (5) prevents the penetration of dirt into the

gear area.

Mounting the conditioner

- is effected in the reverse sequence to

dismounting.

Important!

When mowing

without

conditioner,

protective

elements and

the both swath

formers (SB)

must be mounted

additionally on the

cutter bar. Parts

see spare parts

- 19 -

0400-GB MÄHEN OHNE CR_375

GB

cOnditiOnEr

Take particular notice when the conditioner is

detached rom the cutter bar

Safety hint

A machine with a conditioner (CR) as a complete unit is fitted with proper

protection elements.

Should the conditioner be detached however, the mowing

unit no longer has complete protection covering. In this

situation mowing may not take place without additional

protection elements!

Beware!

Protection elements, especially intended for this mode of

mowing, must be fitted to the mowing unit.

These protection elements are not included in the delivery

of a new machine with a conditioner, the parts must be

additionallyordered(seeSpareParts List, component group

”REAR PROTECTION”).

Optional extra

- Chassis (4)

- Spring-loaded fixing bolts (A-B)

For mowing without conditioner (CR)

- Observe safety hint (above) without

reservation!

Mowing without Conditioner

- 20 -

0400-D ROTOR_377

This manual suits for next models

1

Table of contents

Popular Lawn Mower manuals by other brands

Snapper

Snapper 6413 parts manual

Husqvarna

Husqvarna P 520D With cabin Operator's manual

Yazoo

Yazoo YHRLD21 Illustrated parts list

Cub Cadet

Cub Cadet RZT 50 (w/50" Mower Deck) Operator's manual

Husqvarna

Husqvarna LB448S Operator's manual

Mr. GARDENER

Mr. GARDENER TRIKE 51 BT I Translation of the original instructions