Frost Free Technical Manual

9 | P a g e

Novum

Overseas.

The

Novum

Building

.

Clonshaugh

Ind

Est.

Dublin

17.

Ireland

|

[email protected] |

+35

3

1

803

6400

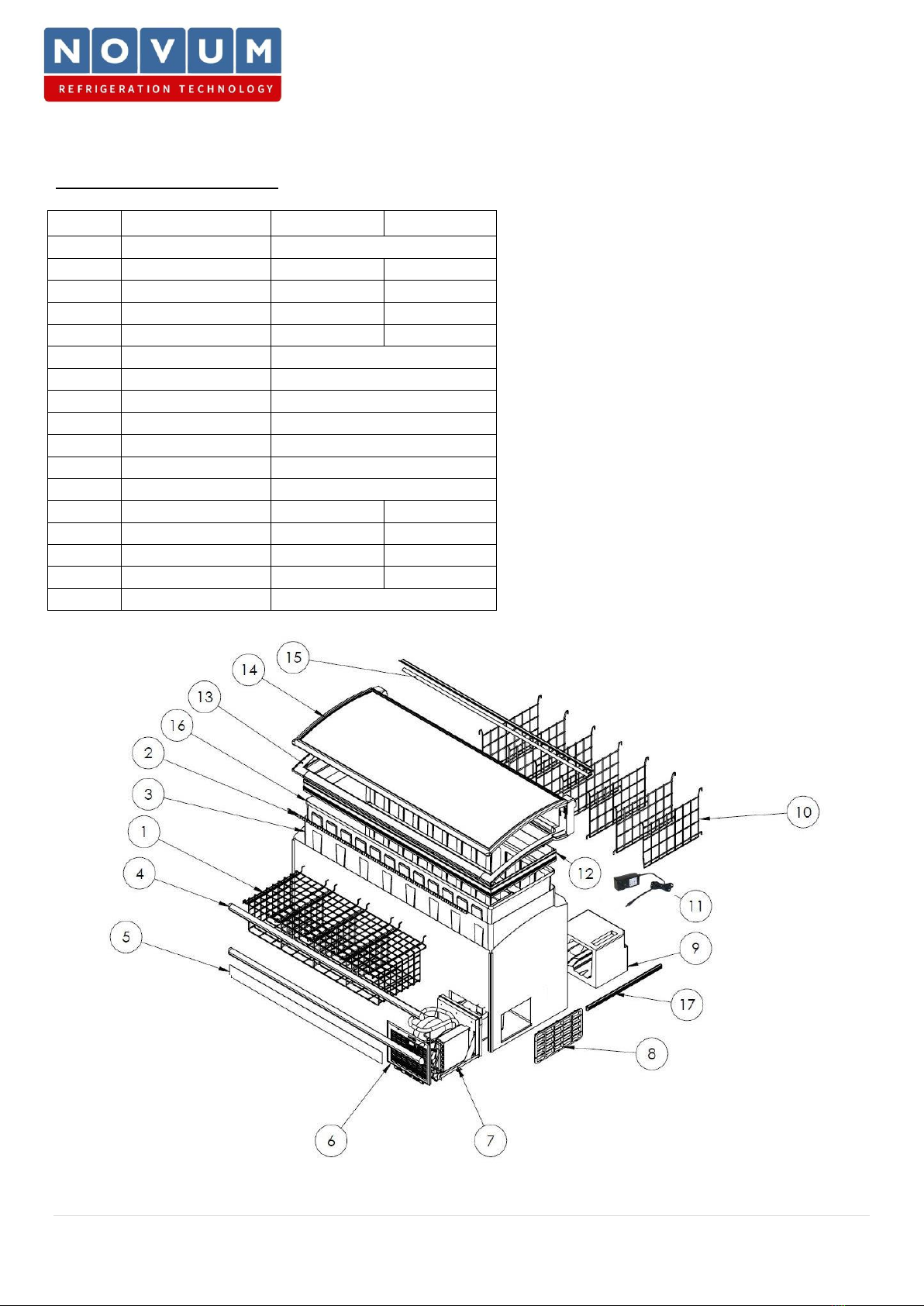

Care & Maintanance______________________________________________________________________

Note! Always unplug your Conservator before beginning any maintenance work.

To ensure trouble free operation of your Novum Cabinet, the following routine should be instituted.

•Inspect the area behind Cabinets

periodically and remove any debris.

•Clean the interior and exterior plastic

components of your cabinet with a mild

detergent. (Never use bleach or

abrasive material)

•Using only a damp cloth, clean the

interior tub and interior plastic

components with a mild detergent,

water/vinegar or ‘Vim’ liquid is also

suitable. (Never use bleach or abrasive

material) After cleaning, wipe away

excess residue.

•Use proprietary glass cleaner with soft

cloth to clean glass lid and front. (Never

use abrasive materials to clean glass)

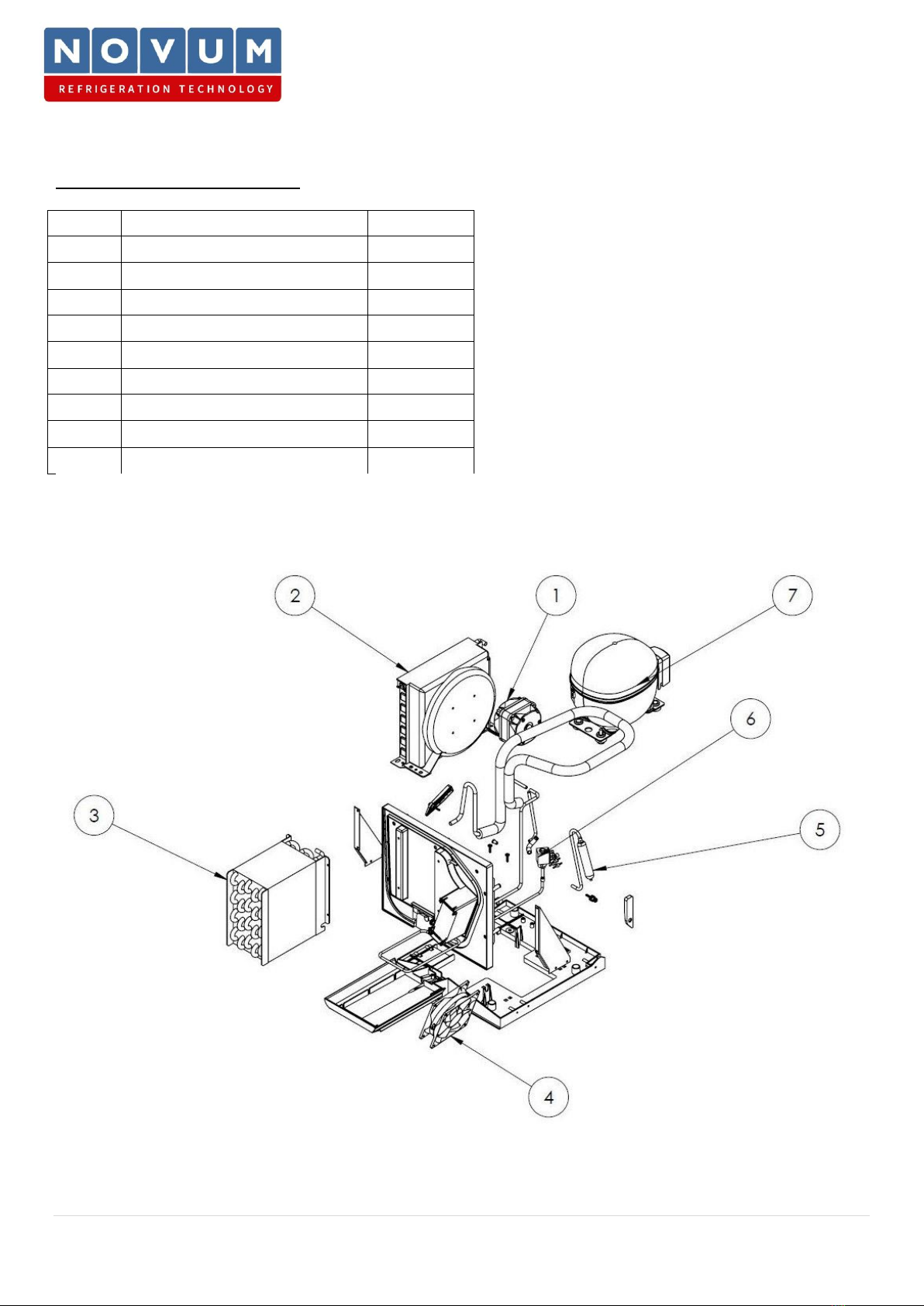

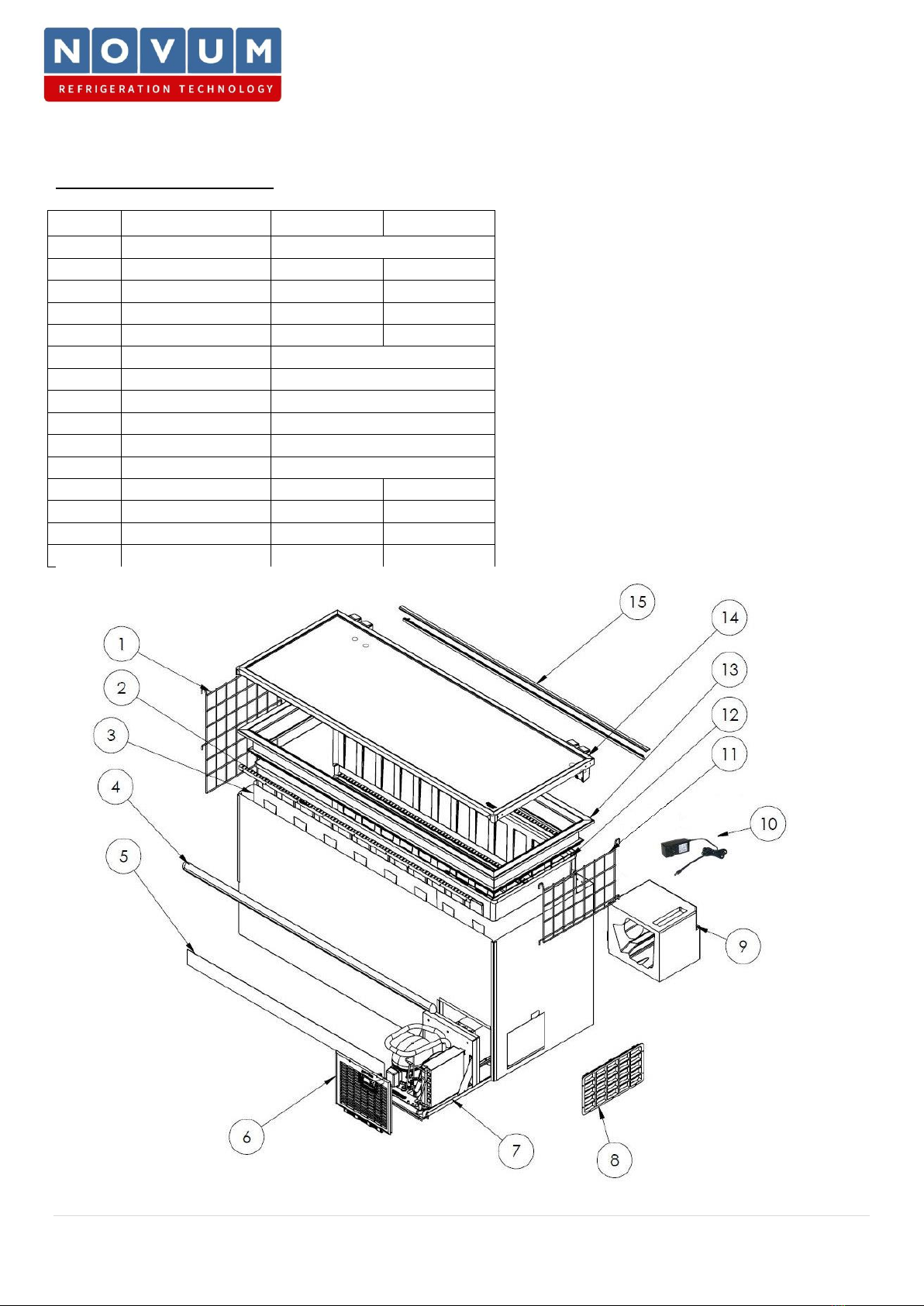

•Periodically inspect the Condenser for dust build up.

oDisconnect freezer from mains supply.

oRemove side grille by removing 4 x screws.

oRemove any dust build up with a non-metallic brush or vacuum cleaner.

oRefit side grille

oCondenser should be checked 3-4 times per year and cleaned as required.

•Best practice demands that all Cabinets should be thoroughly cleaned a minimum of once per year.

•Donotstoreflammablesubstancessuchasaerosolcanswithflammablepropellantinthisappliance.

•Novum Cabinets are conservators in nature and can be used to store and display previously frozen food.

•NEVER merchandise product above the red load limit sticker (565mm from base)

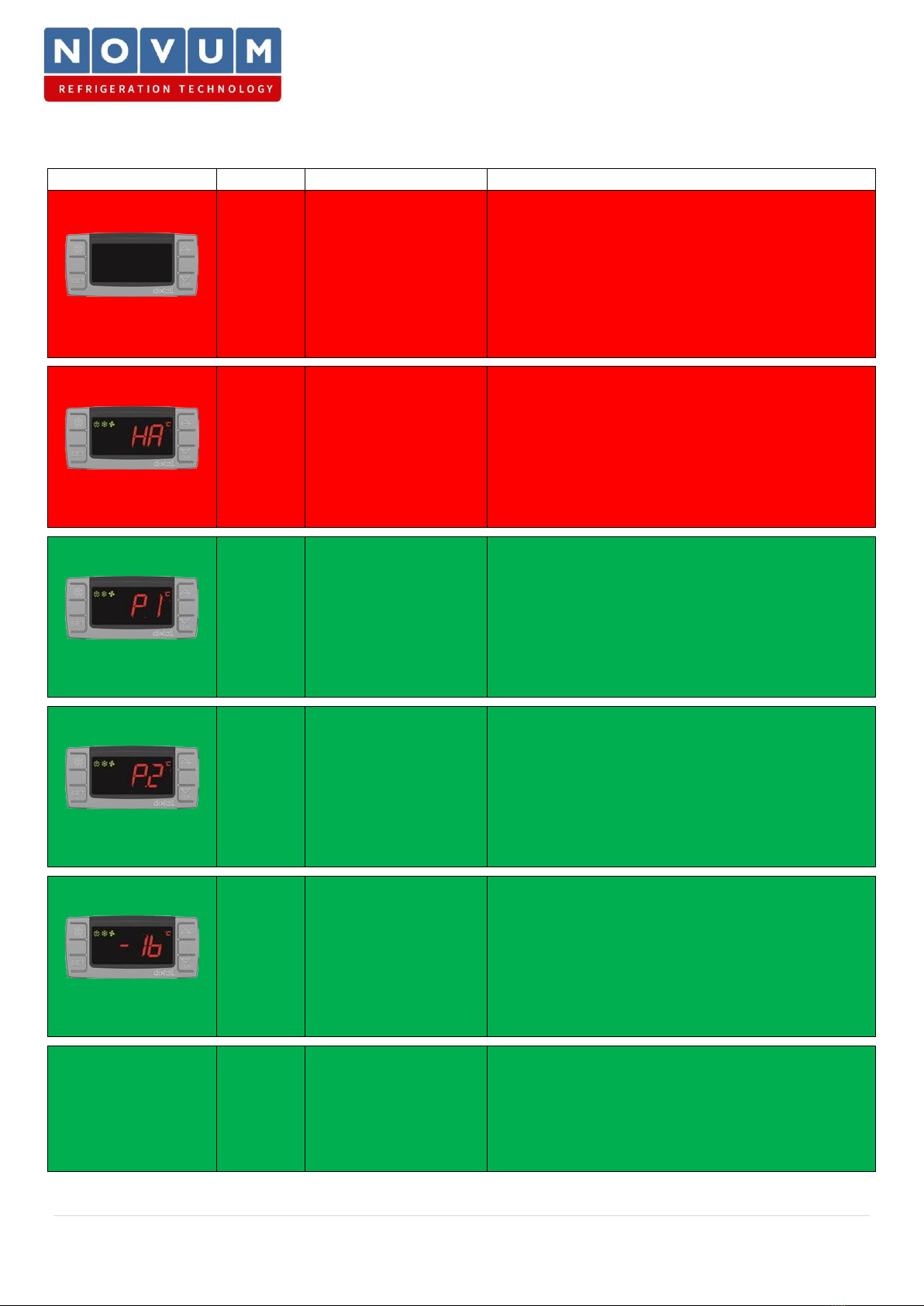

•As soon as the Cabinet has reached a storage temperature of below -18°C (as indicated by the Electronic

Controller display), it can be loaded with Frozen Foods up to the maximum of the Load Limit line.

•Do not load the Cabinet with non-frozen foods or try to freeze products in the Cabinet.

•DO NOT LEAVE LID OPEN for extended periods during merchandising.

•Exercise due care when loading heavy product, do not damage internal liner.