July 5/2011

1INSTALLATION .................................................................................... 3

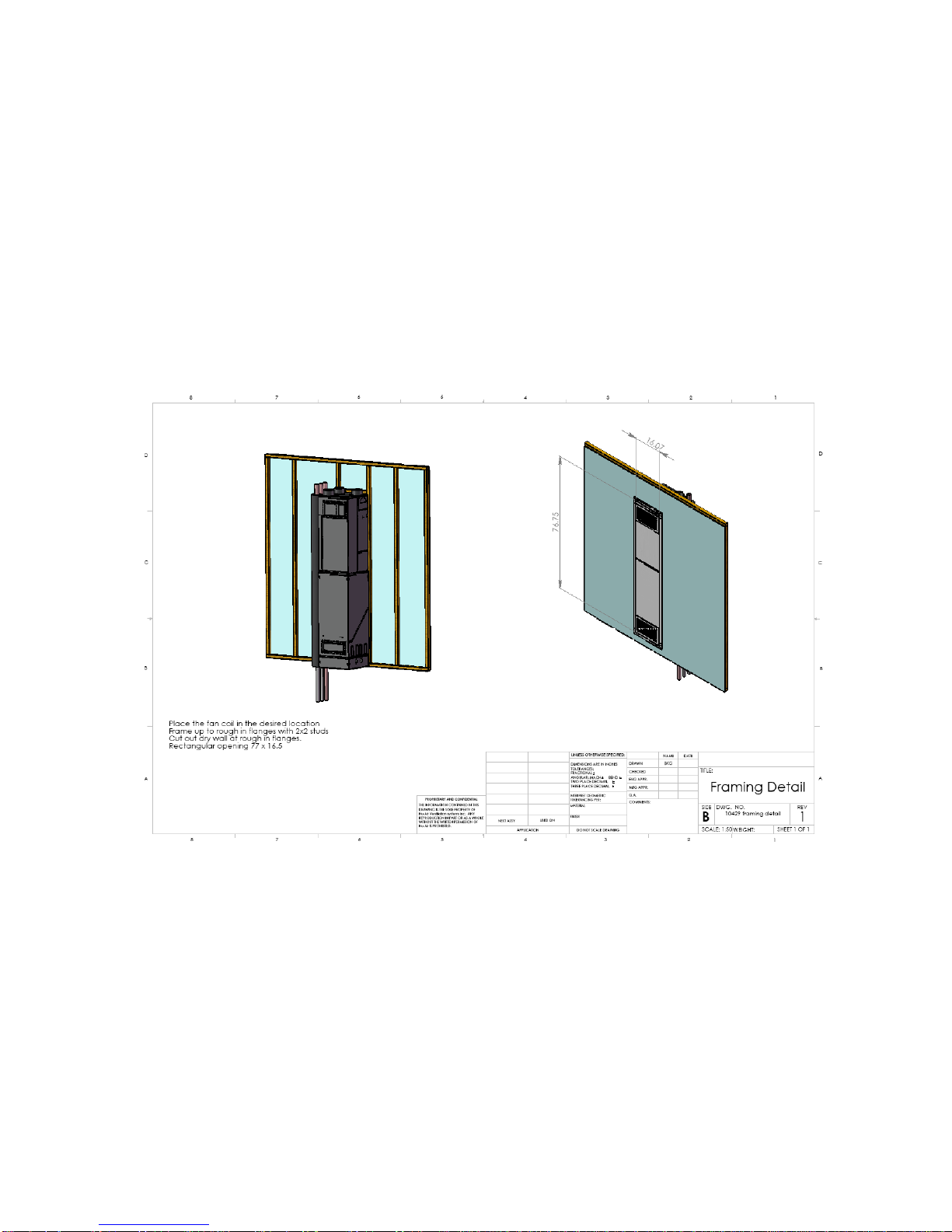

Locating the Fan Coil......................................................................................... 31.1

Framing............................................................................................................... 31.2

Electrical Power Connection............................................................................. 31.3

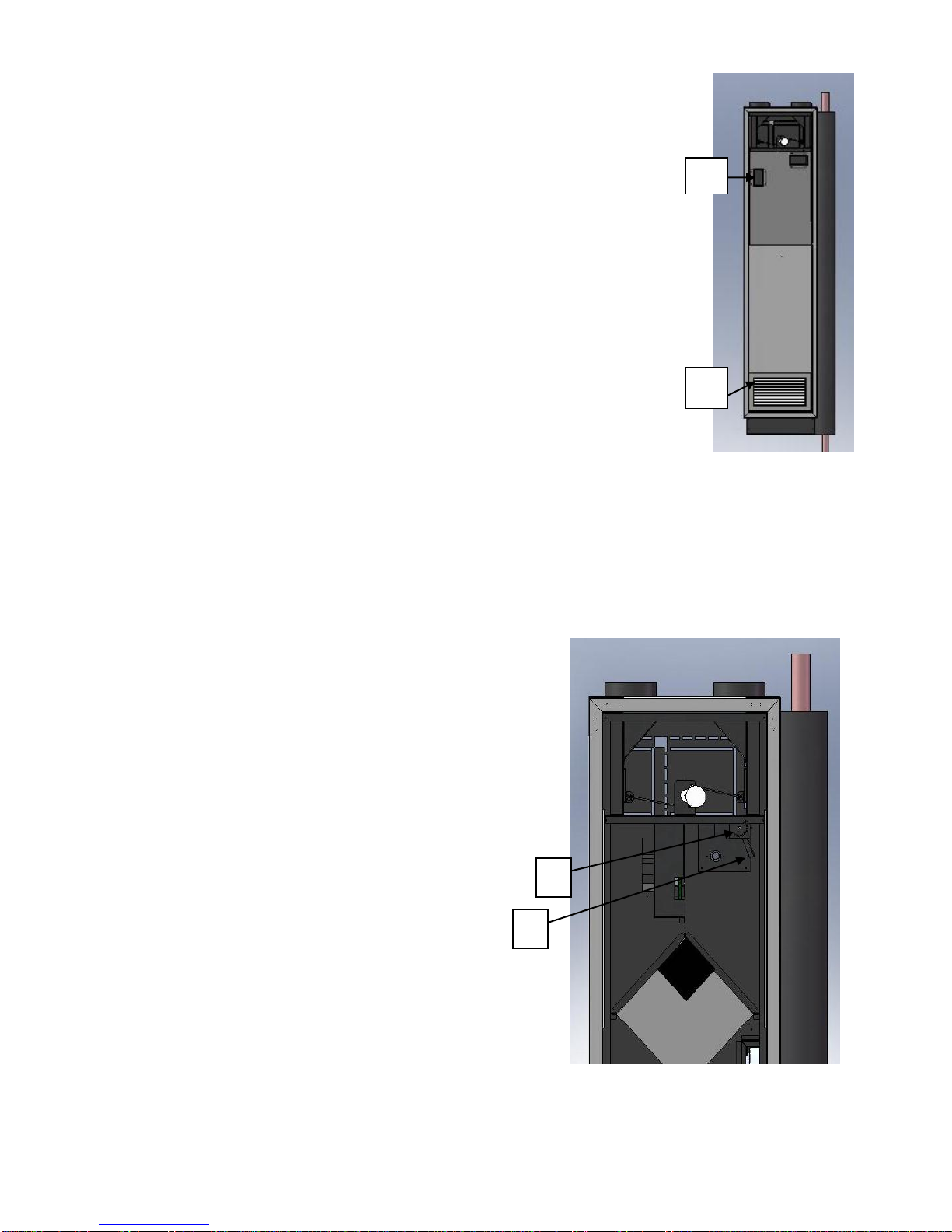

Control and Electrical Connections.................................................................. 41.4

Plumbing............................................................................................................. 41.5

Ducting ................................................................................................................ 41.6

2COMMISSIONING................................................................................ 5

Supply Air Balancing......................................................................................... 52.1

HRV Balancing................................................................................................... 52.2

Water Side Commissioning............................................................................... 82.3

3OPERATING THE FAN COIL AND HRV/ERV................................. 8

General Description ........................................................................................... 8

3.1

Thermostat.......................................................................................................... 93.2

Dehumidistat Control (Optional)...................................................................... 93.3

24V Push Button Timers (Optional)............................................................... 103.4

Recommended Seasonal Settings.................................................................... 113.5

4MAINTENANCE.................................................................................. 12

Maintaining Return Filters and HRV/ERV Core......................................... 124.1

5WARRANTY.......................................................................................... 13

6TECHNICAL INFORMATION........................................................... 14

6.1 Nomenclature..................................................................................................... 14

6.2 Coil Data ............................................................................................................ 15

6.3 4-pipe Heating coil data ..................................................................................... 16

6.4 Fan Curves.......................................................................................................... 17

6.5 Outside Air at Low Speed.................................................................................. 18

6.6 Exhaust Air......................................................................................................... 18

6.7 HRV Efficiency.................................................................................................. 19

6.8 Sound Level Summary....................................................................................... 19

6.9 Shop Drawings................................................................................................... 19

6.10 Electrical......................................................................................................... 25

6.11 Operational States........................................................................................... 28