Shandong Nuoman Engineering Machinery Co.,Ltd

Business Room, No. 7, Zhongshan West Road, Gulou Street Office, Yanzhou Dist., Jining, Shandong, CN

TEL/Fax:+8618266821667 Whatsapp/Wechat:+8618266821667

8. Do not allow other persons to use

the machine before having informed

him on the exact operation and

work instructions, and be assured

that the operator's manual has been

read and understood.

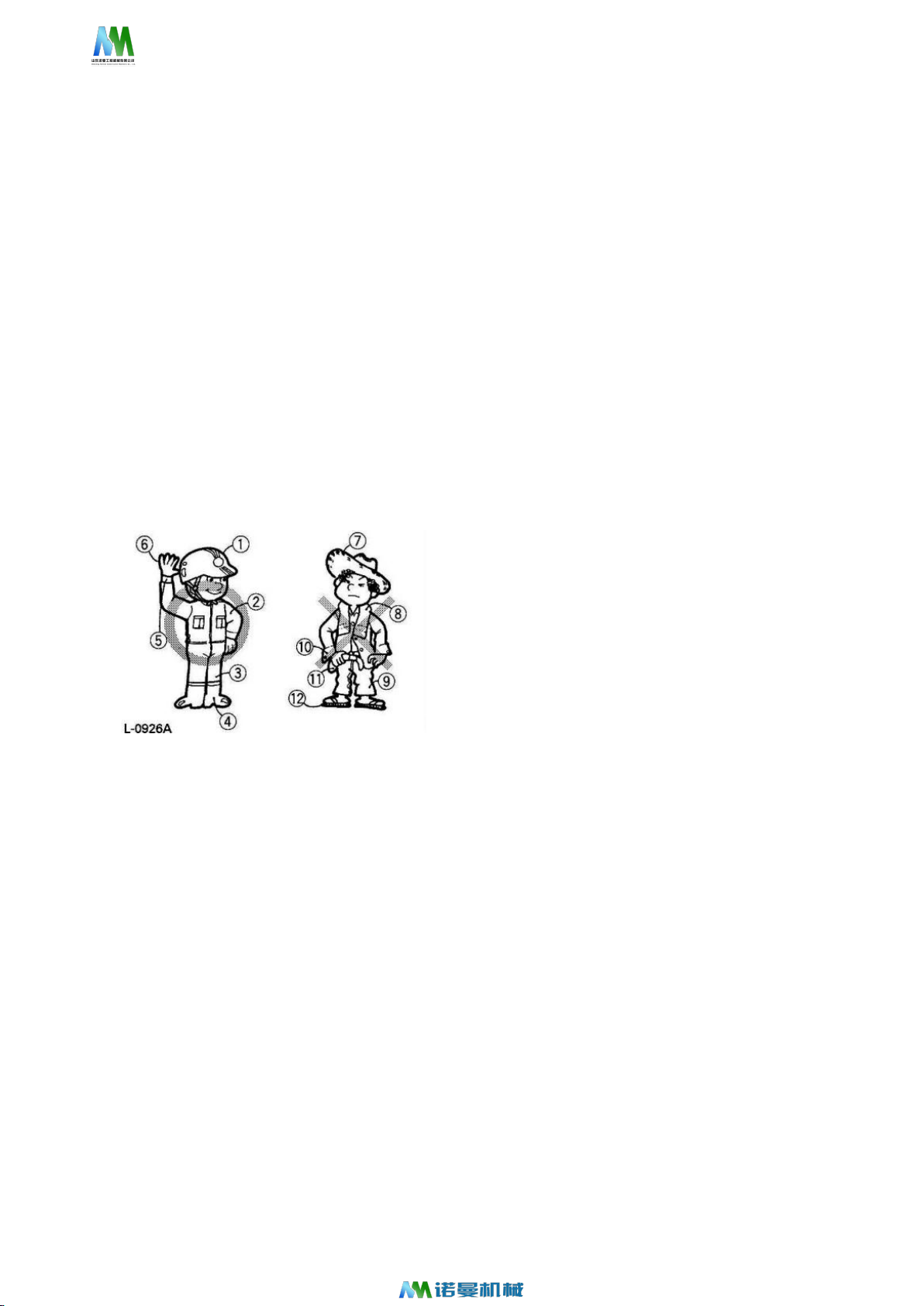

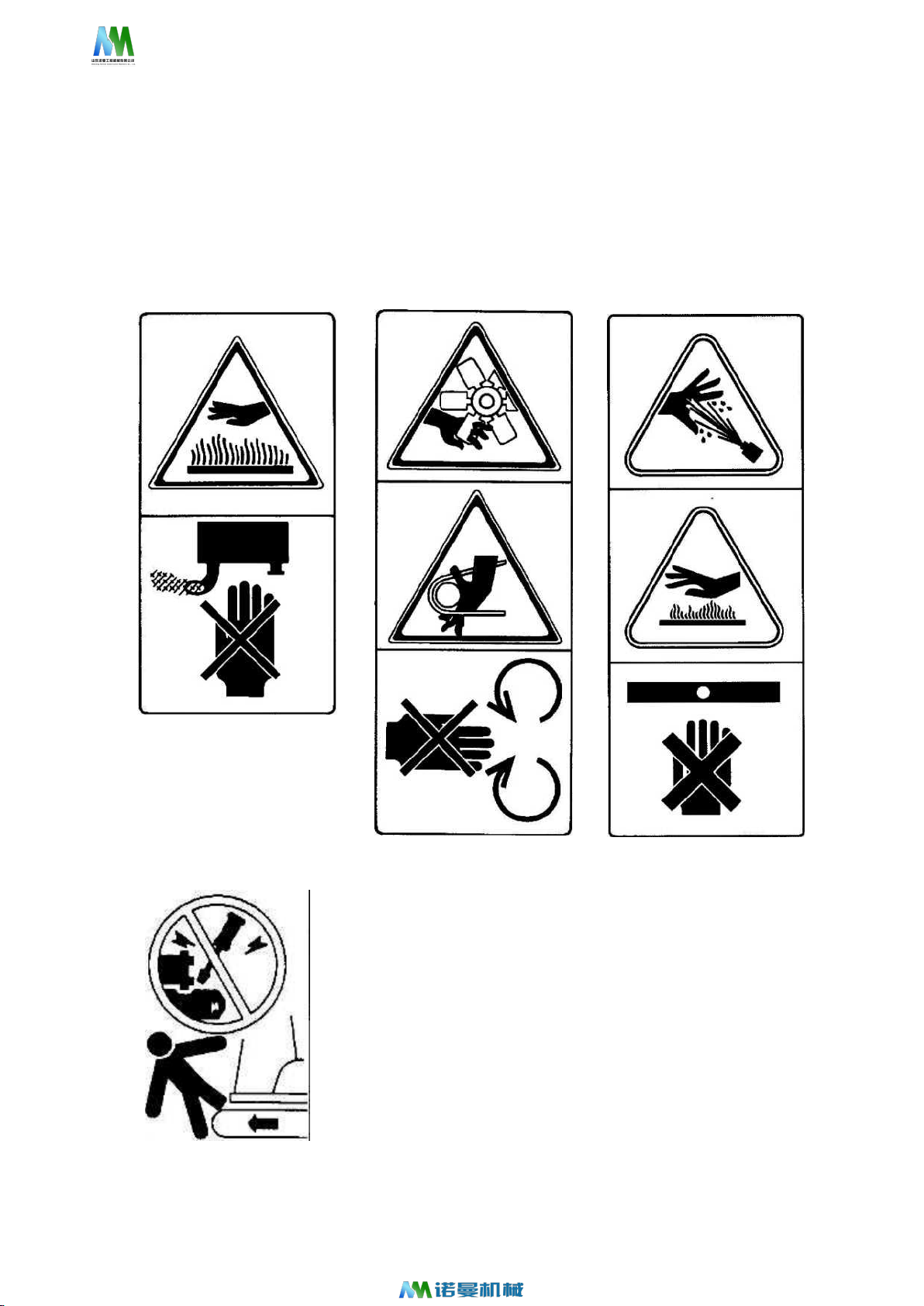

9. Do not wear baggy, tom or too

large clothing when working with

the excavator. Clothing can get

caught in rotating parts or control

elements which can cause

accidents or injuries. Wear

adequate safety clothing, e.g.

safety helmet, safety shoes, eye

protection, ear protection, working

gloves, etc., as necessary and as

prescribed by laws or statutes.

(1) Helmet

(2) Clothing fit for work

(3) Tight seams

(4) Good grip footwear

(5) Well fitting cuffs

(6) Working gloves

(7) Straw hat

(8) Towel

(9) Baggy trousers

(10) Loose cuffs on shirt

(11) Baggy shirt

(12) Rubber sandals

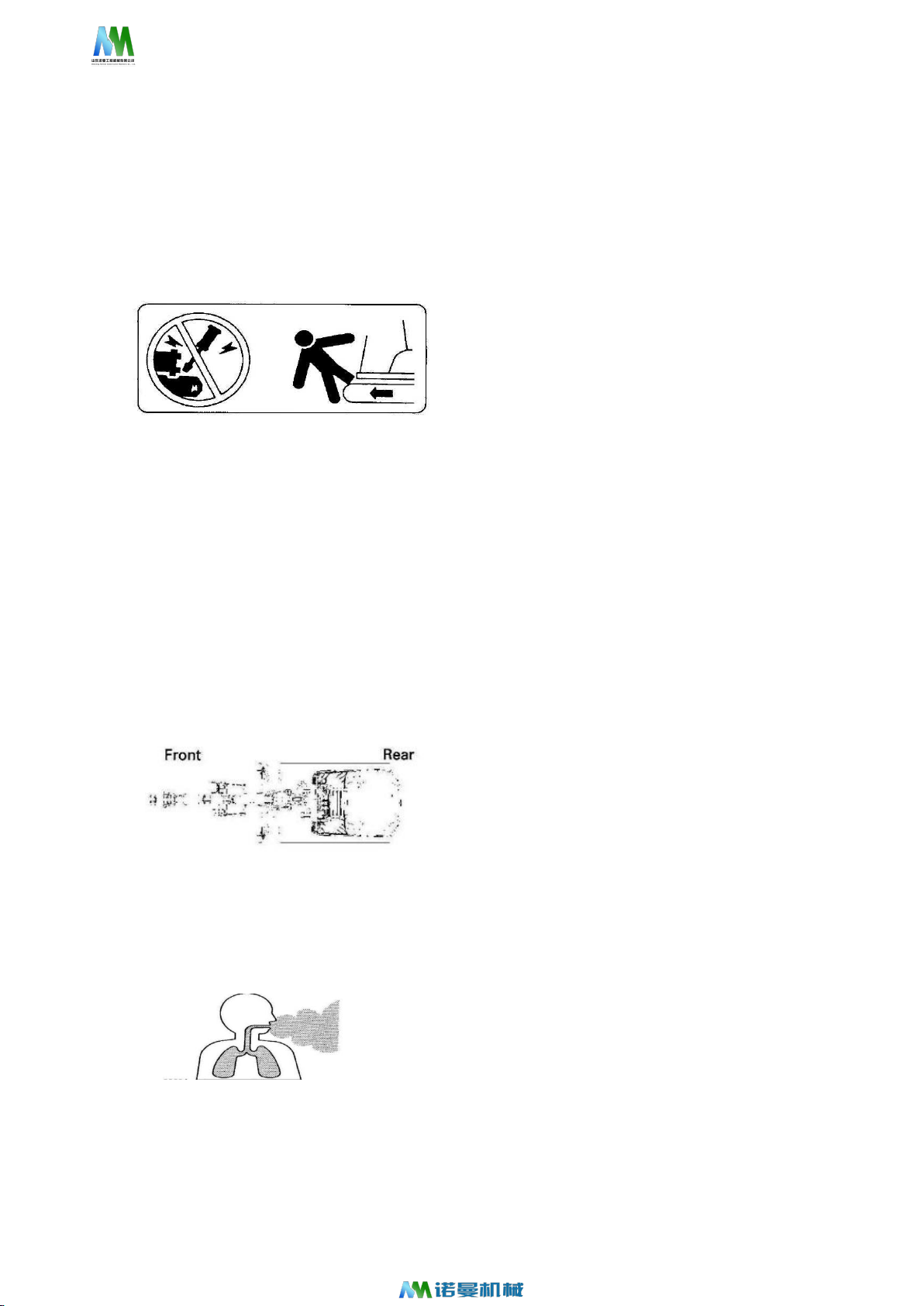

10. Do not allow passengers to get on

any part of the excavator seat

during operation.

11. Check mechanical parts for correct

adjustments and wear. Exchange

worn or damaged parts immediately.

Check nuts and bolts regularly for

tight fitment.

(for details see "Care and

Maintenance").

12. Keep your excavator clean. Heavy

soiling, grease, dust and grass can

inflame and cause accidents or

injuries.

13. Before starting the excavator, be

absolutely sure that the excavator

has been filled with fuel, lubricated,

greased and undergone other

maintenance work.

14. Do not modify the excavator,

otherwise it could lead to

unforeseen safety problems.

2. STARTING OF THE EXCAVATOR

1. Get into and out of the machine

safely.Always face the machine.

Always use handrails and available

steps and keep yourself well

balanced. Do not hold any of the

control levers and switches. Do not

jump on or off the machine, whether

stationary or in motion.

2. Start and control the excavator only

from the operator's seat. The driver

should not lean out of his seat when

the engine is running.

3. Before starting the engine, make

sure that all control levers (including

auxiliary control levers) are in their

neutral positions.

4. Before starting the engine, make

sure that the control levers, travel

lever, pedals and other control

elements are not stuck and can be

moved smoothly. If stuck, for

example, a lever may fail to return,

possibly putting you in danger. If

anything wrong is found,

immediately pinpoint the cause and