3

TABLE OF THE CONTENTS

SECTION 1 ..................................................................................................................................4

INTRODUCTION..........................................................................................................................4

1.1 USE AND FUNCTION .....................................................................................................4

SECTION 2 ..................................................................................................................................5

TECHNICAL SPECIFICATIONS..................................................................................................5

2.1 TECHNICAL SPECIFICATIONS TABLE..........................................................................5

2.2 OPTIONAL ACCESSORIES............................................................................................5

2.3 GENERAL PRESENTATION...........................................................................................6

SECTION 3 ..................................................................................................................................7

INSTALLATION PROCEDURE....................................................................................................7

3.1 LIFTING AND TRANSPORT............................................................................................7

3.2 UNPACKING ...................................................................................................................7

3.3 POSITIONING.................................................................................................................7

3.4 ENVIRONMENTAL CONDITIONS...................................................................................7

3.5 MAINS SUPPLY..............................................................................................................8

3.5.1 Prior to Operation......................................................................................................8

SECTION 4 ..................................................................................................................................8

OPERATING PRINCIPLES..........................................................................................................8

4.1 SWITCHING ON..............................................................................................................8

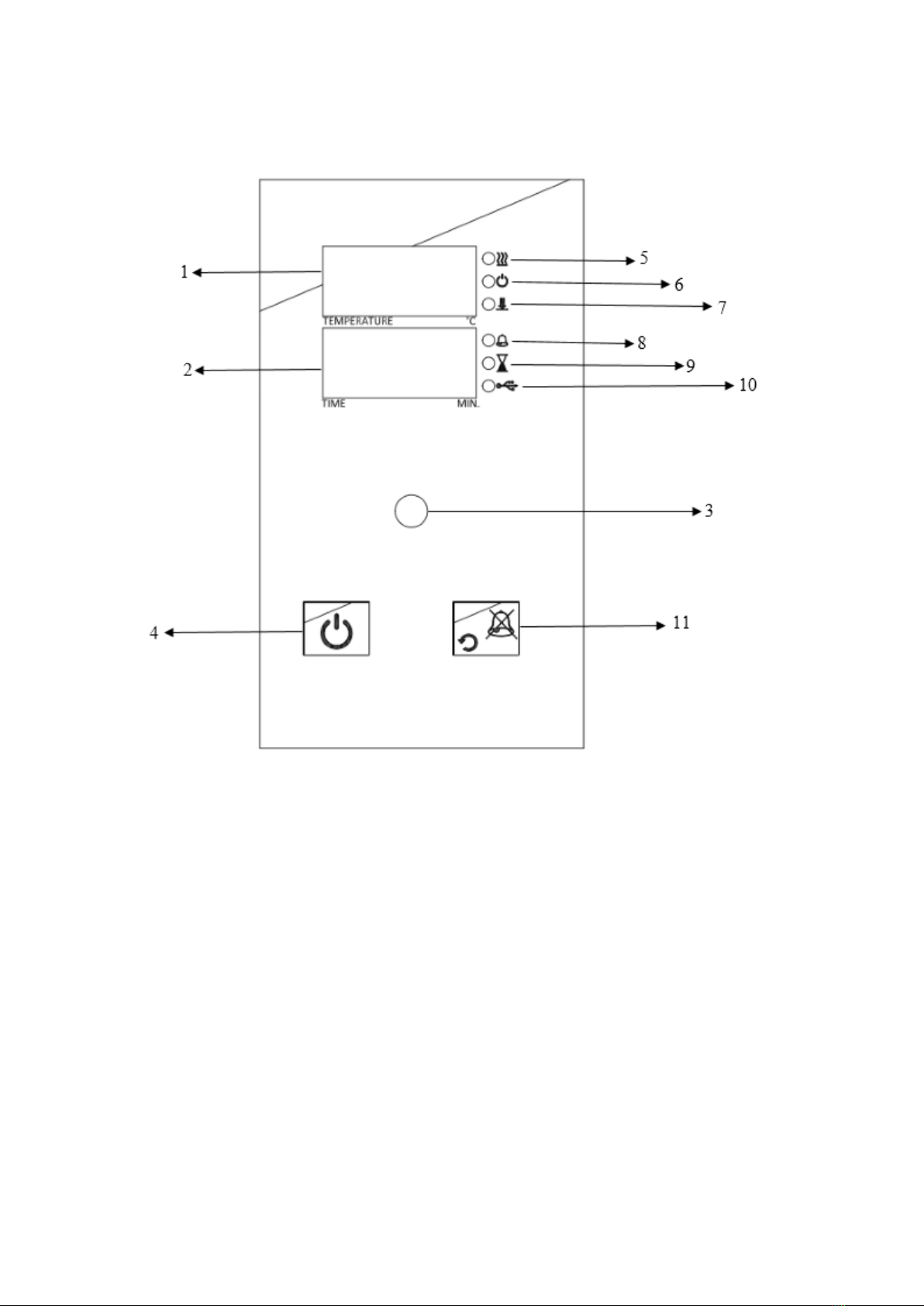

4.2 CONTROL PANEL ..........................................................................................................9

4.2.1 Explanations and Functions for Display and Control Panel........................................9

4.3 PREPARATION OF USER SETTINGS..........................................................................10

4.3.1 oP Operator Menu Parameters................................................................................11

4.4 PROGRAMMING SUMMARY........................................................................................11

WARNİNG!!.............................................................................................................................13

4.5 COMPLETION OF THE WORK.....................................................................................14

SECTION 5 ................................................................................................................................ 14

PERIODIC MAINTENANCE AND CLEANING...........................................................................14

5.1 PERIODIC MAINTENANCE...........................................................................................14

5.2 CLEANING....................................................................................................................14

SECTION 6 ................................................................................................................................ 15

DISPOSAL MANAGEMENT CONCEPT....................................................................................15

SECTION 7 ................................................................................................................................ 15

TROUBLESHOOTING...............................................................................................................15

7.1 ERROR CODES EXPLANATIONS................................................................................15

SECTION 8 ................................................................................................................................ 17

ELECTRICAL CIRCUIT DIAGRAMS .........................................................................................17

10.1 FN 300 ELECTRICAL CIRCUIT DIAGRAMS............................................................17

10.2 FN 400 ELECTRICAL CIRCUIT DIAGRAMS.............................................................18

10.3 FN 500 ELECTRICAL CIRCUIT DIAGRAMS..............................................................19

10.4 FN 400P - 500P ELECTRICAL CIRCUIT DIAGRAMS................................................20

SECTION 9 ………………………….……………………………………………………………………21

WARNING LABELS .…………………………………………………………………………………….21