2 255548 Rev.1

Index

1 Important basic information ............................................... 4

1.1 Target groups ......................................................................5

1.2 Applicable documents ....................................................... 5

1.3 Warnings and symbols ...................................................... 6

1.4 Terminology........................................................................ 6

2 Safety ...................................................................................... 7

2.1 Intended use........................................................................ 7

2.2 Potential misuse.................................................................. 7

2.3 General safety instructions ............................................... 7

2.3.1 Product safety .................................................................. 7

2.3.2 Obligations of the operator............................................ 8

2.3.3 Obligations of the sta.................................................... 8

2.4 Residual risks......................................................................8

2.5 Special risks.........................................................................8

2.5.1 Potentially explosive area...............................................8

2.5.2 Dangerous media to be pumped................................... 8

3 Design and functioning...................................................... 9

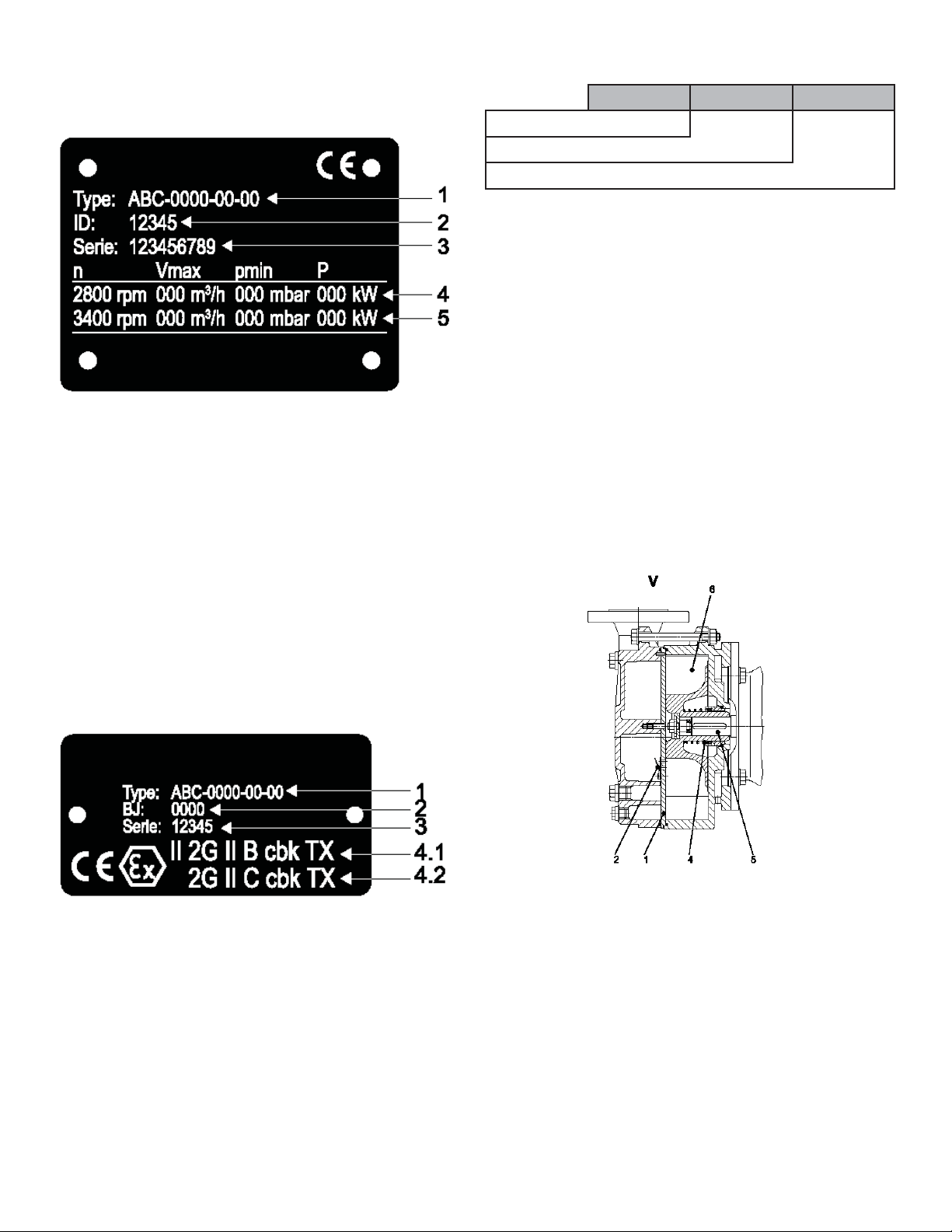

3.1 Marking ............................................................................... 9

3.1.1 Nameplate ........................................................................ 9

3.1.2 ATEX plate....................................................................... 9

3.1.3 Pump type code............................................................... 9

3.2 General description............................................................9

3.3 Design and functional principle..................................... 10

3.4 Sha sealing ......................................................................10

3.4.1 Mechanical seal .............................................................10

4 Transport, storage and disposal......................................11

4.1 Transport...........................................................................11

4.1.1 Unpacking and inspection on delivery ......................11

4.1.2 Manual transport ..........................................................11

4.1.3 Transport with liing gear ...........................................11

4.2 Storage ...............................................................................11

4.3 Preservation ......................................................................12

4.3.1 Preservation inside the system ....................................12

4.3.2 Preservation outside the system..................................12

4.4 Removing preserving agent ............................................13

4.5 Disposal ............................................................................. 13

5 Set-up and connection ......................................................14

5.1 Preparing set-up...............................................................14

5.1.1 Checking ambient conditions......................................14

5.1.2 Minimum clearances for heat dissipation..................14

5.1.3 Preparing installation site ............................................14

5.1.4 Preparing foundation and surface ..............................14

5.1.5 Removing preserving agent ......................................... 14

5.2 Set-up with foundation....................................................14

5.2.1 Placing aggregate on foundation.................................14

5.2.2 Fixing aggregate.............................................................15

5.3 Set-up without foundation..............................................15

5.4 Set-up on level surface/frame.........................................15

5.5 Planning pipe system.......................................................15

5.5.1 Dimensioning supports and connections..................15

5.5.2 Specifying nominal diameter.......................................16

5.5.3 Specifying pipe lengths................................................. 16

5.5.4 Changes in cross-section and direction .....................16

5.5.5 Safety and control devices............................................16

5.6 Connecting pipes .............................................................16

5.6.1 Providing for clean piping............................................ 16

5.6.2 Installing suction pipe .................................................. 16

5.6.3 Installing pressure pipe.................................................16

5.6.4 Stress-free pipe connection.......................................... 16

5.7 Electrical connection .......................................................17

5.7.1 Motor connection .........................................................17

5.7.2 Checking direction of rotation....................................17

6 Operation ............................................................................17

6.1 Preparations for commissioning....................................17

6.1.1 Identifying pump type..................................................17

6.1.2 Removing preserving agent ......................................... 17

6.1.3 Checking shut-down period........................................17

6.1.4 Filling..............................................................................17

6.2 Commissioning ................................................................17

6.2.1 Switch-on .......................................................................17

6.2.2 Switch-o .......................................................................18

6.3 Setting the operating liquid ow rate ............................18

6.3.1 Continuous-ow cooling .............................................18

6.3.2 Open circulation cooling .............................................19

6.3.3 Closed circulation cooling ...........................................19

6.4 Decommissioning ............................................................19

6.5 Re-commissioning ...........................................................20

6.6 Operating stand-by aggregate.........................................20

7 Maintenance and servicing ..............................................20

7.1 Monitoring ........................................................................20

7.2 Rinsing o contaminations.............................................21

7.2.1 Minor ne-grained contamination.............................21

7.2.2 Major ne-grained contamination .............................21

7.3 Prevention of corrosion and deposits............................21

7.4 Disassembly ......................................................................21

7.4.1 Return to manufacturer................................................21

7.4.2 Spare parts...................................................................... 22

7.4.3 Aggregate repairs...........................................................22

7.4.5 Disassembly of SM30....................................................22

7.4.6 Disassembly of SM55-250B .........................................22

7.5 Assembly ...........................................................................23

7.5.2 Assembly of SM30B ......................................................23

7.5.3 Assembly of SM55-250B ..............................................24