OMEGA-VSHP.G-IOM-2205

7

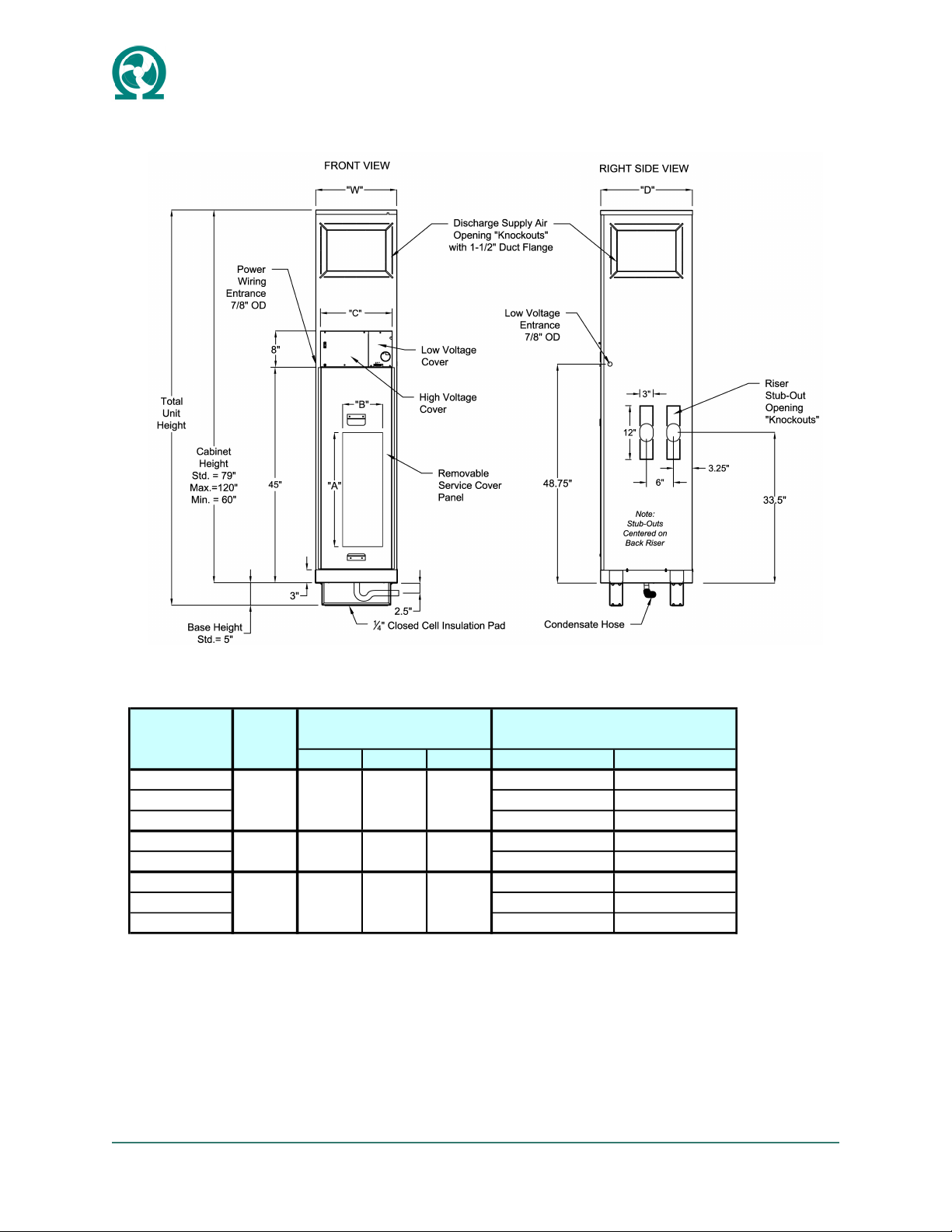

3) Raise the entire cabinet slowly upright while at the

same time lowering the risers through the floor cut-out

opening. Align the risers to the matching swaged section

of the riser on the floor below.

4) Swaged sections are approximately 3 inches deep.

Risers should be inserted at a depth of approximately 2

inches into the 3 inch deep swage. Confirm risers pene-

trate at a minimum of 1 inch into the swage. Do not allow

the riser tailpiece to bottom out fully into the 3 inch deep

swage. This will allow for floor to floor variations, other-

wise riser overlap may not be sufficient on upper floors.

5) Align and center riser positions in the pipe chase and

level cabinet as necessary.

6) Secure the cabinet to the floor. Cabinet base comes

with factory mounted neoprene pads.

7) Center the riser stub-outs in the cabinet openings to

allow for riser expansion and prevent contact with cabi-

net sheet metal. Prevent riser stub-outs from contacting

sheet metal pass through otherwise damage to stub-

outs may occur, resulting in serious water damage.

8) Secure risers to building structure as per engineering

design specifications. Do not allow the risers to be sup-

ported by the cabinets. Field supplied riser compensa-

tors are required if the temperature range of the system

exceeds the expansion and contraction limit.

9) Using industry accepted soldering and brazing stand-

ards and materials to solder or braze the riser joints.

10) Connect supply ducts and discharge grilles.

11) Connect to optional Fresh Outside Air Duct (Snorkel)

when connecting to remote ERV.

RISER LOOP

Do not connect chassis to the water circulat-

ing system when flushing is being conducted

to prevent debris and fouling of the water side

components of the chassis (i.e. auto balanc-

ing valve, auto shut-off valve, coaxial coil).

Do not flush and clean riser system with chas-

sis units connected. Do not allow the flushing

and cleansing solutions to flow in the chassis

water coil. Damage to water components

may occur.

Do not let untreated, standing and/or stag-

nant water sit inside chassis. Connect

chassis water connections by opening

isolation valves only when riser system is

treated and flowing.

Servicing

To enable system flushing, servicing and balancing of

supply and return risers the following field supplied com-

ponents are required: shut-off valves, drain tees and

drain valves, and flow measuring devices. Refer to the

job site engineering design specifications and building

drawings for more detailed information.

Flushing & Cleaning

Once the riser system is complete the riser system must

be cleaned and flushed, refilled and chemically treated

with industry accepted inhibitors. Untreated riser loop

water will result in premature wear and potential failure

of system components due to water coil leaks inside

chassis. Filters must be installed in riser loop system

and checked, cleaned as per regular maintenance

schedule.

Supply and return pipes must be interconnected, at a

minimum in the top and bottom units of each riser, with

factory supplied hoses to properly flush system and en-

sure adequate elimination of foreign material and clean-

ing of riser system.

1) Use only clean water to fill water circulation system.

Fill the water circulating system at the municipal water

makeup connection with all air vents opened.

2) After air vents have been sequentially closed and

riser system is primed begin water circulation of the sys-

tem to purge remaining trapped air bubbles.

3) Shut off the circulating pump and open all the drains

and vents to completely drain the system.

4) The riser system should be cleaned after the initial

flush and flushed a second time to adequately rinse the

riser system of cleaning solution.

5) Riser system is then re-filled with clean city water and

chemically treated to inhibit corrosion, oxidization and

fouling of the riser loop system. Do not use untreated

water to run heat pump chassis units.

Chassis installation is permitted only once the riser

system is thoroughly flushed, cleaned, and commis-

sioned by the riser treatment company and contrac-

tor.

RISER SYSTEM LOOP TEMPERATURE

Correct riser system loop temperature settings are im-

portant for optimal unit operation. Temperatures outside

of the recommended range will affect overall unit operat-

ing performance (capacity and efficiency), long term

reliability and sound performance.

Cooling Season

In cooling mode recommended riser loop temperatures

should be maintained between 85oF to 90oF. Higher riser

loop temperatures reduce unit cooling capacity and effi-

ciency. Lower riser loop temperatures will increase unit