Table of contents" #....................................................................................................................................2

1. Safety requirements" #...........................................................................................................................4

2. Operation principle" #.............................................................................................................................5

2.1.Features and advantages!..............................................................................................................................................5

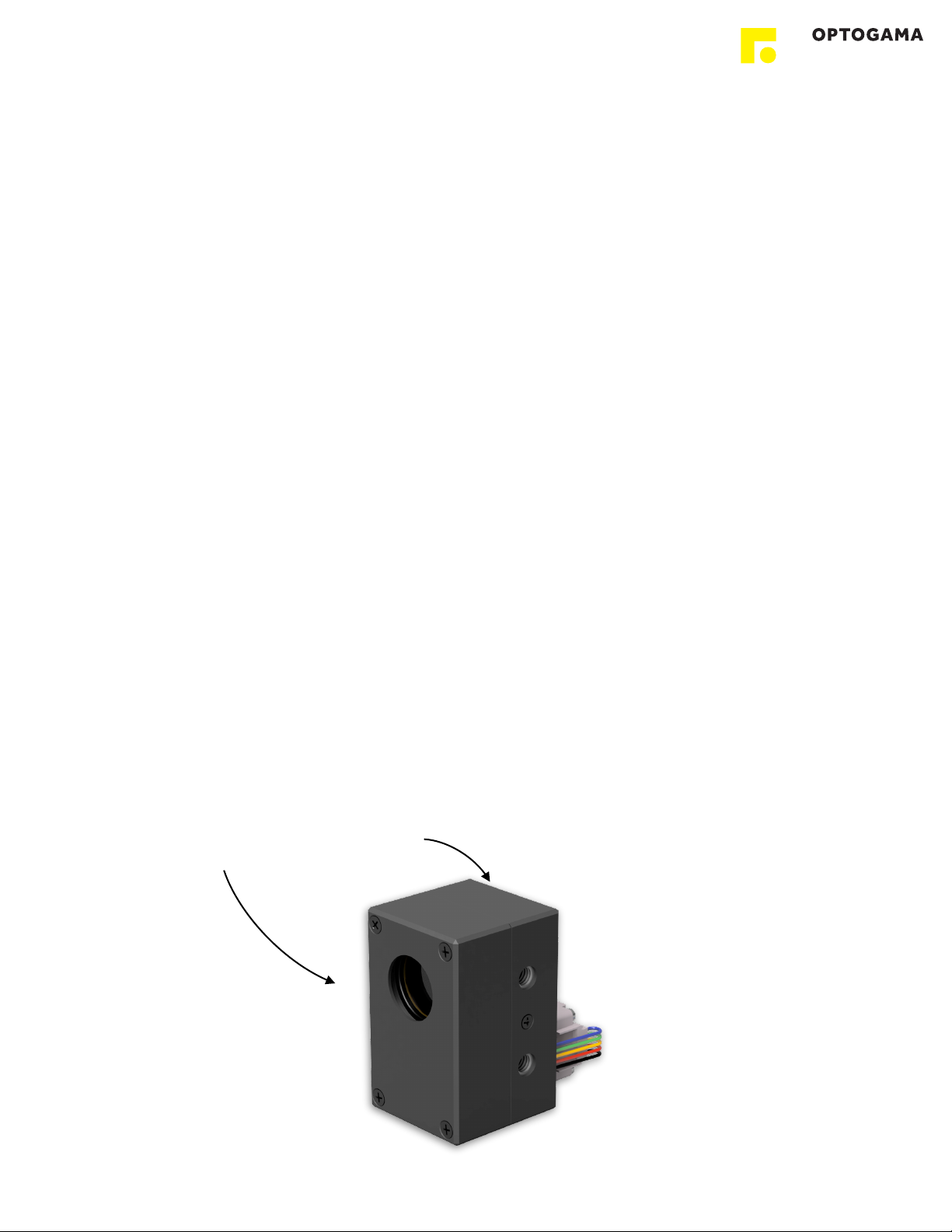

3. Product description" #............................................................................................................................6

3.1.Optical specifications!....................................................................................................................................................6

3.2.Mechanical specifications!.............................................................................................................................................6

3.3.Electronic specifications!................................................................................................................................................6

3.4.Conditions!....................................................................................................................................................................6

3.5.Controller!......................................................................................................................................................................7

3.5.1.Interfaces, pinout!..................................................................................................................................................7

3.5.2.LEDs, Buttons functions!.......................................................................................................................................7

3.5.3.Mounting!..............................................................................................................................................................8

3.6.Voltage levels!................................................................................................................................................................8

3.7.What’s in the box?!........................................................................................................................................................8

4. Software" #.............................................................................................................................................8

4.1.Minimum Hardware requirements (recommended)!........................................................................................................8

4.2.System requirements!....................................................................................................................................................8

4.3.Supported client operating systems!..............................................................................................................................8

4.4.Installing the software!...................................................................................................................................................8

4.5.Using the software!......................................................................................................................................................10

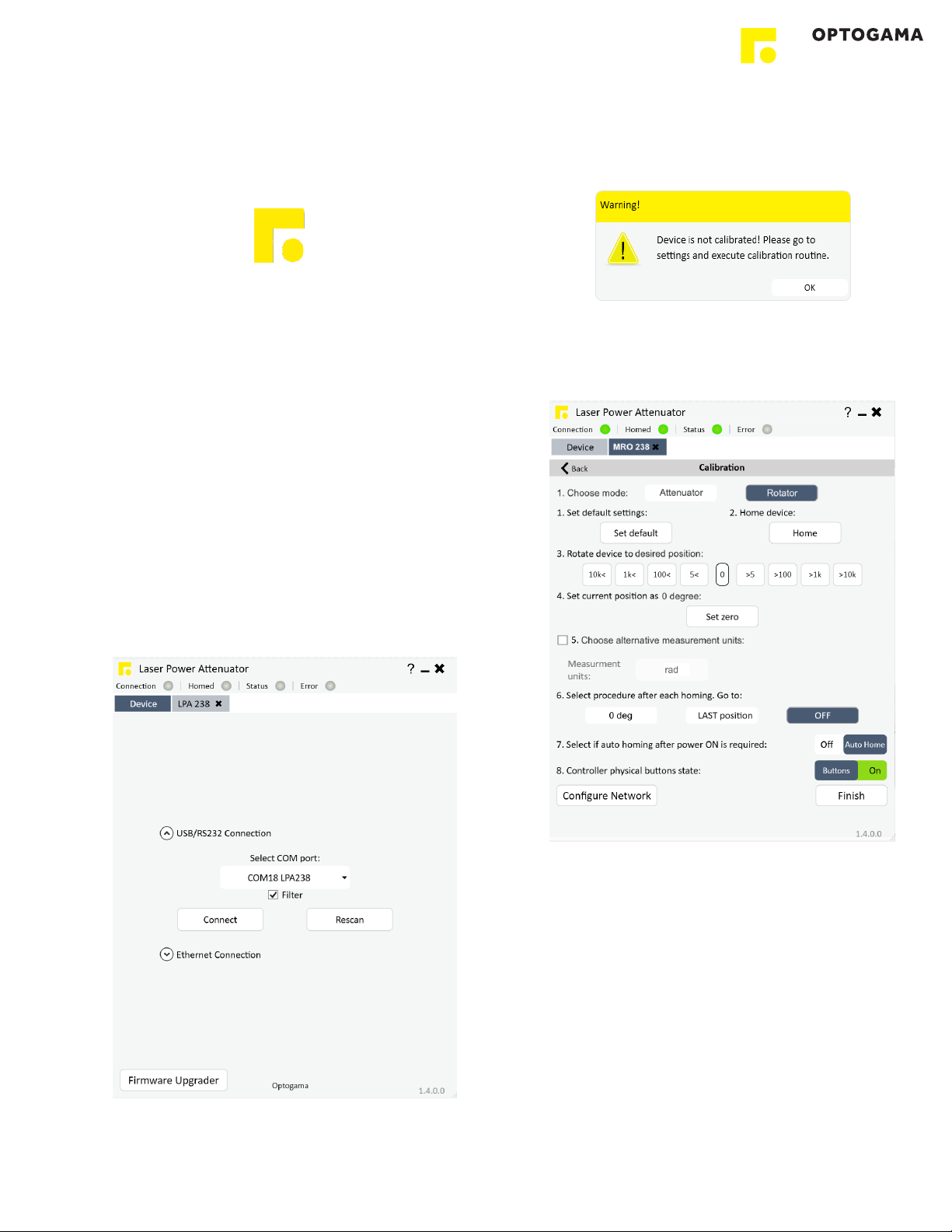

4.5.1.Connection!............................................................................................................................................................10

4.5.2.Settings, calibration!................................................................................................................................................10

4.5.3.Main window!..........................................................................................................................................................11

4.6.Ethernet connection!...................................................................................................................................................12

4.6.1.About TCP/IP pMROocol!.......................................................................................................................................12

4.6.2.Client and Server Connection!.................................................................................................................................12

4.6.3.Ethernet configuration using MRO software!...........................................................................................................13

4.6.4.Ethernet connection using MRO software!..............................................................................................................13

4.6.5.Ethernet configuration using commands!................................................................................................................14

4.7.Updating the firmware!................................................................................................................................................15

4. Commands" #......................................................................................................................................16

4.1.Interface!.....................................................................................................................................................................16

4.2.Description!.................................................................................................................................................................16

5. Troubleshooting" #................................................................................................................................19

5.1.STATUS bits explanation!.............................................................................................................................................19

5.2.Serial communication example in Python!....................................................................................................................20

6. Technical information" #.......................................................................................................................21

6.1.MRO drawings!............................................................................................................................................................21

6.2.MRO controller drawing!..............................................................................................................................................22

6.3.Power supply!..............................................................................................................................................................23

6.4.RS232 cables!.............................................................................................................................................................24