CONTENTS

IMPORTANT

WARNING

......ssccssssssssseeensesense

sahara

eaathl

ctsaieeleties

SERVICING

NOTICES

ON

CHECKING.....

HOW

TO

ORDER

PARTS.

«..-ssecssssssssssssssessssssstensseens

TAPE

REMOVAL

METHOD

AT

NO

POWER

SUPPLY

........sssccsssssssssssesssssesssssesnsseeeenseneed

At-2

DISC

REMOVAL

METHOD

AT

NO

POWER

SUPPLY

.....ssccssssssssssssssssessssessssserenseetecnnee

At-2

PARENTAL

CONTROL-RATING

LEVEL

....-scssessessssssssssssestssennsssssttnsrseeeusssssnasionunsseneunsee

At-2

CONTENTS

sescrscsisscccieseitencencs

sons

cracesldatalasieasrainet

la

ee

ei

ia

ter

caster

A2-1

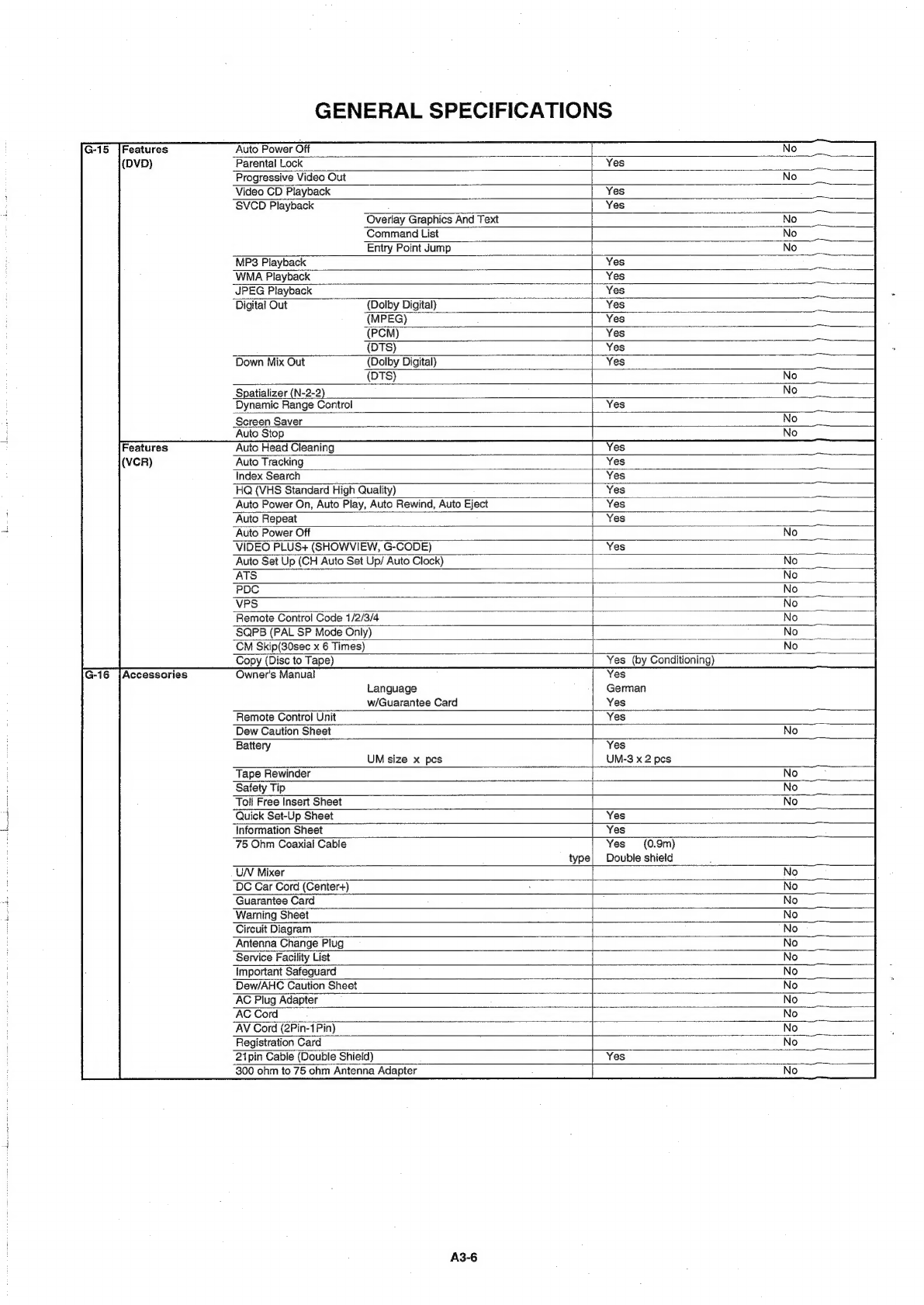

GENERA

SPECIFIGATIONS

s5-.62507.0h-

esata

aca

wecan

tameetn

aiasan

Marien

A3-1~A3-7

DISASSEMBLY

INSTRUCTIONS

1.

REMOVAL

OF

MECHANICAL

PARTS

AND

P.

C.

BOARDS

wu.....:ssssessssseseesesssssssesseneens

B1-1,

B1-2

2x

REMOVAL

OF

VGR:DEGK

PARTS

..cs.2tiasggicnnicenenncnnaiaiaciatatatn

aii

B2-1~B2-6

3.

REMOVAL

AND

INSTALLATION

OF

FLAT

PACKAGE

IC

...ssssssssssssssssesesssesesssssseeseenas

B3-1,

B3-2

KEY

TO

ABBREVIATIONS

cscs

.5:5sjo-4nsereessncoesivirceny

Atte

totes

beveeeaneatuantiiencee

C1-1,

Ct-2

SERVICE

MODE

LIST

ose

cases

anantannnmase

eee

aanennains

2-1

PREVENTIVE

CHECKS

AND

SERVICE

INTERVALS

.........-ccccsssssssssssssesssessssesessseseeesesssenes

C3-1,

C3-2

WHEN

REPLACING

EEPROM

(MEMORY)

IC

.....saccssesssssssssssssssssssesssssssseeusseesnssnesensenesens

C4-4

SERVICING

FIXTURES

AND

TOOLS

.....ccccssssssssssssssssssssseussesinsetseusssstsinssseearetnnssertensee

D1-1

PREPARATION

FOR

SERVICING

....acscsssssessesessessestsssessenseestntesnsenensnsssessuassseensssnnssteseenee

Dt1-1

MECHANICAL

ADJUSTMENTS

f5sscisnccrivicncctesstitenccondictersnatsleesecveaeeluanansonssiteuncarsioutaiy

D2-1~D2-4

ELECTRICAL

ADJUSTMENTS:

sods

scoiiesiisccivieniatea

tata

naan

anenanains

D3-1,

D3-2

BLOCK

DIAGRAMS

DIU

reciente

cieimiec

tae

teres

altaya

Ue

pac

ee

cles

SY

GAUDI

ND

ANA

asin

uclek

adalah

aden

ec

alin

ta

NN

SYTEM

CONTROL/SERVO/TIMEPVOSD

...ssssssessessssssesernseesesnsssssentsnassnsesensstereessessnees

s

REGULATOR

ss

instiete

CAG

aaleicteia

seine

canta

hatin

a

aon

att

toads

OP

ERATIONIDISPLA

Yost

taccatcanatieeat

is

ithnadis

Suan

deatn

leat

Mnannane

TUNER/Hi-Fi/21

PIN/OSD/G-STEREO/NICAM

.....sssssssssssssseesssorsessnonseesnsat

BOWER

icaniaiuntaceisidemncsteoinehtimnettatcat

blu

ianeedemten

ani

tetaniannns

PRINTED

CIRCUIT

BOARDS

VORIDVD

Seccccrsshesinunsant

POWER/OPERATION

SCHEMATIC

DIAGRAMS

VICIATID

OMFIE

RD.

ADAP

sissceatscsecu

ts

cusedecehanasinacioutasbevewiendeerinsbanbeadashacolinbaatttae

aeallenaeae

G-1,

G-2

SVSCON/SEAVO/TIME

RIV

PSS

fcc

seerscestevilacentsartoloastsistaelossagsistes

ccsesenncccutselretgneg

G-3,

G-4

DAP

INTOUNER

35

cct

cat

fc

nc

temic

cancherten

tes

eeecreats

Sate

eaua

aneleatialanda

ttaafanwlaned

G-5,

G-6

PREETI

a

ctes

cise

sactseranssvine

cpcaen

eechee

ete

aaa

ROIs

ton

sal

Saanceae

G-7,

G-8

OPERATION

DISPLAY.

sash

acs5cs.

scste

se

Sianea

a

nti

es

eteaeetalece

ep

retailed

ala

G-9,

G-10

Hi

E

MOD

DIATOM

a2

ciatieeriatueitlanarkoneactietics

adi

tataahena

tite

Sintia

aia,

G-11,

G-12

MPEGIMIOON

sciset

se

cuincts

desea

tates

tseetecineaseece

ee

pe

lid

Rascnrndbega

tacit

tatvccastes

G-13,

G-14

DAES

HOA.

che

chic

eae

bs

haceabas

poche

psn

asec

arbitrate

Manne

esac

cuvette

G-15,

G-16

NG

Paez

actasedicee

ade

cues

steensiugshieee

eae

eee

uan

tcc

atzA

Nii

eal

led

G-17,

G-18

MOTOR

DRIVE

sictarhnd

enya

a

tem

BAA

ihenei

pt

caicnouatidcchiucdda

Coalhantala

hy

G-19,

G-20

LEAD

GHANINEELL

>

steseaces(seresen

sheeheuan

ce

a

calender

noe

G-21,

G-22

ALI

ONIN

O

cess

aisascb

see

vatclstee

ccna

naycscnbc

veoh

oa

naaeig

chickens

da

G-23,

G-34

POWER

sishecshigsescesteite

accede

cbelur

teeta

cea

LS

ate

per

aaah

ante

redciaatia

G-25,

G-26

OR

ERATION

A

scales

sitensastsvboss

ee

saranieter

bs

ierieie

becreteleveaslicputeelet

a

inacgnaliiansia

cuntliatan:

G-27,

G-29

INTERCONNECTION

DIAGRAM

......ccscscssssssssssesecseessssssssssssesstuenssesunsssetnsneseensseensssatnssst

G-29,

G-30

WAWEPORIAS

oi.

ccccsdscissssovceonutasniyenercsrrtia

enstilenso

to

aad

lied

Mich

eataldionacestbadiail

H-1~H-2

MECHANICAL

EXPLODED:

VIEW

accosescscssiessisioti

De

cceirais

sipeatiiuccattinedNantdlaleaitostice

1

GHASSIS

EXPLODED

VIEWS

's.cciir5ssosin

all

rectacatstaies

hurt

ayaseinravn

cher

tastsisiatintediacat

12-1,

12-2

MECHANICAL

REPLACEMENT

PARTS

LIST

«.....ccssssssssesssssssstnsssesesssseeesseetsnsseernsnstenss

Jit

CHASSIS

REPLACEMENT

PARTS

LIST

....scsssscsssssesessssssstssssesssesseusssstennsseeeseenssnaeesni

J2-1

ELECTRICAL

REPLACEMENT

PARTS

LIST

......csscssssssssssssssssssssseseessessnnsseeenteenaneeeenisnt

J3-1~J3-3