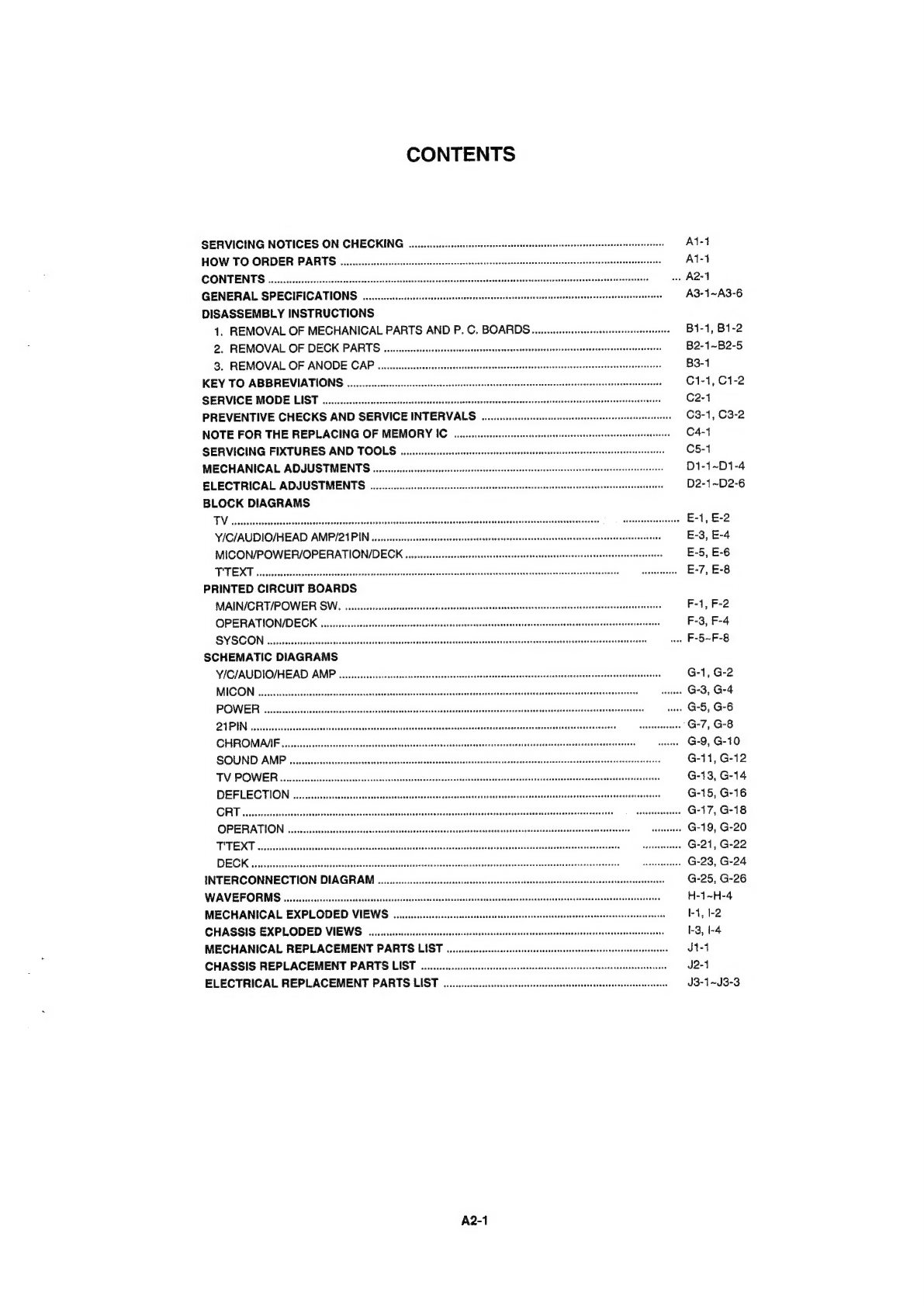

CONTENTS

SERVICING

NOTICES

ON

CHECKING

veccsseteeesee

AST

HOW

TO

ORDER

PARTS.

0...

esecsssssssesseeeesesenessscsnesneasrevenenecesssenenssecssecennecersnenesseseeans

Re

Ai-1

CONTENTS

a

.

A2-1

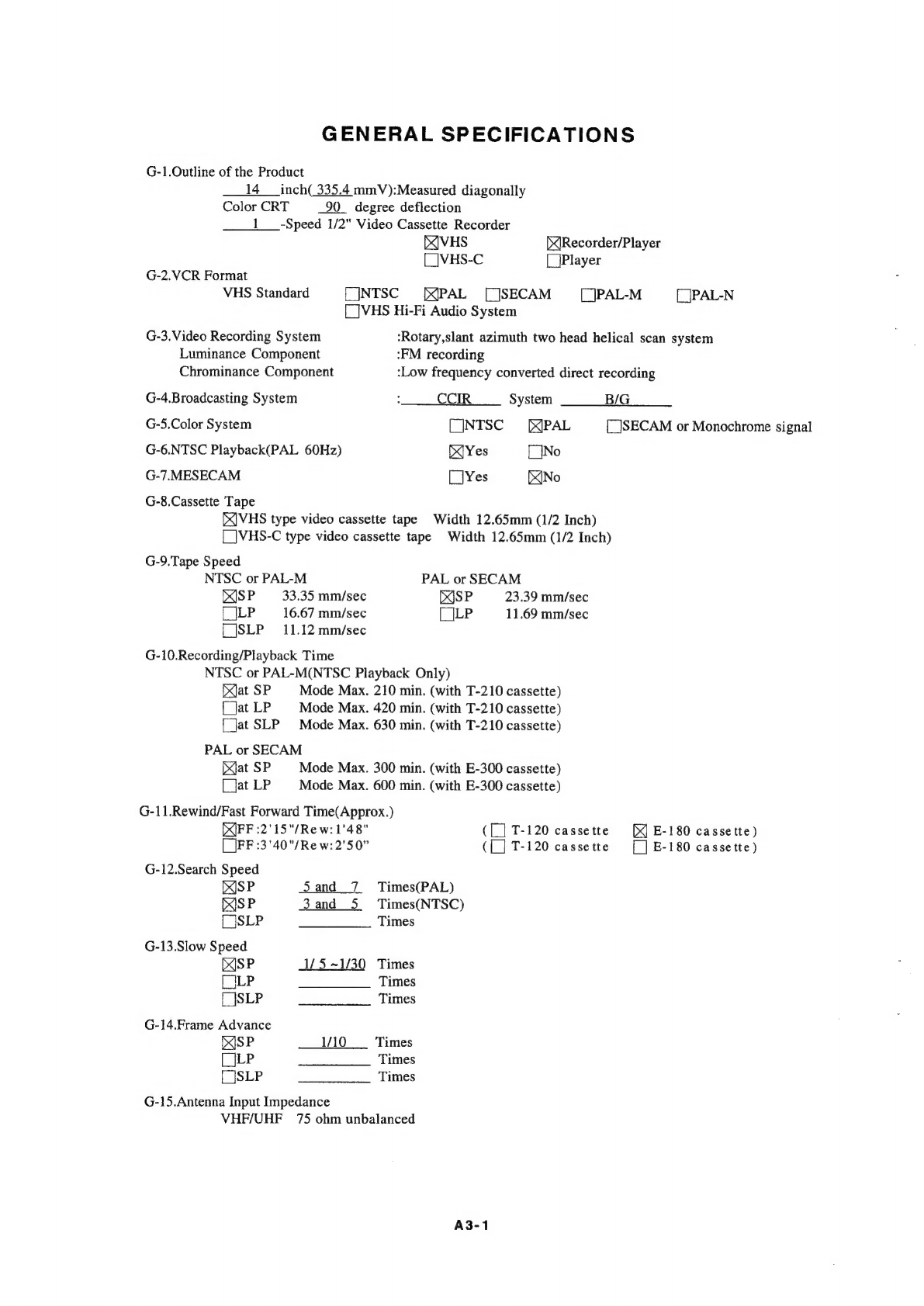

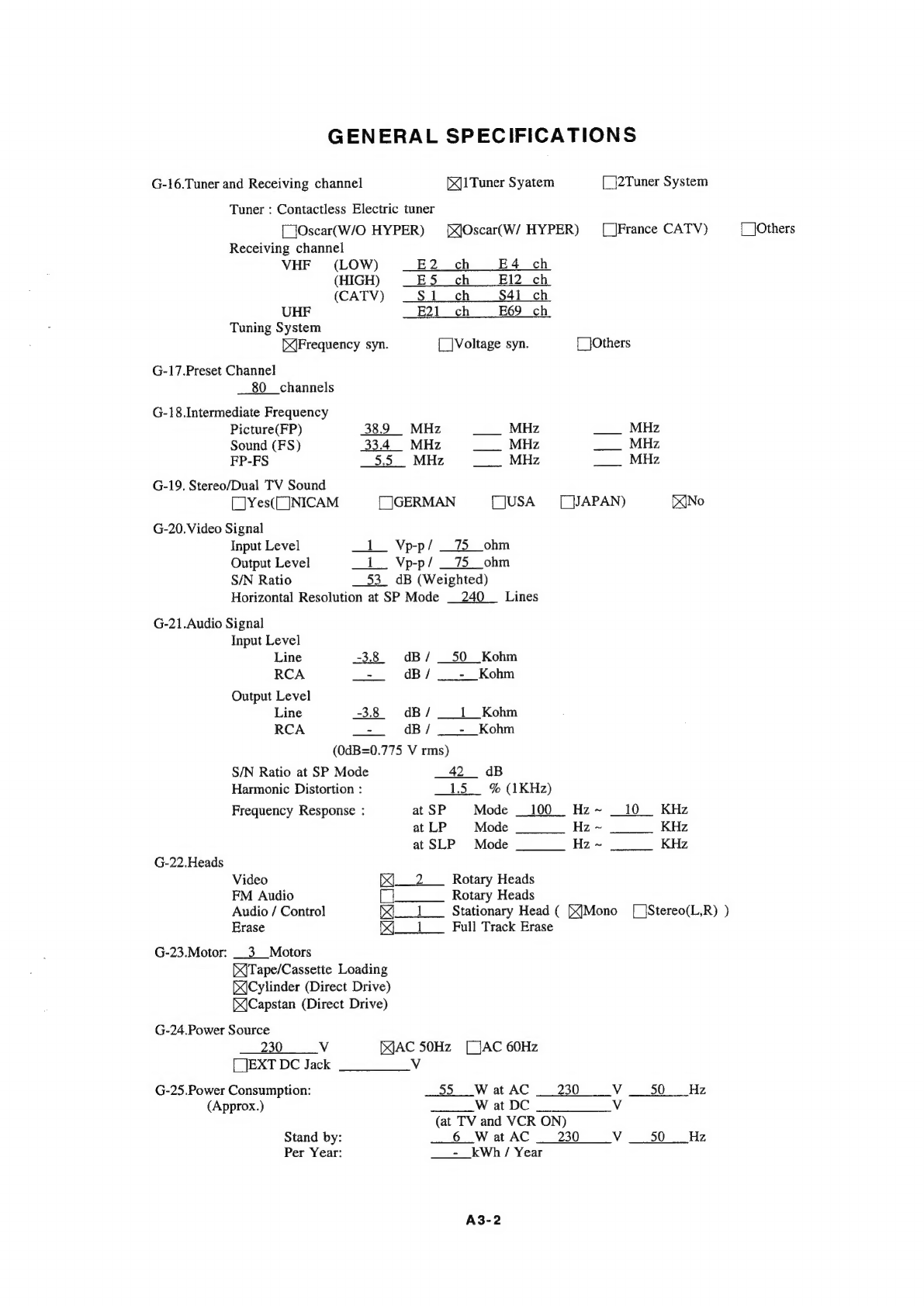

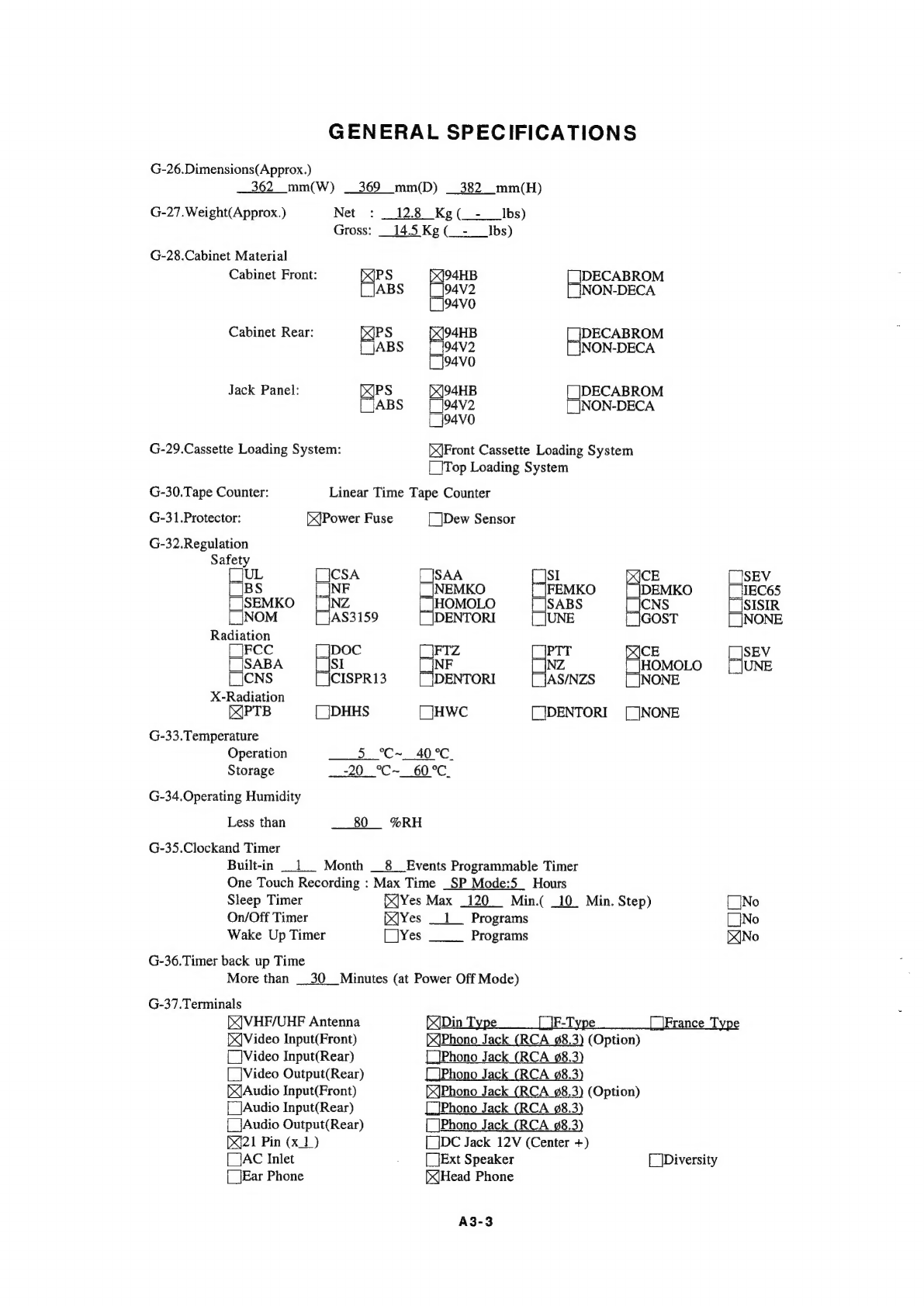

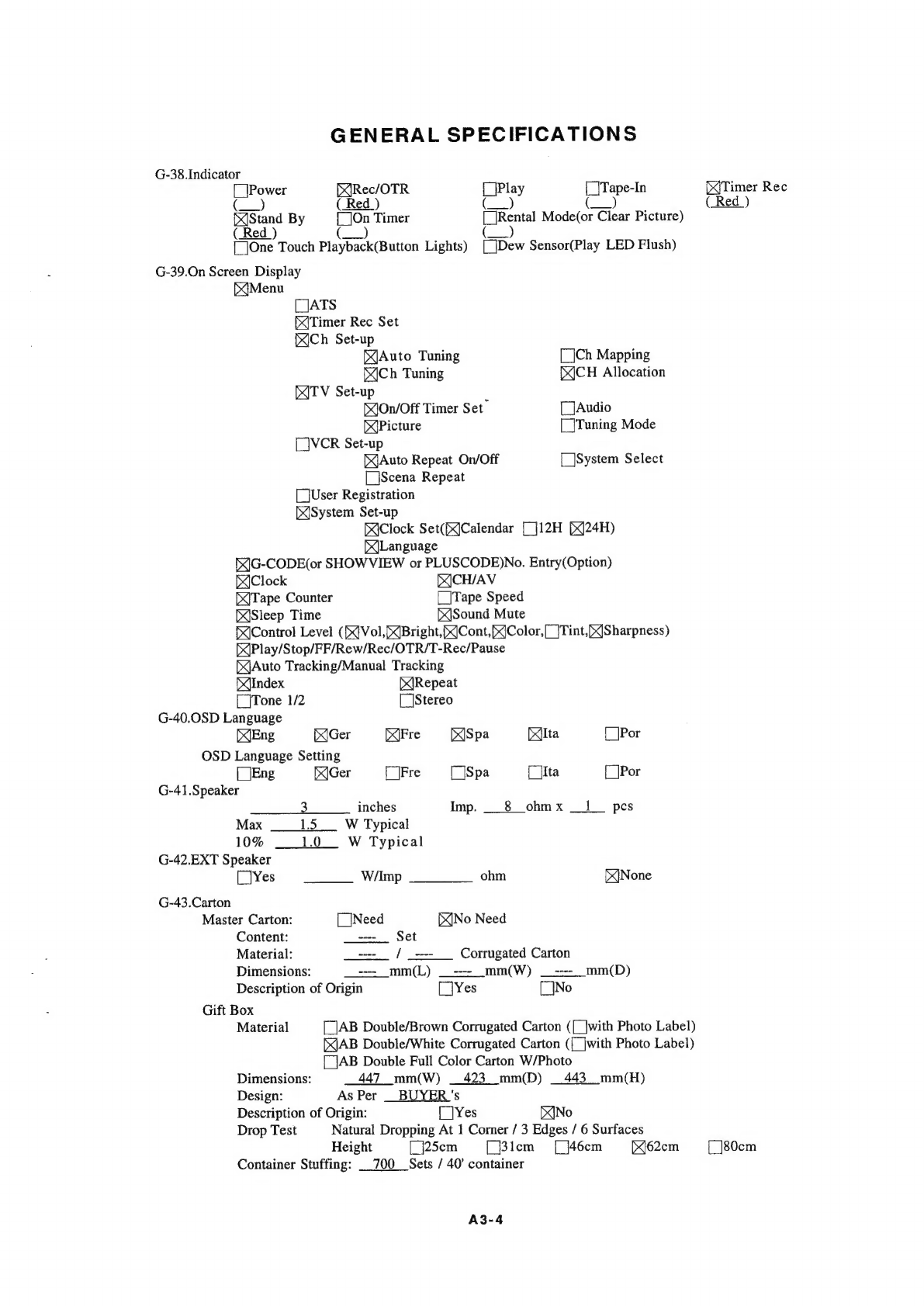

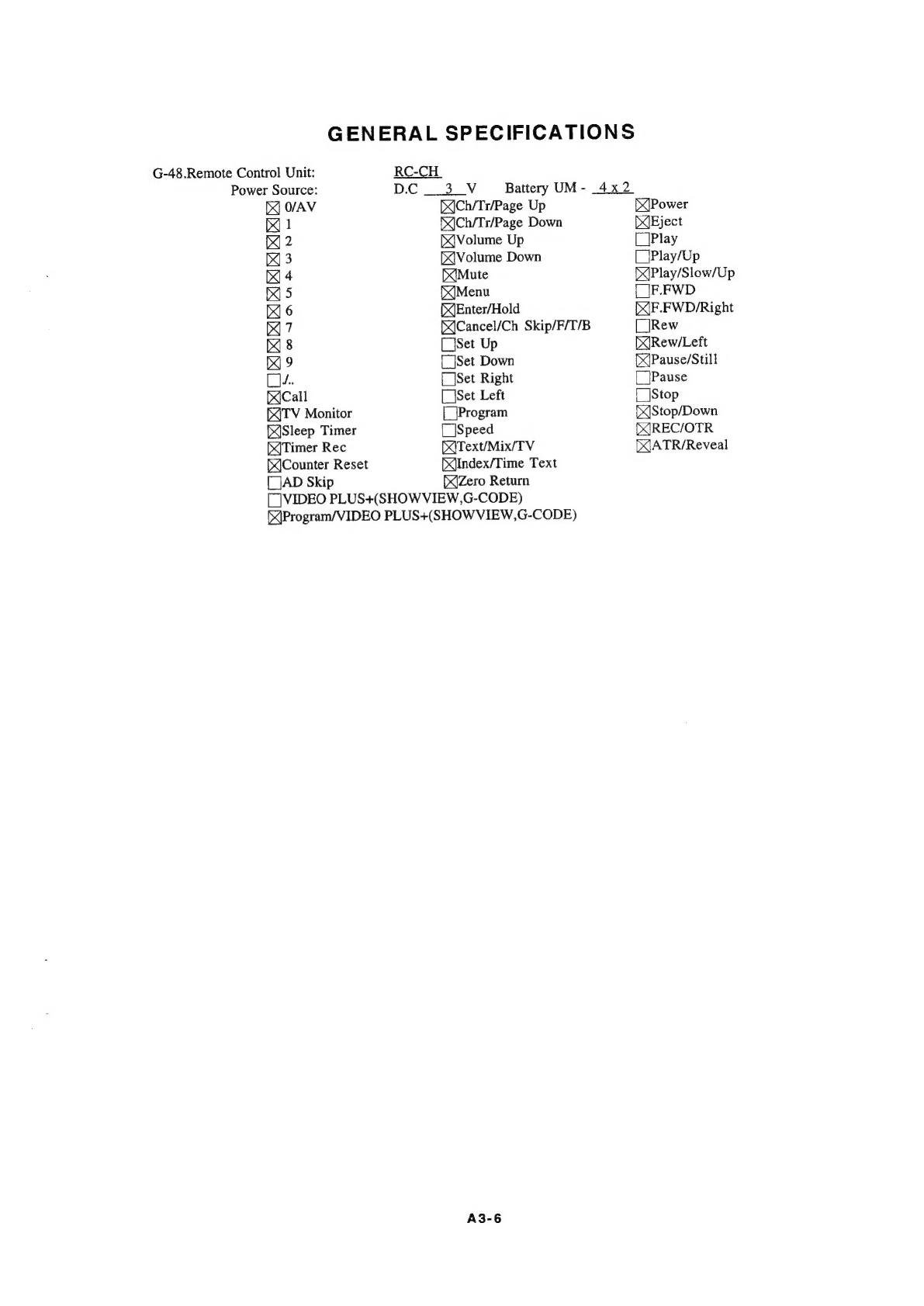

GENERAL

SPECIFICATIONS.

ou...

cscssssescsesssssesssssnecessesecnenensasvensentsssassceneracersnesenennsensneoess

A3-1~A3-6

DISASSEMBLY

INSTRUCTIONS

1.

REMOVAL

OF

MECHANICAL

PARTS

AND

P.

C.

BOARDS........ecsseseseerseseserensensssceneennees

Bi-1,

B1-2

2.

REMOVAL

OF

DECK

PARTS.

......cssssssssessssssresesesnesnssenracscensssscensnsrssecacasscseavavaneaescsseateeees

B2-1~B2-5

3.

REMOVAL

OF

ANODE

CAP

qu...

csssssssescsssseessesenenetensssnescesasseneneaeanansescesseneseneeaeeenesenenanans

B3-1

KEY

TO

ABBREVIATIONS

Qo...

cesscccessessssessssersssesrenseecsesnesessensuseesesenanenssusnssesareenessssseanesesscersees

C1-1,

C1-2

SERVICE

MODE

LIST

...........scecessesssesenscnescneeeenenserenee

‘

C2-4

PREVENTIVE

CHECKS

AND

SERVICE

INTERVALS

..................

wwe

63-1,

C3-2

NOTE

FOR

THE

REPLACING

OF

MEMORY

IC

.........eseeseeeeees

wee

C464

SERVICING

FIXTURES

AND

TOOLS.

...........csessssseeeterteseeseesesseeeescesennsessessenseneeseeeseets

.

C51

MECHANICAL

ADJUSTMENTS

...........ccccsesssssessesensssenensecssacensaessanenseneansscisseesnneneaes

i

D1-1~D1-4

ELECTRICAL

ADJUSTMENTS.

ou...

sssescesessssereecsesesenecsssssssesenensssnsereosoesarssenseesesisanenenseseesess

D2-1~D2-6

BLOCK

DIAGRAMS

To

rcssasecessbcutesSusout

eleveevssonsduosedickeacbiedicsencvdstatesdussecesedvaressussveasessavtoccdeceiaveneséeypaeasatands

|

|

gesndscaceedeenssee

E-1,

£-2

YICIAUDIO/HEAD

AMP/21PIN

uu...

sscssssesesssssesessrsnsssstsessenseeeeeenssssersesecnsasasanseneasceresscesseneaseseesene

E-3,

E-4

MICON/POWER/OPERATION/DECK

......sescssssssesscerssssesssseseesacsnenssnsssurnssneassesnscaenannrarssssecusenees

E-5,

E-6

TTEXT

u.cecessssessssssesessecsssesessessssesssnssssassevesesessencssscescsnsnsnnenennsgeassaseasdensvescansanssesssusossansets

senenenee

E-7,

E-8

PRINTED

CIRCUIT

BOARDS

MAIN/CRT/POWER

SW,

uu...

eesssssssssstssssrtsnscsessnseeessesarsesseasasenevenennesenecusnecnsnsseseananensaeransneesenense®

F-1,

F-2

OPERATION/DECK

.

a

F-3,

F-4

SYSCON

onvcscccsssssssesessssssecsvsscecsesscsscsesseeseensesseeesncsrsneessaceussessssenenseaesessegeenanseaenentananenenevenu

assert

wee

F-5~F-8

SCHEMATIC

DIAGRAMS

Y/CIAUDIO/HEAD

AMP

G-1,

G-2

MICO

.....c.ssescssccsossessscsscsesscessosscsennessusorsserssacoussscavensaneansnesetecosscanesescensensas

‘

G-3,

G-4

POWER

uu.

eeeesscssesessccscsessssssecssscsssoeensenessesnsossesssnenesnsenenssscansncosnseseeesesoasegusanensssecocssaranesenennenas

G-5,

G-6

QIPIN

vcsscesessssesscesseesesscsececsssoesssssnsarsenssuceesecaeseseseseessesnenseeracarsesesanseennsesssnesanarsnesensrseter

sraeanrareees

G-7,

G-8

CHROMA

SIF

........sscscscessssecsesesesessecsssvsessssssnsssessnssanesssonsneassesersnsecessesesecnesassnseensseazenanunanseneos

—

avenene

G-9,

G-10

SOUND

AMP.

......sssessssssessssssssesersssessssssessossssonessenvenssssansssnressacneaccanonassacsasenssesennonusoseraseuevseasorsee

G-11,

G-12

TV

POWER

...sscccsssesscessscesesnsssssssssssesacsnsevescersucesssnsesneassosnenecseaavencaecesesasnvsasaceuscecessssasnerrenstsenss

G-13,

G-14

DEFLECTION

......cssssessccsssssrssssessssrssesenessesesessesenssensusacestssserseneensscasoneasaveassscavansecsansustsesaneeanenegss

G-15,

G-16

CRT

cnesscsscssssscsesscssesscvsscssssososscssssssssnssacanssuesusnsorassesnsrauseescnsevensarsusssscucacsseseansonsesarasssess

—

sauseeananenaes

G-17,

G-18

OPERATION

......csssessssssessseesssssccsssssssnsesssessesessecessnesasssescnesersenerssecseansessnsneassassearanennescensns

—

aanseeseas

G-19,

G-20

TTS

TEXT:

Sissscsvecettcsan

ence

vssuectescvesvsssussosascnssesteveshscccsansssscuctecsessst

evsbucaebncoiveedisedisosesdvacuansdegesss

©

“ssetyZeedistee

G-21,

G-22

DEGK

sesocicdessctiicsasticesieteoscdsenccnsdensschssssdeinsebelasiaacesosdsiiecosobenstedoisosscosteobsbendeesdestnaielaescen:

©

oapbéterteedt

G-23,

G-24

INTERCONNECTION

DIAGRAN

.

ae

G-25,

G-26

WAVEFORMS

......

cc

cssessssessssesesessnsscsersseersesesesesennesssanensernasnenerensrennies

H-1~H-4

MECHANICAL

EXPLODED

VIEWS.

.........::scessssssssesseneesesseenseneneeses

a

1,

1-2

CHASSIS

EXPLODED

VIEWS.

.......usesssssesssesesserensenessenesssecaseenesnsssneeussssesensnenensnsoesegnenseneersaseats

1-3,

I-4

MECHANICAL

REPLACEMENT

PARTS

LIST

............ecccsecssssssesesssnsneesenesssensnenensssanseeerseencarenees

Jt-4

CHASSIS

REPLACEMENT

PARTS

LIST

...........:sscsssssssssssenscessensssenenssssereneesessnansscessnessenssonecsoes

J2-1

ELECTRICAL

REPLACEMENT

PARTS

LIST

............csssssssssseseessssesrenseseensersseenenenensensnenesecenenes

J3-1~J3-3

A2-1