Orwak 5070 User manual

Edition 4, From serial no. 106000-

Publ. no 4867331-03

OM 5070, 2012-02

Orwak 5070

OPERATING INSTRUCTIONS (IN THE ORIGINAL)

8

English

SAFETY

Please read the operating instructions BEFORE operating the machine.

Our warranty/product responsibility requires that:

• instructions are followed, and that no conversion or modication is carried

out.

• original spare parts, and hydraulic oils and lubricants recommended by the

machine manufacturer are used.

• at least one annual service is carried out.

The user of the machine is responsible for the safety checks, and for ensuring that

daily maintenance of the machine is carried out. The user is responsible for seeing to

it that defects are rectied, and that neither the user nor other persons are subjected

to danger.

The owner is responsible for ensuring that all laws and instructions are complied with

when using the machine.

This symbol means WARNING or DANGER - personal safety instruction!

This machine is designed for ONE MAN OPERATION.

Only the operator is allowed in the machine’s working area.

The machine must not be used if the safety functions (e.g. switches and pro-

tections) have been deactivated, damaged or removed.

Lost or damaged parts must be replaced withoriginal spare parts.

The machine has a high centre of gravity. If the machine needs to be moved,

the press platemust be lowered fully before moving.

Installation and service work may only be performed by qualied and com-

petent staff, and in accordance with the installation and service instructions.

The machine must not be used by minors.

Never climb on the machine.

Use both hands when pushing the press unit over to the next chamber and do

notllhigherthan100mmfromthetopofthechamber.

DO NOT OVERFILL THE CHAMBER

The machine may only be operated by a person who has received training and

has experience of the machine.

SAFETY FEATURES

The machine is equipped with the following safety features:

Mechanical and electrical switches that prevent the machine from being used when the

compactor head is being moved, the front cover is opened, mechanical interlocking of

doors and cover plates that protect the operator from the machine’s moving parts.

RANGE OF APPLICATION

The machine is a hydraulically operated baler intended for compacting bulky materi-

als such as cardboard, paper and plastic. The material being compacted must be

evenly distributed in the chamber. The machine may only be used in areas that have

a roof, protection against wind and normal lighting. The machine is intended for use

withinthetemperaturerange-10°Cto+40°C.Alow-temperatureoiland/orheatershouldbe

usedattemperatureslowerthan+5°C.

Materials that are ammable or of an explosive nature, such as pressurised

containers or equivalent which, when exposed to pressure or sparks, could

causedamage,reoranexplosion,must not be compacted in the machine.

Use only straps recommended bythe machine manufacturer.

NOTE! If this machine is supplemented with containers(400Lor660L)

the entire supplementary operating instructions for CONTAINERS must be

read through prior to use.

CONTENTS

Safety ................................8

Operating instructions........9

Technicalspecications....10

Dimensional sketch .........10

Transport .........................10

Installation .......................11

Weekly inspection and

maintenance....................12

CE....................................13

Errors and omissions excepted.

2

3

4

4

4

5

6

7

2

1

2

3

4

7

5

8

9

11

12

13

14

15

16

17

6

10

9

4872248-00(VG13)

=

Paper Plastic

English

OPERATING INSTRUCTIONS

Mounting the strap

Compaction

Baling

Pull the compactor unit to

one side.

Pull the strap through the slot

on the rear of the container.

Thread the strap through the

slot in the door and secure

the strap with a loop on the

front.

Use the bale tool and posi-

tion the strap in the slot at

the bottom and rear of the

container.

1

2

3

4

WARNING!

Only the opera-

tor is allowed in the

machine’s working

area!

Place the waste evenly

distributed in the chamber.

Pull the compaction unit over

the waste.

Press the lever for an auto-

matic press cycle.

5

6

7

Mounting the strap

Compaction

8Pull the strap through the slot

from the rear of the chamber.

9Pull the strap over the waste and

through the slot at the front of

the chamber.

10 Cut the strap with the knife.

15 Pull the compactor unit to one

side.

16 Open the door.

17 Remove the bale.

11 Press down the lever.

12 Wait until the press plate is just about to turn.

13 Turnthebaleswitchto0justasthepressplateis

about to turn upwards.

14 Tie the straps.

3

A=2160

B=735

C=1740

D=1205

E=656

F=138

G=1660

H=1430

H

B

EF

C

G

A

D

5070 std.

4890045-00

OK

OK

522 kg

157 kg

10

DIMENSIONAL DRAWING

TRANSPORT

English

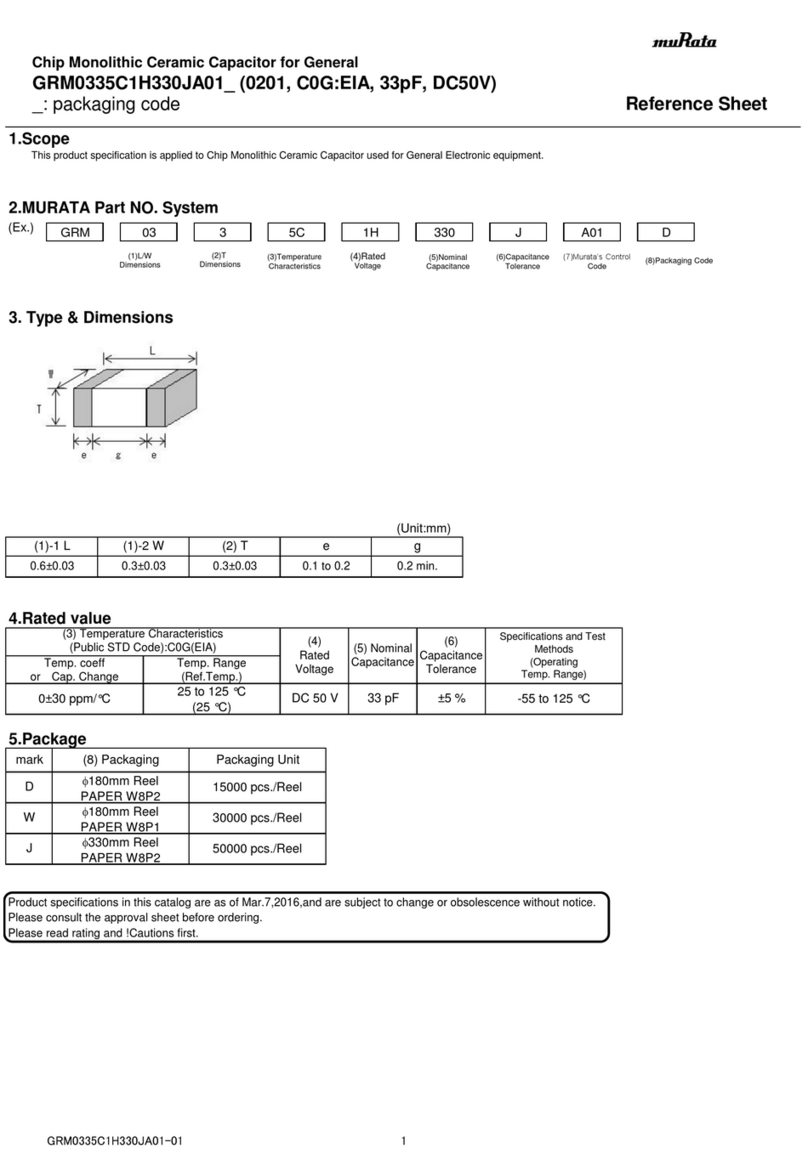

TECHNICAL

SPECIFICATIONS

(Valid for 490 5070-00 unless other-

wise indicated)

GENERAL DATA

Doublecontainer: 365kg(833lbs)

Compactorunit: 157kg(352lbs)

Totalweight: 522kg(1,185lbs)

Dimensions:

Height: 2160mm(7’1’’)

Width: 1740mm(69’’)

Depth: 880*mm(35’’)

Transportheight: 2160mm(7’1’’)

*includingstrapholders

Recommended oor space for a

machine in operation:

Height: 2160mm(7’1’’)

Width: 2940mm(116’’)

Depth(opendoor): 2030mm(80’’)

Container dimensions:

Height: 960mm(38’’)

Width: 700mm(28’’)

Depth: 500mm(20’’)

Bale size:

Height: 700mm(28’’)

Width: 700mm(80’’)

Depth: 500mm(20’’)

Weight (paper): up to 50 kg

Weight (plastic): up to 80kg

Noise level: 70(±1.0)dB(A)

(ISO11200&11202)

Paint: Two-part paint and powder coat

with phosphatising as base.

ELECTRICAL DATA

Operating power: 230V,50Hz

Electric motor: 1.1kW

Electrical connection: 10A

Protection class: IP55

HYDRAULIC DATA

Working pressure:

110bar(1595psi)

Relief pressure:

140bar(2030psi)

Compacting force:

3t(30kN)(6,600lbs)

Surface pressure:

0.9kg/cm²(12.8psi)

Cycle time total: 36s.

Piston stroke: 790mm(31’’)

Oil volume, tank: 4.9L(1.3gal.)

Max. temperature: 70°C(158°F)

Recommended hydraulic oil:

+5°C to +60°C: ISOVG32-68,

Mineral oil

below 5°C:

A special oil or a heater may be

needed at lower

temperatures.

4

OK.

1

3

7

8

4

2

6

0,9 m

min 0,6 m min 0,6 m min 0,6 m

2 m

5

5 mm

45 Nm

13 mm

Box 58

576 22 Sävsjö

Sweden

Type Serial No

Product No Date

V

Weight

Hz kW A

** *

***

11

INSTALLATION

English

5

HYDRAULIC

OIL VG 32-68

+5 C

o

B

4 C

o

= =

A

=

SAE 20

=

Special oil

Mineral oil

10A

0

OFF

12

SAFETY CHECK

- Check annually the limit switch and the piston activated by the switch in accordance with the service

instructions. NOTE! In extremely dusty environments, this check should be performed quarterly. Contact

authorised service personnel immediately if the press plate can be started in any position other than directly

above the container, or with the front door open.

- Check that all covers and guards are intact.

- Check that there are no oil leaks on the machine.

- Check that the electrical supply cable is intact and properly protected against impact.

If any faults are discovered in the functions listed above, the machine must not be used until it has been

repaired by authorised service personnel.

Service and repairs are only to be performed by qualied and competent staff, and in accordance with the

machine manufacturer’s instructions.

Oil change: Contact the local authorities for advice regarding how to reduce the environmental impact when

dealing with residual oil.

NOTE! During inspection and maintenance, service work

and the removal of trapped waste, etc.:

1.Disconnectthecurrenttothemachine.

2.Donotworkinsidethemachine

WEEKLY INSPECTION AND MAINTENANCE

English

TROUBLESHOOTING: FIRSTLY, CHECK

NORMAL TRIPPED

MOTOR PROTECTION

6

Box58

S-57622Sävsjö,Sweden

Tel:46-382-15700

Telefax:46-382-10607

Sävsjö2012-02-01

AB ORWAK

4905070-00 - 4905070-99

4905070-S001 - 4905070-S999

13

2006/42/EEC(MachineryDirective)

2004/108/EEC(EMCDirective)

2009/125/ECErPDirective(Energy-relatedProducts)

ThemachinefullstherequirementsofPL=

candcategory1accordingtoENISO13849-1:2008

EN60204-1 (SafetyofMachinery–ElectricalEquipmentofMachines)

EN61000-6-1 (EMCImmunityforresidential,commercialandlight-industrialenvironments)

EN61000-6-2 (EMCImmunityforindustrialenvironments)

EN61000-6-3 (EMCEmissionstandardforresidential,commercialandlight-industrial

environments)

EN61000-6-4 (EMCEmissionstandardforindustrialenvironments)

ENISO13849-1 (SafetyofMachinery–Safety-relatedpartsofcontrolsystems)

to which this declaration relates is in conformity with the following

standards or other normative documents following the provisions of Directive

declares under its sole responsibility that the product model

(serialnumberspeciedontherstpage)

EC DECLARATION OF CONFORMITY

We

Product Manager and compiler of technical documentation

English

7

Orwak is a world leader in compaction and baling solu -

tions for solid waste material at source. We develop,

manufacture and market a comprehensive range of

waste compactors, baling systems and “Brickman” bri -

quette presses for recyclable materials that make waste

management more profitable. This is where Orwak’s

unequalled technology, expertise and service support

make all the di erence. When you partner with Orwak,

you also gain access to the vast experience we have

built up since 1971.

Orwak is wholly owned by the Norwegian company

Tomra, a leading global player in providing integrated

solutions for recovering and recycling used packaging.

Leader in compaction

and baling solutions

www.tomra.com

Other manuals for 5070

1

Table of contents

Popular Industrial Electrical manuals by other brands

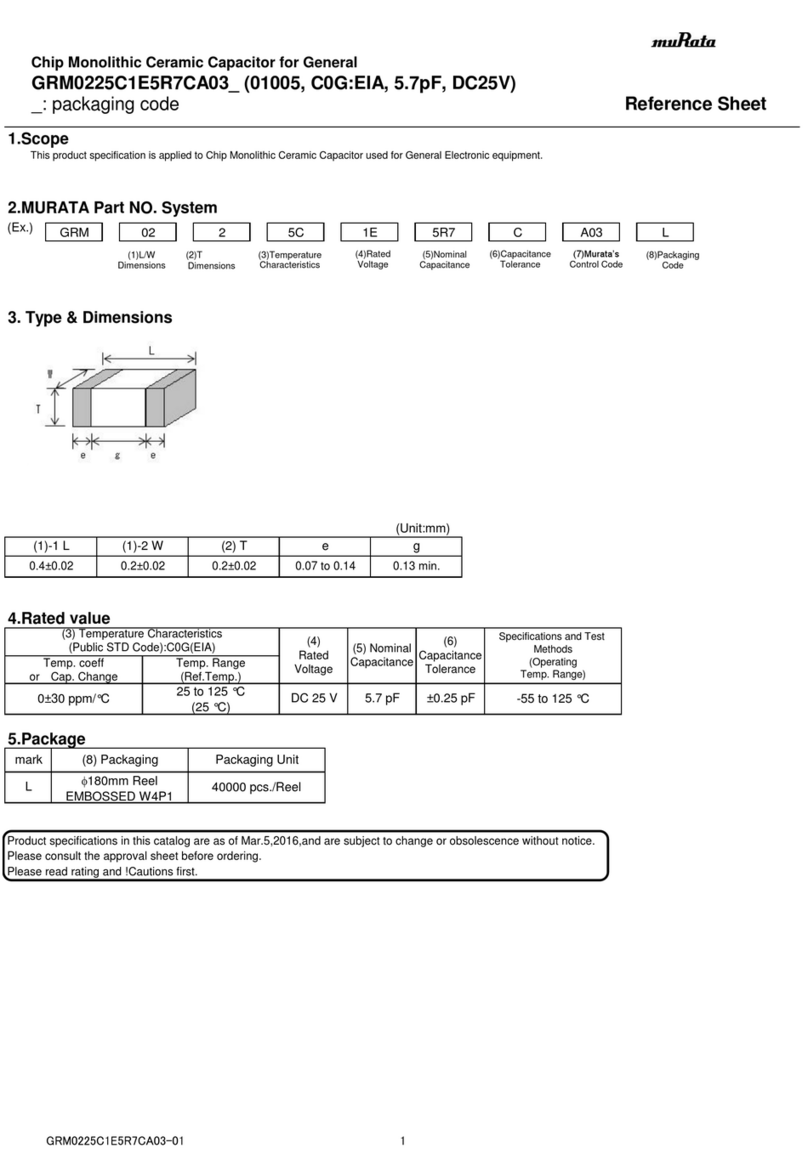

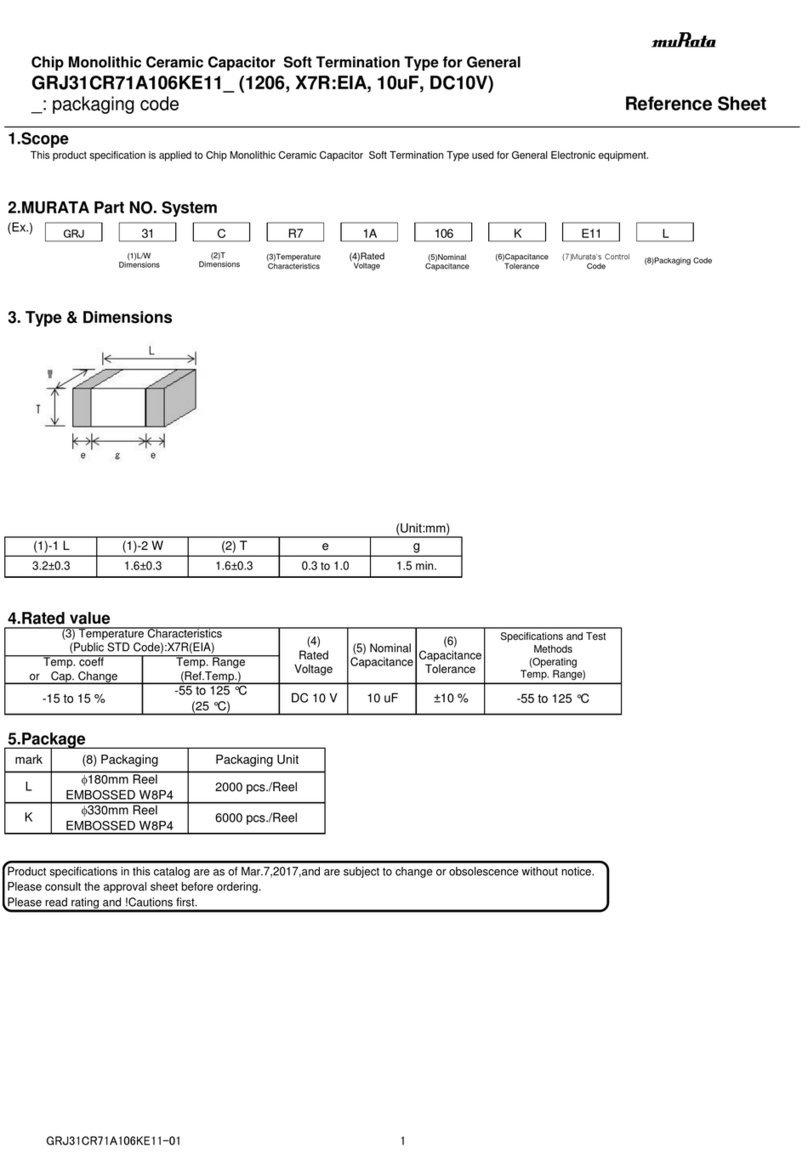

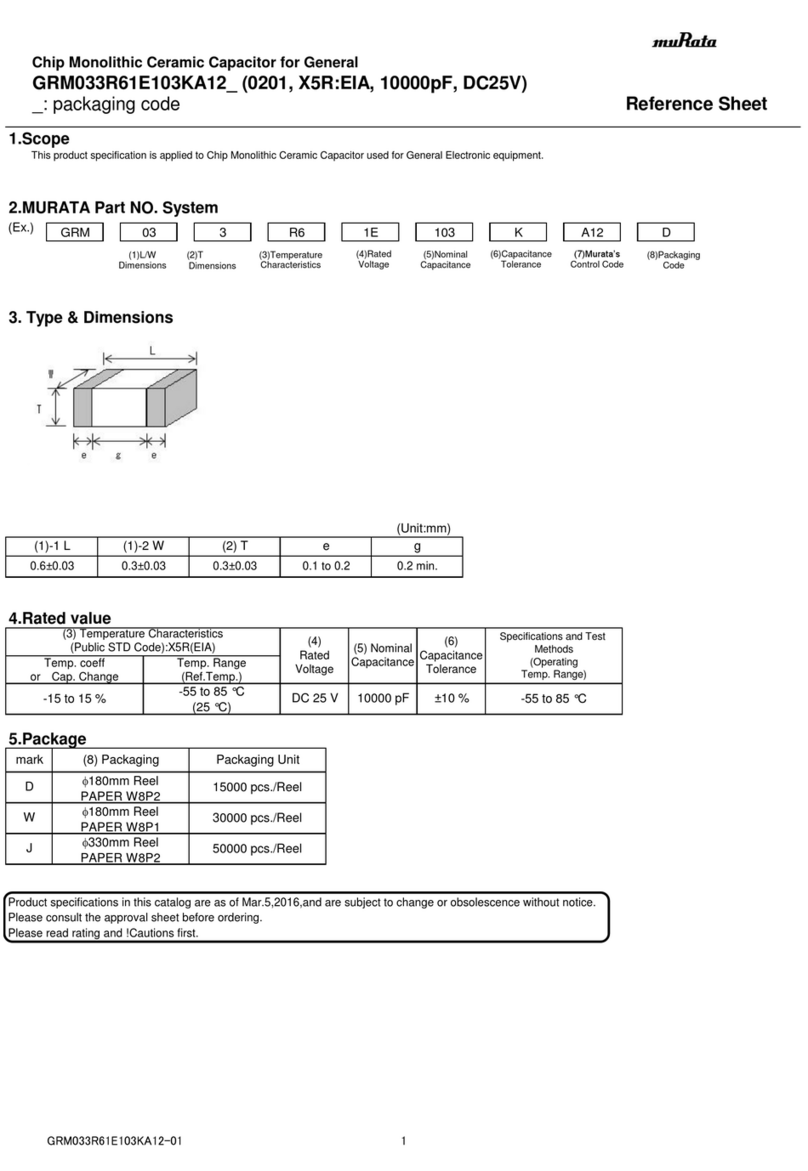

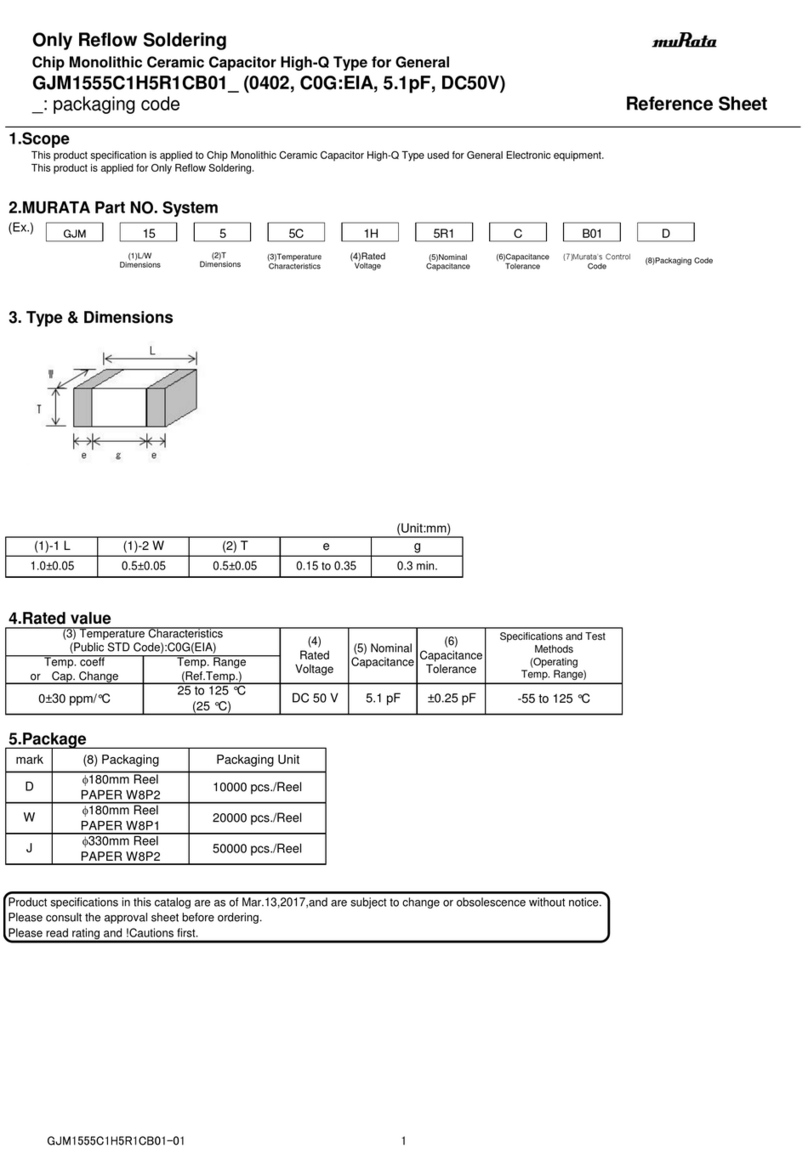

Murata

Murata GRM033R61E103KA12 Series Reference sheet

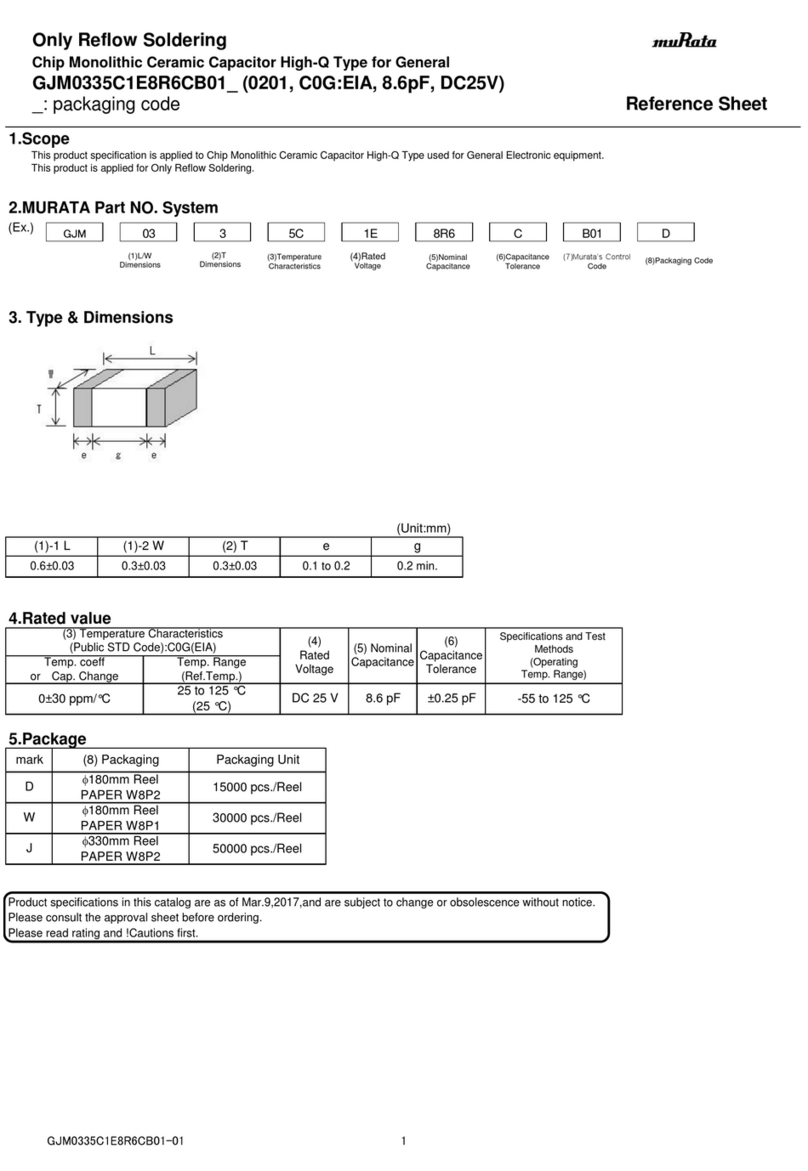

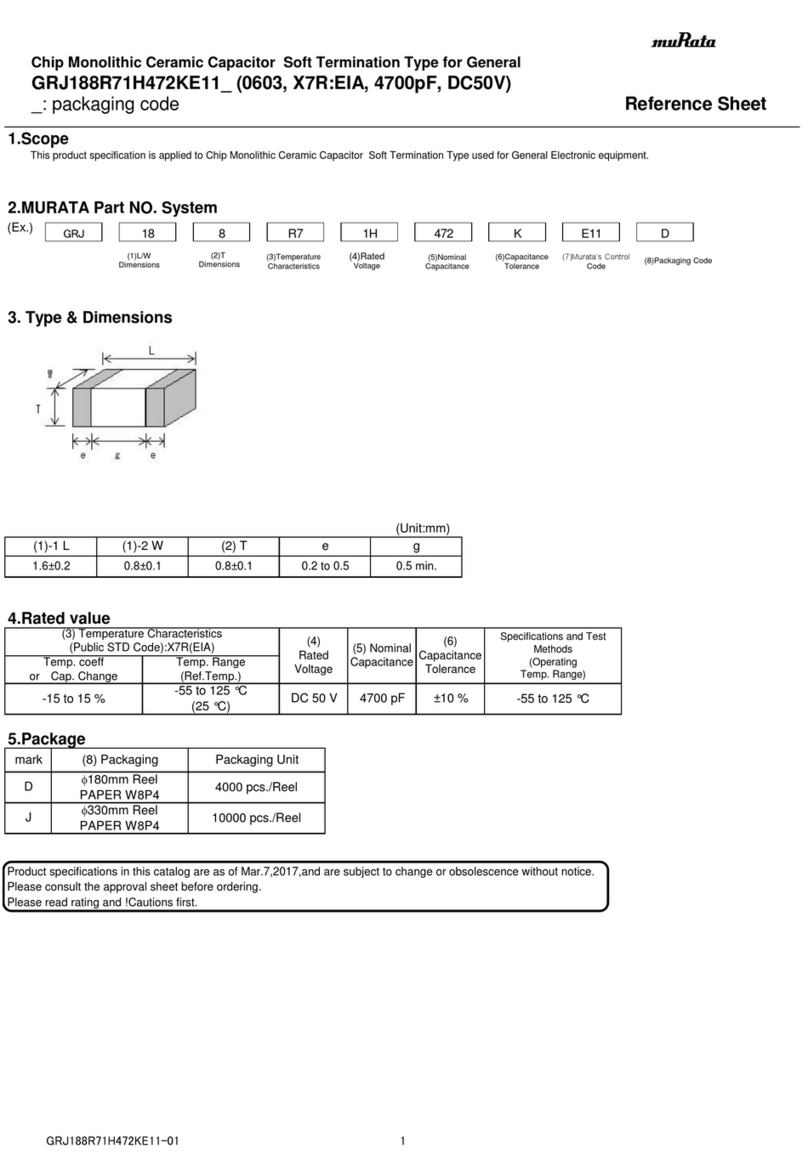

Murata

Murata GRJ188R71H472KE11 Series Reference sheet

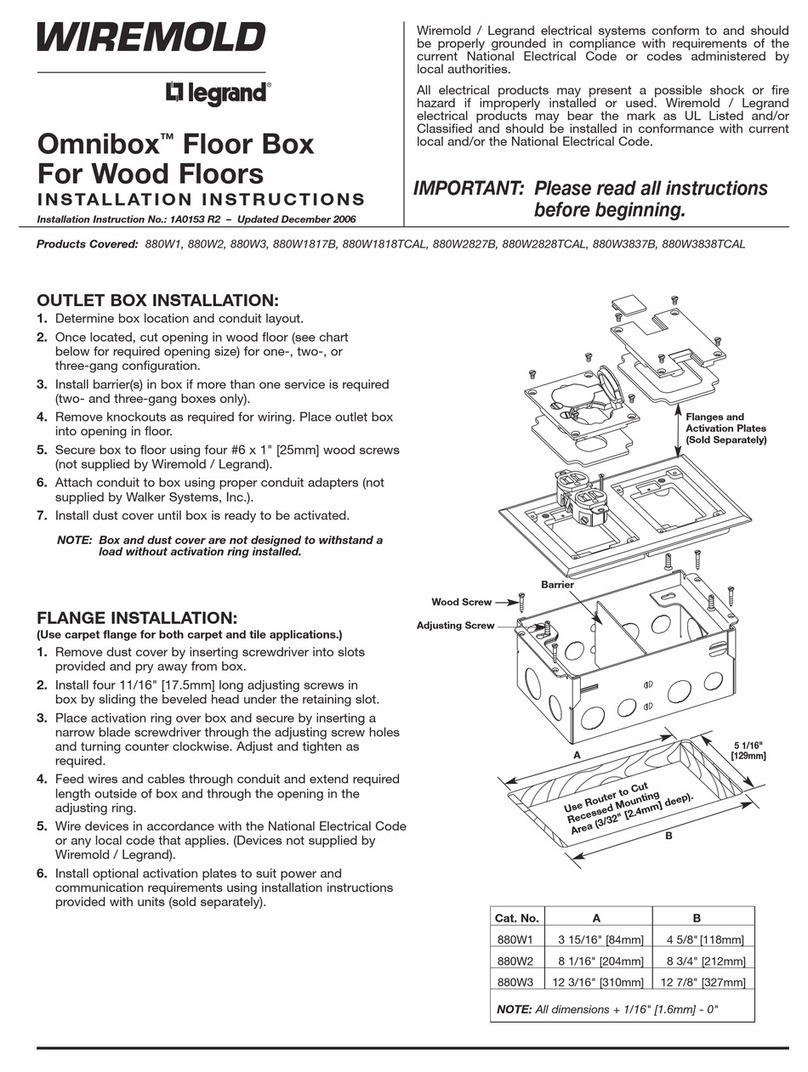

Wiremold

Wiremold Legrand Omnibox installation instructions

Murata

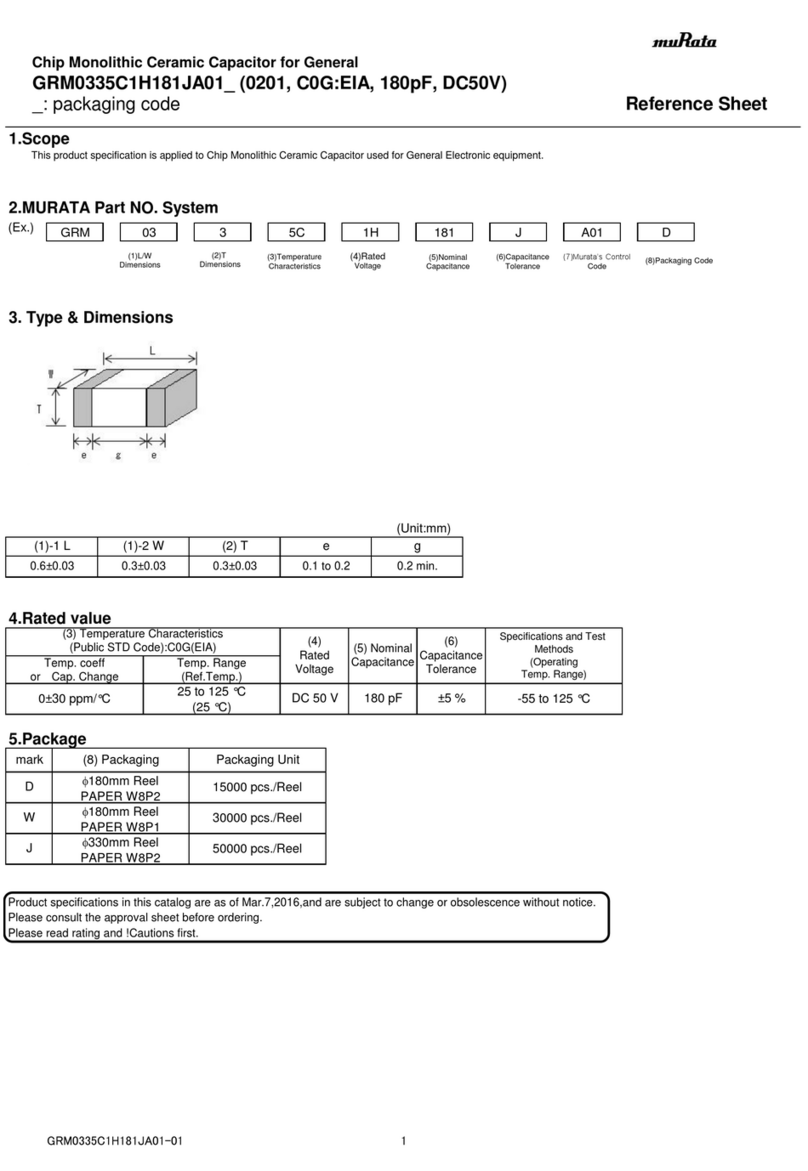

Murata GQM1885C1H100JB01 Series Reference sheet

Gilson

Gilson MD-2000F operating manual

Murata

Murata GJM1555C1H5R1CB01 Series Reference sheet