INSTRUCTIONS FOR INSTALLATION

We reserve the right of alternations

Contents

1. Introduction ....................................................................................................................... 1

1.1. A licable documents................................................................................................. 1

1.2. Retention of documents .............................................................................................. 1

1.3. Features & benefits..................................................................................................... 1

1.4. O eration of domestic hot water (where a licable).................................................... 1

1.4.1. Availability ............................................................................................................ 1

1.4.2. O eration.............................................................................................................. 1

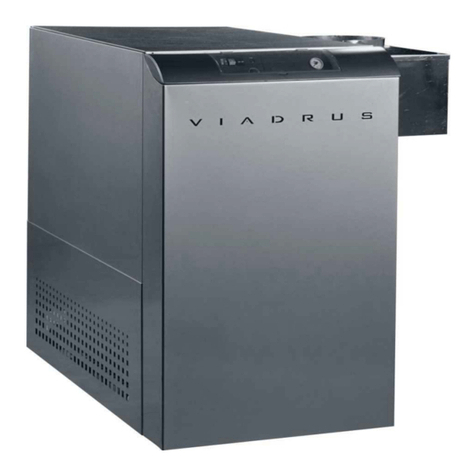

2. Termo M range.................................................................................................................. 2

2.1 Key to Termo boilers.................................................................................................... 2

2.1.1 Termo RS - M........................................................................................................ 2

2.1.2 Termo Plus - M...................................................................................................... 4

2.1.2 Termo PTV - M...................................................................................................... 6

2.2 Ex ansion Vessel Characteristics (Plus And PTV Boilers) ........................................... 8

2.3 Power su ly characteristics 240V............................................................................... 8

3.0. Installation ...................................................................................................................... 9

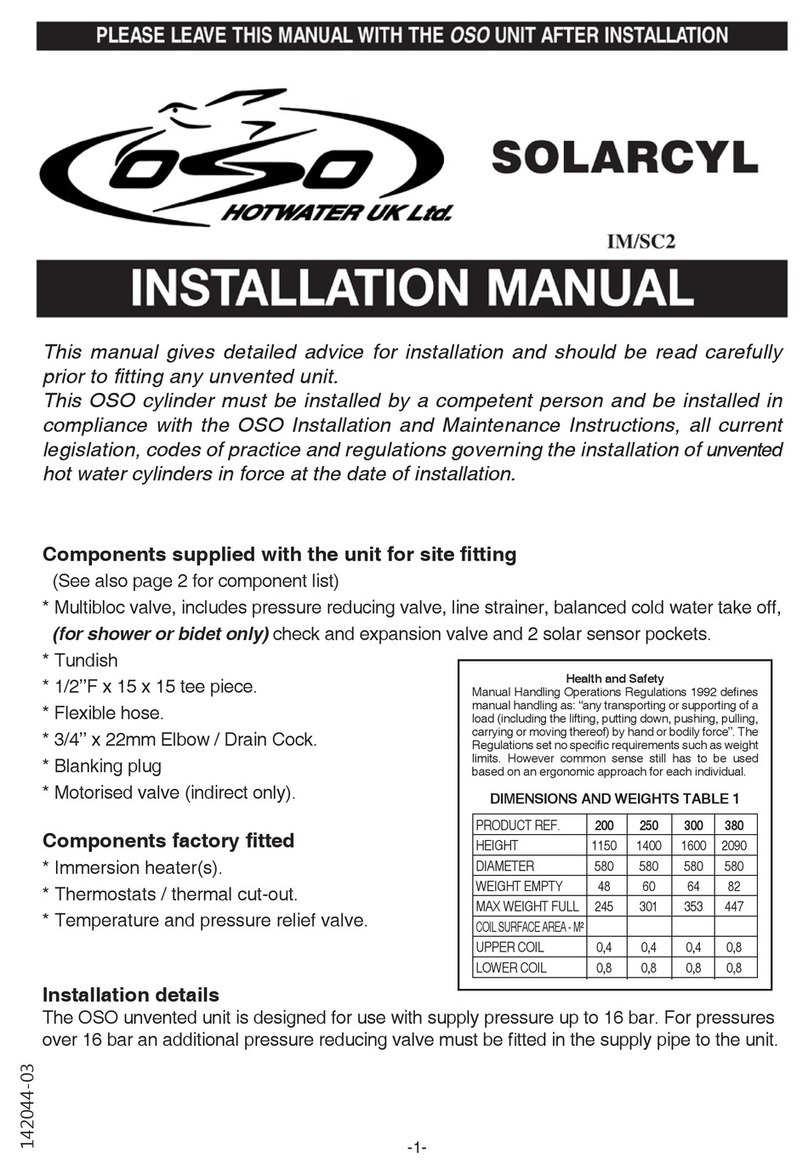

3.1. Content included in delivery ........................................................................................ 9

3.2 Standards & Regulations ............................................................................................. 9

3.3. Physical Installation site.............................................................................................. 9

3.3.1 Select osition for boiler .......................................................................................10

3.3.2 Fitting the boiler hanging bracket..........................................................................10

3.3.3 General recommendations when handling............................................................10

3.3.4. Removing/fixing the front and to case................................................................11

3.4. Plumbing & Heating installation & commissioning ......................................................11

3.4.1 Installation ............................................................................................................11

3.4.2 Ancilliary com onents...........................................................................................11

3.5. Connection to the electrical mains su ly ..................................................................12

3.6. Connecting external controls......................................................................................13

3.6.1 Connect room thermostat/ rogrammer.................................................................13

3.6.2. Connecting external um on TERMO RS boilers ...............................................13

4. Commissioning.................................................................................................................14

4.1. Control anel key.......................................................................................................14

4.2 Protection from freezing..............................................................................................14

5. Fault finding guide ............................................................................................................15

6. Maintenance.....................................................................................................................21

6.1. Periodic checking.......................................................................................................21

7. After Sales service information .........................................................................................21

8. Cascade ower limiter ......................................................................................................21

9. OSO Hotwater UK Ltd ......................................................................................................21

10. A endices.....................................................................................................................22

10.1 Termo RS-M with s ace heating and water heating ..................................................22

10.1.1. Hydraulic diagram Termo RS-M ........................................................................22

10.1.2. Electric diagram Termo RS-M............................................................................22

10.1.3. S- lan wiring layout ...........................................................................................23

10.2 Termo RS s ace heating only...................................................................................24

10.2.1 Hydraulic diagram Termo RS-M .........................................................................24

10.2.2. Electric diagram Termo RS-M............................................................................24

10.2.3. S-Plan wiring layout Termo RS-M......................................................................24

10.3 Termo Plus - M .........................................................................................................25

10.3.1. Hydraulic sketchs Termo lus-m.......................................................................25