SYSTEM STARTUP

WARNING: DO NOT ALLOW THE AERATOR TO OPERATE “DRY” OUT OF THE WATER

B. Energizing the Unit (To be performed by a qualified technician)

1. Single Phase Units: Correct motor rotation is factory determined and not field adjustable. Three Phase Units:

Verify correct motor rotation (Counter Clockwise looking at the top/impeller end of the unit). Check current

readings on each phase. Verify three phase operating currents are balanced within 5%. When correct, record

the operating voltage & amperage on the inside door of the PCC or motor controls.

To calculate the percent of current unbalance determine the Average Current: (a) Measure each of the three

phase currents. (b) Add the three phase amperage values together. (c) Divide the sum by three. (d) This is the

average current value. Determine Current Unbalance: (a) Select the phase current with the greatest difference

from the average (calculated above). (b) Determine the difference between this phase current and the average

current value. (c) Divide the difference by the average. (d) Multiply the result by 100 to determine percent of

unbalance.

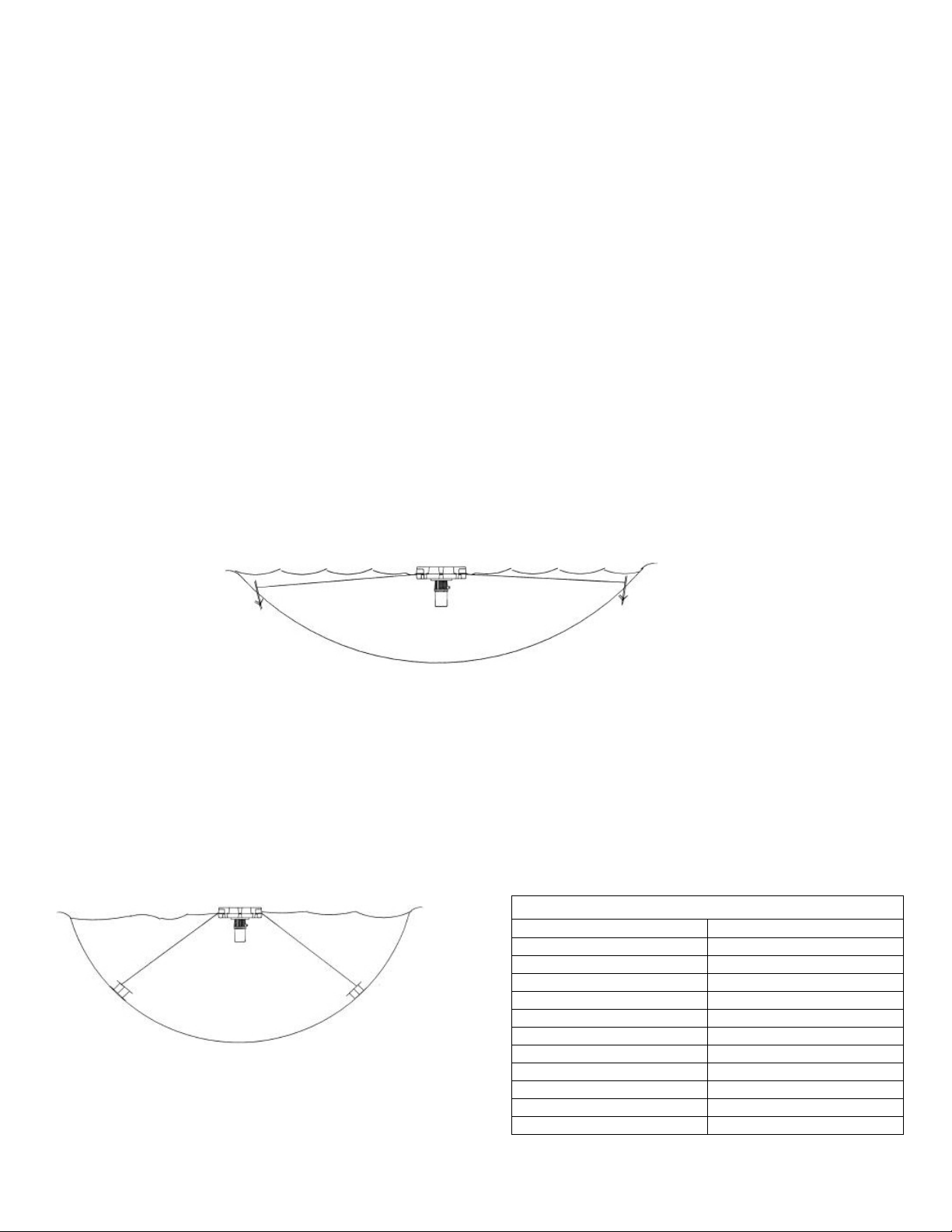

3. Use connection diagram 1, 2 or 3 (below) which results in the lowest current unbalance. Roll the motor cable

leads on the aerator output terminal block in the same direction to avoid motor reversal. If the current

unbalance is not corrected by rolling leads, locate the source of the unbalance and correct it. When the phase

farthest from the average stays on the same power lead after being moved the primary cause of unbalance is

the power source. When the phase farthest from the average moves on each of the hookups with a particular

motor lead, the primary cause of unbalance is the "motor side" of the circuit. Consider: damaged cable, leaking

splice, poor connection, or a faulty motor as possible causes.

PUMP PUMP PUMP

DIAGRAM 1 DIAGRAM 2 DIAGRAM 3

MAINTENANCE

This unit requires periodic maintenance: Once a year, disconnect the unit from the power source and

physically inspect the unit and cable for any cuts, cracks or breaks. These may cause oil leaks and/or electrical

shorts. Inspect and clean the pumping chamber and screen. After every three running seasons, a simple oil

change is needed to keep your unit running smoothly. Otterbine oil must be used, contact your Otterbine

distributor to order a maintenance kit, P/N: 12-0077.

WINTERIZATION

If you are located in a region that experiences long periods of cold weather you need to remove your unit from

the water and store it in a dry, secure location where the temperature does not get below freezing. If a unit

becomes frozen-in, it could damage the unit. Damage caused by freezing conditions is not covered under

warranty.