IMPORTANT SAFETY INFORMATION –PLEASE READ THESE INSTRUCTIONS

CAREFULLY PRIOR TO COMMENCING INSTALLATION

Responsibility for the correct and safe installation rests with the installer.

Read through the full manual prior to installation.

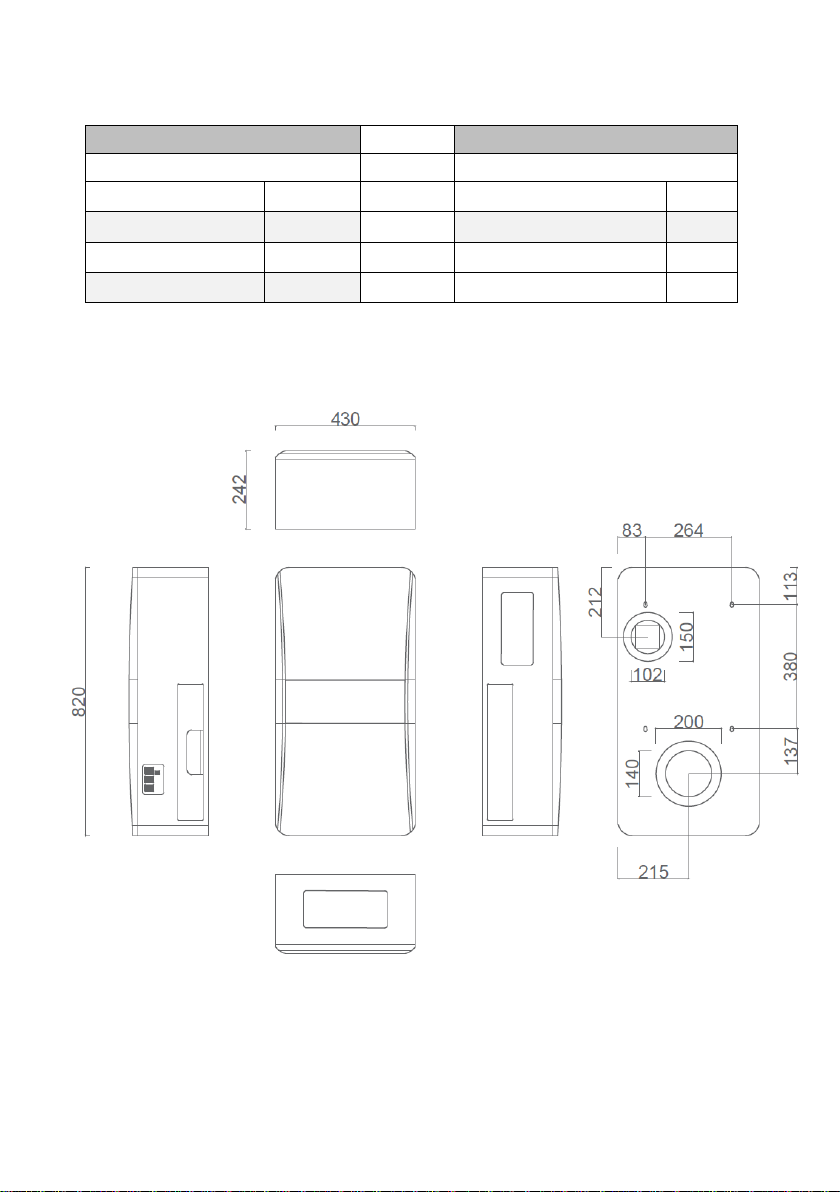

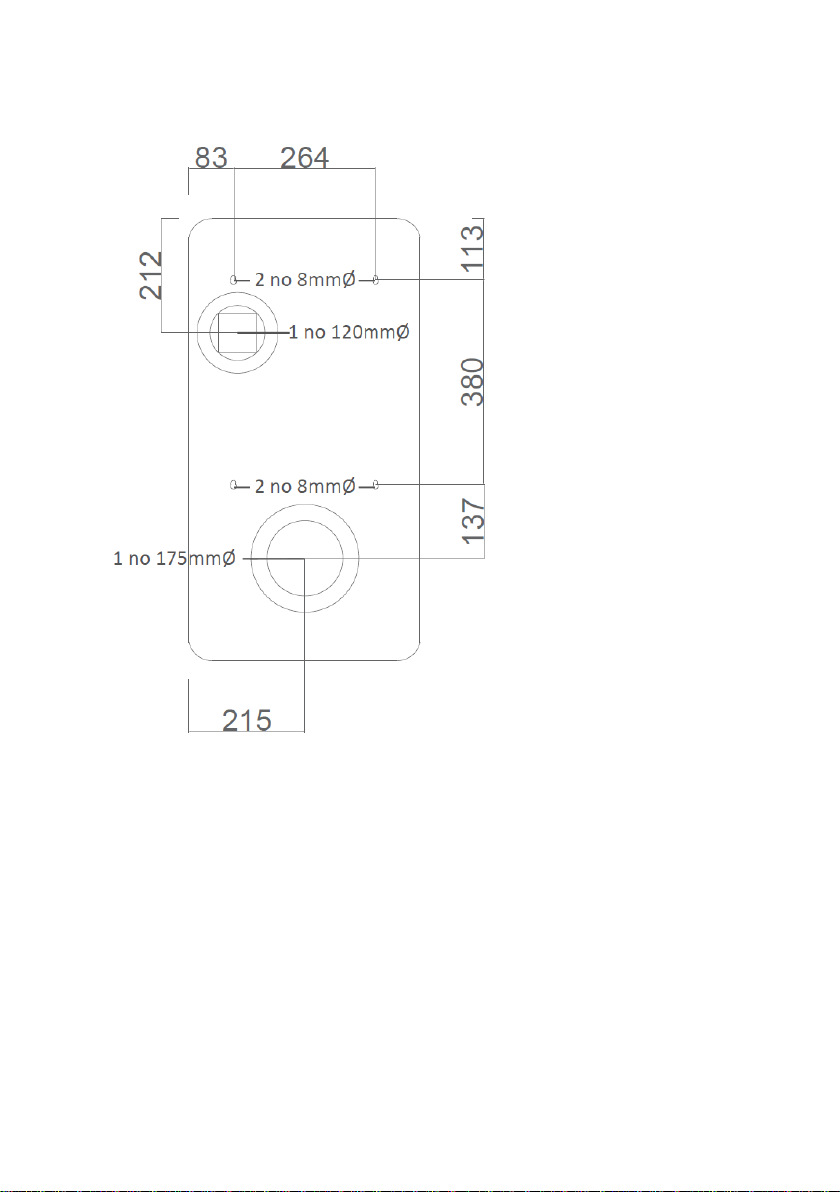

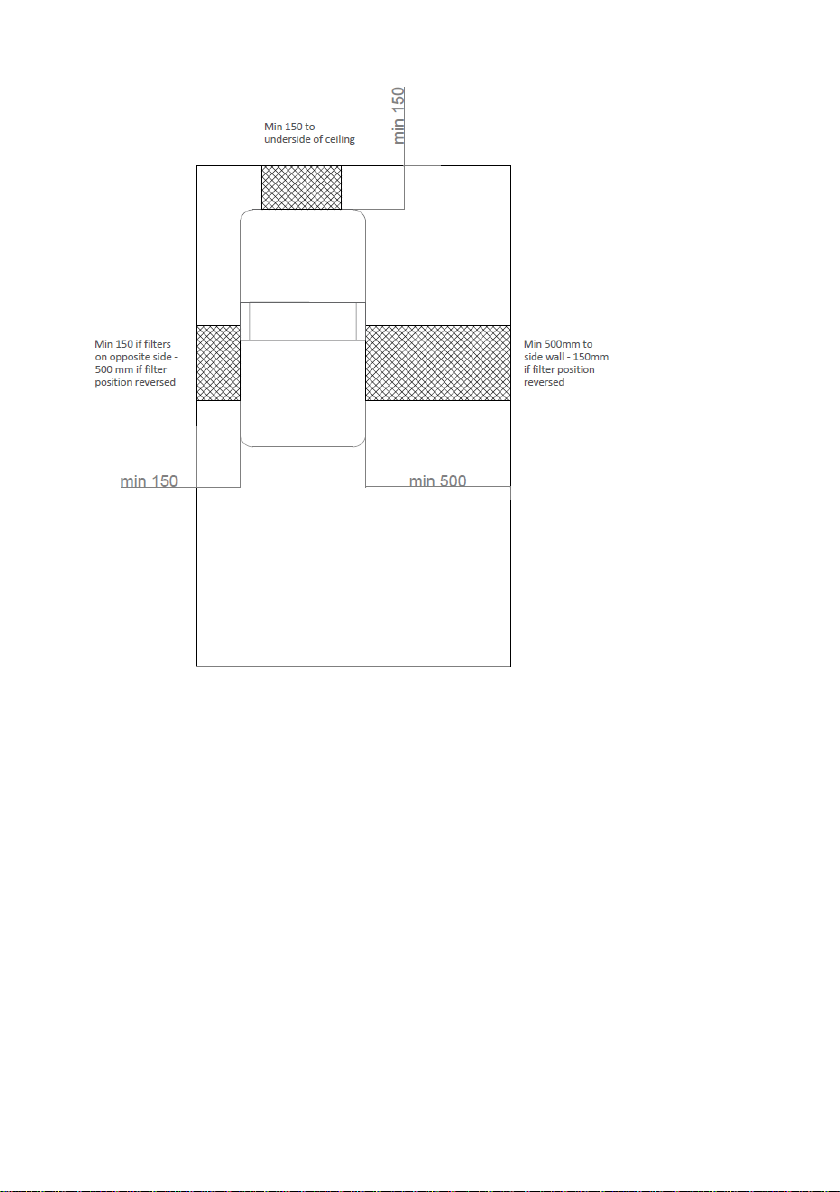

Make sure there is sufficient space to install the unit for effective operation and to

ensure access for maintenance and servicing.

Take care to ensure the external air intake is positioned so that it is not near

combustion gases, boiler vents or other open flues.

Any electrical work must be done by a qualified and licensed electrician.

If the power cable is damaged, do not use the unit and contact the supplier.

Use at the rated voltage.

Install the unit to a sufficiently strong wall surface with appropriate anchors for the

weight.

Do not use is excessively hot temperatures (above 40C) or excessively cold

environments (less than -20C).

In areas prone to strong winds, install a 90-degree bend on the wall termination kit if

the prevailing winds are liable to blow directly at the external intake or extract louvre.

This appliance is not intended for use by persons (including children) with reduced

physical, sensory or mental capabilities, or lack of experience and knowledge, unless

they have been given supervision or instruction concerning use of the appliance by a

person responsible for their safety.

Young children should be supervised to ensure they do not play with the appliance.

Turn the unit off whilst undertaking any building renovations.

Before doing any maintenance work, including changing or cleaning filters, the unit

must be isolated from the electrical supply.