palmiye SILVER PLUS User manual

Popular Outdoor Light manuals by other brands

Kichler Lighting

Kichler Lighting HELEN 37536 instructions

Thorn

Thorn OXANE L installation instructions

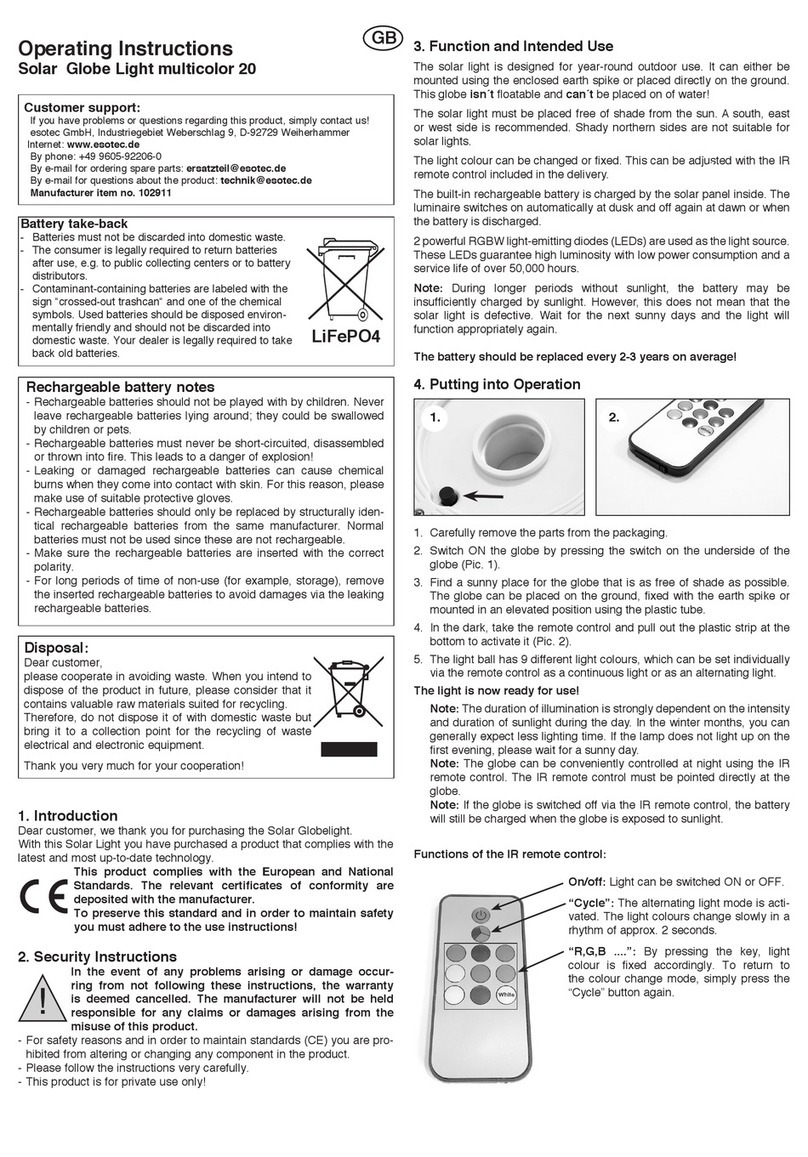

esotec

esotec Solar Globe Light multicolor 20 operating instructions

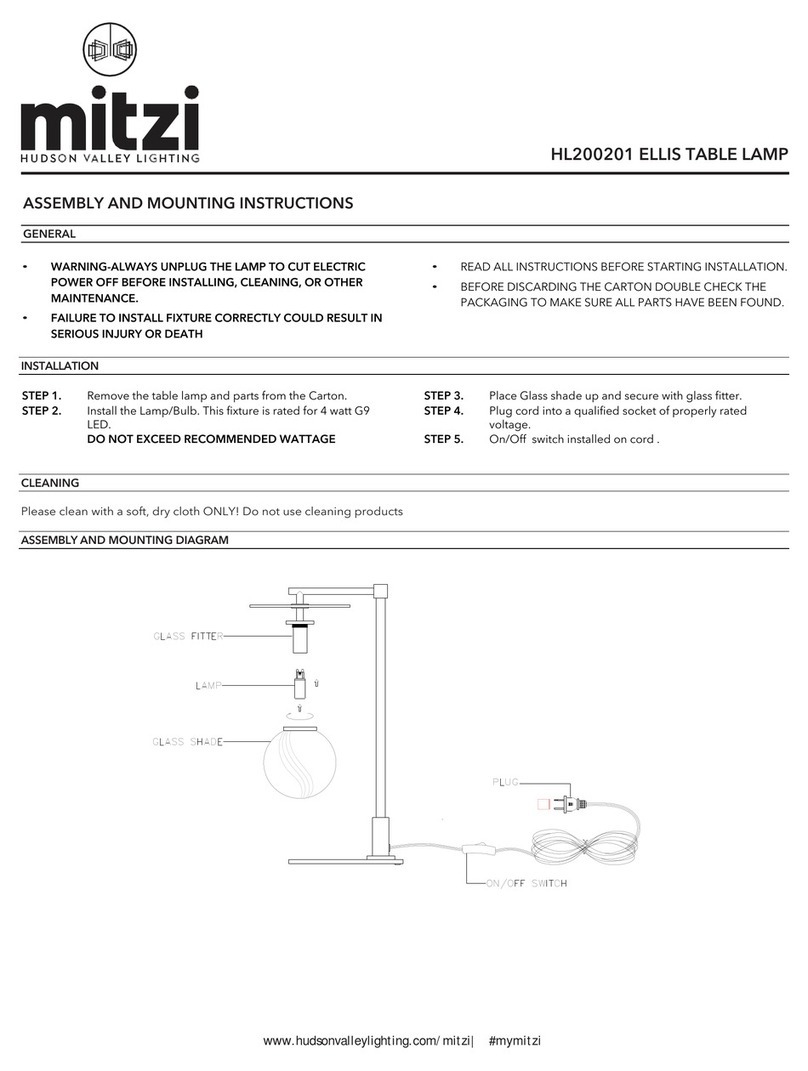

mitzi

mitzi HL200201 ELLIS Assembly and mounting instructions

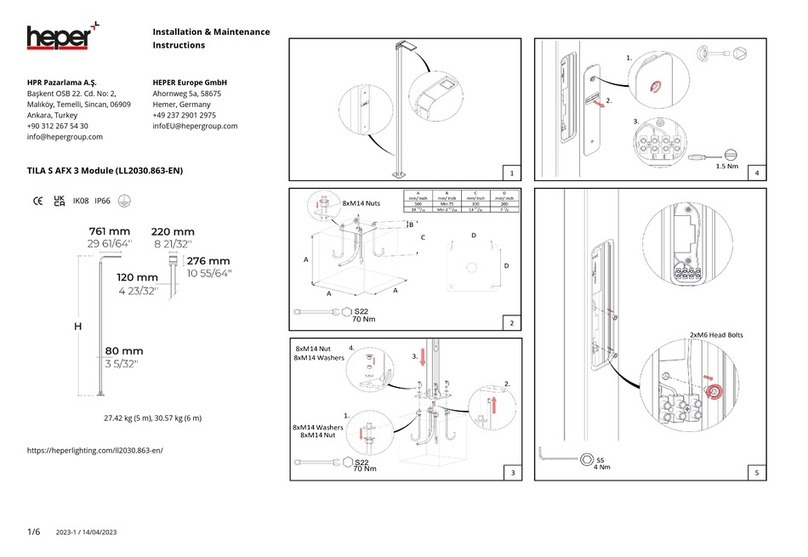

HEPER

HEPER TILA S AFX 3 Module Installation & maintenance instructions

Designplan

Designplan TRON 180 installation instructions

BEGA

BEGA 84 253 Installation and technical information

HEPER

HEPER LW8034.003-US Installation & maintenance instructions

HEPER

HEPER MINIMO Installation & maintenance instructions

LIGMAN

LIGMAN BAMBOO 3 installation manual

Maretti

Maretti TUBE CUBE WALL 14.4998.04 quick start guide

Maxim Lighting

Maxim Lighting Carriage House VX 40428WGOB installation instructions