Park Scale Models NS-TKAT User manual

Other Park Scale Models Toy manuals

Park Scale Models

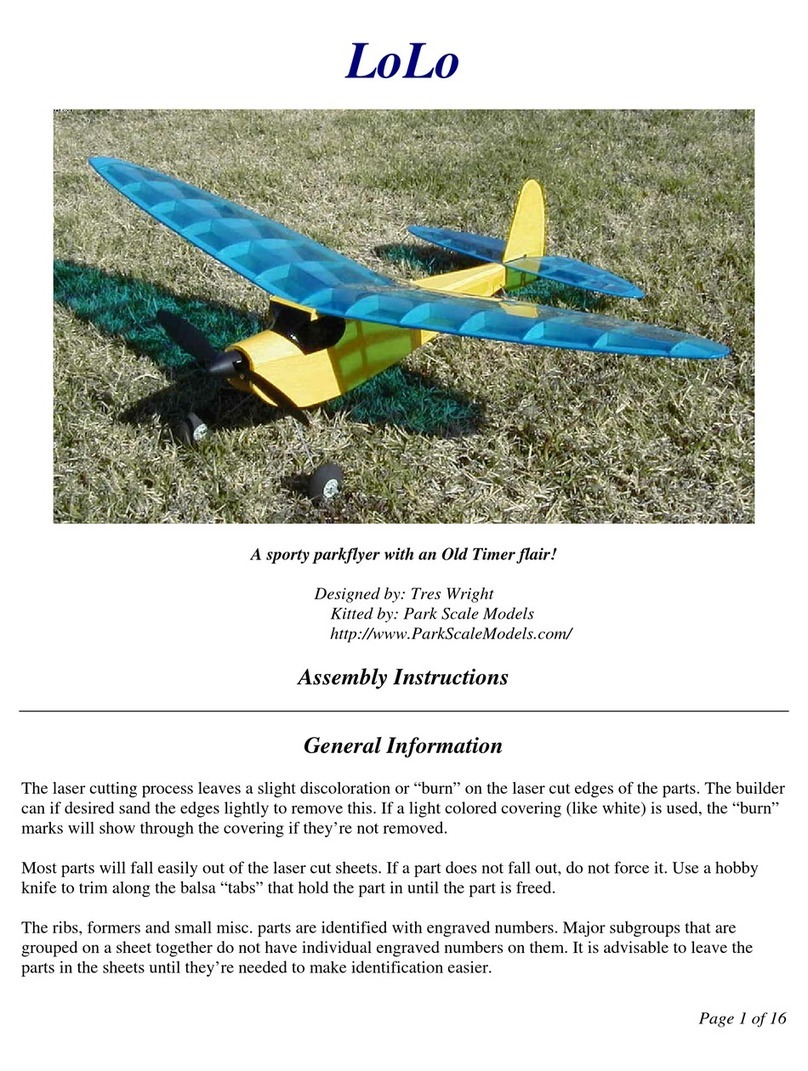

Park Scale Models LoLo User manual

Park Scale Models

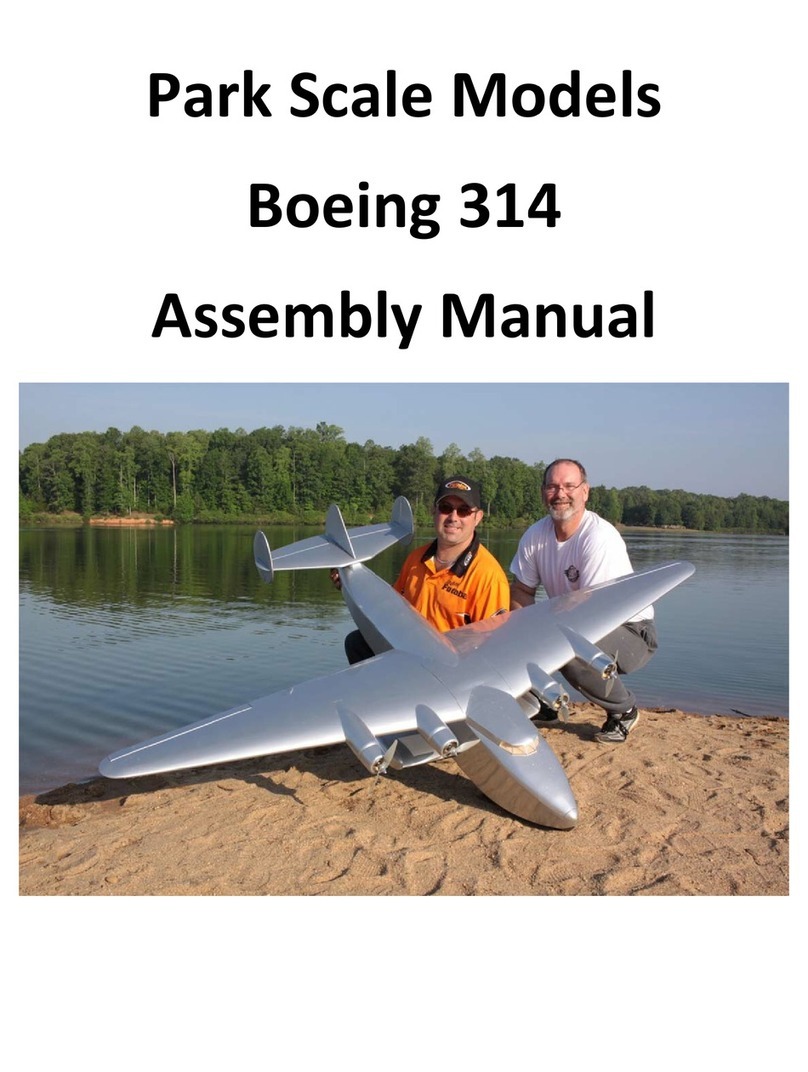

Park Scale Models Boeing 314 User manual

Park Scale Models

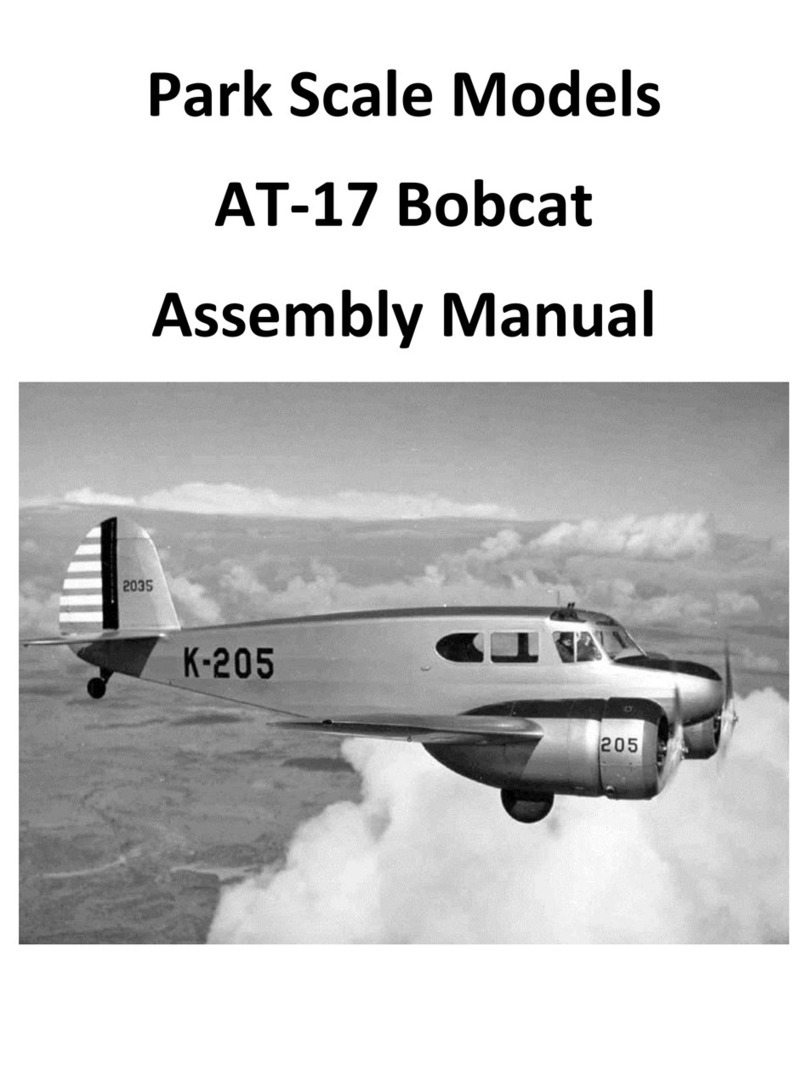

Park Scale Models AT-17 Bobcat User manual

Park Scale Models

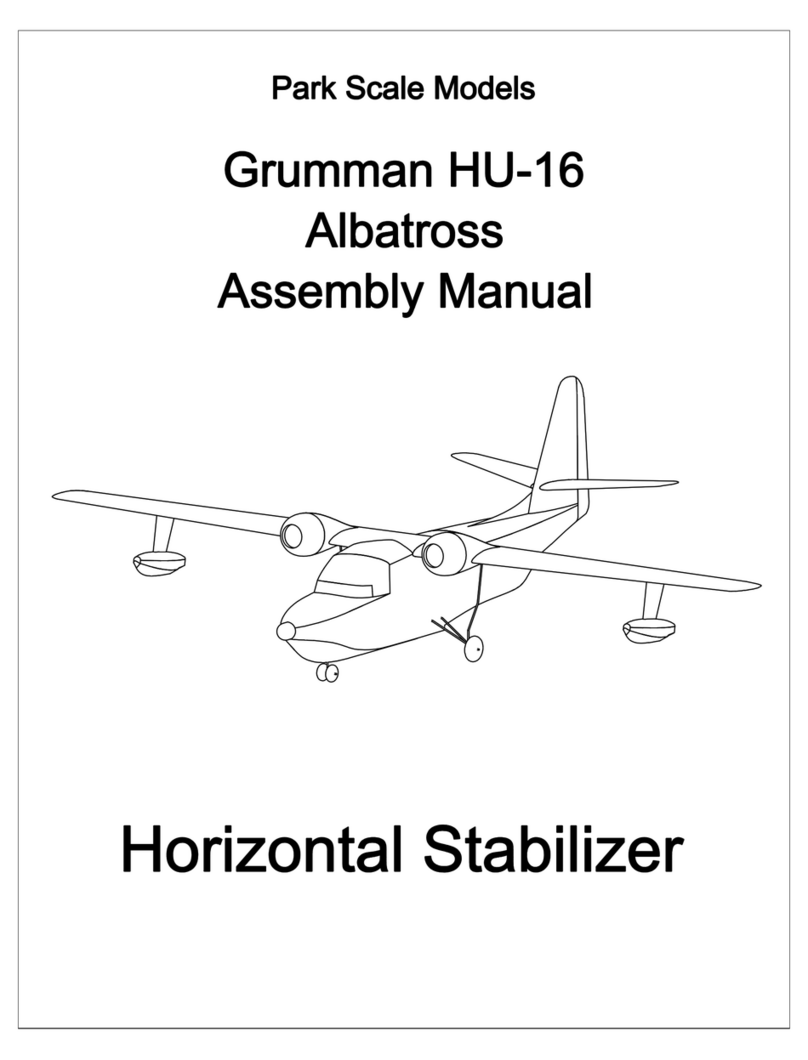

Park Scale Models Grumman HU-16 Albatross User manual

Park Scale Models

Park Scale Models Mini Drake User manual

Park Scale Models

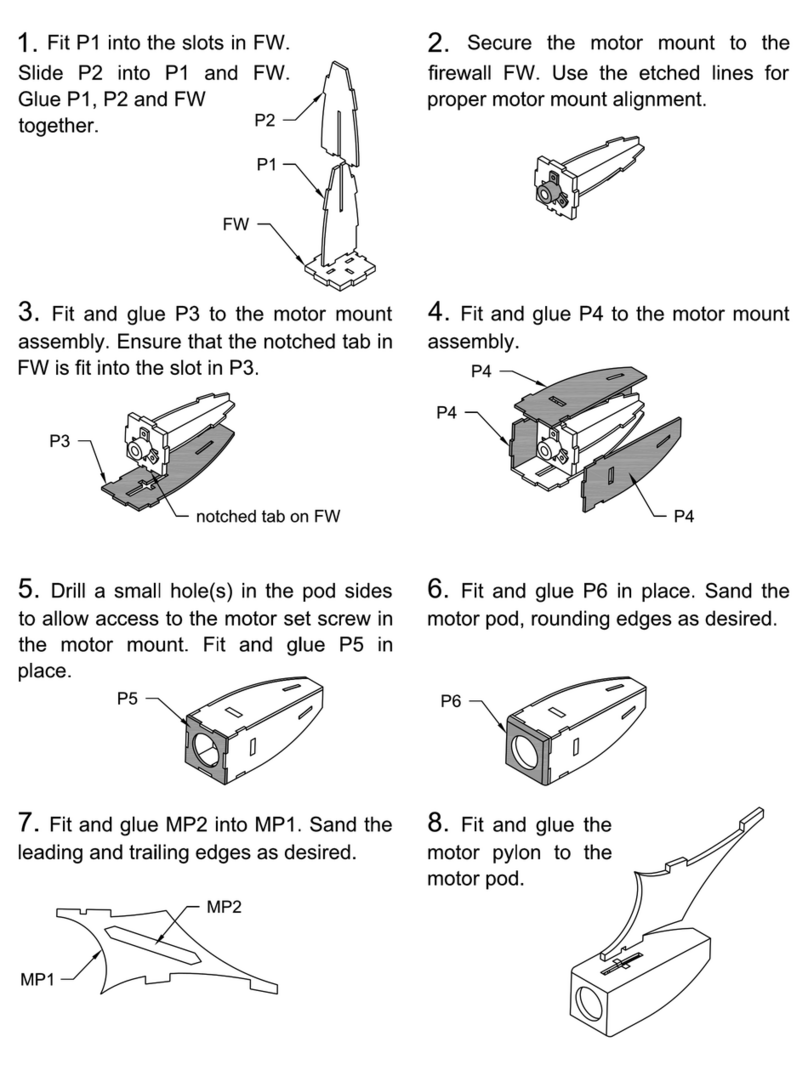

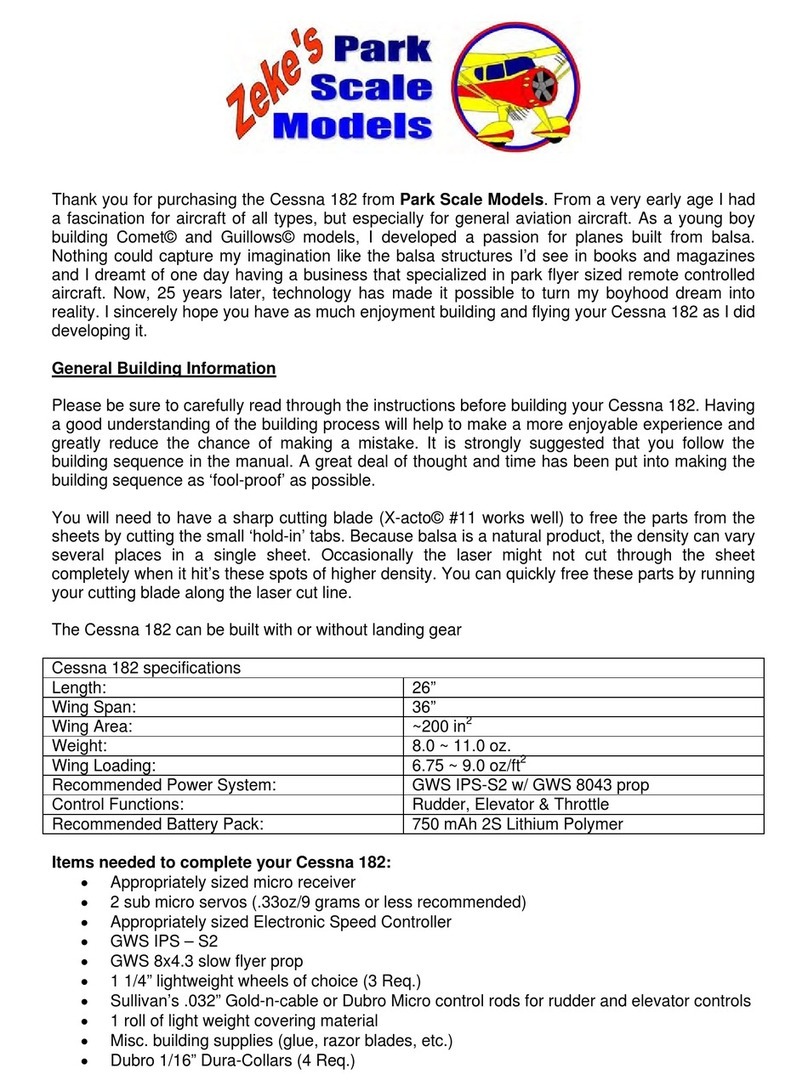

Park Scale Models Cessna 182 User manual