PAGE 6

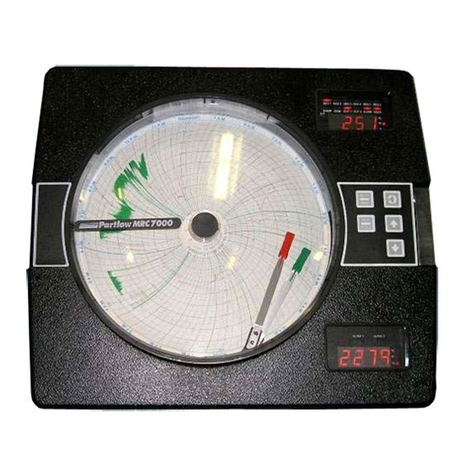

1.1.2 RECORDING

The instrument records the selected process variable on a 10-inch circular chart. One box of

standard charts is provided with each recorder. Charts are available in a wide selection of

ranges. Chart rotation speed is programmable from 0.1 to 999.9 hours per revolution in 0.1

hour increments. The instrument can be ordered with one or two pens. Pen 1 is red and Pen 2

is green. Pens are the disposable fiber-tip type.

1.1.3 DISPLAYS

Each instrument is provided with a digital display and status indicator for each pen provided

(See Figure 1-1). The display may be configured to display the Dry Bulb Temperature, Wet

Bulb Temperature, or the Relative Humidity as the process value. During configuration the

display(s) is/are used to show the enabled modes of operation and the parameter codes.

The display in the upper right corner is for Pen 1, the display in the lower right corner is for

Pen 2 (if provided). The upper display provides status indication for the Manual mode

operation, Output 1, Output 2, Alarm , Setpoint, negative value, degrees C, degrees F, and

engineering units, Ramp, Soak and six Segment lamps. The lower display( if provided)

includes status indicators for Manual mode operation, Output 1, Output 2 , Alarm, Setpoint,

negative value, degrees C, degrees F, engineering units. (Relative Humidity will be indicated

in engineering units.) See Figure 1-2 (page 7).

Display resolution is programmable for 0.1 or 1 degree for thermocouple and RTD inputs, and

none, one, two or three decimal places for other input types. Relative Humidity will be

indicated as whole numbers only.

1.1.4 CONTROL

The instrument can be provided with relay, solid state relay driver and milliamp DC outputs.

Instruments can be programmed for on-off, time proportioning, current proportioning or

position proportioning control depending upon the output(s) present. Relay(s) and Solid State

Relay Driver(s) may be assigned to be on or off during the profile ramp and soak of a profile

segment. Switching between the Control mode and the Manual mode of operation is easily

accomplished with a dedicated key on the keypad. Switching is bumpless from the Control to

the Manual mode, and while in manual, adjustment of proportional outputs is possible. Each

pen of a dual pen recording controller is provided with its own AUTO/MANUAL key . Other

standard control features include proportional control output limits, setpoint limits, anti-reset

windup and a unique Automatic Transfer function. If configured, the Automatic Transfer

function allows manual control of the proportional output until the process reaches the setpoint

at which time the instrument will go into the Control mode of operation.

1.1.5 ALARM

An Alarm indicator is standard for each pen. Two alarm functions are provided for each pen

and the alarm indicator will light if either alarm for that pen is on. Alarm settings are program-

mable. Alarm type may be selected as process direct or reverse (high or low), deviation from

setpoint direct or reverse, and deviation band open or closed within the band. Alarm outputs

can be provided by assigning any relay(s) Single Pole/Single Throw (SPST) or Solid State

Relay (SSR) driver to the respective alarm.

1.1.6 PROCESS VALUE RE-TRANSMISSION OUTPUT

If an instrument is specified with mADC current output(s), any of the outputs may be pro-

grammed to operate as a process value re-transmission output. The output is scaleable but

can not be used as a control output while assigned as a process value re-transmission output.