SPECIFICATIONS Low Rider® Series

FOLD FOLD

FOLD FOLD

The Low Rider is specifically designed

for sub-woofer use, with extremely

high output capabilities and massive

power handling. While most sub-

woofer applications are below 150 Hz,

it is usable to frequencies as high as

500 Hz.

The compact enclosure designs are

ideal for instrument amplification

and high portability applications

such as DJ and small touring bands.

They provide solid bass performance

in extraordinarily small enclosures.

Bandpass enclosures also fit into this

range as stand-alone sub-woofers.

The medium sized enclosures are still

smaller than usual and have more bass

extension and much higher output

capabilities than conventional designs.

They are excellent choices for high

performance sound reinforcement.

These designs are the best combination

of size and bass performance.

For permanent installations and

applications requiring extremely

deep bass performance, the large

vented enclosures are ideal. The low

frequency extension and high sound

pressure levels these systems can

produce is astounding. As is typical

in large, vented systems with low vent

tuning, power handling is reduced by

at least 15% due to the increased cone

excursion.

Due to the Low Rider's high output

capabilities, excessive levels may

cause structural damage to buildings or

indue permanent hearing loss, nausea,

vertigo or intestinal disturbances in

listeners. Please be cautious when

setting maximum sound pressure

levels.

To assist with the growing interest in

home-built enclosure designs, Peavey

provides complete parameter data

on these drivers, as well as several

recommended enclosures for each

model. This information and much

more can be found online at www.

peavey.com.

The 18" Low Rider driver performs best

with vented enclosures between 5 and

9 cubic feet (142 to 255 liters) and vent

tunings from 30 to 45 Hz. The Low Rider

18 is optimized for vented systems but

will also work with appropriate single-

reflex bandpass enclosures. Sealed,

infinite baffle, horn, transmission line

and dual-reflex bandpass enclosures

are not recommended.

The 15" Low Rider driver works best

in vented enclosures between 2 and

5 cubic feet (56.6 to 141.6 liters)

and vent tunings from 34 to 45 Hz.

It can also be used in certain single-

reflex bandpass designs. As with the

Low Rider 18, sealed, infinite baffle,

horn, transmission line and dual-

reflex bandpass enclosures are not

recommended.

Active filtering must be included with

amplifiers greater than 750 watts. This

filter should be a high pass 24 dB

Butterworth at minimum of 25 Hz for

the 18" and 32 Hz for the 15". Filtering

is also recommended below 750 watts

in order to conserve amplifier power

and reduce excessive cone motion.

Failure to use filtering with high power

operation may cause driver damage

that can void your warranty.

Enclosures should be built of best

quality 3/4" to 1-1/4" (20 mm to 32

mm) marine, 7-ply birch or other high-

grade plywood. If construction plywood

must be used, inspect each sheet

thoroughly and use at least BC grade.

Do not use plywood thinner than 3/4".

Other materials such as particle board

and MDF are not acceptable.

Use quality wood glue, fit joints

tightly. Dado corner joints are highly

recommended. Wood screws or a

pneumatic nailer should be used to

assemble the enclosure during gluing

to maximize joint strength.

The strength of the completed

enclosure has a great effect on the

bass performance of the finished

system. Internal bracing is required

to improve the structural strength of

the cabinet. Low Riders can generate

enormous forces inside the enclosure,

and panels that aren't stiff enough will

vibrate — reducing bass and creating

undesired sounds of their own. If

your cabinet vibrates or if the cabinet

panels are not stiff enough, add more

bracing.

Vents shown in the examples require

standard Schedule 40 PVC pipe for

vent construction. The pipe should be

dadoed tightly into the back of the

baffle and glued firmly in place with

high quality epoxy or high-strength,

industrial-grade hot glue. Rough up

the outside of the pipe to improve

the glue bond. Radius the insides of

the vent ends to improve air flow and

reduce vent noise.

Vents for these enclosures are much

longer than typical for a sound

reinforcement sub-woofer. This reflects

the special characteristics of the Low

Rider's design that make it possible to

combine a large, high excursion woofer

with an unusually small enclosure.

For best performance, the inside ends

of the vents should be a distance of

at least one vent diameter from any

interior wall of the enclosure. The vent

should be straight, without elbow

fittings or other methods to bend it for

greater length.

Be sure to allow for the displacement

to the vent, bracing and woofer or

your enclosure design before building

it. Mistakes in net volume will mis-

tune the enclosure and can drastically

reduce performance. This requires

a considerable amount of planning

before construction, but is well worth

the extra effort.

Line the inside of the enclosure with

polyester fiber batting such as quilt

stuffing. For bandpass, loosely fill the

sealed side, leave the vented side

empty, and place the Low Rider's

magnet in the vented side for cooling.

The batting material should conform

to California bedding fire codes. Attach

the batting with spray adhesive or

staples and keep material away from

the end of the vent tube where it can

be pulled in by airflow.

Handles, protective corners, cabinet

covering, grille materials and

crossovers are available through

Peavey Accessories. Take particular

care when positioning handles, as sub-

woofers tend to be large and heavy.

Do not use 1/4" phone plugs or jacks

in the construction of your enclosures.

Power capacity of Low Rider sub-

woofers is well above safe limits for

phone plugs and jacks. Neutrik®

Speakon® connectors are highly

recommended, and internal cabinet

wiring should be at least 16-gauge

stranded copper wire.

Flying of sub-woofers is not

recommended. An array of sub-

woofer enclosures at ground level

will typically outperform any other

possible arrangement. Peavey does

not supply hardware required for the

manufacturing of flying systems, and

recommends that builders should

not suspend or fly any enclosure not

certified for such applications.

These instructions are a general

guideline for design. Proper

construction techniques, good

planning and common sense will

result in a reliable, high quality, high

performance system.

Peavey in no way accepts liability for

any damage, accidents or injury that

may result from construction or use

of enclosures using this information.

Due to Peavey’s continuing efforts to

improve its products, features and

specifications are subject to change

without notice.

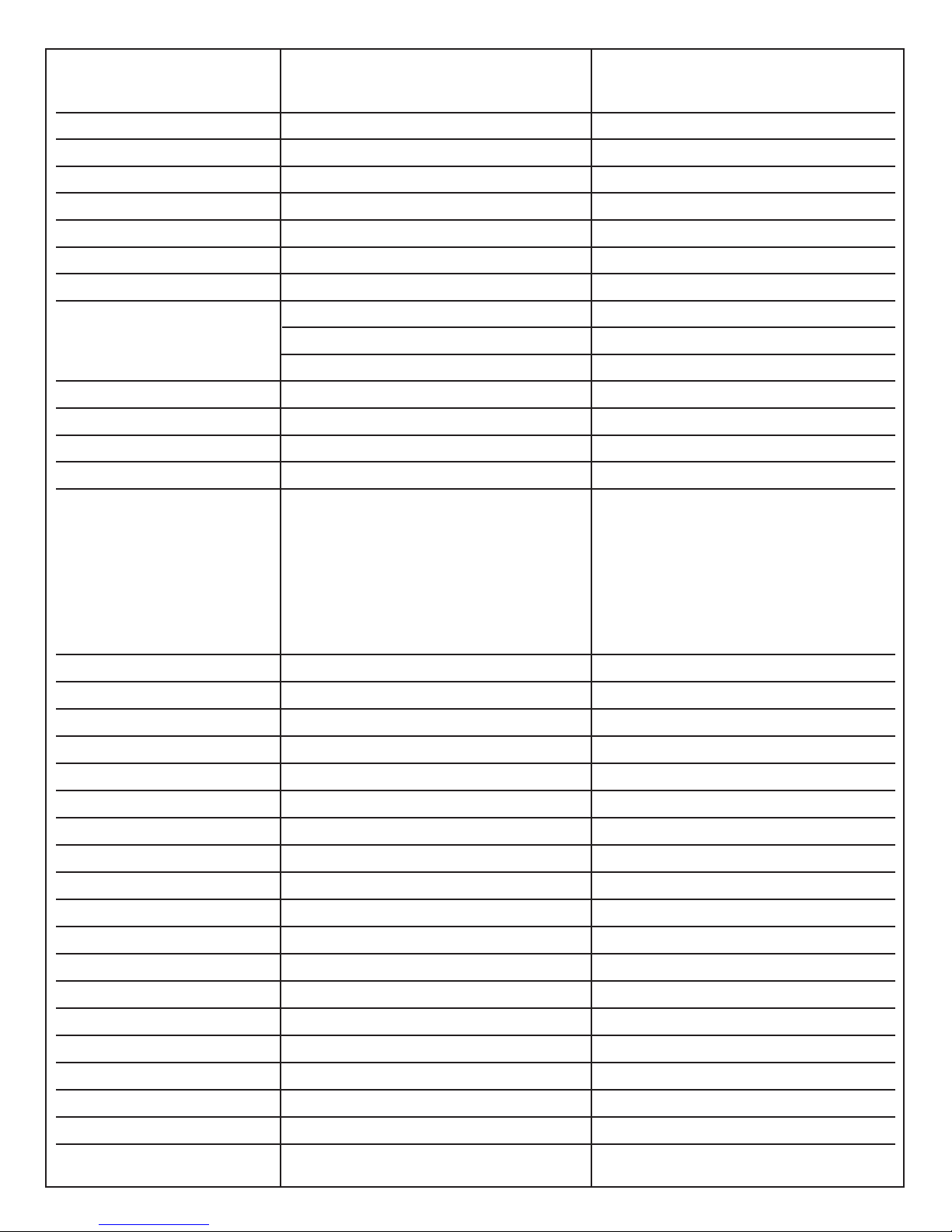

Thiele-Small parameters for Low Rider

subwoofers follow. This data is for use in

designing enclosures. Numerous software

packages are available that use this data

to simulate the response of the driver

and enclosure together for optimum

performance in any application.

The nominal impedance of the driver

in ohms.

DC resistance of the driver in ohms

Also known as Re.

The functional radiating surface area of

the cone assembly in meters2.

Efficiency of the voice coil and magnet

system in Telsa Meters.

Also known as Fs, the free air resonance

of the driver.

Volume of air having the same

compliance (springiness) as the driver’s

suspension.

Restorative force of the driver’s

suspension in micrometers/Newton.

The total mass of the moving parts

of the loudspeaker, including the air load, in

grams.

Resonance characteristics of the

mechanical factors of the loudspeaker.

Resonance characteristics of electrical

factors of the loudspeaker.

Resonance characteristics of the

electrical and mechanical factors combined

together.

Distance the cone can move in one

direction before the coil begins to leave the

magnetic gap.

Inductance of the voice coil in

millihenries.

Typical sound pressure level at 1 watt,

1 meter.

Electrical-to-acoustical conversion

efficiency in percent.

Air displacement of the driver from

negative Xmax to positive Xmax, in milliliters.

Maximum continuous program power

in watts.

Volume displaced by the driver inside

the cabinet when mounted on its rear flange,

in inches3.

SPECIFICATIONS Low Rider® Series SPECIFICATIONS Low Rider® Series

Part # 00560600 00560310

Size (inches/mm) 18" / 460 mm nominal 15" / 380 mm nominal

Frame OD 18-1/8" / 460 mm 15-1/4" / 387 mm

Bolt circle 17-3/8" / 441 mm 14-9/16" / 370 mm

Cutout diameter 16-3/4" / 425 mm 14" / 356 mm

Depth 6-3/8" / 162 mm 5-1/4" / 133 mm

Impedance: 8 ohms 8 ohms

Power Capacity: 3,200 W peak

1,600 W program

800 W continuous per AES 2-1984,

40 Hz - 500 Hz

3,200 W peak

1,600 W program

800 W continuous per AES 2-1984,

50 Hz - 500 Hz

Sensitivity: 97.3 dB/1 W 1 m 93.6 dB/1 W 1 m

Usable freq. range: 25 Hz ~ 1 kHz 30 Hz ~ 1 kHz

Cone: Kevlar®-impregnated cellulose Kevlar®-impregnated cellulose

Voice coil diameter: 4.0" / 100 mm 4.0" / 100 mm

Voice coil material: Polyamide coated copper ribbon wire

Polyamide-impregnated berglass

former

Nomex® stiffener

Solderless diffusion welded OFHC

copper leads

Polyamide coated copper ribbon wire

Polyamide-impregnated berglass

former

Nomex® stiffener

Solderless diffusion welded OFHC

copper leads

Net weight: 22 lbs. / 10 kg 21 lbs. / 9.5 kg

Driver Parameters

Znom (ohms) 8 8

Revc (ohms) 6.21 6.21

Sd (Square Meters) 0.1237 0.084

BL (T/M) 22.73 22.73

Fo (Hz) 28.9 33.916

Vas (liters) 403.9 155.06

Cms (uM/N) 185.9 154.8

Mms (gm) 163.2 142.3

Qms 8.770 10.669

Qes 0.356 0.364

Qts 0.342 0.352

Xmax (mm) 9.6 9.6

Le (mH) 0.87 0.82

SPL (1 W 1 m) 97.3 93.6

No (%) 2.65% 1.33%

Vd (in3 / ml) 145 / 2375 98.3 / 1611

Pmax (watts pgm.) 1,600 1,600

Disp (in3 / ml) 235 / 3852 204 / 3344

Kevlar® is a registered trademark of DuPont.

Nomex® is a registered trademark of DuPont. Rubatex® is a registered trademark of Rubatex Corporation.