2

GENERAL INFORMATION

Your fuel pump is designed for use with aviation gasoline

(AVGAS 100LL) and kerosene grade (Jet A). Do not use this

pump for dispensing any uids other than those for which it

was designed. Using the pump with other fuels can damage

components and void the warranty.

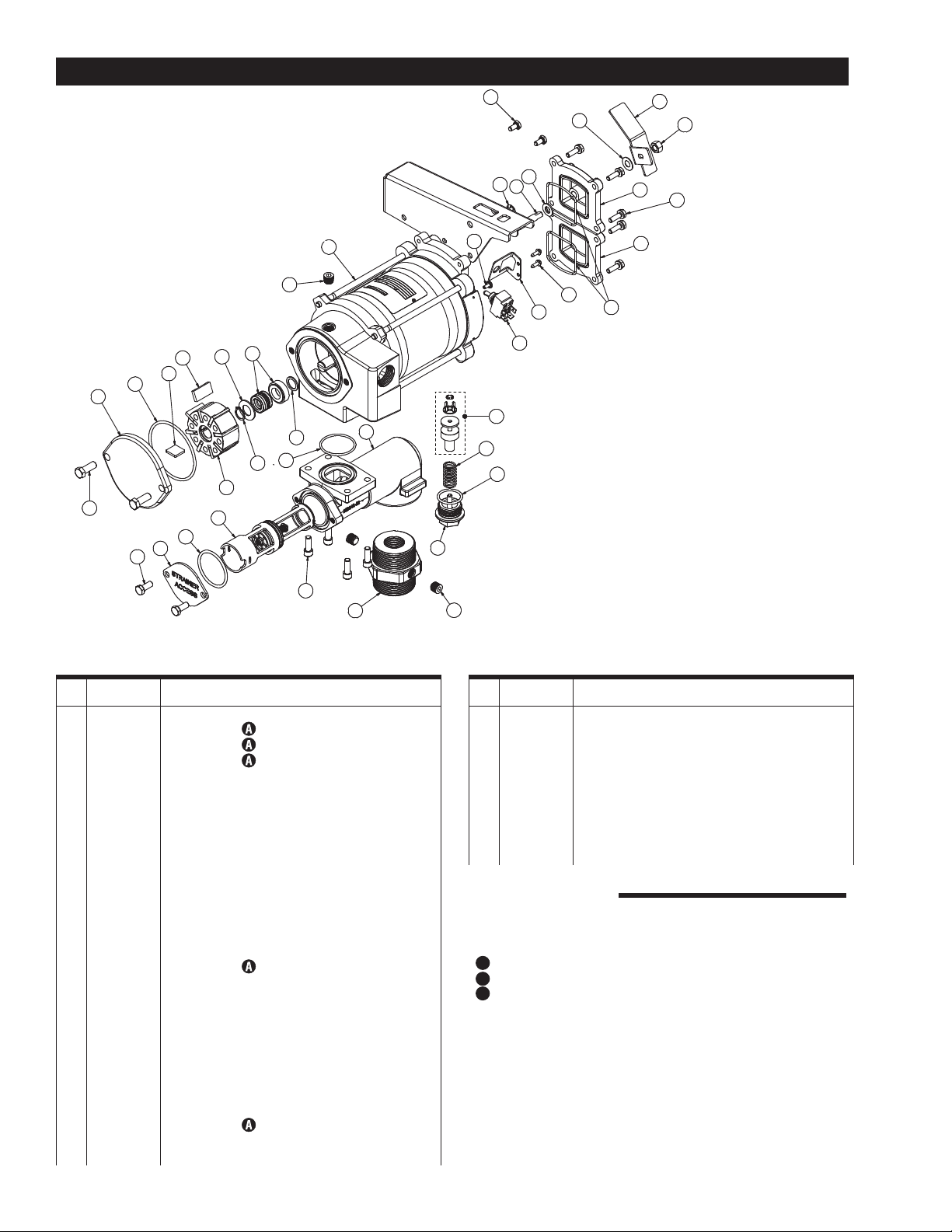

Model Components

PRO20-115PO-AV: Includes pump only and components to

assemble to unit before use.

NOTE: Sufx PO is for ordering purposes only.

For ground-based refueling only. Do not use in or on the aircraft.

WARNING

SAFETY INSTRUCTIONS

The following safety alert symbols are used in

this manual. Obey all safety messages that follow

this symbol to avoid possible injury or death.

DANGER DANGER indicates an

imminently hazardous

situation which, if not avoid-

ed, will result in death or

serious injury.

WARNING WARNING indicates

a potentially hazardous

situation which, if not avoid-

ed, could result in death or

serious injury.

CAUTION CAUTION indicates

a potentially hazardous

situation which, if not avoid-

ed, may result in minor or

moderate injury.

CAUTION CAUTION used without

the safety alert symbol

indicates a potentially

hazardous situation which,

if not avoided, may result in

property damage.

There are inherent dangers wherever ammable fuel and

AC electrical sources are in close proximity.

Static electricity as a source of sparking is always a

concern and requires extreme care in the installation and

operation of your entire fuel transfer system.

Additional components such as meters, automatic nozzles

and lters must be listed for use with fuel transfer systems.

The ow of fuel through a hose and nozzle can generate

static electrical charges and dangerous sparking can

result in re or explosion. Hoses and nozzles must be

electrically conductive and bonded to ground.

It is your responsibility to:

• Know and follow applicable national, state and local

safety codes pertaining to installing and operating

electrical equipment for use with ammable liquids.

• Know and follow all safety precautions when handling

petroleum fuels.

• Ensure that all equipment operators have access to

adequate instructions concerning safe operating and

maintenance procedures.

Appropriate hose, nozzle and suction pipe not

included. Items must meet NFPA 407 guidelines.

For ground-based refueling only. Do not use in or on the aircraft.

For use with aviation gasoline (AVGAS 100LL) and kerosene grade

(JET A).

User should consult NFPA 407 Standard for Aircraft Fuel Servicing

for safety requirements during ground fuel servicing of aircraft

using liquid petroleum fuels. This product has no actual or implied

compliance with this standard.

WARNING

INSTALLATION

Coverplates protect the operator from moving parts. Never

operate the pump without coverplates in place. Never apply

electric power to the pump without coverplates in place.

Always disconnect power before repairing or servicing.

WARNING

Mechanical Connections

All threaded fuel connections must be sealed with thread

tape or a pipe thread sealing compound approved for

use with petroleum fuels and tightened securely to pre-

vent leakage.

Your pump must be mounted on a vented tank. If the

tank is not vented, contact your GPRO™ distributor for

the correct vent cap.

This pump has a built-in check valve to keep the pump

primed. No additional check valve is required on suc-

tion pipes shorter than 15 feet (4.6 meters). Make sure

any check valves or foot valves used are equipped with

proper pressure relief valves.

Your pump is designed to mount directly to a standard 2

in. female tank tting. For the suction pipe, a 1 in. pipe

cut to length and threaded on one end may be used.

Suction pipe should extend to within 3 inches of tank

bottom. Apply thread tape to the suction pipe thread and

securely tighten the suction pipe to the tank adapter. Once

suction pipe is attached to tank adapter, insert suction

pipe into tank and tighten tank adapter to tank tting.

Install Nozzle Hanger

Attention:The nozzle hanger for your pump was removed

before shipping to protect against damage.

To reinstall the nozzle hanger follow the steps below.

1. Remove the two (2) 1/4"-20 x 1/2" bolts from the

switch coverplate.

2. Place the nozzle cover on the switch coverplate and

align holes.

3. Insert the two (2) 1/4"-20 x 1/2" bolts through the

nozzle cover and thread into the switch coverplate.

Torque bolts to 45-60 in/lb (Figure 1).