Contact

PELA Tools

Solängsvägen 13

SE-513 70 Borås

Telefon: 033-202650

Environmental protection/

Scrapping

Recycle any unwanted material, do not

throw it in the household rubbish. All

machines, accessories and packaging

must be sorted and left at a recycling center and

disposed of in an environmentally friendly

manner.

Specifications

Drilling capacity in metal 30 mm

The movement of the pinole 150 mm

Spindle speed 75-3010 rpm

Spindle speeds 8 st

Spindle cone MK3 T-slot 14 mm

Dimensions base plate (LxW) 320x320 m

Work table dimensions (diameter) 500 mm

Engine power 1100 W

Voltage 400 V

Cleaning

All bright parts of the machine are treated with

rust preventive. By removing this, be careful not

to use too strong cleaning compound. The paint

might then get damaged.

Installation

The machine must be installed on a rm

foundation. The baseplate must be levelled with

washers on the foundation bolls to prevent

harmful stresses when the nuts are tightened.

Lubrication

All high-speed shafts and gears are lubricated in

ball bearings or roller bearings, so that the

machine needs very litte lubrication.

THE GEAR HOUSING MUST NOT BE FILLED

WITH OIL

EXCESSIVE LUBRICATION SHOULD BE AVOIDED,

AS EXCESS OIL CAN DROP INTO THE MOTOR

AND DAMAGE ITS INSULATION.

Connections to mains

The connection to be effected direct to the

thermal overload circuit breaker or on

multispindle machines to a junction box common

for all drilling heads.

Note the earth screw!

(See attached wiring diagram.)

Spindle speed selection

The selection ohe different spindle speeds

according to the plate on the front of the drive

gear box is effected by the levers on the left hand

side of the gear box and also by means of the

pole change switch for the motor.

General

IT SHOULD BE NORMAL PRACTICE TO

DISCONNECT THE MACHINE FROM THE MAINS

BEFORE ANY DISMANTLING TAKES PLACE.

MAKE SURE ALL SURFACES ARE CLEAN.

Drive gear box

When it is necessary to disassemble the drive

gear box:

Remove the four screws which connect the drive

gear box to the quill housing. Then take away

the fan cover and the fan from the quill housing.

By knocking slightly on the rotor shaft the drive

gear box can be removed. The gear box casting,

consisting of two halves can be taken apart by

loosening the four screws. All shafts can now be

taken out for further disassembling.

When re-assembling the drive gear box, check

that the shift pin rst properly into the groove of

the dutch. When re-placing the drive gear box

on the quill housing, it must be checked that the

driving keys in the spindle are in place and that

they will properly the corresponding key ways on

the gear box output shaft.

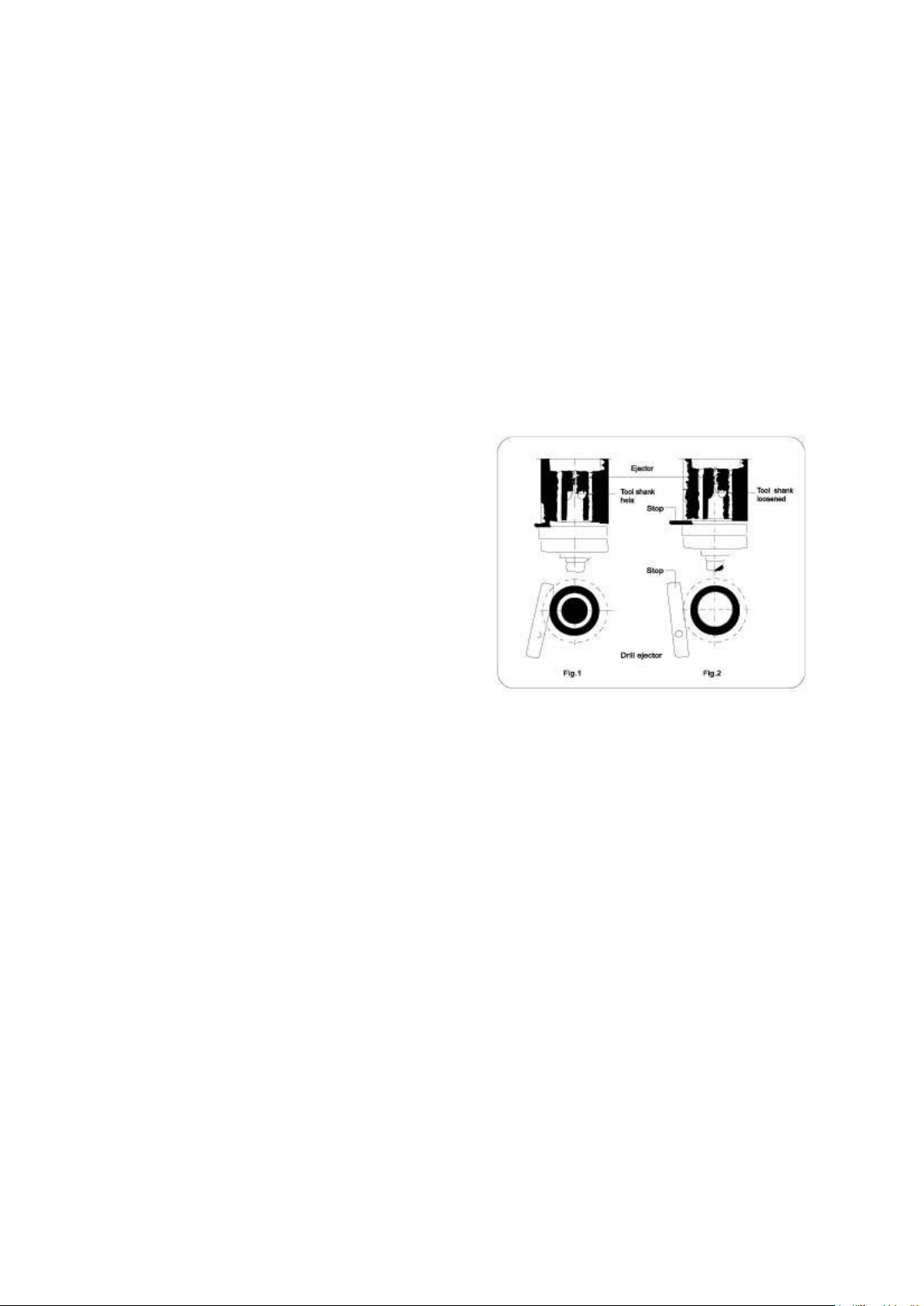

Spindle

The spindle is journaled in the quill by a taper

roller bearing at the bottom and by a radial ball

bearing at the top At the top end of the spindle

there is a nut with which the play in the taper

bearing can be adjusted. This nut can be reached

when the quill is removed from the machine.

Hold the spring housing by co-locating a hex

key in the center of the housing and loosen the

screw. Let the housing to relieve the pressure on

the spring. The quill will then automatically go to

its lowest position.

Remove the stop and loosen the screw, which

keeps the feed shaft in its position.

Hold the quill with one hand and push the feed

drive shaft so far to the right lo disengage the

teeth from the quill feed rack. Then remove the

quill. When re-assembling, the keys on the

spindle are to coincide with the keyways in the

spindle shaft. Take care to avoid damaging the

keys when sliding the quill into position.