1: SAFETY

Safety instructions for power tools

For your own safety, please read the manual

before using this equipment

1. Keep the work area clean. A messy workplace

increases the risk of accidents and injuries.

2. Consider the circumstances. Do not use the

machine in damp, wet or poorly lit places.

Donot expose to rain.

3. Keep children away. All children must be kept

away from the work area. Do not let them

handle the machine or extension cords.

4. DO NOT LEAVE UNUSED ACCESSORIES IN

FRONT. When not in use, accessories should be

stored in a dry place to inhibit rust. If possible,

store in an area out of the reach of children.

5. DO NOT OVERLOAD THE MACHINE. It will

do the job better and safer at the rate it was

intended for.

6. USE THE RIGHT TOOLS. Don't force a smaller

machine or accessory to do the same job as

a larger industrial tool. Do not use a tool for

apurpose for which it was not intended.

7. Dress accordingly. Do not wear loose clothing

or jewellery. They can be caught in moving

parts. Protective gloves and non-slip shoes are

recommended when working. Use protective

hair clothing to keep long hair out of the way,

sothat it does not get caught in the machine.

8. USE EYE PROTECTION. Use ISO-approved

safety glasses.

9. SAFE WORK. Use clamps or a screw to hold

theworkpiece if possible. It is safer than using

your hands and it frees both hands to operate

the machine.

10. DO NOT OVER STRETCH. Keep the right footing

and balance at all times.

11. HANDLE TOOLS WITH CARE. Keep them clean

for better and safer performance. Follow the

instructions for lubrication and replacement

ofaccessories. Inspect tool cords regularly

and if damaged, have them repaired by an

authorized service centre. Keep handles dry,

clean and free from oil and grease.

12. REMOVE ADJUSTMENT KEYS AND GUARDS.

Make it a habit to check that wrenches and

wrenches are removed from the tool or

machine work surface before use.

13. BE ALERT. Always watch what you are doing,

use common sense. Do not use the machine

when you are tired.

14. CHECK DAMAGED PARTS. Before using any

tool, any part that appears damaged should

be carefully inspected to determine that it

is functioning properly and can perform its

intended function. Check alignment of moving

parts, breakage of parts, assembly and other

conditions that may affect its operation.

Any part that is damaged must be properly

repaired by an authorized service center unless

otherwise specied in the instruction manual.

15. EXCHANGE OF PARTS AND ACCESSORIES.

Only use identical spare parts when servicing.

Only use accessories intended for use with this

tool. Approved accessories are available from

the dealer.

16. DO NOT USE THE MACHINE IF YOU ARE UNDER

THE INFLUENCE OF ALCOHOL OR DRUGS.

Read prescription warning labels to determine

if your judgment or reexes are impaired while

taking drugs. If there is any doubt, do not use

the machine.

17. NEVER STAND ON THE MACHINE. Serious

injury can occur if the machine tips over

18. KEEP PROTECTION IN PLACE AND IN

WORKING ORDER. Never use the machine

unless all guards are working properly.

19. NEVER USE A TOOL IF ITS HOUSING OR ANY

BOLTS ARE MISSING. If covers or bolts have

been removed, replace them before use.

Maintain that all parts are in good condition.

20. WIPE UP SPILLS, ETC., TO AVOID SLIP

ACCIDENTS. Keep the oor clean and free of

all liquids and other spills that could cause

slipping. Check the material data sheet for

proper cleaning procedures.

You need this manual for safety instructions,

assembly instructions, operating instructions,

partslist and diagrams. Write your invoice number

on the inside of the front page. Put both your

manual and invoice in a safe, dry place for future

reference.

Additional safety instructions for a Floor

Drill Press.

1. ALWAYS USE YOUR FLOOR DRILL PRESS

AT SPEEDS appropriate for drill size and the

material you are drilling.

2. LOWER THE DRILL EVENLY INTO THE

WORKPIECE. Back the drill out of deeper holes

and clean the residue with a brush after turning

off the machine.

3. BE SURE THAT THE DRILL YOU ARE USING

IS SECURED PROPERLY. Use only round,

hexagonal or triangular shank drills.

4. NEVER PERFORM MAINTENANCE OR CHANGE

SPEED WITH THE MACHINE ON.

5. NEVER USE TOOLS THAT ARE IN POOR

CONDITION, Dull or damaged cutting tools are

difcult to control and can cause serious injury.

6. NEVER DRIL IN SHEET METAL UNLESS IT IS

PROPERLY FIXED INTO THE WORK TABLE.

7. THE WORKPIECE SHOULD BE PLACED IN

SUCH A MANNER AS TO AVOID DRILLING INTO

THE WORK TABLE.

8. A FACE PROTECTION ALONG WITH GOGGLES

SHOULD BE USED.

9. ALWAYS CLAMP THE WORKPIECE TO THE

TABLE BEFORE STARTING DRILLING. Never

hold a workpiece by hand while drilling.

10. If in any way you experience problems

performing the intended work, stop using

themachine! Contact our service department

or ask a qualied expert how the work should

be carried out.

11. REMOVE ADJUSTMENT KEYS AND OTHER

KEYS. Before turning on the machine, make

ita habit to check that all adjustment keys

andkeys have been removed.

12. HABITS, GOOD OR BAD, are hard to break.

Develop good habits in your business and

thatsafety becomes second nature to you.

2: INTRODUCTION

Unpacking

If the machine is moved up or down stairs,

the machine must be disassembled and moved

in smaller pieces. Ensure that floors and stair

structures can support the combined weight of

the machine parts and the people moving them.

The oor drill press is delivered from the

manufacturer in a carefully packed carton. If you

discover that the machine is damaged after receiving

it, call the Toolbox immediately for advice. Once you

are completely satised with the condition of your

shipment, you should inventory your parts.

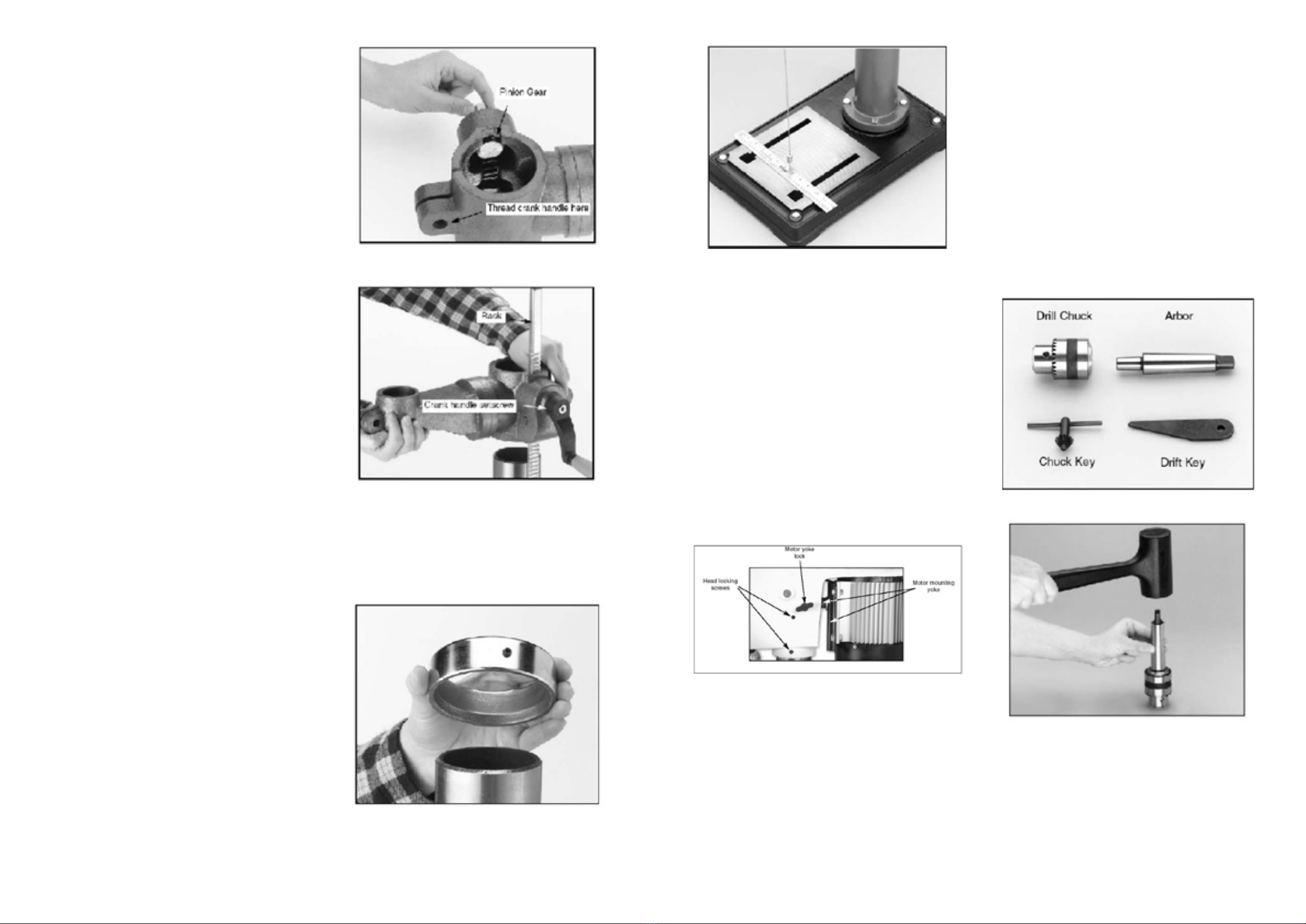

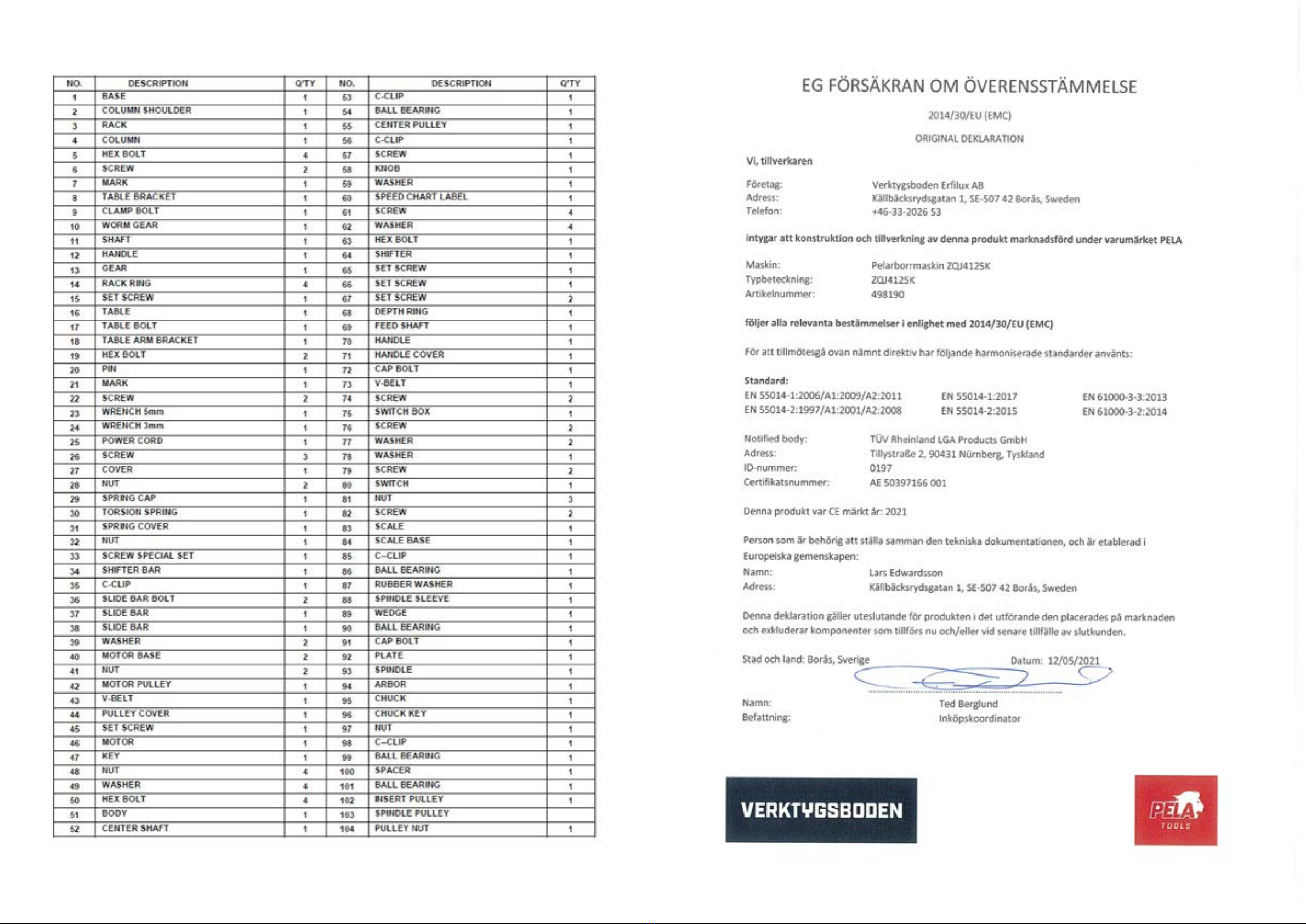

TABLE OF CONTENTS:

A complete list of parts and exploded views

canbe found at the end of this manual. For easier

assembly, or to identify specic parts, refer to the

detailed illustrations at the end of the manual.

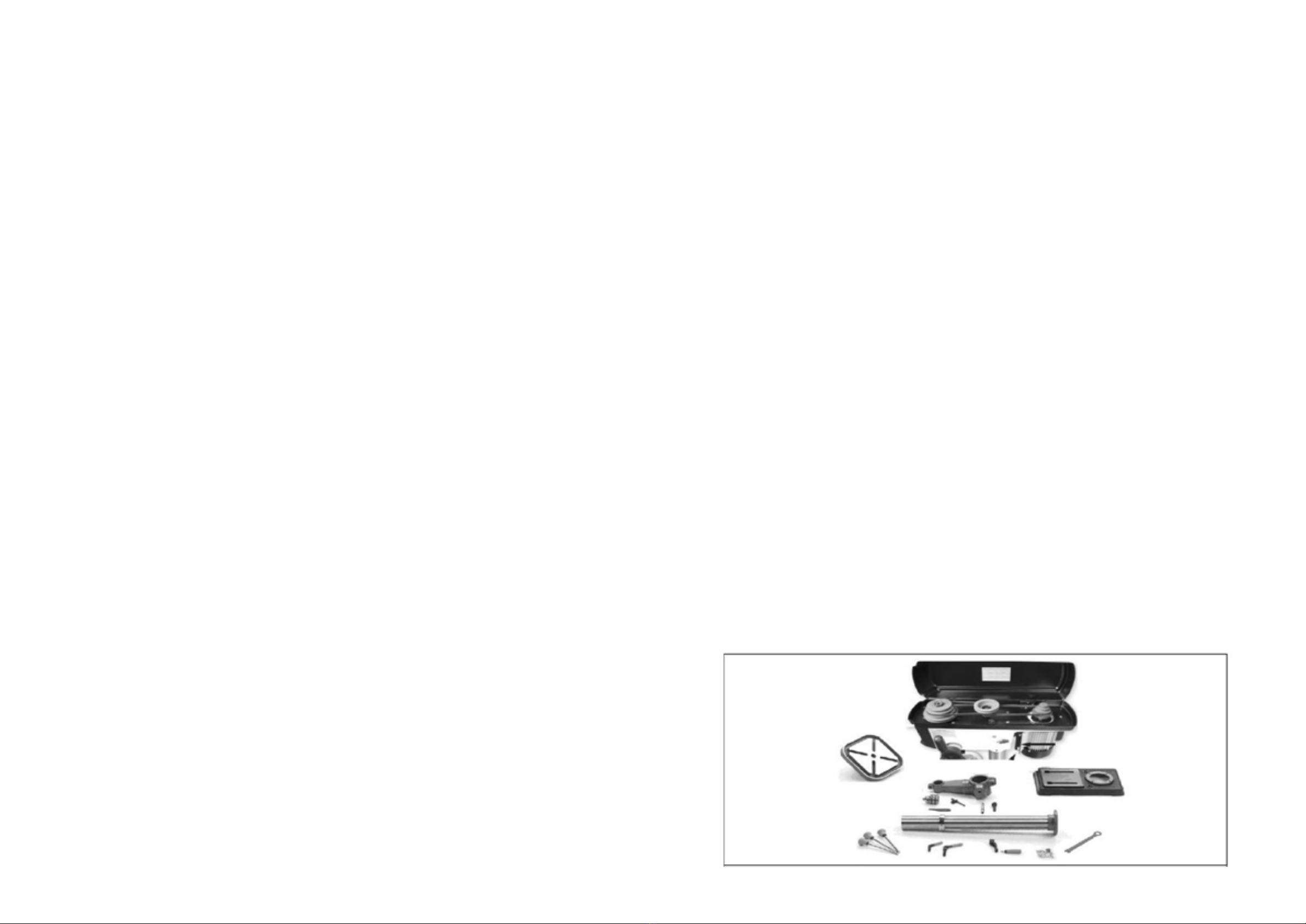

Once all the parts have been removed from the box,

you should have:

• Spindle Chuck

• Work table

• Column mounting

• Base

• Drill chuck and key

• Wedge chaser

• Hex bolts, M10 x 25 or 40 (4)

In the event that any non-proprietary parts are

missing (eg a nut or washer) we are happy to

replace them or, if more convenient, replacements

can be obtained from your local hardware store.

Fig. 2A