- 7 -

Commissioning, Start-Up, Operation, Shutdown

Before attempting to operate your Cleanload, the following must be understood and followed to ensure safe operation.

Information

Readtheoperatinginstructions(tofollow)completelybeforeusingtheCleanload.

• Always read and follow the chemical label instructions exactly. Understand safe practices for chemical handling,

mixing,loading,cleaning,andrstaid.

• Always wear proper Personal Protective Equipment when handling chemicals, including gloves, eye protection,

respirator and safety shoes.

• Always pay attention to wind conditions when using the Cleanload. DO NOT use Cleanload in wind in excess of

10MPH due to possibility of tipping.

• Always check to make sure that there are no loose objects surrounding the Cleanload that could cause damage to

the hopper tank or hoses.

• WhenoperatingtheCleanloadatnight,ensureproperlighting(200to300Lux)ispresent.

IMMEDIATELY SHUT DOWN the system if leaks, errant spray, operation error, or malfunction occur.

Start-up, Operation, Shutdown

Before Operation

• Inspect the assembly for signs of leaks.

• Ensure check valve is working properly.

• Inspect window gasket for debris.

• Inspect latches for wear or aging.

• EnsureallhosesorttingsareproperlyattachedtotheClosedsystemCleanload.

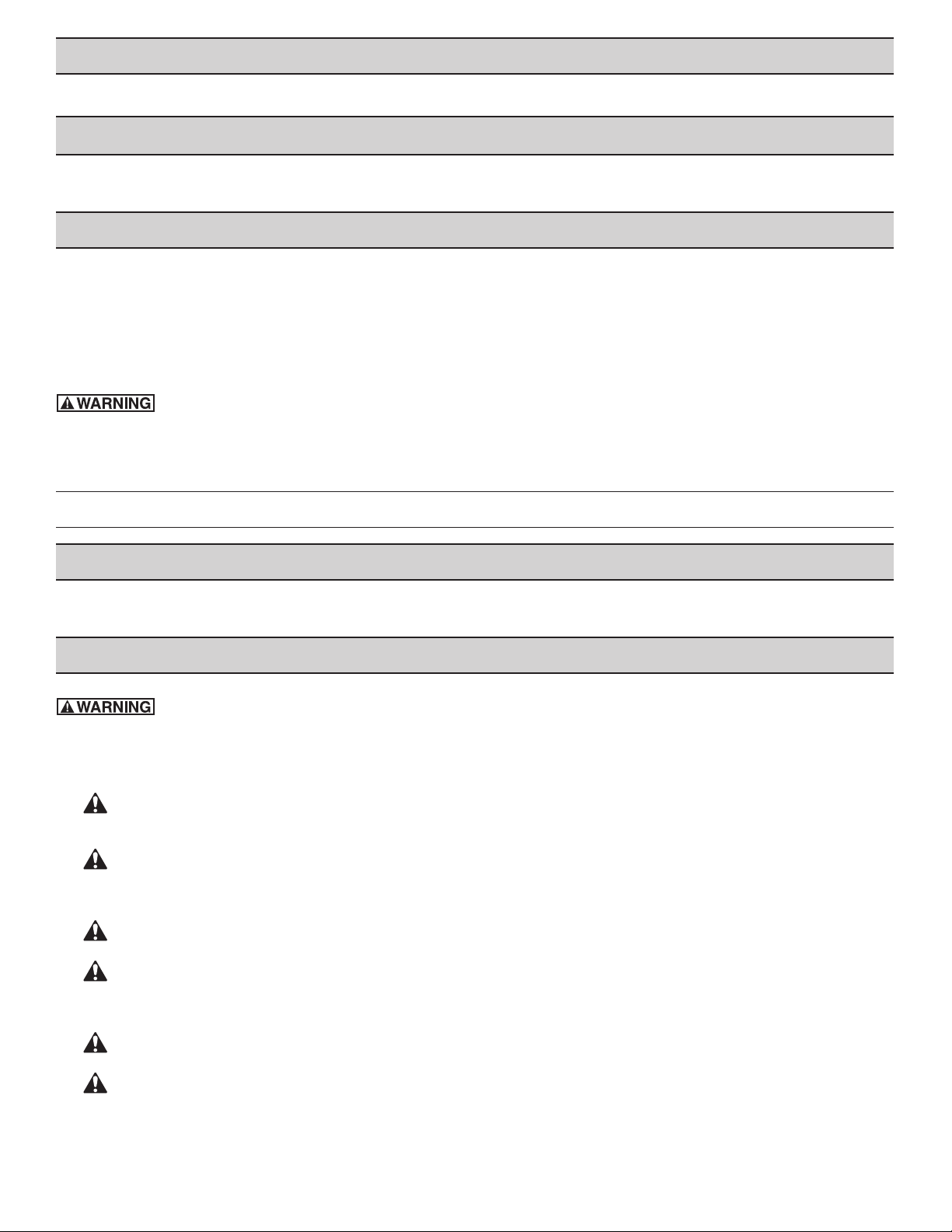

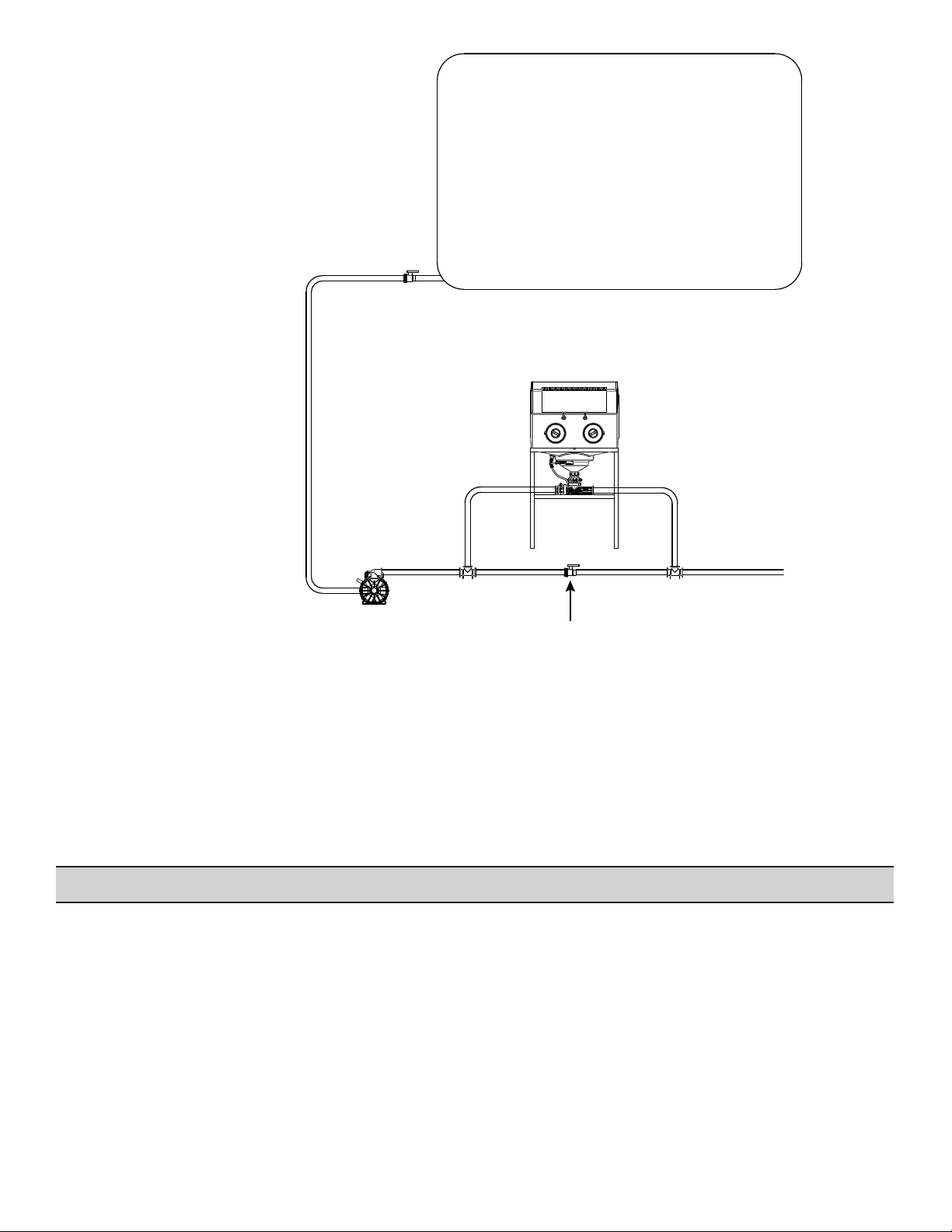

• Ensuretankvalve(red)andCyclorinsevalve(grey)areintheclosedpositionandthattheinlethandlevalve(yellow)

is in the open position.

• Ensureproperpump/systemsizingforpropereductorfunctionpriortousingchemicals.Trialwithwateris

recommended to ensure safe operation. Proper function is indicated by water being drawn into the line, and not

backing up inside the enclosure.

• Ifwaterbacksupinenclosurewhenthepumpison,ensurethetankvalve(redhandle)isopentoallowowfromthe

enclosure.Ifthebackuppersists,immediatelyclosetheCycloRinse(grayvalve)andthetankvalve(redvalve,and

shut off the pump. Review outlet plumbing to minimize restrictions or blockages.

• Ifglovesbecomeexcessivelyinated,closetankvalve(redhandle)immediatelyandensurethevacuumreliefcheck

valve is functioning normally.

Start-up, Operation, Shut Down

1. Placechemicalcontainer(s)intheclosedsystemenclosureandsecurethewindowlatches.

2. Turn on the pump to generate clean water flow.

3. Openthetankvalve(redhandle)andtheenclosurerinsevalve(grayvalve).

4. Inspectassemblyforleaks.

5. Open the chemical container, pour and measure the chemical. Pour the measured chemical down through the grate.

6. Triple rinse the measurement container.

7. Ifmorethanonechemicalisneededrepeatsteps4&5foracontaineralreadyintheenclosure.

8. Rinsechemicalcontainer(s)toensureanychemicalsontheexteriorareremoved.

9. Ifcontainer(s)areempty,triplerinsethecontainer(s).

10. Turn off the Cyclo Rinse valve (gray valve). Use hand to depress the ProClean bottle rinse for 2 min to rinse the

enclosure. If using a larger chemical container be sure to move the container and initiate ProClean again to ensure all

surfaces are adequately rinsed.

11. TurnontheCyclorinsevalve(grayvalve)andrunfor30secondsforafinalrinse.

12. ClosetheCyclorinsevalve(greyvalve)andwaitfor15seconds.Closethetankvalve(redhandle).

13. Remove chemical container form enclosure. If more chemicals need to be added to the tank repeat steps 1-11.

14. Continuetotransferwaterasneededorshutoffpump.