3

English (EN) Installation and operating manual

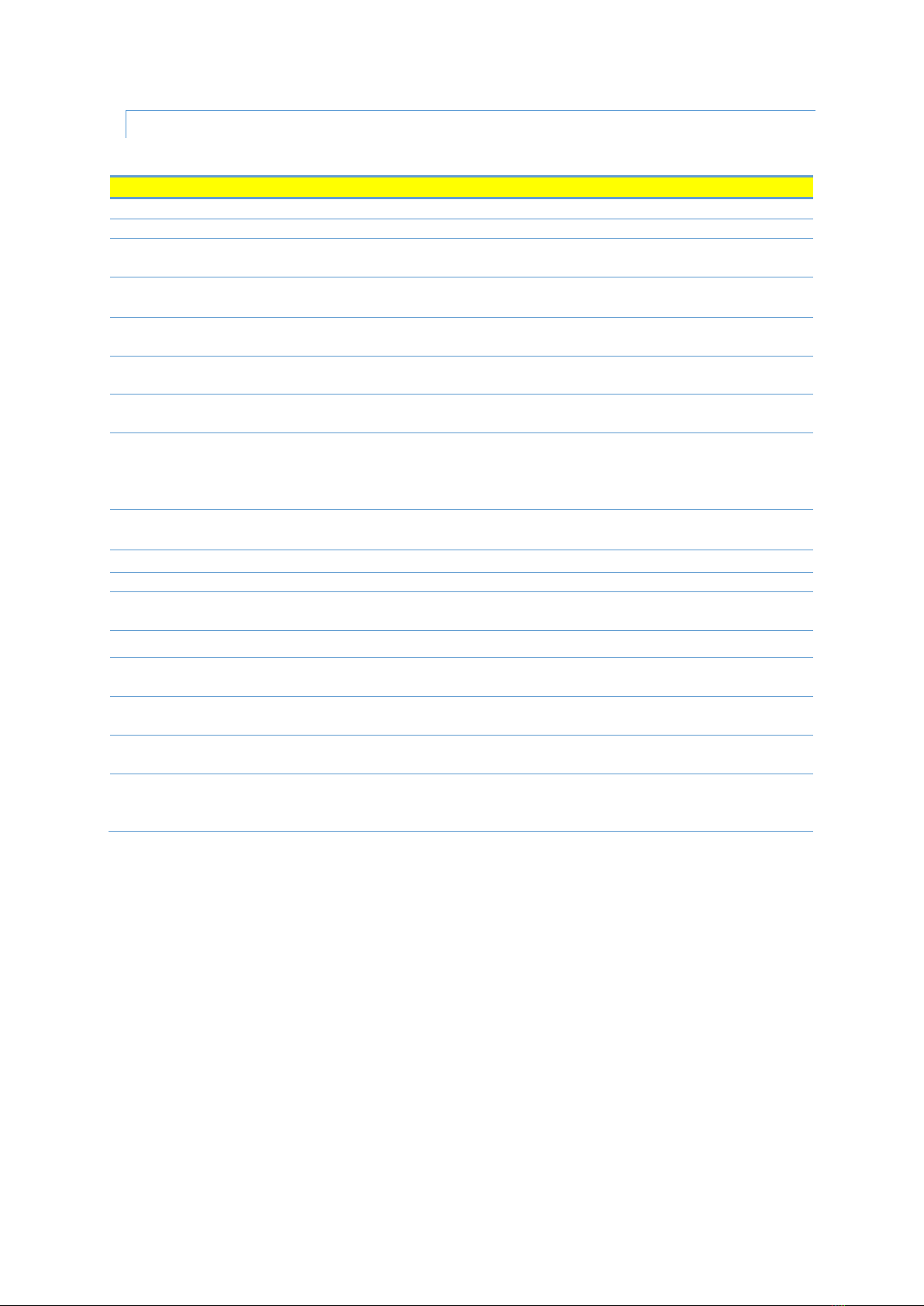

TABLE OF CONTENTS

1 General information..........................................................................................................................4

1.1 Uses ........................................................................................................................................................4

1.2 Pump labeling .........................................................................................................................................4

1.3 Pump maintenance, spare parts and decommissioning.........................................................................4

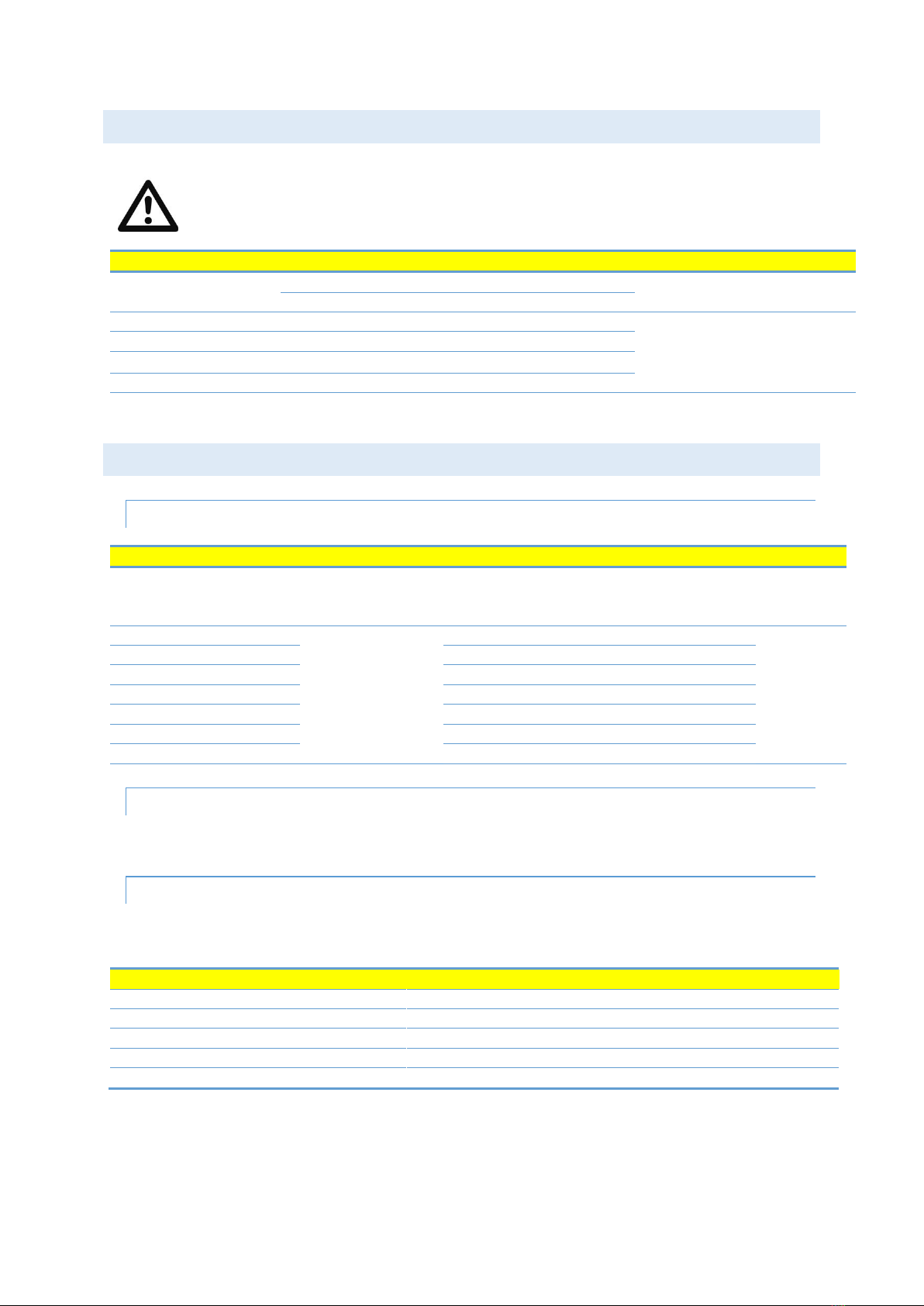

2 Safety ................................................................................................................................................5

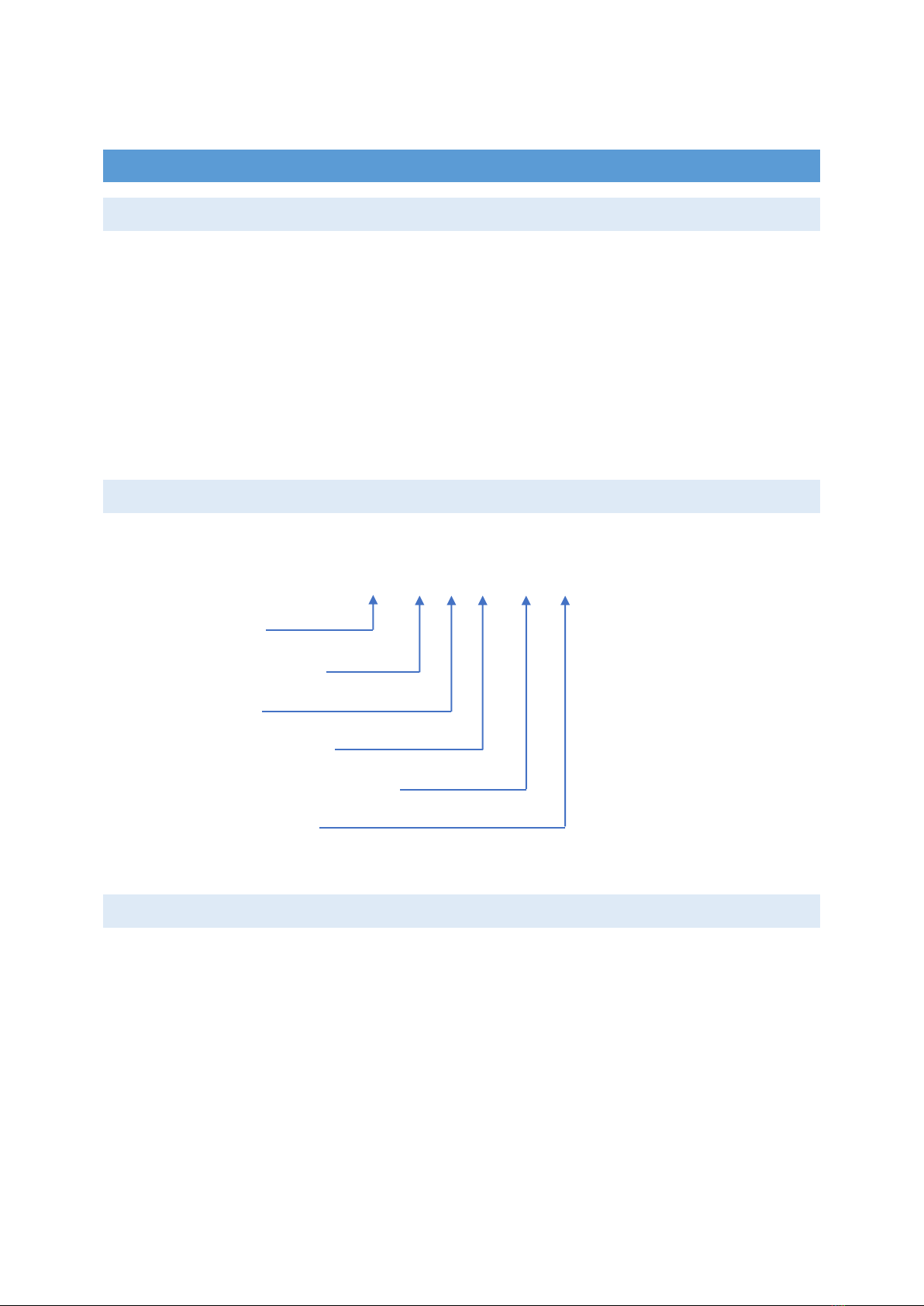

3 Tehnical specifications ......................................................................................................................5

3.1 Standards and protections .....................................................................................................................5

3.2 Pump medium ........................................................................................................................................5

3.3 Temperatures and ambient humidity.....................................................................................................6

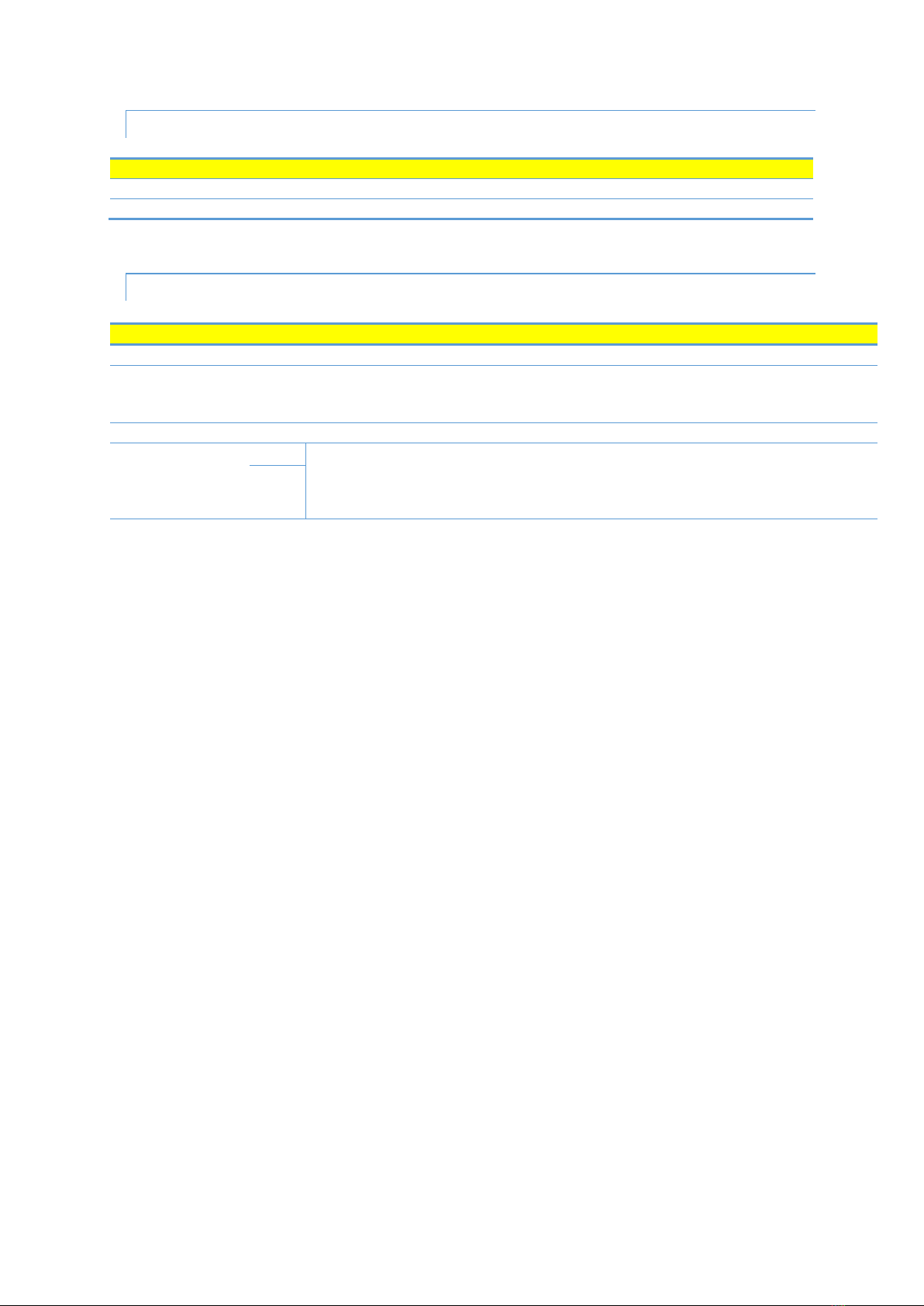

3.4 Electrical specifications...........................................................................................................................6

4 Pump installation ..............................................................................................................................9

4.1 Installation into pipe lines ......................................................................................................................9

4.2 Electrical installation.............................................................................................................................10

4.3 Communication installation....................................................................................................................6

5 Setup and operation ...................................................................................................................... 11

5.1 Control and functions ...........................................................................................................................11

5.2 Operation..............................................................................................................................................17

6 Error and Troubleshooting............................................................................................................. 19

7 Fault finding ................................................................................................................................... 19

7.1 Error codes ...........................................................................................................................................19

8 Images............................................................................................................................................ 21

Symbols used in this manual:

Safety precautions which, if ignored could cause personal injury or machinery damage

Tips that could ease pump handling.